Low-cost preparation method of graphene

A graphene, low-cost technology, applied in the field of low-cost graphene preparation, can solve problems such as difficulty in precise control, difficulty in precision control, and difficulty in large-scale preparation, and achieve the effects of low cost, short cycle, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) 10g graphite powder with a particle size of 50μm and 20ml methylpyrrolidone (NMP), stir and mix in a beaker to form a paste-like mixture;

[0023] (2) Disperse the mixture obtained in (1) ultrasonically for half an hour in a water bath at 60°C, stirring continuously during the ultrasonic process;

[0024] (3) Weigh 100g of alumina grinding balls with particle size gradation and pour the mixture obtained in (2) into the resin ball mill tank, and then add 10ml of NMP to dilute the mixture;

[0025] (4) Put the ball mill tank in (3) into the planetary ball mill, and set the ball mill speed to 400r / min. The milling time is set to 12 hours;

[0026] (5) Add the mixture obtained in (4) to 10 ml of deionized water, and ultrasonically disperse for 15 minutes at room temperature, stirring continuously during the ultrasonic process;

[0027] (6) Pour the mixture in (5) into the tray, and the powder obtained after drying is graphene.

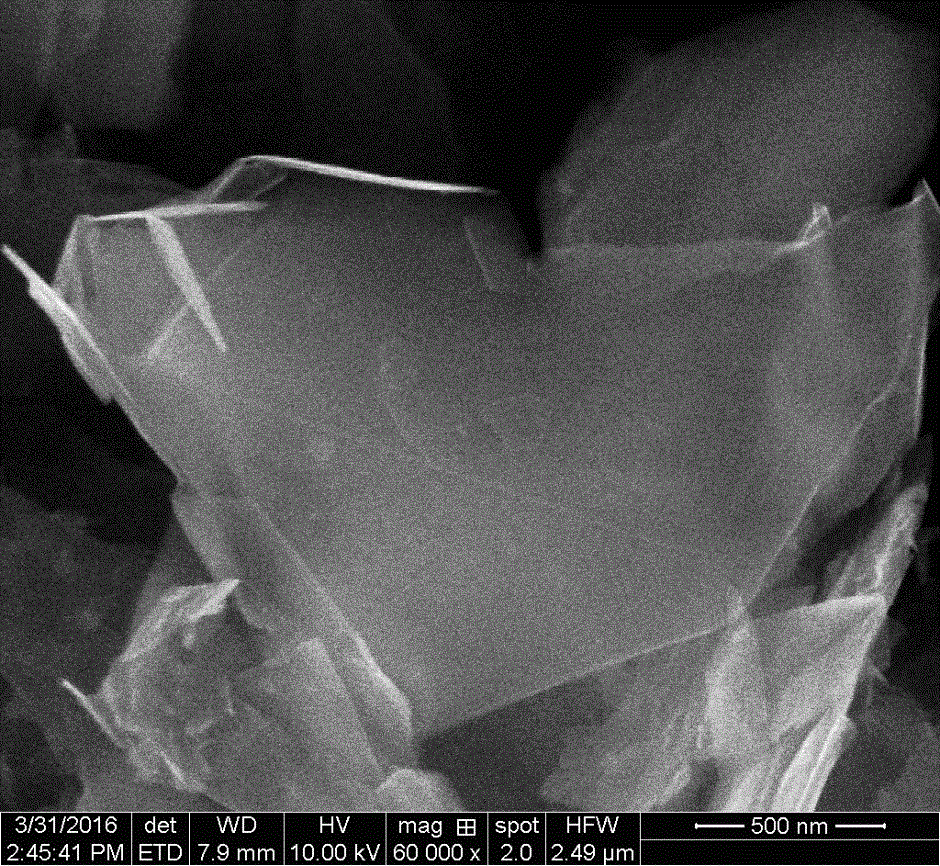

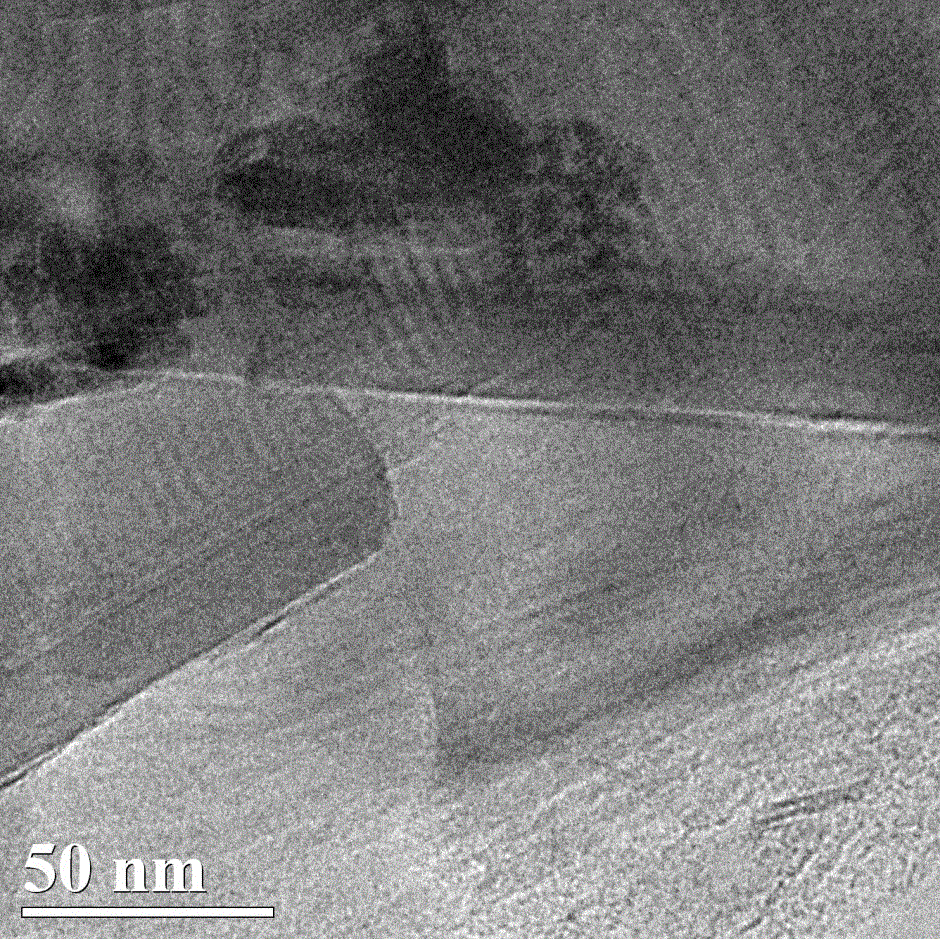

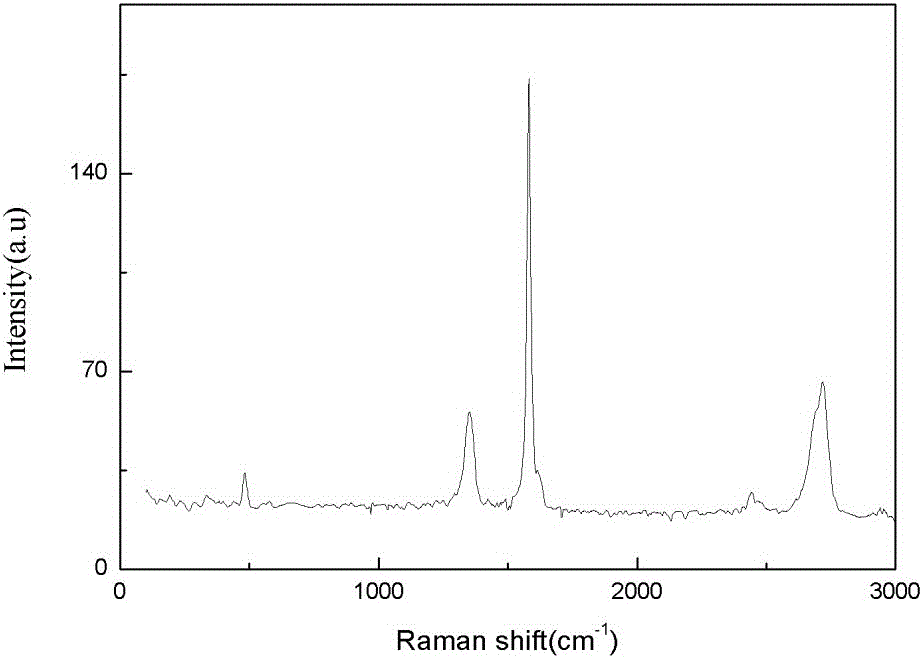

[0028] Attached figure 1 Scanning electron microgra...

Embodiment 2

[0030] (1) Take 10g of graphite powder with a particle size of 50μm and 30ml of methylpyrrolidone (NMP), stir and mix in a beaker to form a paste mixture;

[0031] (2) Disperse the mixture obtained in (1) ultrasonically for half an hour in a water bath at 60°C, stirring continuously during the ultrasonic process;

