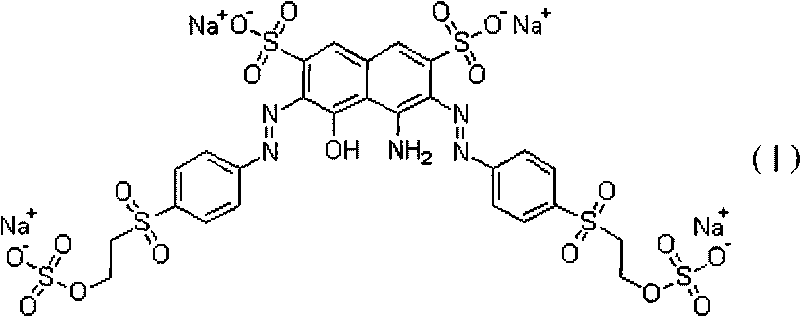

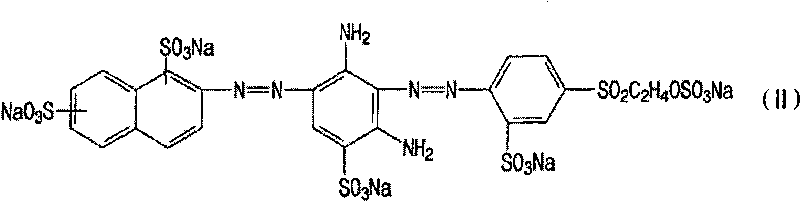

Black dye composition

A technology of dye composition and black dye, which is applied in the field of dye composition, can solve problems such as head-to-tail color difference, achieve the effects of reducing processing costs, uniform dyeing liquor, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1740kg of reactive black 5, 538.79kg of reactive orange 142 and 257.01kg of sodium sulfate are directly mixed through dry blending equipment, and mixed thoroughly to obtain a black dye composition, or equivalent to containing 1740kg of reactive black The liquid dye of 5, the liquid dye equivalent to 538.79kg of reactive orange 142 and the sodium sulfate of 257.01kg are fully stirred and mixed uniformly in the liquid blending equipment, and the black dye composition can be obtained after drying and spraying.

Embodiment 2

[0022] 500kg of reactive black 5, 154.73kg of reactive orange 142 and 73.82kg of sodium sulfate are directly mixed evenly through dry blending equipment to prepare a black dye composition, or a liquid dye equivalent to 500kg of reactive black 5 With the liquid dye equivalent to 154.73kg of reactive orange 142 and 73.82kg of sodium sulfate in its liquid blending equipment, after fully stirring and mixing, the black dye composition can be obtained after drying and spraying.

[0023] The blended product of embodiment 1 is made into 100ml of dye liquor of 10 grams per liter, the strip shape of cotton fabric 0.1m * 12m, continuous pad dyeing on cotton fiber under the same condition. After the pad dyed fabric is treated, the color measurement is performed with a color measurement instrument at intervals of 1m. The color measurement data are shown in Table 1:

[0024] Table 1 Color measurement data of dyed fabrics

[0025] serial number

[0026] It can be seen from the dat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water solubility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com