Patents

Literature

126 results about "Thorium oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thorium dioxide (ThO2), also called thorium(IV) oxide, is a crystalline solid, often white or yellow in color. Also known as thoria, it is produced mainly as a by-product of lanthanide and uranium production. Thorianite is the name of the mineralogical form of thorium dioxide.

Calcium oxide-based ceramic core for casting titanium alloy and manufacturing method thereof

The invention discloses a calcium oxide-based ceramic core for casting titanium alloy and a manufacturing method of the calcium oxide-based ceramic core. The calcium oxide-based ceramic core comprises the following components by weight percent: 1.0-15.0% of zirconium dioxide, 0.5-10.0% of yttrium oxide, 0.05-0.1% of thorium oxide and the balance of calcium oxide, and the sum of the contents of the above the component is 100%. According to the ceramic core, the bending strength is 15-30Mpa at room temperature, the bending strength is 5-10Mpa at high temperature, the high-temperature deflection is 0.2-0.5%, the firing shrinkage ratio is 1-1.5%, and the porosity is 40-50%. Compared with the existing commercial alumina-based ceramic core and silicon oxide-based ceramic core, the calcium oxide-based ceramic core of the invention greatly reduces the reactivity with molten titanium, and has the advantages of high temperature resistance, easiness in core leach, low in cost and the like.

