Non-halogen phosphoric acid ester combustion inhibitor for engineering plastic and method of preparing the same

A technology of halogen-free phosphate esters and engineering plastics, which is applied in the direction of fire-resistant coatings, etc., can solve problems such as application restrictions, and achieve the effects of reducing production costs, good processing performance, and reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

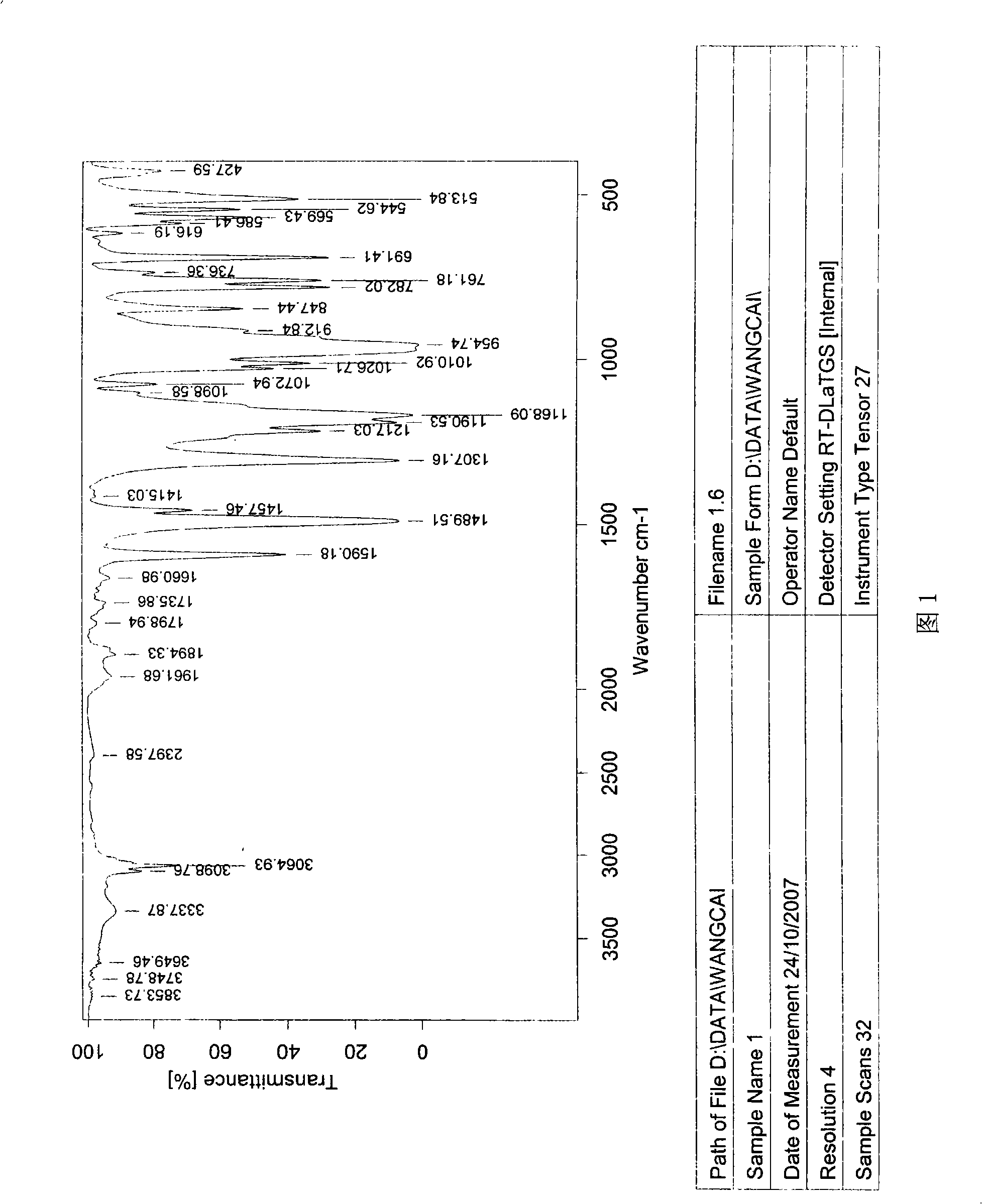

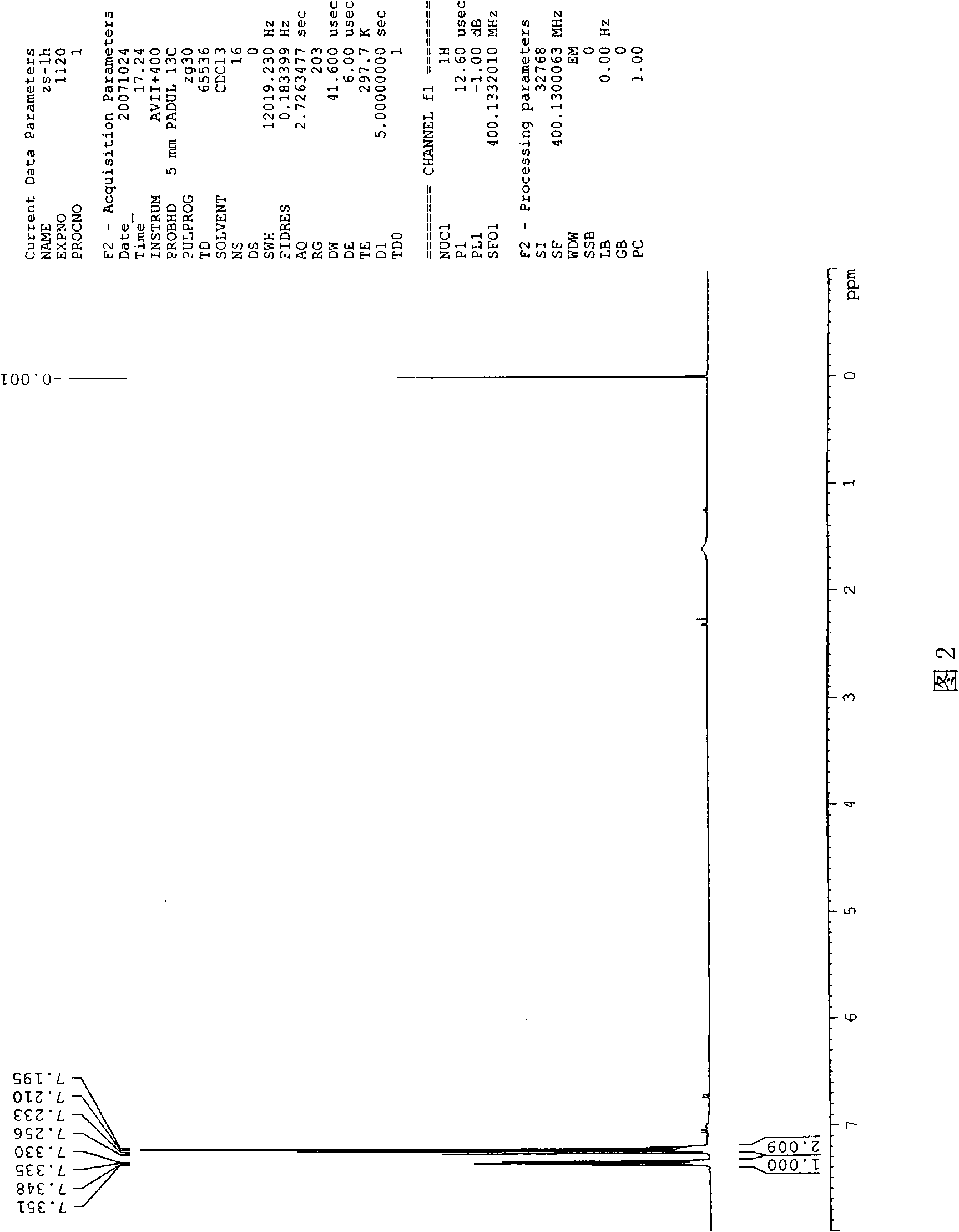

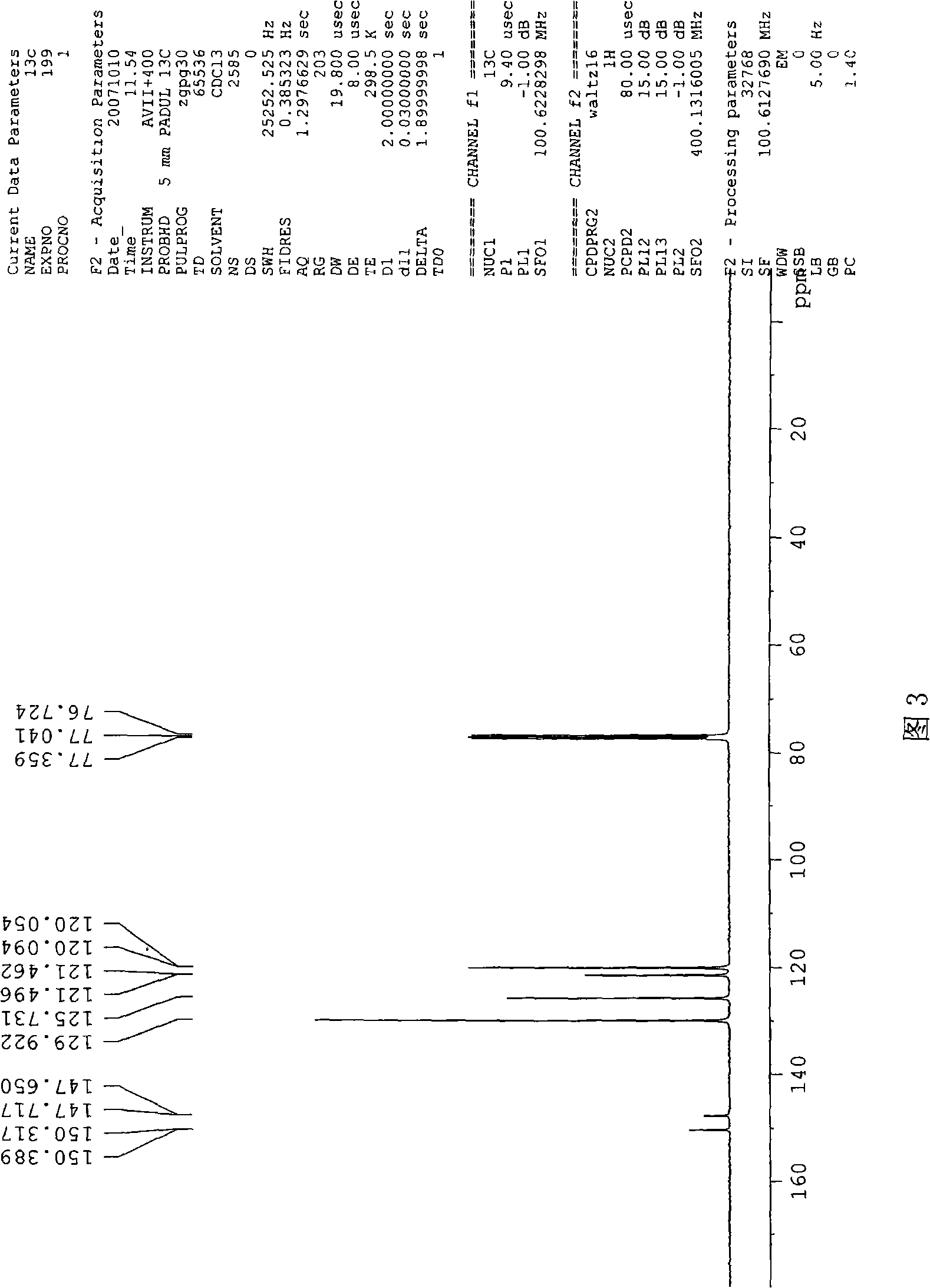

Method used

Image

Examples

Embodiment 1

[0040] In the first step, add 1mol (110g) hydroquinone, 6mol ( 920g) phosphorus oxychloride and 1.2g aluminum trichloride, slowly heat up to 60°C, a large amount of hydrogen chloride