Method for rapidly extracting and purifying glycyrrhizic acid and salts thereof

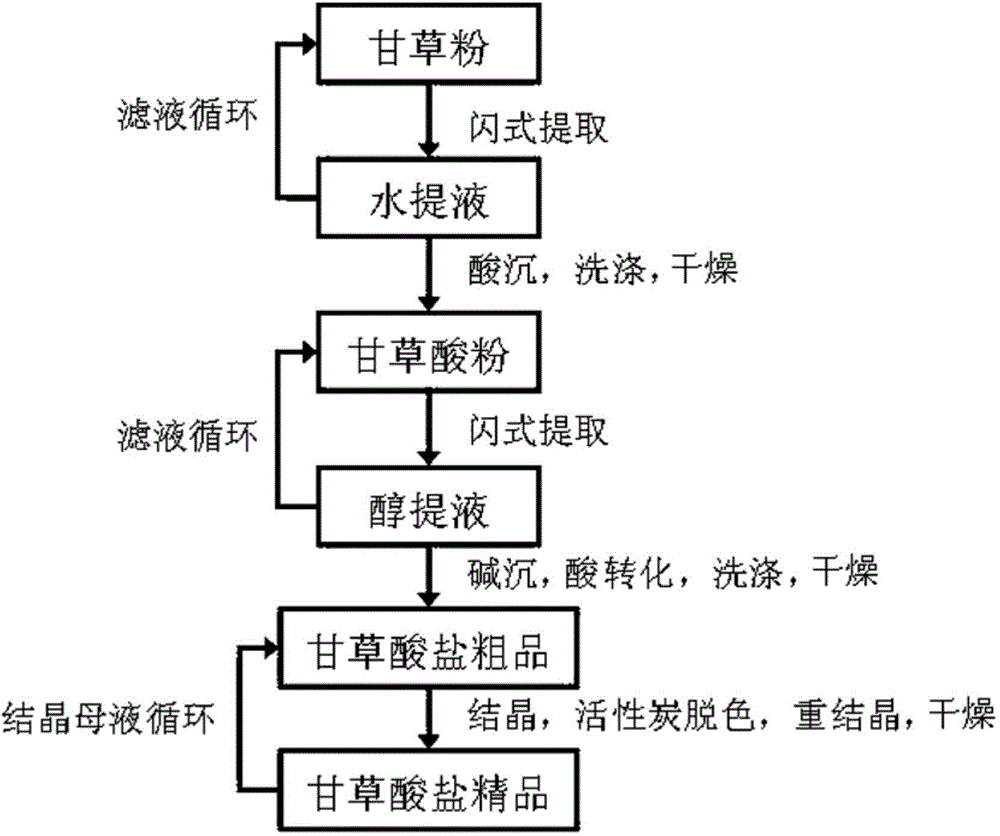

A technology of glycyrrhizinate and extraction method, which is applied in the direction of chemical instruments and methods, organic chemistry, steroidal compounds, etc., can solve the problems of low extraction efficiency, 2-6 hours, and large amount of extracting solution, so as to improve product quality , shorten the extraction time, reduce the effect of waste liquid volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] Preparation of Glycyrrhizic Acid Powder by Flash Water Extraction

