Synthesis method of tackifying alkylphenol formaldehyde resin

A kind of technology of alkylphenol formaldehyde resin and synthesis method, which is applied in the field of phenol formaldehyde tackifying resin, can solve the problems of difficult removal of acid catalyst, influence of resin performance, high content of free phenol, etc., and achieve the effects of low vapor pressure, complete reaction and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

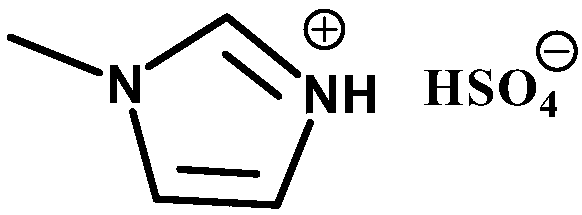

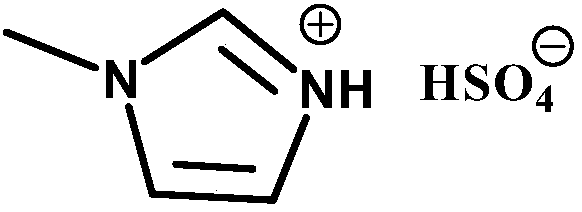

[0024] The synthesis of p-tert-butylphenol-formaldehyde resin, 1-methylimidazolium bisulfate as acidic catalyst and solvent, p-tert-butylphenol: formaldehyde (molar ratio)=1:0.85; Add formaldehyde aqueous solution (37% ).

[0025] Step 1: Add 46.5g (0.31mol) of p-tert-butylphenol and 3g of 1-methylimidazolium bisulfate to a 500ml four-necked round-bottomed reaction flask equipped with a mechanical stirrer, a thermometer, a reflux condenser and a dropping funnel ;

[0026] Step 2: The temperature of the reaction system was raised to 50°C, and 15.1 g of formaldehyde aqueous solution (37%) was slowly added through the dropping funnel. After the dropwise addition was completed, the temperature of the reaction system was raised to 90°C, and the reaction was refluxed. After 1.8 hours of reaction, the distillation was started. Continue to raise the temperature to 100-110°C, stop the distillation after distilling all the water out; slowly add the remaining formaldehyde aqueous soluti...

Embodiment 2

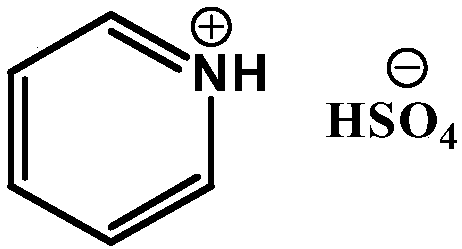

[0031] Synthesis of p-tert-butylphenol-formaldehyde resin, pyridine bisulfate as acidic catalyst and solvent, p-tert-butylphenol: formaldehyde (molar ratio) = 1:0.85; add formaldehyde aqueous solution (37%) twice.

[0032] Step 1: in the 500ml four-neck round-bottomed reaction flask that mechanical stirrer, thermometer, reflux condenser and dropping funnel are equipped with, add 46.5g (0.31mol) p-tert-butylphenol and 3g pyridine bisulfate;

[0033] Step 2: The temperature of the reaction system was raised to 50°C, and 15.1 g of formaldehyde aqueous solution (37%) was slowly added through the dropping funnel. After the dropwise addition was completed, the temperature of the reaction system was raised to 90°C, and the reaction was refluxed. After 1.8 hours of reaction, the distillation was started. Continue to raise the temperature to 100-110°C, stop the distillation after distilling all the water out; slowly add the remaining formaldehyde aqueous solution from the dropping funne...

Embodiment 3

[0038] Synthesis of tert-octylphenol-formaldehyde resin, pyridinium bisulfate as acidic catalyst and solvent, p-tert-butylphenol: formaldehyde (molar ratio) = 1:0.8; formaldehyde aqueous solution (37%) was added twice.

[0039] Step 1: in the 500ml four-neck round-bottomed reaction flask that mechanical stirrer, thermometer, reflux condenser and dropping funnel are housed, add 63.8g (0.31mol) p-tertoctylphenol and 6g pyridine bisulfate;

[0040] Step 2: The temperature of the reaction system was raised to 50°C, and 17.0g of formaldehyde aqueous solution (37%) was slowly added from the dropping funnel. After the dropwise addition was completed, the temperature of the reaction system was raised to 95°C, and the reaction was refluxed. After 2.5 hours of reaction, the distillation was started. Continue to raise the temperature to 100-110°C, stop the distillation after all the water is distilled; slowly add the remaining formaldehyde solution from the dropping funnel, continue the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com