Owner:BEIHANG UNIV

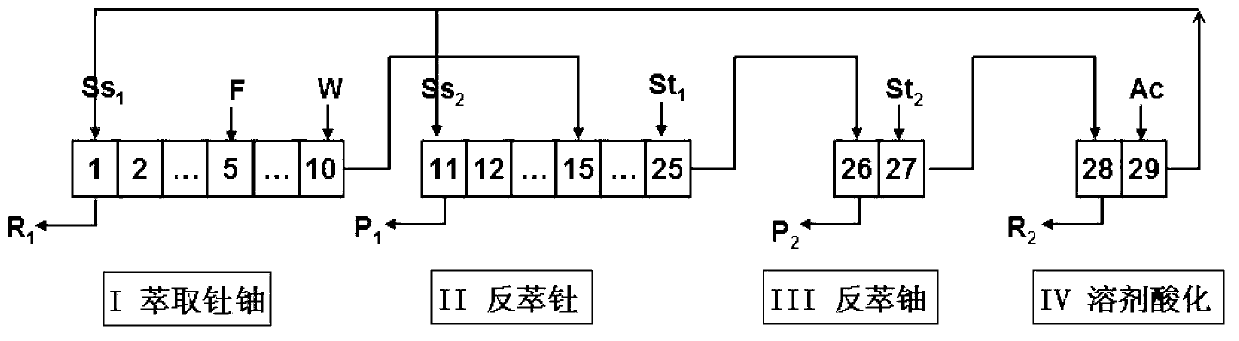

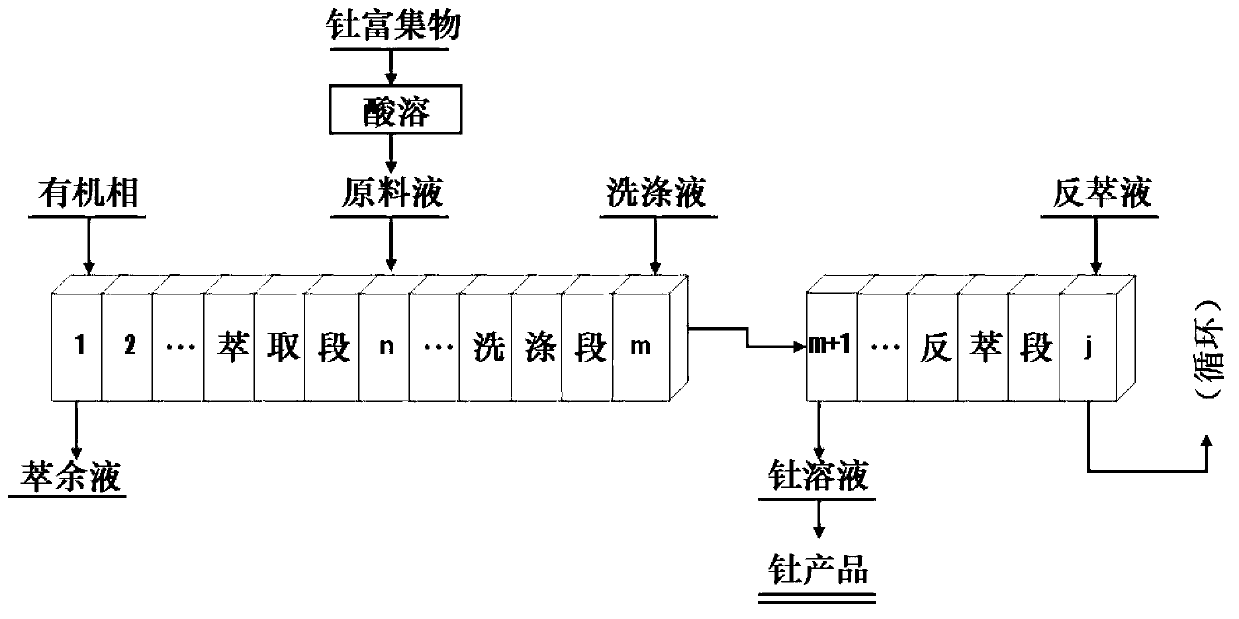

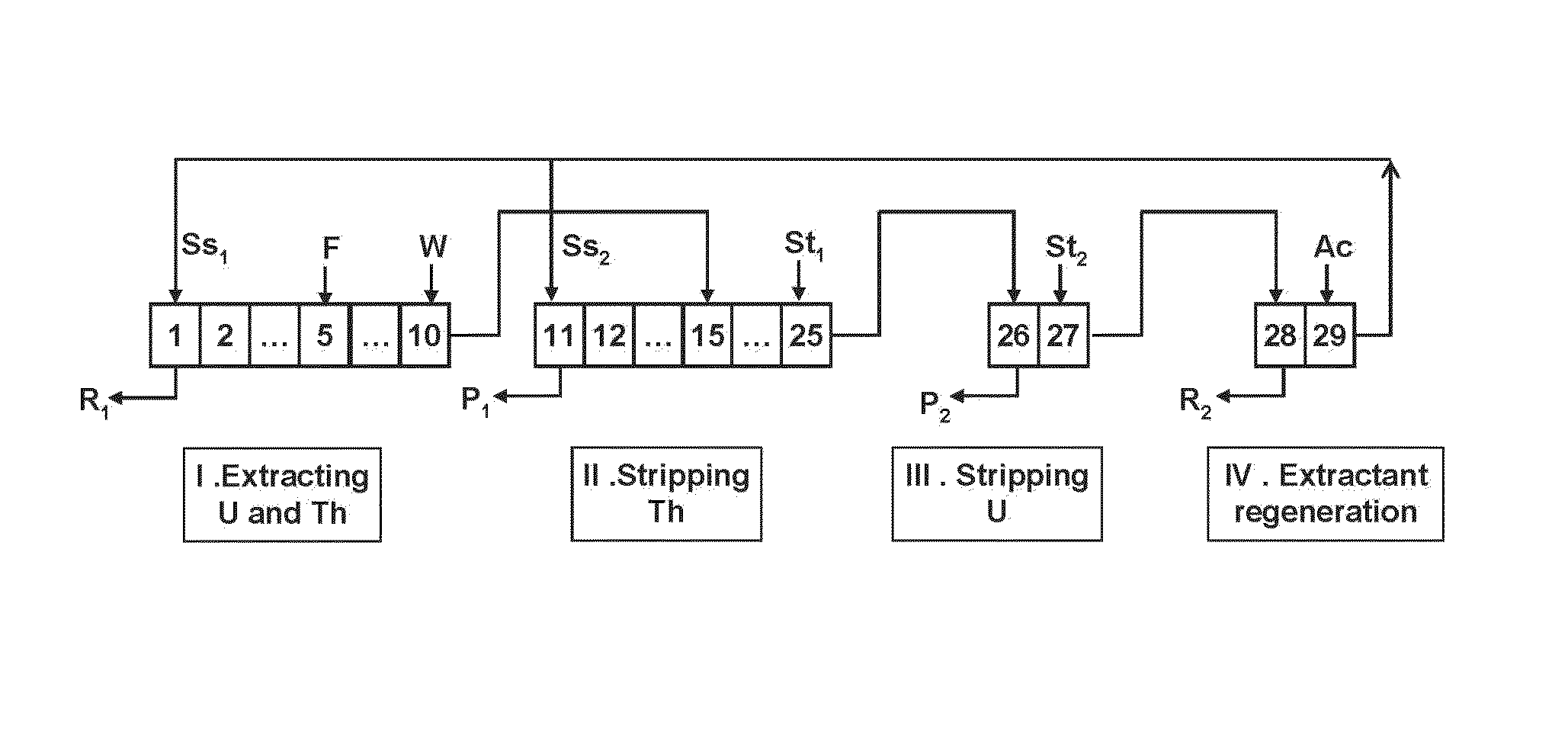

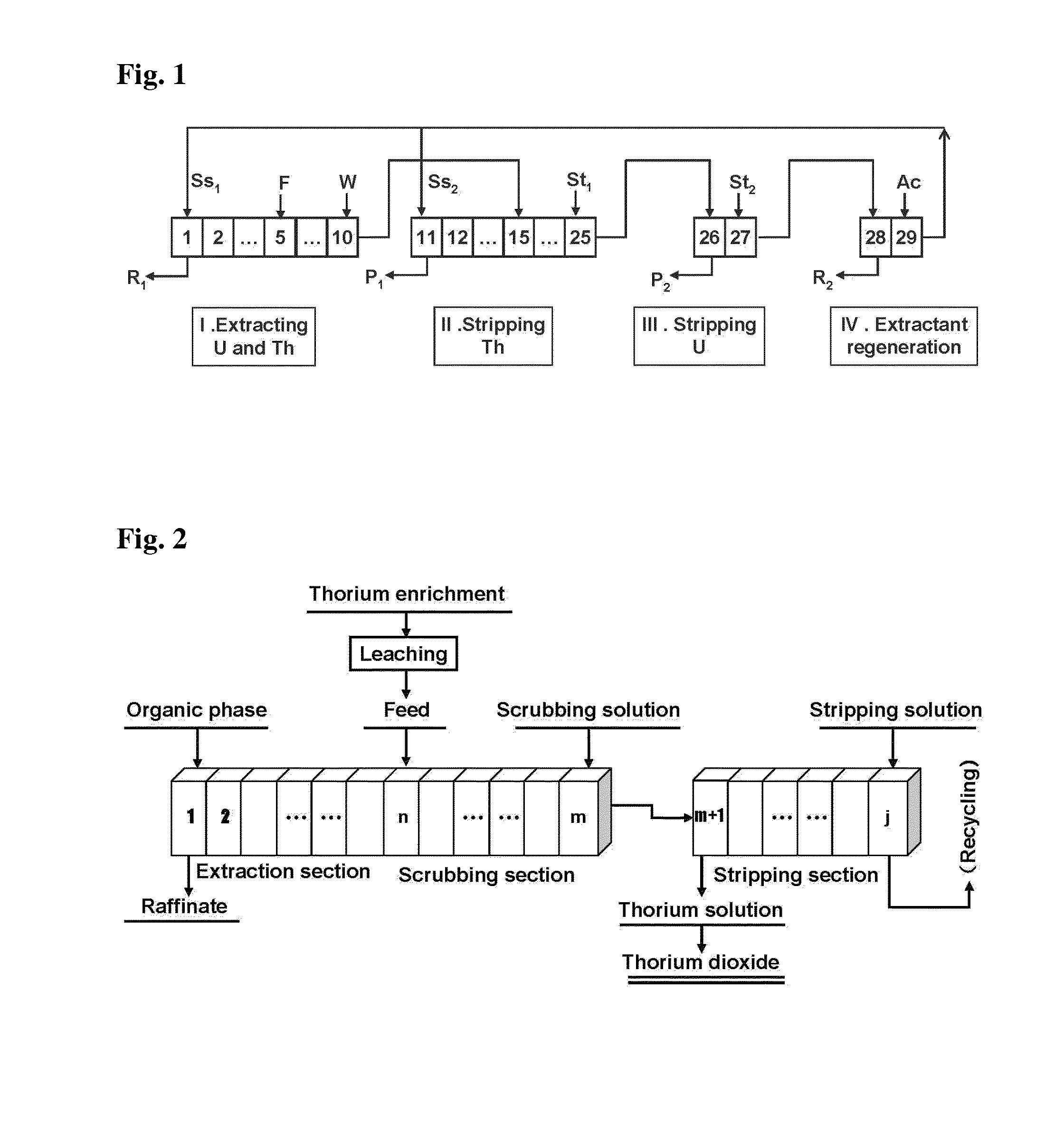

Method for separation and purification of thorium

The invention relates to a method for separation and purification of thorium by a solvent extraction method, wherein the method comprises the following steps of: 1) mixing a thorium enrichment with inorganic acid, to prepare a raw material liquid; 2) mixing a neutral phosphine extracting agent with an organic solvent, to obtain an organic phase; 3) extracting the raw material liquid by the organic phase to obtain the first extracting liquid; 4) washing the first extracting liquid by a washing liquid, back-extracting the thorium element in the first extracting liquid by a back-extracting liquid to obtain the second extracting liquid; and 5) mixing oxalate with the second extracting liquid to obtain precipitate; and burning the precipitate to obtain thorium oxide. According to the method for separation and purification of the thorium, the purity of the thorium is improved to be above 99.99% from 80-99%, and the yield is greater than 98%.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Catalyst for synthesizing isobutanol by utilizing synthesis gas as well as preparation method and application of catalyst

ActiveCN103272609AEmission reductionReduce energy consumptionOrganic compound preparationHydroxy compound preparationIsobutanolThorium oxide

The invention relates to a catalyst for synthesizing isobutanol by utilizing synthesis gas. The catalyst comprises the following components in percentage by weight: 5.0-15.0% of copper oxide, 45.0-60.0% of zirconium oxide, 10.0-20.0% of zinc oxide, 1.0-5.0% of lanthanum oxide, 5.0-20.0% of cerium oxide, 0-5.0% of nickel oxide, 0-5.0% of samarium oxide, 0-5.0% of thorium oxide, 0-5.0% of vanadium pentoxide and 1.2-5.2% of potassium oxide. The catalyst has the advantages of high isobutanol selectivity and warm operation process condition.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

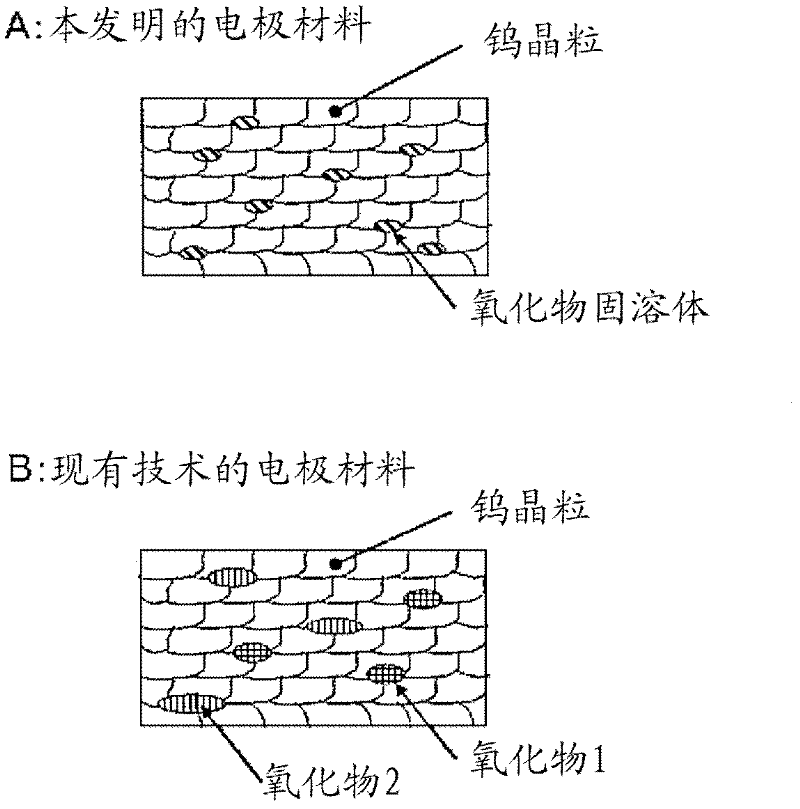

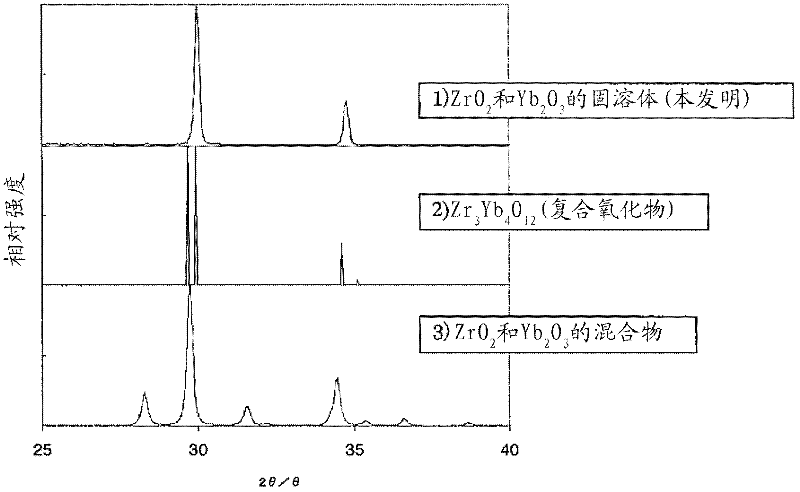

Tungsten electrode material and thermal electron emission current measurement device

InactiveCN102246260ALong electrode lifeAccurate evaluation of electrode characteristicsOxide conductorsDischarge tube/lamp detailsMeasurement devicePower flow

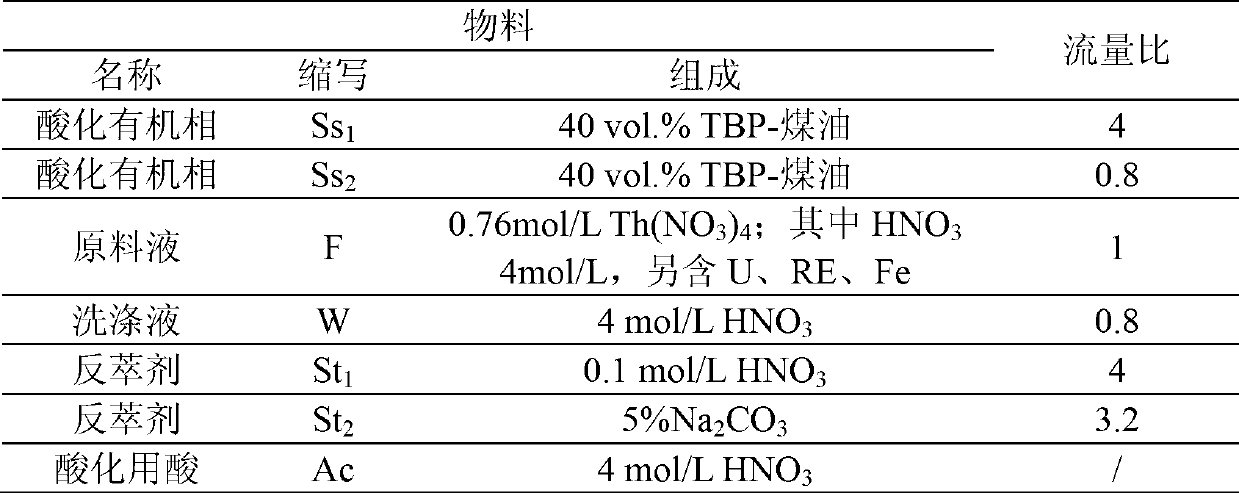

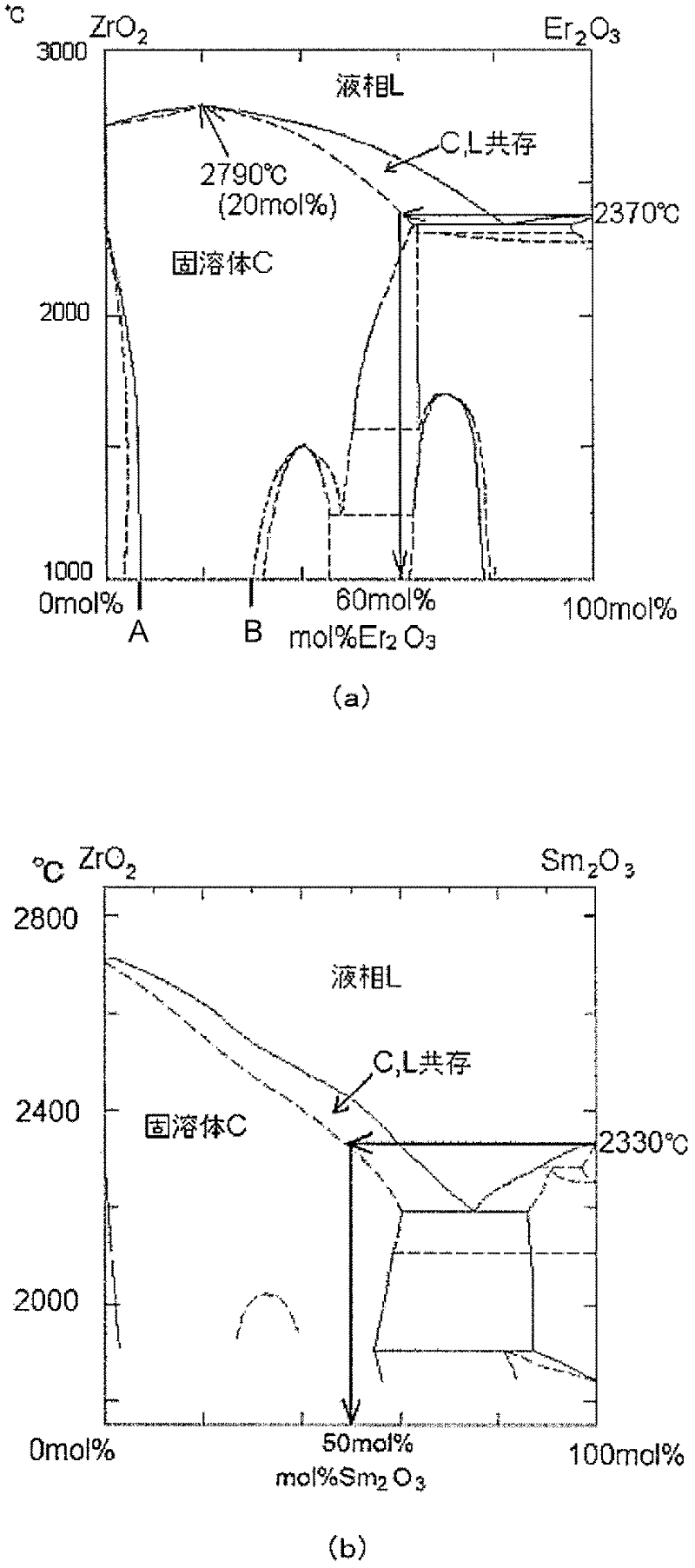

Provided is a tungsten electrode material which uses a material to replace thorium oxide so as to improve the electrode service life as compared to the conventional technique. The tungsten electrode material has a tungsten base and oxide particles dispersed in the tungsten base. The oxide particles are prepared as an oxide solid solution containing in a solid solved state: a Zr oxide and / or a Hf oxide and an oxide of at least one rare earth selected from a group consisting of Sc, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu.