gas is produced, then slowly heat up to 110°C, keep warm until no hydrogen chloride is released, and the reaction is complete; (50-60kPa), and then under high vacuum (95-97kPa) at about 100 ° C to distill off excess phosphorus oxychloride to obtain the intermediate hydroquinone bisphosphoryl chloride oligomer, the yield of the intermediate 93%, and the recovery rate of phosphorus oxychloride is about 95% (according to the generation of bisphosphoryl chloride).

[0041] After the second step, the first step is completed, the intermediate is left in the reaction flask, and the intermediate is kept in a liquid state (above 100° C.), and 1.0 g of aluminum trichloride is added to the material, and 4mol ( 376g) anhydrous liquid phenol; raise the temperature of the material to 110-120°C, start adding ph...

Embodiment 2

[0044] With embodiment 1, but replace the 1.2g aluminum trichloride among the example 1 with 2.0g magnesium chloride in the first step reaction, replace the 1.0g aluminum chloride among the example 1 with the 1.6g magnesium chloride in the second step reaction. The total yield of the QDP finished product of Example 2 is 82.5%, and the content of n=1 component in the finished product is 83%.

Embodiment 3

[0046] Same as Example 1, but replace 6mmol phosphorus oxychloride in example 1 with 4mmol phosphorus oxychloride in the first step reaction, in the second step reaction and aftertreatment with example 1, the total yield of QDP finished product is 79.6%, finished product The content of n=1 component in it is 76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com