Bag turning centrifugal machine, and dehydration and filter cloth regeneration method thereof

A centrifuge and bag-turning technology, which is applied to centrifuges and centrifuges with rotating drums, etc., can solve the problems of inconvenient operation and maintenance, many auxiliary devices, leaking, leaking, dripping, etc., to avoid leaking, leaking, and production costs Low, good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. All other embodiments obtained below all belong to the protection scope of the present invention.

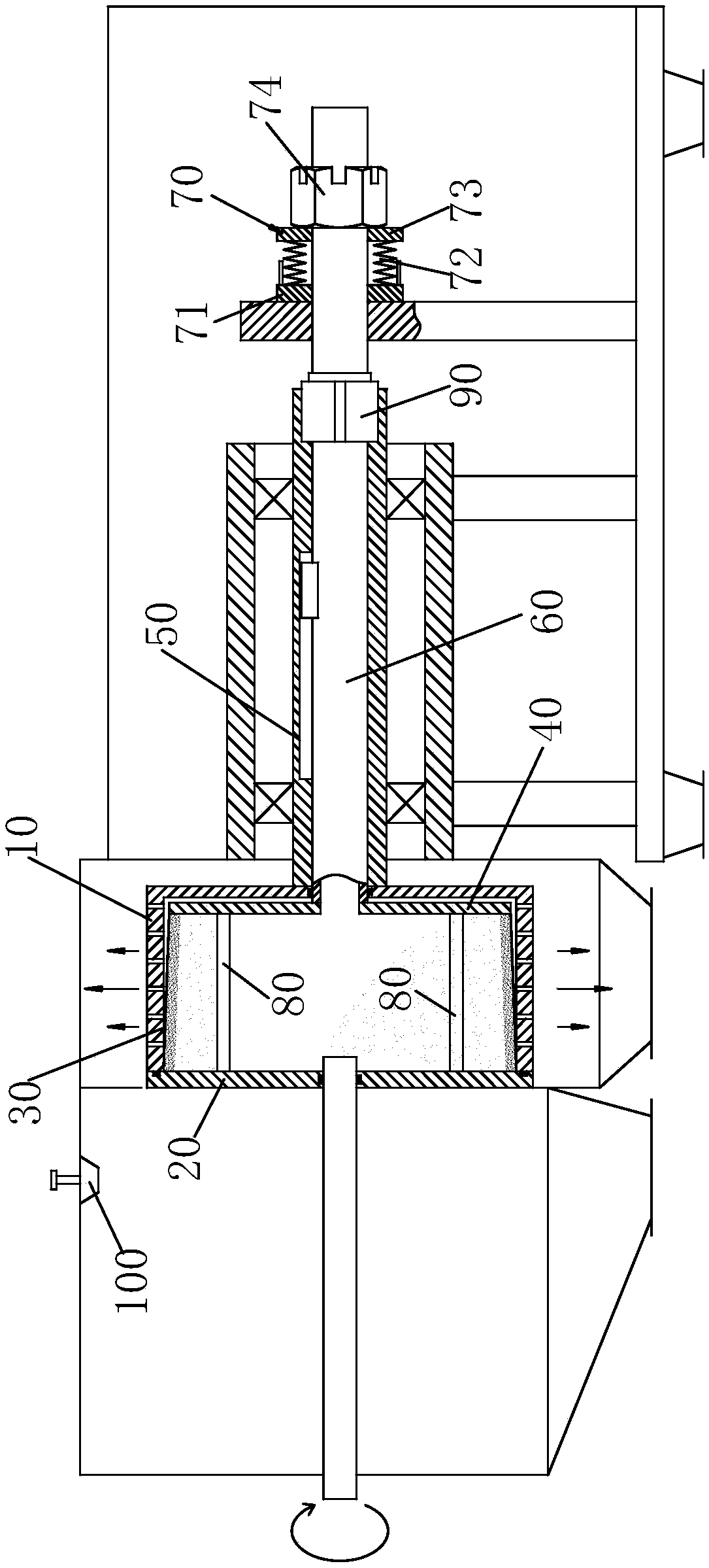

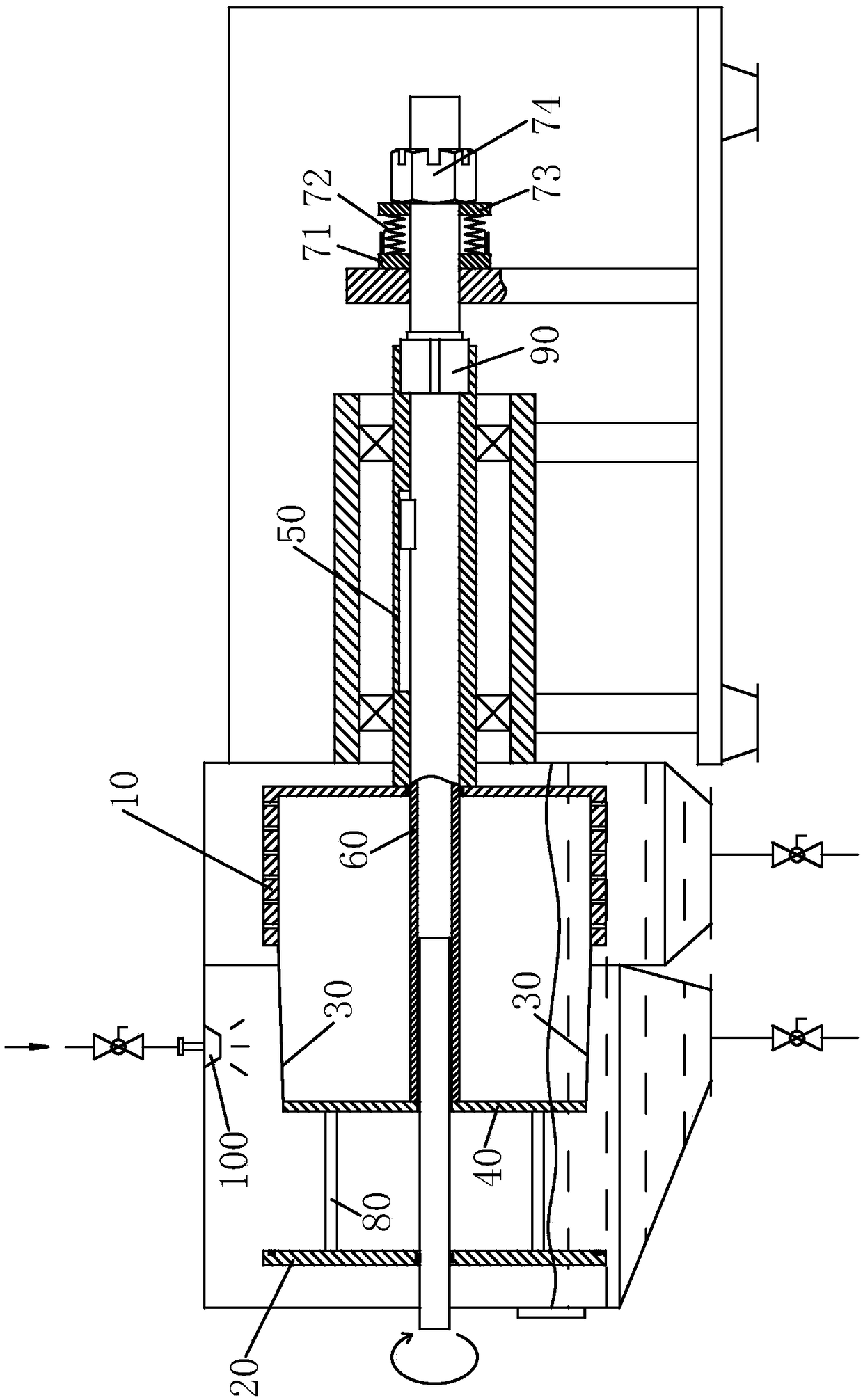

[0032] Such as figure 1 , 2 As shown, a bag-turning centrifuge includes a rotating drum 10 fixed to the hollow main shaft 50 which is rotatably arranged in the casing, and the open end of the drum 10 is provided with a sleeve for closing the drum 10 The front push plate 20 located outside the feed pipe, the inner surface of the drum 10 is provided with a reversible filter cloth 30, the filter cloth 30 is made of a material with certain flexibility and stretchability, such as polypropylene fiber, polyester, etc., the drum 10 is also provided with a rear push plate 40 fixedly connected to the front push plate 20, one end of the filter cloth 30 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com