Owner:ALLIED MATERIAL

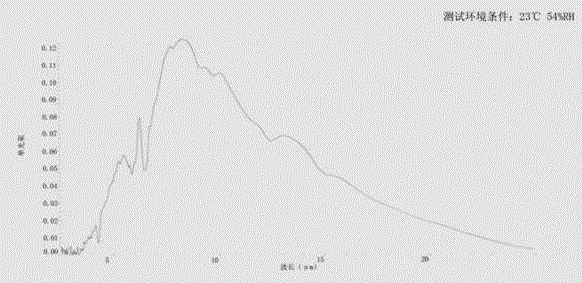

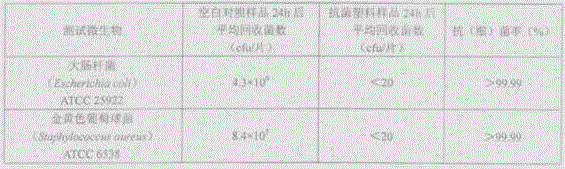

Preparation process of far infrared energy powder and process for manufacturing nanometer quantum wave insole through far infrared energy powder

The invention discloses far infrared energy powder. The far infrared energy powder is prepared from aluminum oxide, silicon dioxide, zirconium sesquioxide, yttrium oxide, ferroferric oxide, magnesium oxide, calcium oxide, potassium trioxide, diboron trioxide, manganese oxide, titanium oxide, thorium oxide and lanthanum oxide. The invention further discloses a preparation process of the far infrared energy powder and a process for manufacturing a nanometer quantum wave insole through the far infrared energy powder. The powder and the process have the advantages that a soft plastic material serves as the body, the far infrared energy powder is added to the body, negative ions and far infrared waves can be released, the magnetic therapy effect is achieved, quite good health care functions are achieved, and good antibacterial performance is also achieved.

Owner:DONGGUAN LYG NANO TECH CO LTD

Liquid nano-catalysis desulfurizer for new dry process cement kiln and preparation method thereof

InactiveCN107174934APrevent compactionRapid responseDispersed particle separationThorium oxidePhenol

The invention discloses a liquid nano-catalysis desulfurizer for a new dry process cement kiln and a preparation method thereof. The liquid nano-catalysis desulfurizer, which is prepared from nano cerium oxide, nano thorium oxide, nano titanium oxide, nano nickel oxide, nano calcium oxide, nano calcium carbonate, carbomite, potassium permanganate, sodium bismuthate, AEO9, octyl phenol polyoxyethylene ether, PEG 200, polymaleic acid, fatty acid polyglycol ester, and diethylene glycol; the allowance is water. In the technical scheme, europium oxide, ferric acetylacetonate and polyoxyethylene ether are added. The desulfurization degree of the liquid nano-catalysis desulfurizer is 100%; sulfur dioxide in smoke gas can be discharged to zero.

Owner:严生

Preparation method for high-density pure tungsten, pure molybdenum, tungsten alloy material and molybdenum alloy material

The invention provides a preparation method for high-density pure tungsten, pure molybdenum and a tungsten alloy material and a molybdenum alloy material. The method comprises the main steps that firstly, raw material powder is crushed, and crushed powder is obtained; secondly, the crushed powder obtained in the first step is subjected to molding, and blanks are obtained; and thirdly, the blanks obtained in the second step are sintered, and the high-density pure tungsten, pure molybdenum and tungsten alloy material and molybdenum alloy material are obtained. The density of the high-density pure tungsten, pure molybdenum and tungsten alloy material and molybdenum alloy material is 98% or above. The hardness, tensile strength, corrosion resisting capacity, machining performance, hot-working performance and other performance of a product in a sintered state can be effectively improved by improving the density of the blanks in the sintered state. The method is suitable for pure tungsten, pure molybdenum, tungsten-lanthanum oxide alloy, tungsten-cerium oxide alloy, tungsten-thorium oxide alloy and other powder metallurgy products.

Owner:安泰天龙钨钼科技有限公司 +1

Mine safety helmet

InactiveCN104886861AImprove fire resistanceImprove stress resistanceHelmetsHelmet coversUranium oxideThorium oxide

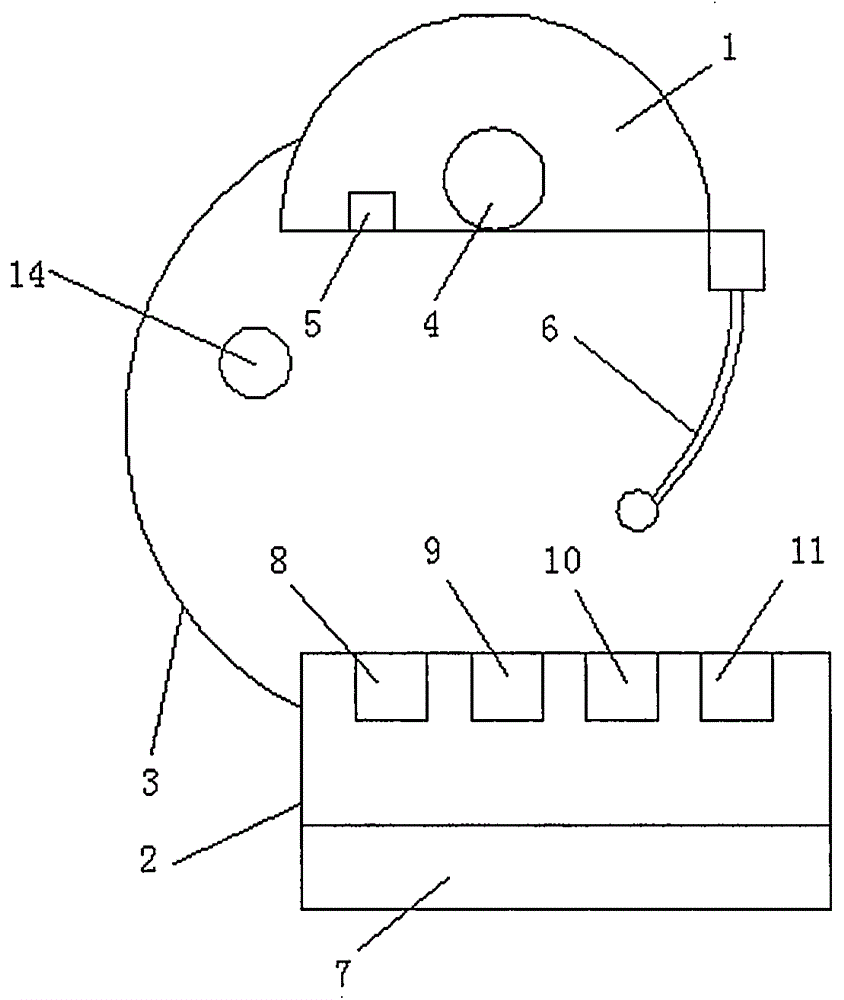

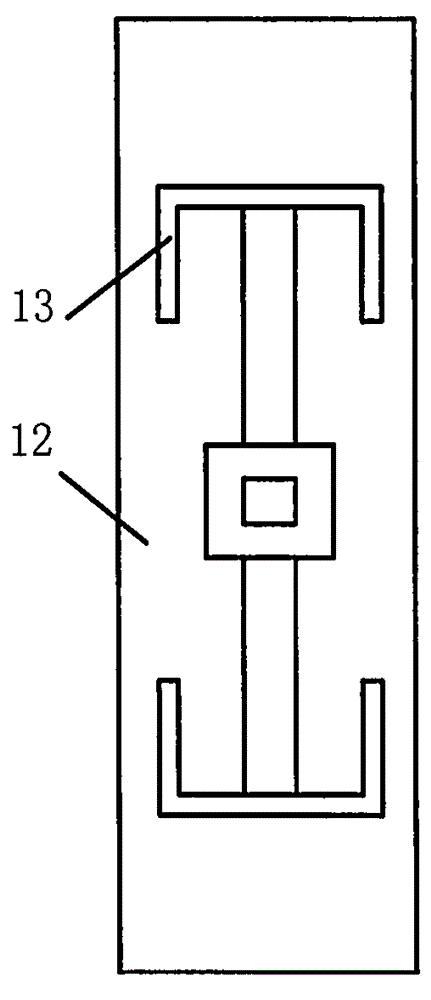

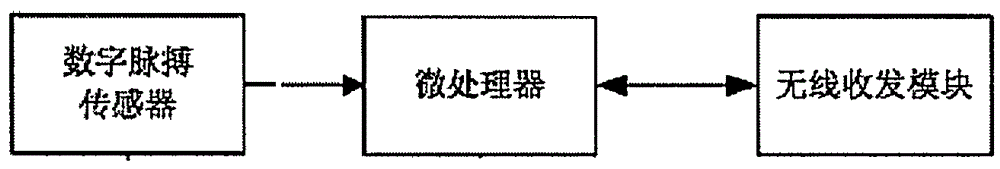

The invention discloses a mine safety helmet. The mine safety helmet comprises a helmet body and a waistband box which are connected through a cable. The helmet body is coated with a silver light layer and comprises an inner layer, a filling layer, a zinc coating and a coating. The inner layer is made of PC materials. The filling layer is an asbestos layer. The zinc coating is colored through static plastic painting. The coating is made of at least one of oxide powder including aluminum oxide, lanthanum oxide, beryllia, calcium oxide, zirconia, uranium oxide, magnesium oxide, cerium oxide, thorium oxide, silicon dioxide and silicon dioxide or the mixture of two or more of the oxide powder. A verbal system, a gas detecting device, a positioning device and a vital sign information wireless transmitting system are additionally arranged on the basis of an ordinary helmet, the function of carrying out safety monitoring on every worker is achieved, and the safety of underground workers is greatly improved.