[0032] (3) Weigh 120g of alumina grinding balls with particle size gradation and pour the mixture obtained in (2) into the resin ball mill tank, and then add 20ml of NMP to dilute the mixture;

[0033] (4) Put the ball mill tank in (3) into the planetary ball mill, and set the ball mill speed to 450r / min. The milling time is set to 18 hours;

[0034] (5) Add the mixture obtained in (4) to 15 ml of deionized water, and ultrasonically disperse for 15 minutes at room temperature, stirring continuously during the ultrasonic process;

[0035] (6) Pour the mixture in (5) into the tray, and the powder obtained after drying is graphene.

Embodiment 3

[0037] (1) Take 8g of graphite powder with a particle size of 50μm and 20ml of methylpyrrolidone (NMP), stir and mix in a beaker to form a paste mixture;

[0038] (2) Disperse the mixture obtained in (1) ultrasonically for half an hour in a water bath at 60°C, stirring continuously during the ultrasonic process;

[0039] (3) Weigh 160g of alumina grinding balls with particle size gradation and pour the mixture obtained in (2) into the resin ball mill tank, and then add 10ml of NMP to dilute the mixture;

[0040] (4) Put the ball mill tank in (3) into the planetary ball mill, and set the speed of the ball mill to 350r / min. The milling time is set to 24 hours;

[0041] (5) Add the mixture obtained in (4) to 15 ml of deionized water, and ultrasonically disperse for 15 minutes at room temperature, stirring continuously during the ultrasonic process;

[0042] (6) Pour the mixture in (5) into the tray, and the powder obtained after drying is graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com