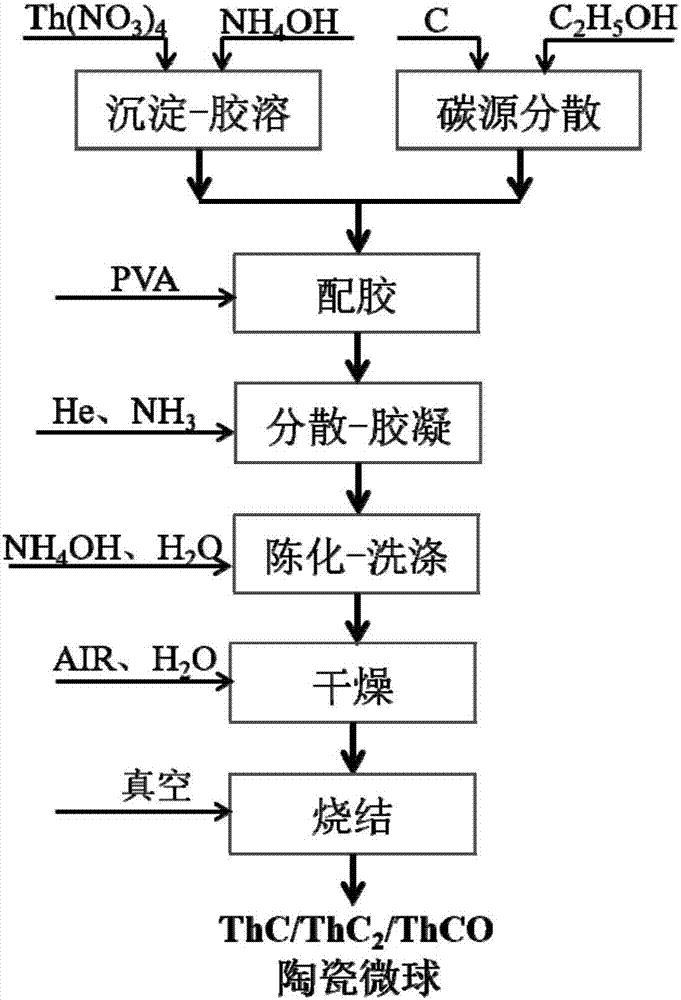

Method for preparing ceramic microspheres of thorium-based carbides and/or thorium-based oxycarbides

A technology of ceramic microspheres and carbides, which is applied in the direction of reactor fuel materials, greenhouse gas reduction, nuclear power generation, etc., can solve the problems that thorium carbide cannot be simply prepared, and achieve uniform drying, cost reduction, high mechanical strength and The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

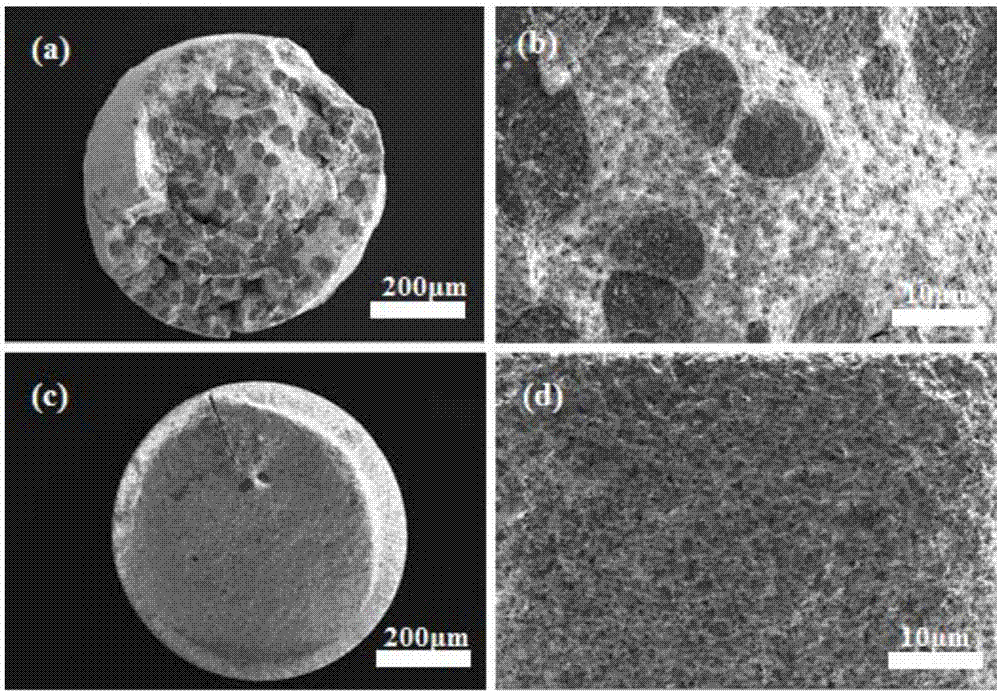

Examples

Embodiment 1

[0024] S1, preparation of carbon-containing colloids: weighing 70.5gTh(NO 3 ) 4 ·6H 2 O is prepared into 100mL of 1.2mol / L thorium nitrate solution, heated to 60°C, and 15mol / L ammonia water is added dropwise at a rate of 1mL / min until the pH of the solution is 3.4 to form a hydrolysis solution; the hydrolysis solution is cooled and stirred Add 20 mL of 100 g / L polyvinyl alcohol (PVA) to form a sol. Weigh 4.8 g of carbon powder with a particle size of 7-11 μm, add 20 mL of absolute ethanol and stir evenly to form pre-dispersed carbon powder. Slowly add the sol to the carbon powder pre-dispersed with ethanol, stir well and then let it stand to eliminate air bubbles to form a carbon-containing colloidal solution.

[0025] S2, gel particle dispersion: the carbon-containing colloidal solution is dispersed into droplets and then passes through the helium gas zone, the ammonia gas zone, and the ammonia water zone in sequence to form gel particles.

[0026] S3, aging, washing and...

Embodiment 2

[0029] S1, preparation of carbon-containing colloids: weighing 60g Th(NO 3 ) 4 ·6H2 O is prepared into 100 mL of 1.0 mol / L thorium nitrate solution, heated up to 80°C, and 15 mol / L ammonia water is added dropwise at a rate of 1.5 mL / min until the pH of the solution is 3.86 to form a hydrolyzed solution; the hydrolyzed solution is cooled and stirred Add 25mL of 100g / L PVA to form a sol. Weigh 2.4 g of carbon powder with a particle size of nanometer size, add 10 mL of absolute ethanol and stir evenly to form pre-dispersed carbon powder. Slowly add the sol to the carbon powder pre-dispersed with ethanol, stir well and then let it stand to eliminate air bubbles to form a carbon-containing colloidal solution.

[0030] S2, gel particle dispersion: the carbon-containing colloidal solution is dispersed into droplets and then passes through the helium gas zone, the ammonia gas zone, and the ammonia water zone in sequence to form gel particles.

[0031] S3, aging, washing and drying:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com