Owner:SHANGHAI VIRGIN TECH CO LTD

High-refraction low-dispersion optical glass

Owner:CDGM OPTICAL GLASS

Preparation method of sulfide mineral collector

The invention relates to a preparation method of sulfide mineral collector. The method comprises the following steps: sodium sulfide and phosphoric acid are weighed according to the mol ratio of 2 to 3:3 to 6 and added into a gas generator; generated gas is collected and charged into a high-pressure reactor charged with 10 to 13 C of fatty alcohol, thorium oxide catalyst or strongly acid cation resin; the mol ratio of the alcohol to gas is kept to be 1 to 2:1.2 to 2.5; the reaction is performed for 6 to 8 h under the condition that the pressure is 12 to 15 MPa and the temperature is 300 to 450 DEG C to obtain liquid mixture; distillate is collected by distillation under normal pressure at 180 to 300 DEG C according to different carbon numbers, and after the refracting index is detected to be qualified, transparent, colorless and adhesive liquid substance with peculiar odor is obtained, which is the sulfide mineral collector. By adopting the sulfide mineral collector, sulphide ore can be efficiently recovered without active agent, the overall recovery of the sulphide ore reaches larger than 89 percent, and the production cost is reduced.

Owner:广西华锡集团股份有限公司 +1

Process of separating and purifying thorium

ActiveUS20140170039A1Reduce consumptionLow costSolvent extractionTransuranic element compoundsOxalateOrganic solvent

The present invention relates to a process of separating and purifying thorium by solvent extraction, comprising: 1) mixing a thorium enrichment with an inorganic acid to produce a feed; 2) mixing a neutral phosphorus extractant with an organic solvent to obtain an organic phase; 3) extracting from the feed with the organic phase to obtain a loaded organic phase; 4) scrubbing the loaded organic phase with a scrubbing solution and then back-extracting thorium with a stripping solution to obtain a thorium solution; 5) mixing the thorium solution with an oxalate to obtain a precipitate, which is then sintered to obtain thorium oxide. The present process allows to increase the purity of thorium from 80%-99% to 99.99% or more with a yield of more than 98%.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Novel powder nanometer catalytic sulfur fixation agent for dry cement raw material, and preparation method thereof

InactiveCN107164013ALower activation energyEmission reductionSolid fuelsTitanium oxideFixation agent

The invention discloses a novel powder nanometer catalytic sulfur fixation agent for a dry cement raw material, and a preparation method thereof, wherein the novel powder nanometer catalytic sulfur fixation agent comprises nanometer lanthanum oxide, nanometer thorium oxide, nanometer praseodymium oxide, nanometer titanium oxide, nanometer nickel oxide, nanometer magnesium oxide, nanometer calcium oxide, nanometer calcium carbonate, hydroxyl calcium, potassium permanganate, potassium bismuthate, fly ash, carbon black, and the balance of a dispersion carrier. According to the technical scheme, by adding europium oxide and aluminum acetylacetonate, the sulfur fixation efficiency can achieve more than 98%. According to the present invention, the product is mixed into the raw material through the air chute in front of the homogenizing bin, and at the high temperature, the surface activity of the raw material is improved and the activation energy of the reaction with sulfur dioxide is sufficiently reduced through catalysis, oxidation and metal ion exchange, such that SO2 generated during the combustion process generates the sulfate-like solid material, and sulfate-like solid material is subjected to solid solution into the cement clinker so as not to cause corrosion and other side effects on the cement pre-heater, the kiln and other equipment.

