Etching solution managing apparatus, dissolved metal concentration measuring apparatus and dissolved metal concentration measuring method

A technology for managing device and metal concentration, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze fluids, electrical components, semiconductor/solid-state device manufacturing, etc., and can solve problems such as product quality deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

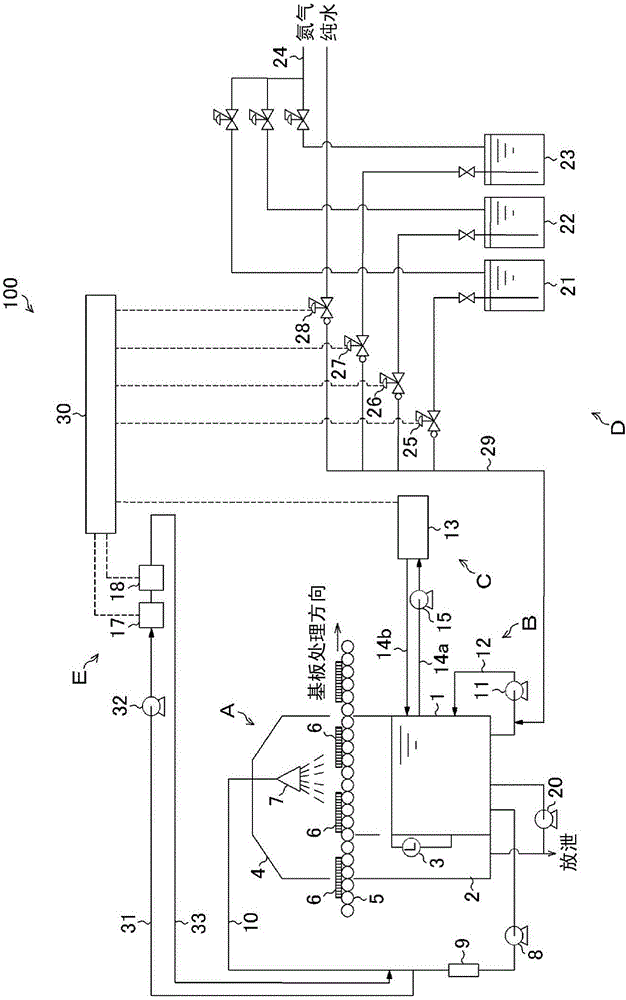

[0066] figure 1 It is a system diagram of an etching processing mechanism 100 including the etching liquid management device according to the first embodiment of the present invention.

[0067] The etchant management device of this embodiment is mainly used in the etching process of etching a metal film or a metal compound film, where the etchant is an acid-containing aqueous solution and the management of the acid concentration and dissolved metal concentration of the etchant is important. exist figure 1 In the system diagram of the figure, it is provided with: an etching treatment part A connected to the etching solution management device of the present invention and including an etching treatment tank 1 in which an etching solution maintained and managed at a predetermined component concentration is stored; The etchant circulation unit B that circulates and stirs the etchant stored in the etchant treatment tank 1; the dissolved metal recovery and removal unit C that recove...

no. 2 approach 〕

[0185] Image 6 It is a system diagram of the etching processing mechanism 110 including the etching liquid management device according to the second embodiment of the present invention. The etchant management device of the second embodiment differs from the etchant management device of the first embodiment in that, in the measuring section E of the etchant management device of the first embodiment, the first physical property value measuring device 17 , In addition to the second physical property value measuring device 18, a third physical property value measuring device (third physical property value measuring means) 19 is further provided. The third physical property value measuring device 19 measures a third physical property value related to the concentration of the oxidizing agent in the etching solution. By utilizing the previously obtained correlation between the concentration of the oxidizing agent in the etching solution and the third physical property value, the co...

no. 3 approach 〕

[0193] The etchant management device according to the third embodiment of the present invention is configured by replacing the first physical property value measuring device 17 of the etchant management device according to the first embodiment with a device for measuring at least a physical property value related to the acid concentration of the etchant. The measuring device replaces the second physical property value measuring device 18 with a measuring device that measures at least the physical property value related to the dissolved metal concentration of the etching solution, and has the physical property value of the etching solution measured by the above measuring device and utilizes multivariate analysis. Method (for example, multiple regression analysis method) to calculate the acid concentration of the etching solution and the calculation function (calculation mechanism) of the dissolved metal concentration. The etching treatment mechanism including the etchant managem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com