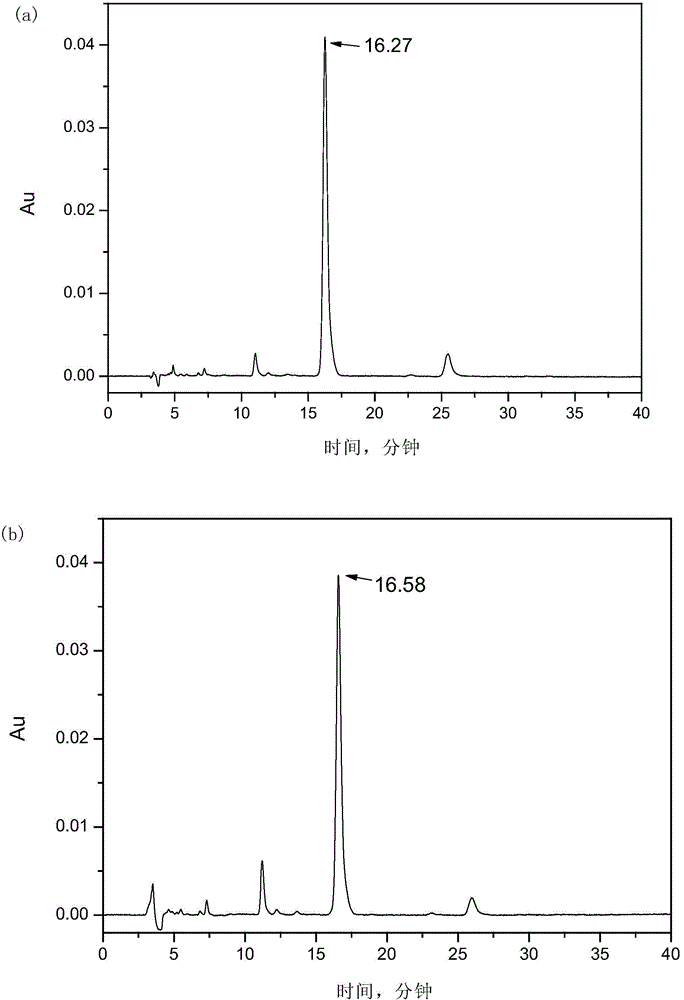

[0128] Glycyrrhiza rhizomes are crushed and passed through a 40-mesh standard sieve to obtain licorice powder. Take 20 g of licorice powder, disperse it with 400 mL of deionized water, place it in a flash extractor, and extract it at room temperature at 10,000 rpm for 5 minutes to obtain an extract. Filtrate was obtained by filtration, and the pH was adjusted to 2.0-2.5 with concentrated sulfuric acid; glycyrrhizic acid was precipitated, centrifuged, and the obtained precipitate was washed with a small amount of water, then centrifuged again, and the precipitate was vacuum-dried at 35°C to obtain glycyrrhizic acid powder. The purity of glycyrrhizic acid was 25.3% by HPLC analysis.

[0129] After the supernatant obtained from the above centrifugation process was combined, calcium hydroxide powder was added to adjust the pH to 7.0-7.5 to form calcium sulfate precipitate, which was settled for half an hou...

Embodiment 2

[0136] Preparation of Monoammonium Glycyrrhizinate Coarse Powder by Flash Alcohol Extraction

[0137] The glycyrrhizic acid powder prepared by the flash extraction method was crushed and passed through a 40-mesh standard sieve. Take 5g of glycyrrhizic acid powder, disperse it with 100mL of 95wt% ethanol, place it in a flash extractor, and extract it at room temperature at 10,000 rpm for 5 minutes to obtain an extract. The filtrate was obtained by filtration, and the pH was adjusted to 8.0-8.5 with 22-25% concentrated ammonia water; triammonium glycyrrhizinate precipitated, filtered, and about 3 g of the obtained filter cake was dissolved by heating with 6 mL of glacial acetic acid at 60°C. After cooling, monoammonium glycyrrhizinate precipitated out. Filtrate to obtain crude wet crystals of monoammonium glycyrrhizinate, wash with 3 mL of glacial acetic acid and 3 mL of absolute ethanol in turn, and then dry in a vacuum desiccator at 35°C for more than 8 hours. The purity of ...

Embodiment 3

[0144] Preparation of Monopotassium Glycyrrhizinate Coarse Powder by Flash Alcohol Extraction

[0145] The glycyrrhizic acid powder prepared by the flash extraction method was crushed and passed through a 40-mesh standard sieve. Take 5g of glycyrrhizic acid powder, disperse it with 100mL of 95wt% ethanol, place it in a flash extractor, and extract it at room temperature at 10,000 rpm for 5 minutes to obtain an extract.

[0146] The filtrate was obtained by filtration, and the pH was adjusted to 8.0-8.5 with 20 wt% potassium hydroxide ethanol solution; tripotassium glycyrrhizinate precipitated out, filtered, and about 3 g of the obtained filter cake was dissolved by heating at 60° C. with 6 mL of glacial acetic acid. After cooling, monopotassium glycyrrhizinate precipitated out.

[0147] Filtrate to obtain wet crystals of crude monopotassium glycyrrhizinate, wash with 3 mL of glacial acetic acid and 3 mL of absolute ethanol in turn, and then dry in a vacuum desiccator at 35°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com