Owner:严生

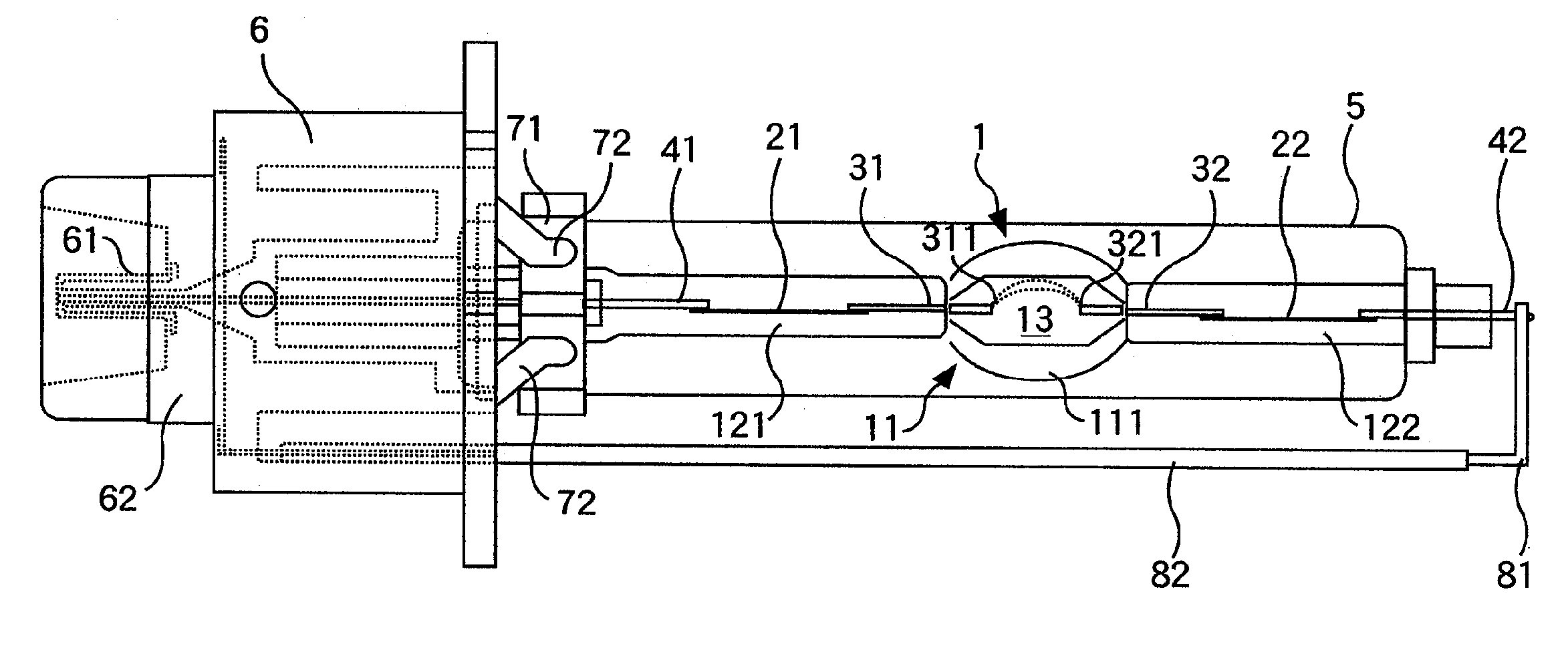

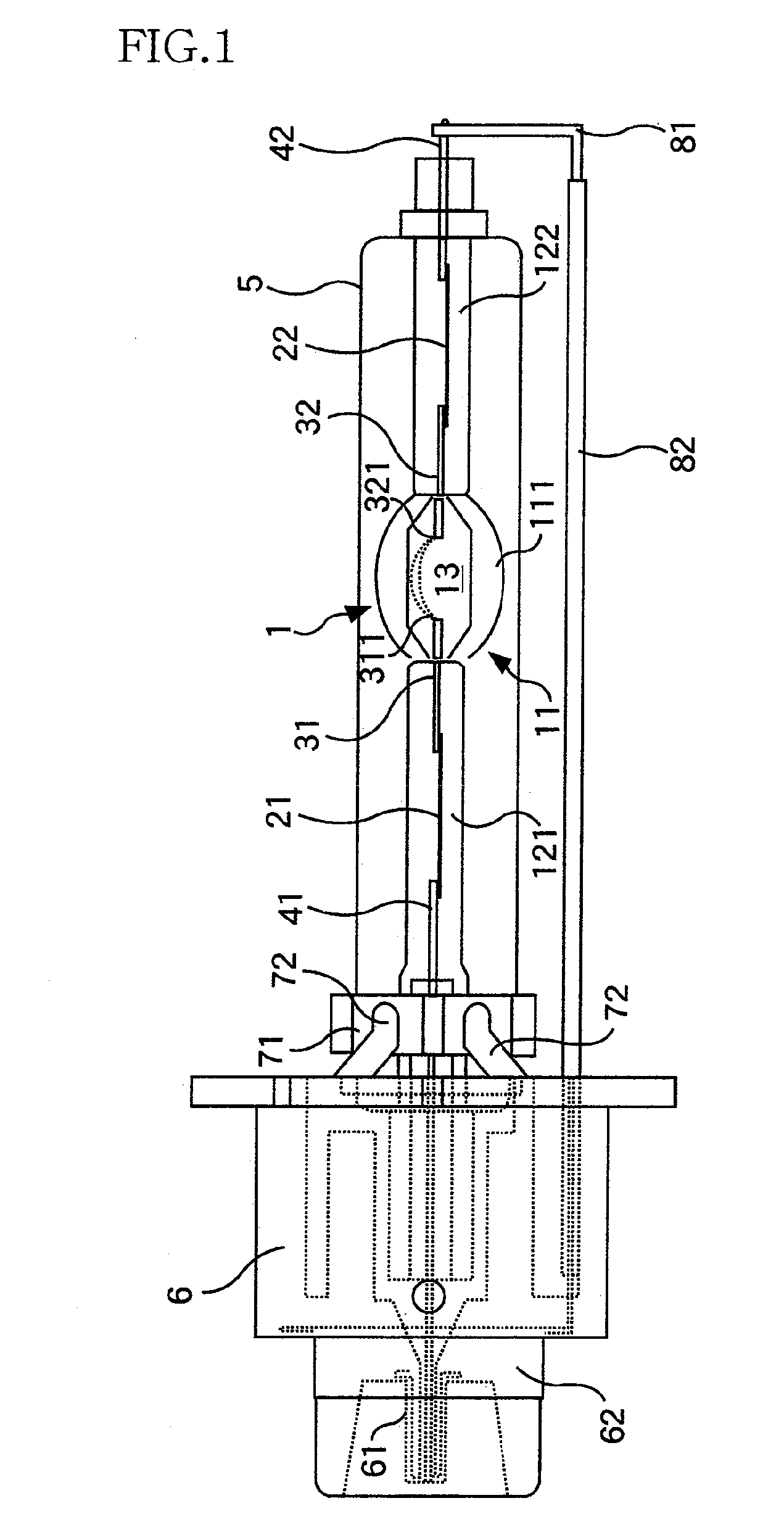

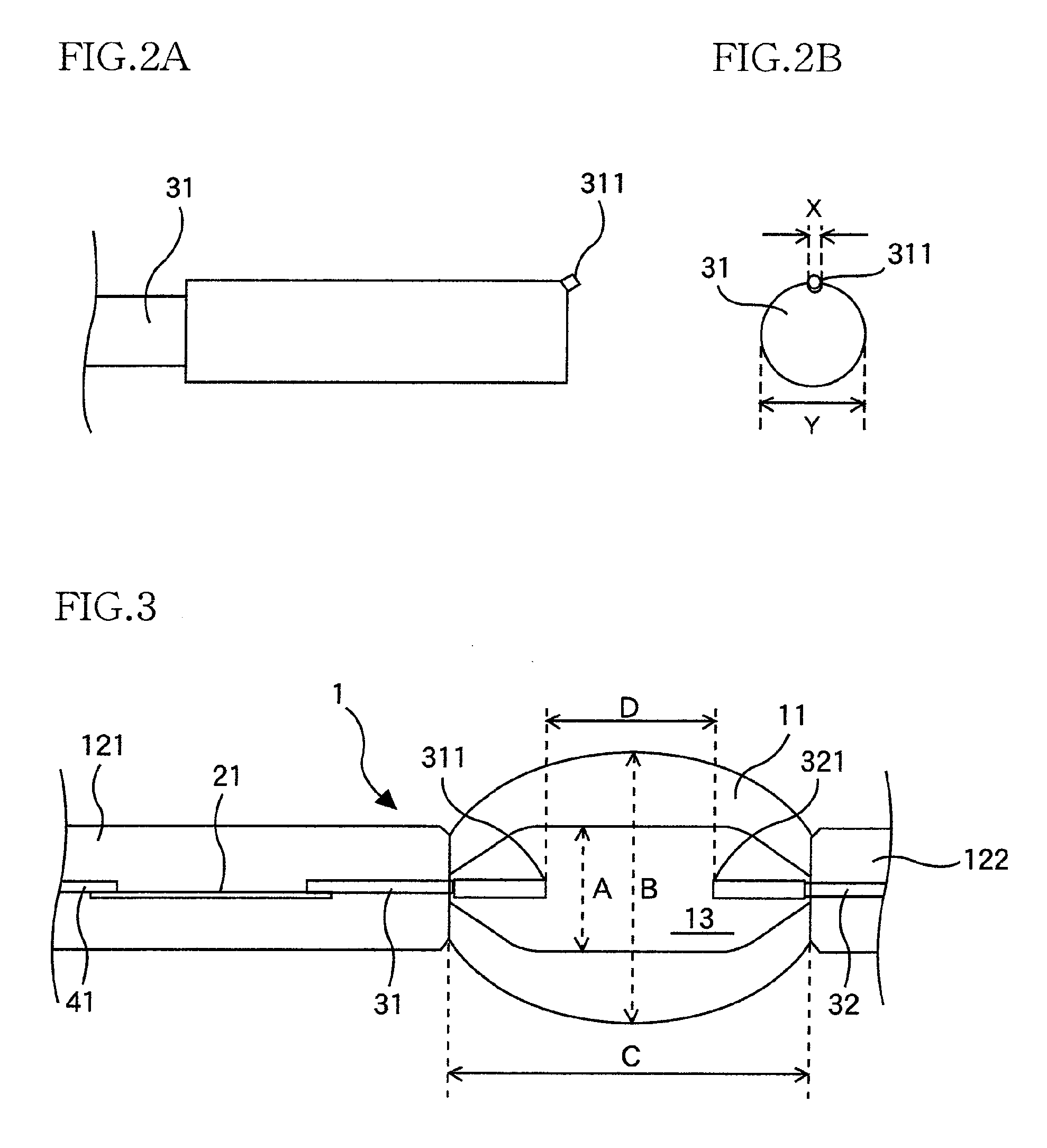

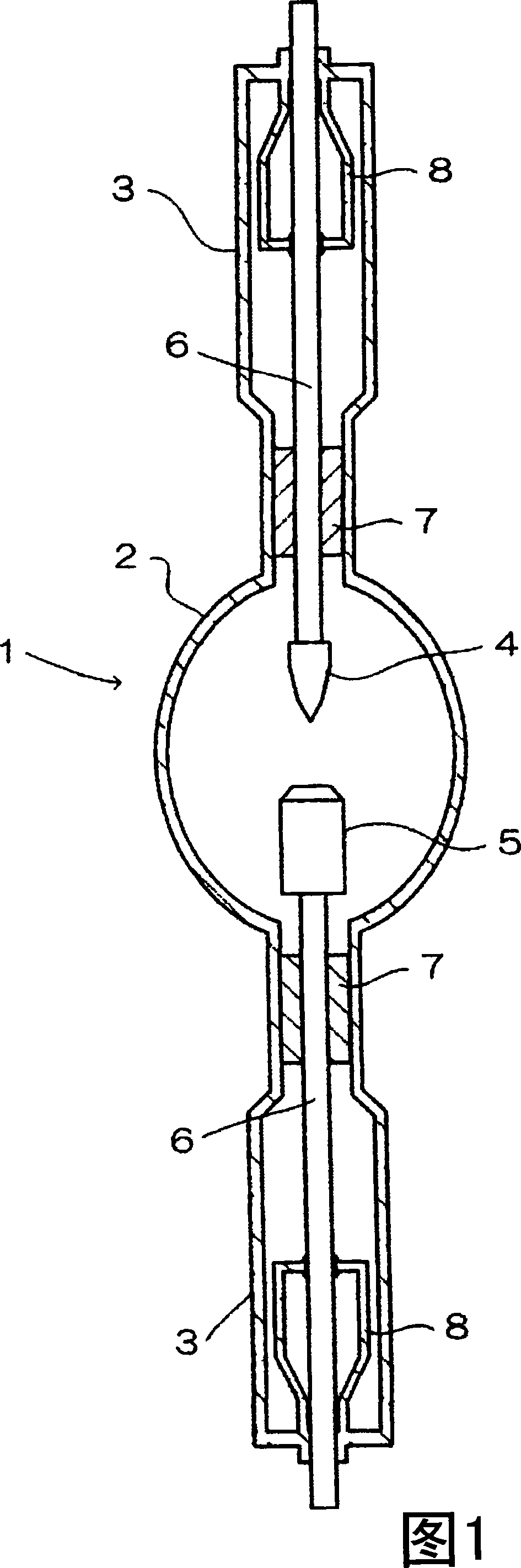

Metal halide lamp and lighting device using therewith

InactiveUS20090129070A1Suppress generationSuppress fluctuationsLighting support devicesProtective devices for lightingNoble gasThorium oxide

A metal halide lamp comprises a translucent air tight vessel (1) having an arc tube section (11) forming a discharge space (13) and sealing portions (121, 122) formed at the both ends thereof, a discharge medium with which the discharge space is filled, and a pair of electrodes (31, 32) projecting into the discharge space. The discharge medium is composed of a metal halide and rare gas and essentially containing no mercury. The pair of the electrodes is composed of tungsten containing thorium oxide. Protrusions (311, 312) are formed respectively, on the pair of electrodes and arc is formed between them when the metal halide lamp is operated.

