Method for preparing three-dimensional porous polymer electrolyte film

A three-dimensional porous, electrolyte membrane technology, applied in the field of electrochemistry, can solve the problems of harsh template removal conditions, complex procedures, environmental pollution, etc., and achieve excellent cycle stability, uniform pore size distribution, and simple and easy preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

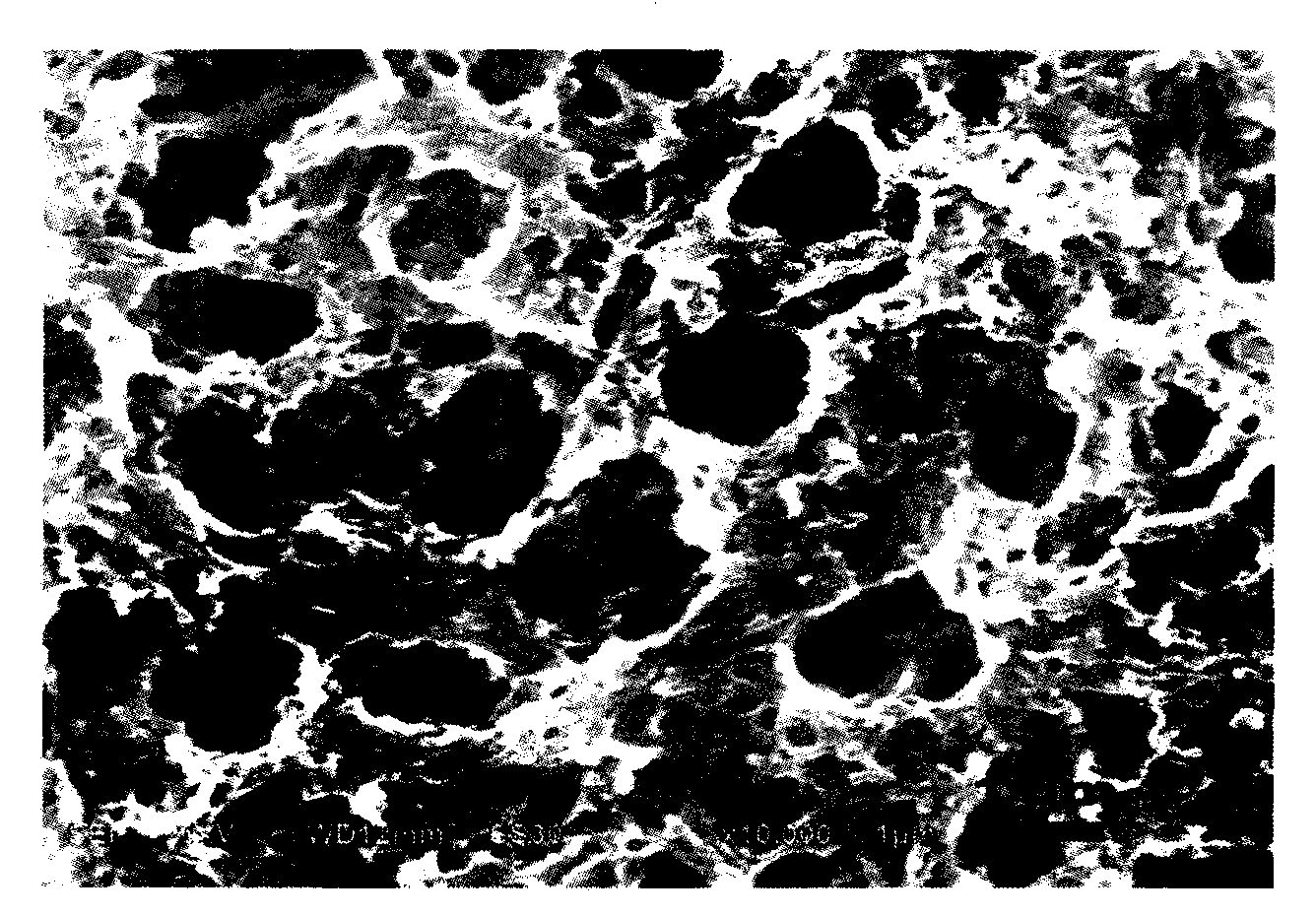

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0029] (1) Configure 0.2 mol / L CaCl 2 solution and 0.2 mol / L Na 2 CO 3 Each solution is 50ml. Add 0.8422g oleic acid, 180ml ethanol and Na 2 CO 3 Solution, under rapid stirring, slowly drop CaCl 2 Solution, continue to react for 2-3 hours after dripping, the precipitate (CaCO 3 Nanoparticles) after suction filtration, washing with water and alcohol, place and dry naturally for use.

[0030] (2) In a 100ml round bottom flask filled with 50ml ethanol and 10ml distilled water, add 6 grams of CaCO obtained in step (1) 3 Nanoparticles, stir quickly, heat up to 50 ° C, and then slowly add the equivalent of CaCO 3 3% titanate coupling agent TC-114, continue to stir for 4 hours, cool, centrifuge, wash with distilled water, wash with ethanol, and dry naturally to obtain m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com