Owner:HARISON TOSHIBA LIGHTING CORP

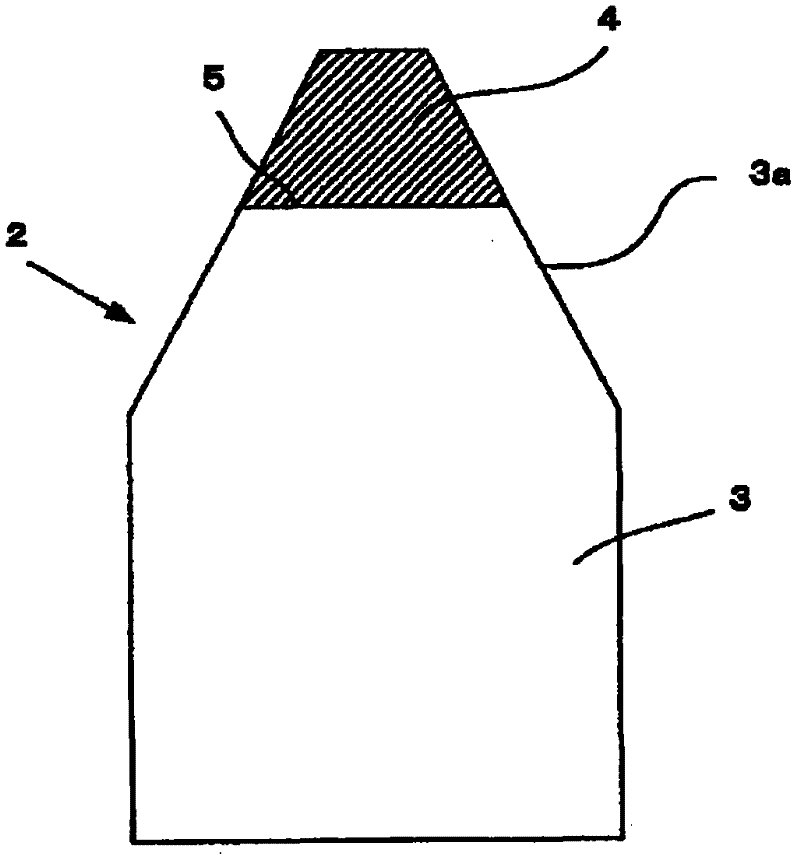

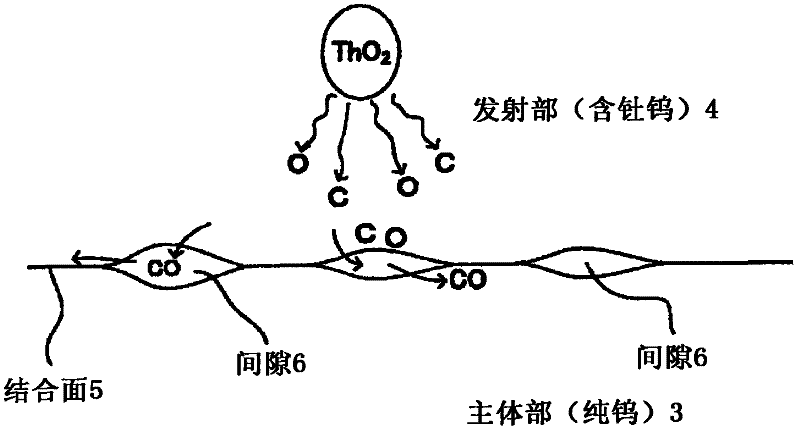

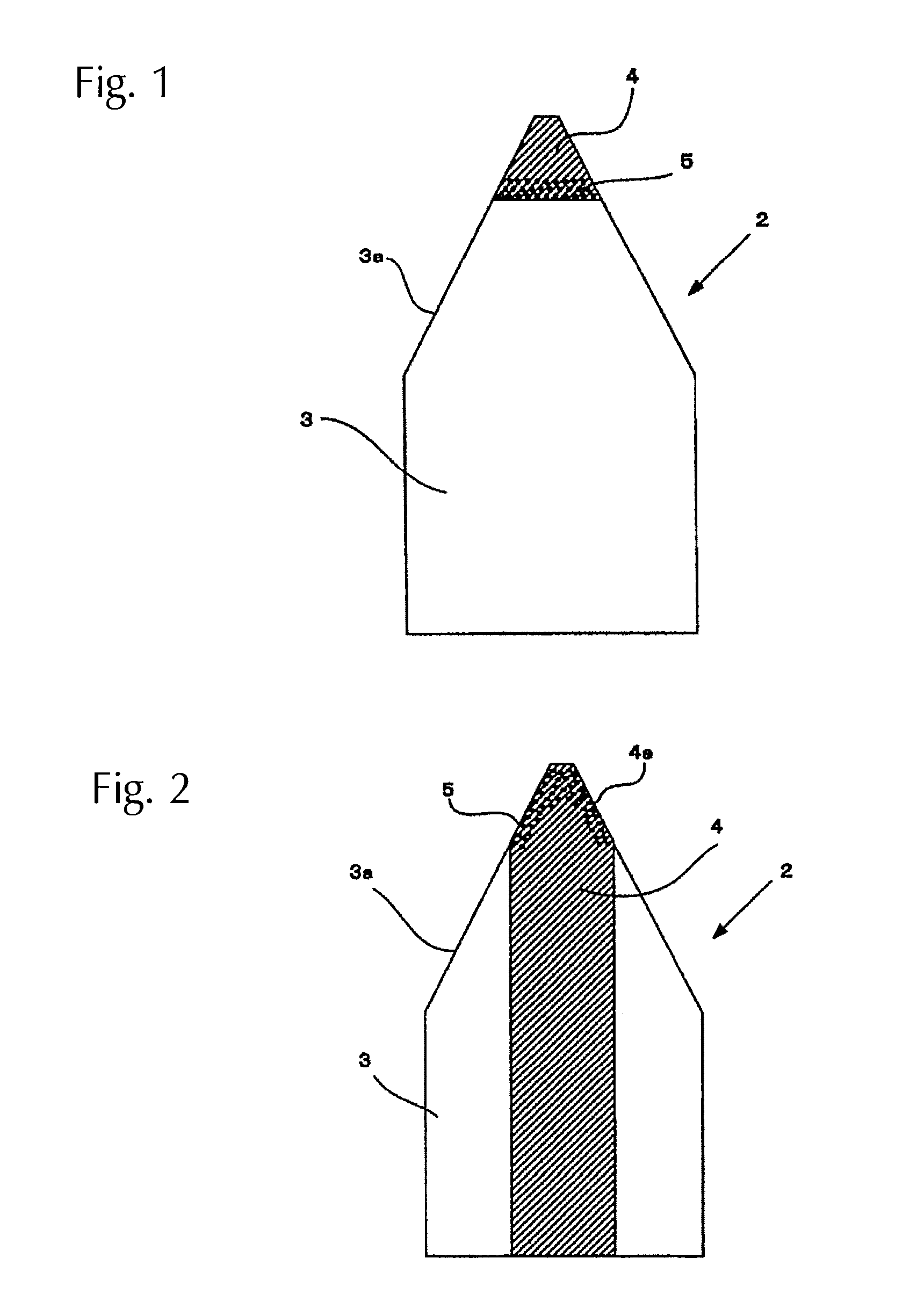

Short arc type discharge lamp

ActiveCN102315078AEfficient use ofNo depletionHigh-pressure discharge lampsThorium oxideOptoelectronics

A short arc type discharge lamp wherein a cathode and an anode are arranged opposite to each other in an interior of a light emitting tube and said cathode comprises a main part made from tungsten and an emitter part made from thoriated tungsten. The cathode effectively utilize thorium oxide contained in the emitter part, and provides a configuration preventing exhaustion of the thorium oxide on the surface of the emitter part.The short arc type discharge lamp is characterized in that gaps are formed locally at a joint face of said main part and the emitter part, and carbonic oxide produced by a reduction reaction of the thorium oxide contained in the emitter part is emitted to the outside.

Owner:USHIO DENKI KK

Rare-earth modified active carbon catalytic material and preparation method thereof

InactiveCN103566922AReduce manufacturing costSimple production processOther chemical processesDispersed particle separationThorium oxideGadolinium oxide

The invention relates to a rare-earth modified active carbon catalytic material, which is prepared from the following raw materials in parts by weight: 130 to 140 parts of active carbon, 1 to 3 parts of lanthanum oxide, 1 to 3 parts of thorium oxide, 1 to 3 parts of terbium oxide, 1 to 3 parts of dysprosium oxide, 1 to 3 parts of cerium oxide, 1 to 3 parts of neodymium oxide, 1 to 3 parts of gadolinium oxide, 10 to 13 parts of chitosan, 10 to 13 parts of rectorite, 2 to 3 parts of nano white mica powder, 5 to 8 parts of sodium silicate, 1 to 2 parts of sodium benzoate, 4 to 5 parts of modified diatomite and an appropriate amount of water. The active carbon is loaded with rare-earth metal oxide and nano white mica powder, so that the carbon oxide (CO) can be adsorbed and eliminated at the normal temperature, the conversion rate of the catalytic material on the CO is 99.97 percent, the catalytic activity still can reach 99.2 percent after the catalytic material is continuously used for 600 hours; moreover, the production process is simple, and the preparation cost of the catalyst is low; by utilizing the rectorite, the catalytic material has an ion exchanging function; the rare-earth modified active carbon catalytic material is suitable for catalytically oxidizing the CO and also can be used for purifying the water.

Owner:BENGBU HUAFANG FILTER

High fire resistance ceramic tile and production method thereof

The invention discloses a high fire resistance ceramic tile and a production method thereof. The high fire resistance ceramic tile is formed by the following raw materials of, by weight, 41 to 53 parts of periclase, 34 to 46 parts of cyanite, 27 to 39 parts of diaspore, 13 to 19 parts of aluminum dihydrogen tripolyphosphate, 11 to 17 parts of boride silicon, 10 to 15 parts of waste silica bricks, 2 to 4 parts of thorium dioxide, 5 to 8 parts of hydroxy ethyl methacrylate, 17 to 23 parts of compound clay, 3 to 5 parts ofalpha-olefin sulfonate, 1 to 2 parts of lauramidopropylamine oxide, 2 to 3 parts of anhydrous sodium sulphate and 1 to 2 parts of neopentyl glycol. According to the high fire resistance ceramic tile, the fire resistance is excellent, the refractoriness reaches 1250 DEG C, the strength is high, the abrasion resistance, the chemical corrosion resistance and the cracking resistance are achieved, and the high fire resistance ceramic tile can be widely applied to high fire resistance rating requirements of buildings.

Owner:安徽省亚欧陶瓷有限责任公司

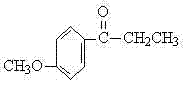

A kind of preparation method of pharmaceutical intermediate p-methoxypropiophenone

InactiveCN102260156AReduce pollutionEasy to separate and purifyCarbonyl compound preparation by condensationPropanoic acidThorium oxide

The invention discloses a preparation method of a medical intermediate p-methoxypropiophenone, which uses p-methoxybenzoic acid and propionic acid as raw materials to prepare p-methoxypropiophenone by reacting in the presence of a composite catalyst; The composite catalyst is composed of iron powder, manganese oxide and thorium oxide. The present invention uses p-methoxybenzoic acid and propionic acid as raw materials to synthesize p-methoxypropiophenone under the action of the composite catalyst. The separation and purification process is simple and the reaction time is short. Short, high product yield, so that the product yield reaches more than 71%, high product purity, low energy consumption, small environmental pollution, low cost, is an ideal process for industrialized production.

Owner:NANTONG UNIVERSITY

Method for preparing fuel particles and core-shell fuel particles prepared by using method

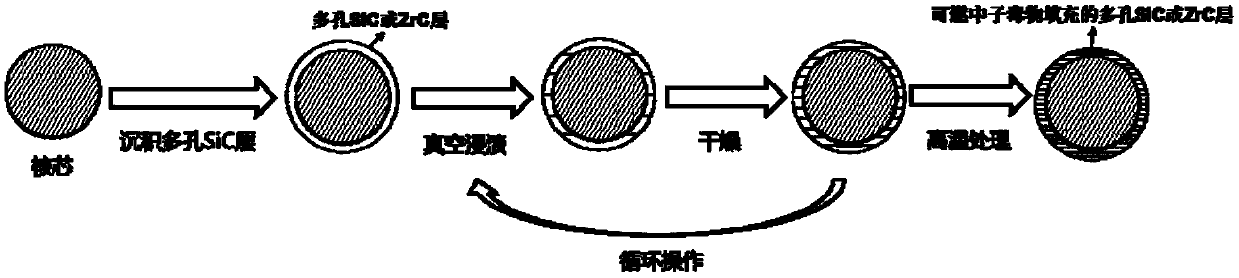

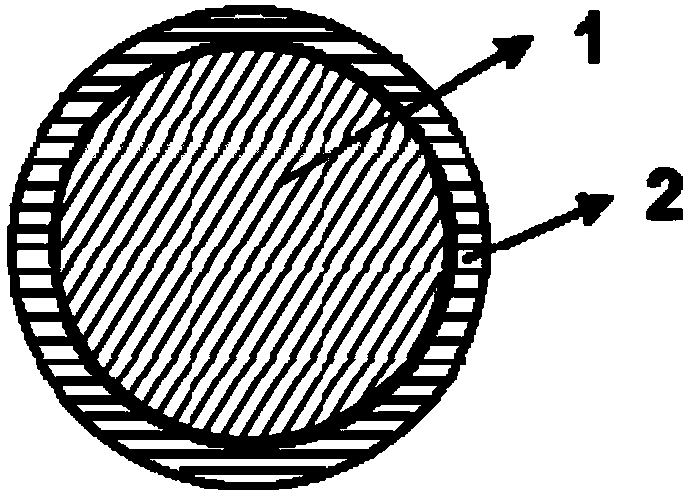

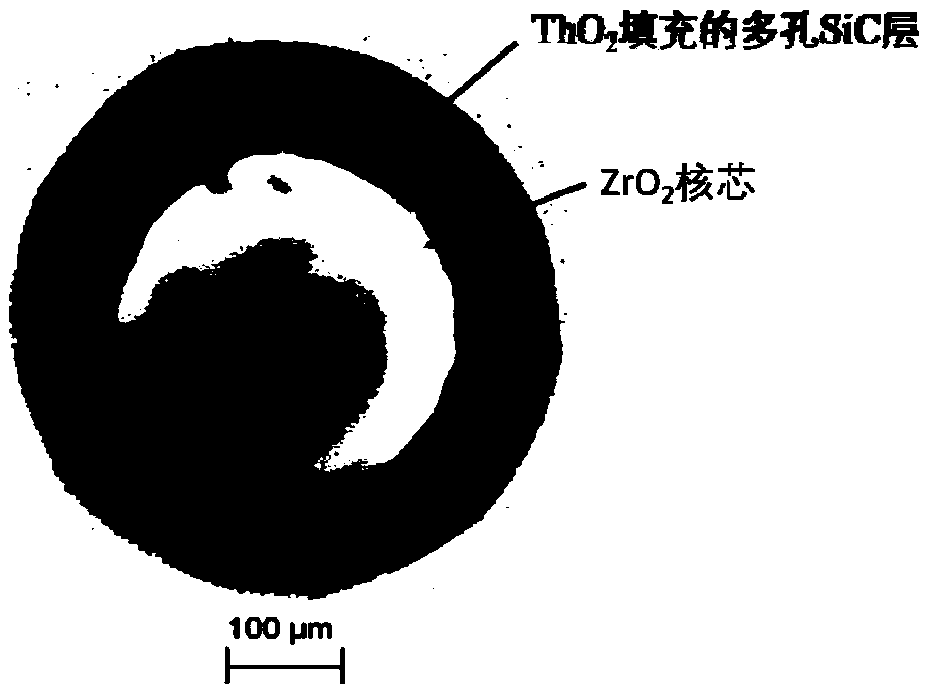

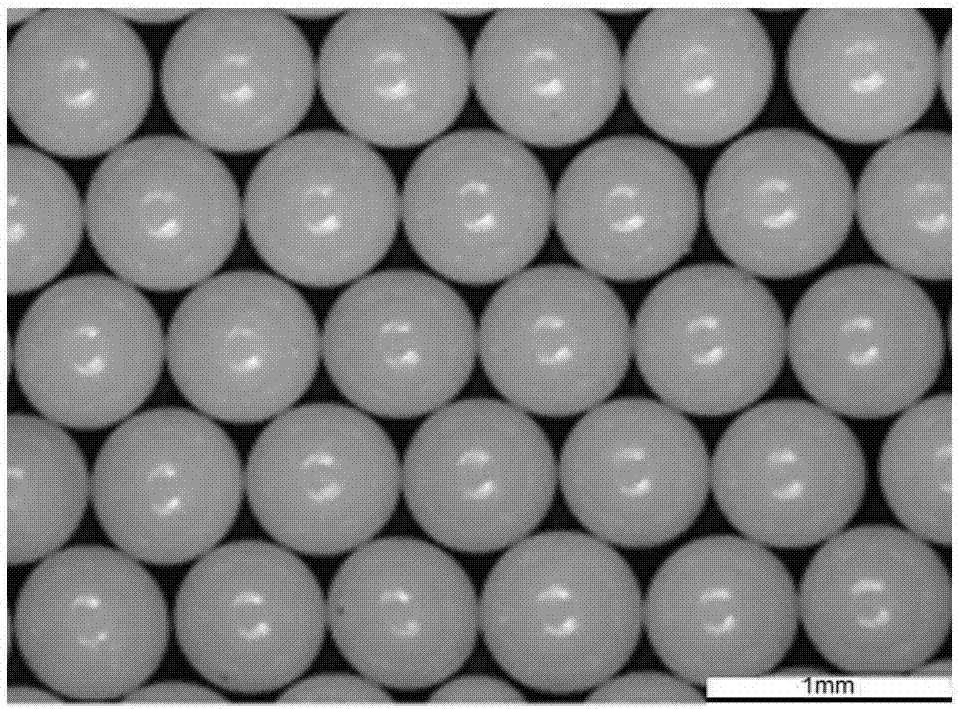

ActiveCN109545414AImprove securityImprove economyNuclear energy generationReactors manufactureNeutron poisonThorium oxide

The invention relates to a method for preparing fuel particles. The method comprises the steps: supplying a spherical core, performing formation of a porous silicon carbide layer or a zirconium carbide layer on the core through chemical vapor deposition so as to obtain porous silicon carbide layer / zirconium carbide layer-coated particles, soaking the porous silicon carbide layer / zirconium carbidelayer-coated particles in an active liquid for vacuum impregnation so as to obtain compound-filled porous silicon carbide layer / zirconium carbide layer-coated particles, and decomposing compounds which are filled in the compound-filled porous silicon carbide layer / zirconium carbide layer-coated particles so as to form combustible neutron-poison oxides or thorium oxide and finally obtain the fuel particles. The invention also provides core-shell fuel particles prepared by using the method. The fuel particle safety which is stack safety is improved through coating of the silicon carbide layer orthe zirconium carbide layer outside the core, and meanwhile the stack economy can be improved through the combustible neutron-poison oxides or thorium oxide filled in the silicon carbide layer or zirconium carbide layer.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Special toughened high-temperature-resistant ceramic for fuel engine cylinder liners and preparation method thereof

The invention discloses a special toughened high-temperature-resistant ceramic for fuel engine cylinder liners and a preparation method thereof. The special ceramic is prepared from the following raw materials in parts by weight: 42-54 parts of anorthite, 24-36 parts of kyanite, 38-49 parts of zirconite, 22-34 parts of bauxite, 16-22 parts of magnesium oxide, 13-19 parts of molybdenum disilicide, 2-4 parts of lanthanum oxide, 10-15 parts of silicon nitride, 5-10 parts of ferric oxide, 4-7 parts of hafnium boride, 11-17 parts of calcium oxide, 1-3 parts of thorium oxide, 5-8 parts of sorbitol, 2-4 parts of sodium oleate, 4-7 parts of triisopropanolamine, 3-5 parts of carboxymethyl alantin sodium, 10-15 parts of water glass, 8-14 parts of polyvinyl acetate, 3-6 parts of hydroxypropyl distarch phosphate and a right amount of deionized water. The molybdenum disilicide, silicon nitride, hafnium boride and sintering technique are adopted to enhance the heat resistance and toughening performance of the ceramic; abundant stable lanthanum oxide, calcium oxide and thorium oxide stabilizers are utilized to lower the sintering temperature and difficulty; and by using the stabilizers, the high-temperature resistance is up to 2000-2500 DEG C, the high-temperature resistance time is up to 760-850 hours, the toughness KIc is 4-6, and the folding strength is 400-600 MPa.

Owner:南通拓创光电材料科技有限公司

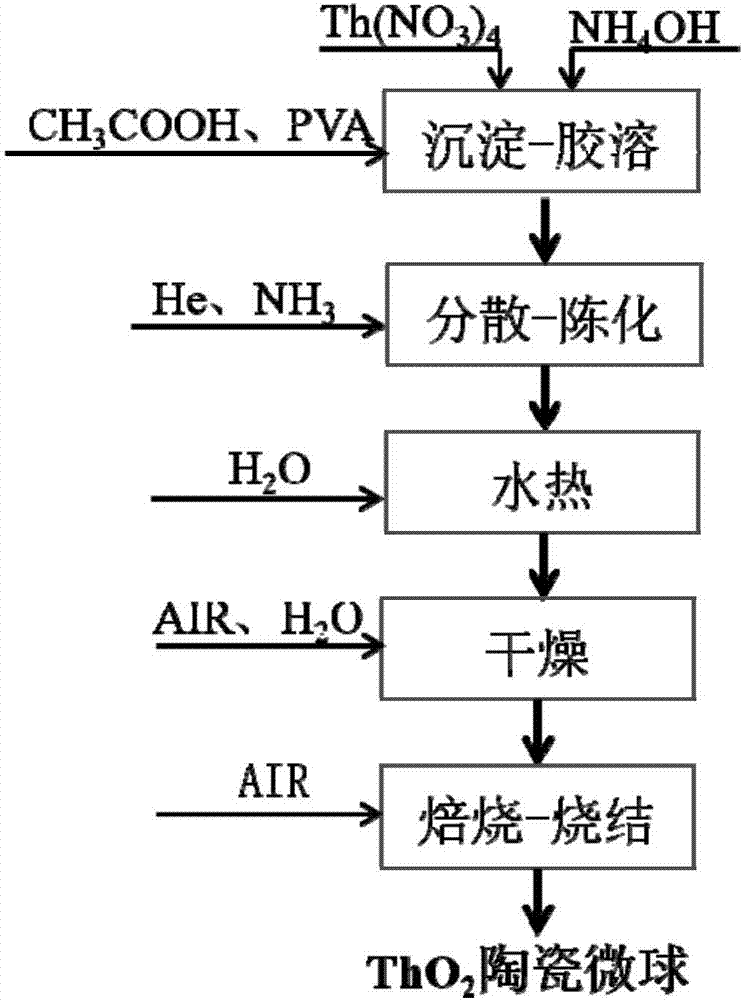

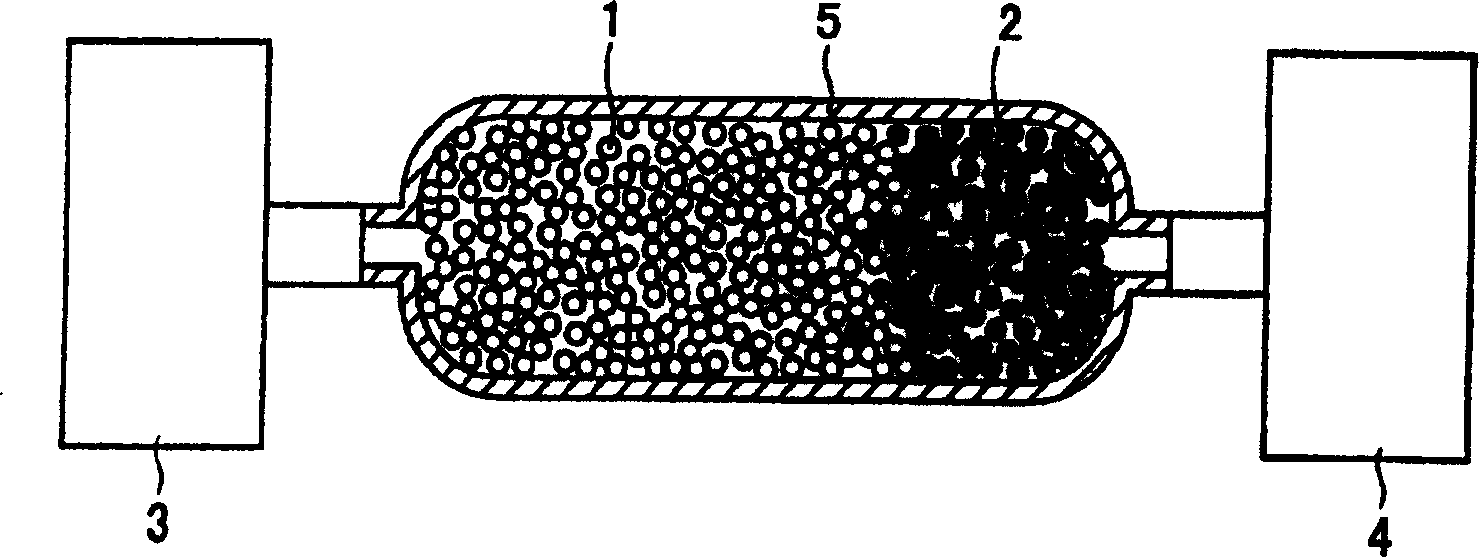

Method for preparing ceramic micro-spheres of thorium oxide

ActiveCN107010955AReduce the probability of ruptureAvoid breakingNuclear energy generationReactors manufacturePolyvinyl alcoholThorium oxide

The invention relates to a method for preparing ceramic micro-spheres of thorium oxide. The method includes dropwise adding ammonia water into thorium nitrate solution to form hydrolysis solution, dropwise adding glacial acetic acid into the hydrolysis solution to regulate the pH (potential of hydrogen) of the hydrolysis solution, and adding polyvinyl alcohol into the hydrolysis solution under stirring conditions to form thorium oxide colloidal solution; dispersing the thorium oxide colloidal solution to obtain liquid drop and allowing the liquid drop to sequentially flow through helium zones, ammonia gas zones and ammonia water zones; arranging dispersed gel particles in strong ammonia water and aging the dispersed gel particles; adding the aged gel particles and deionized water into a hydrothermal reaction kettle and carrying out temperature reaction; placing gel particles into a drying furnace after hydrothermal reaction is carried out on the gel particles, and heating and drying the gel particles under humidity control to form dried gel particles; placing the dried gel particles in a calcination furnace, filling the calcination furnace with air and heating and calcining the gel particles to obtain calcined gel particles; placing the calcined gel particles in a sintering furnace, filling the sintering furnace with air and heating and sintering the calcined gel particles to obtain the ceramic micro-spheres. The method has the advantage that the ceramic micro-spheres of the thorium oxide can be prepared by the aid of simple technologies.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

High-plasticity wear-resistance ceramic material and preparation method thereof

The present invention discloses a high-plasticity wear-resistance ceramic material and a preparation method thereof. The preparation method comprises: weighing 3-9 parts of neodymium oxide, 5-12 parts of alumina, 20-38 parts of silica, 3-8 parts of zirconium oxide, 2-7 parts of boron oxide, and 1-6 parts of thorium oxide, and mixing in a ball mill to obtain a mixture A; adding the mixture A, 8-16 parts of cyclohexane dicarboxylic acid nonyl ester, and 23-35 parts of 2-methyl-2-nitro-1-propanol to a reactor, and carrying out a heating stirring reaction; continuously adding 12-18 parts of cellulose acetate phthalate and 15-25 parts of methyl 2-hydroxyethyl cellulose, and carrying out a stirring reaction at a temperature of 120-150 DEG C; drying in a vacuum oven to obtain mixed powder B; carrying out pressing molding on the mixed powder B under a pressure of 80-95 MPa; and placing into a muffle furnace under nitrogen protection, and calcining for 5-8 h at a temperature of 950-1000 DEG C so as to obtain the high-plasticity wear-resistance ceramic material. According to the present invention, the high-plasticity wear-resistance ceramic material has advantages of high melting point, high hardness, oxidation resistance and the like of the existing ceramic material, and further has good plasticity and good wear resistance.

Owner:YANCHENG SHENYUAN PLASTIC

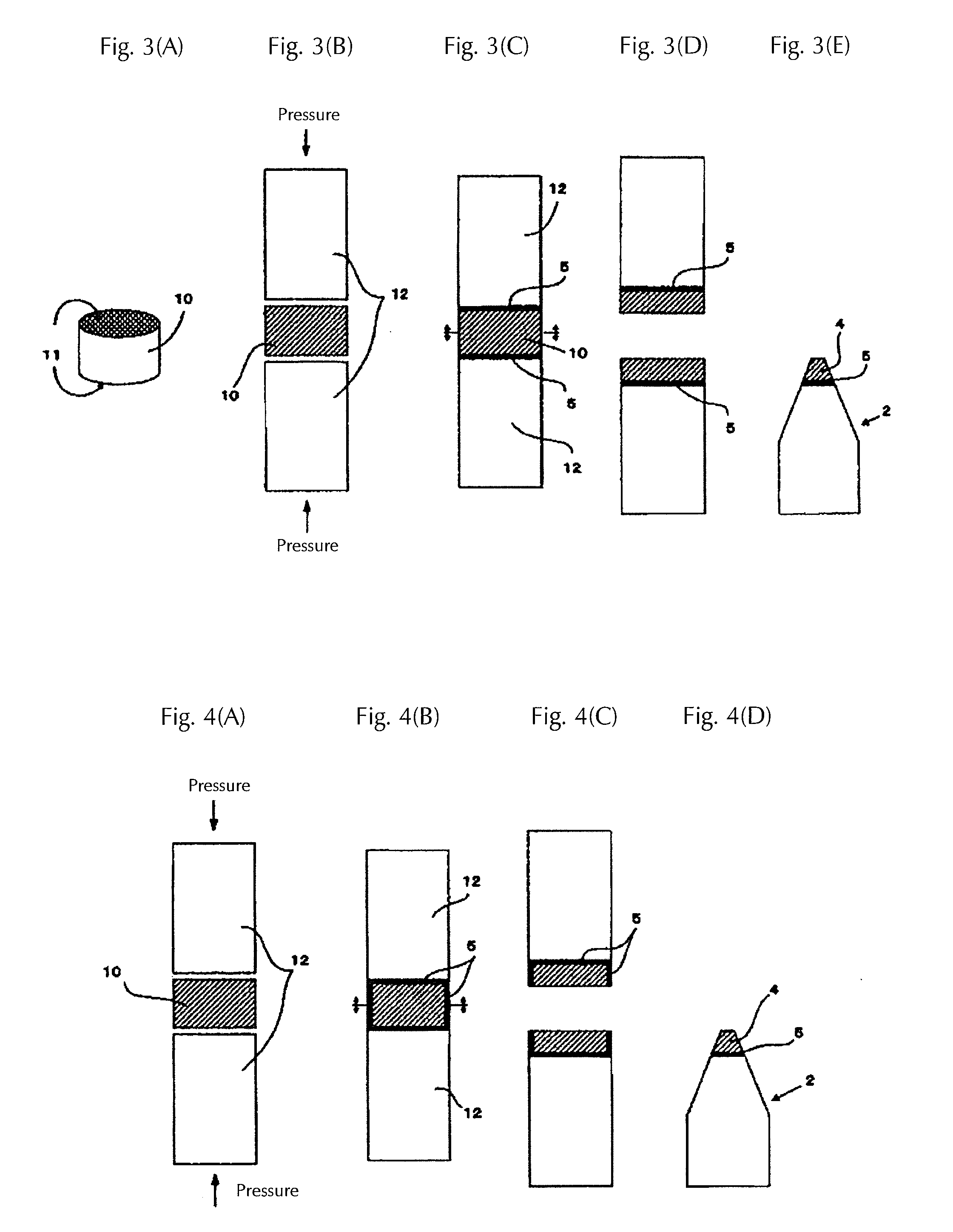

Negative electrode material for high intensity discharge lamp and manufacturing method thereof

ActiveCN103343275AIncrease in crystal defectsExtended service lifeGas discharge lamp detailsCold cathode manufactureManufacturing technologyThorium oxide

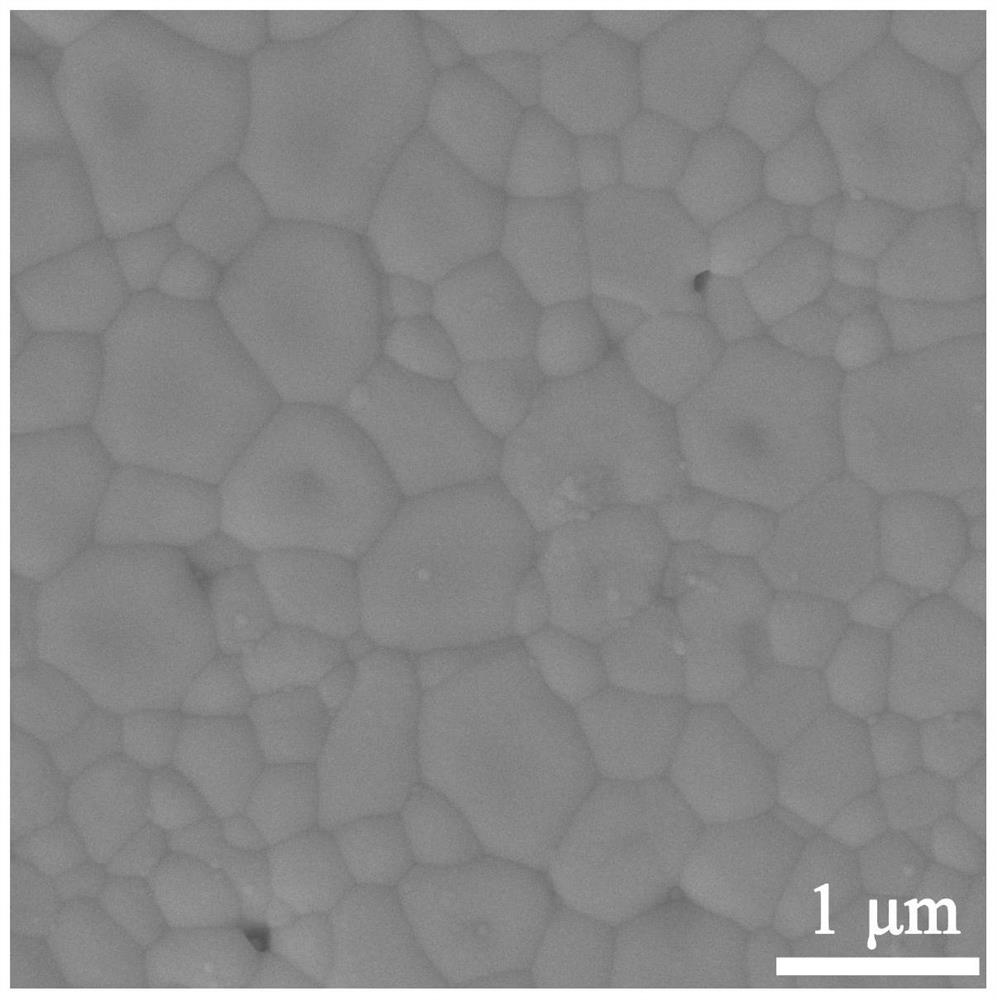

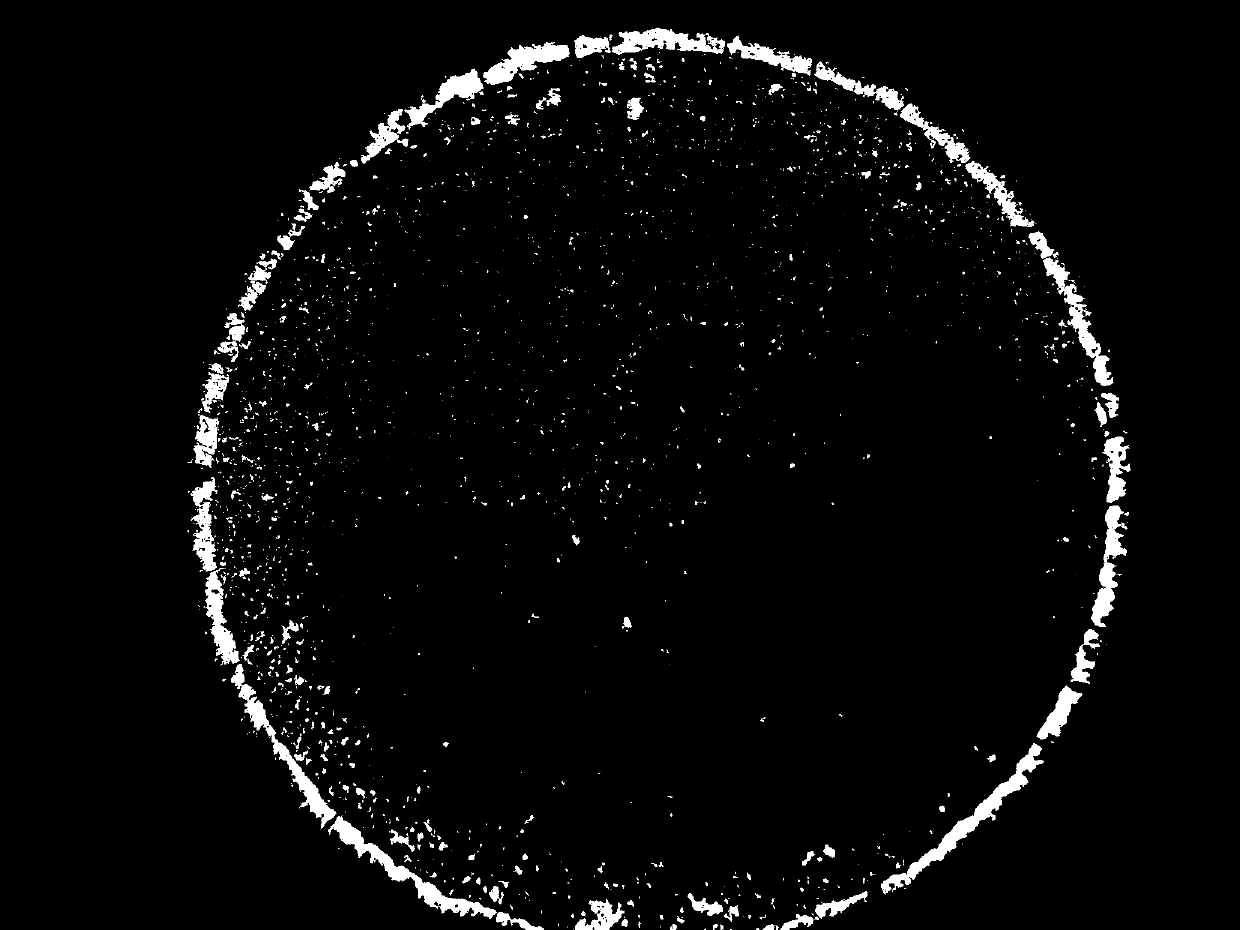

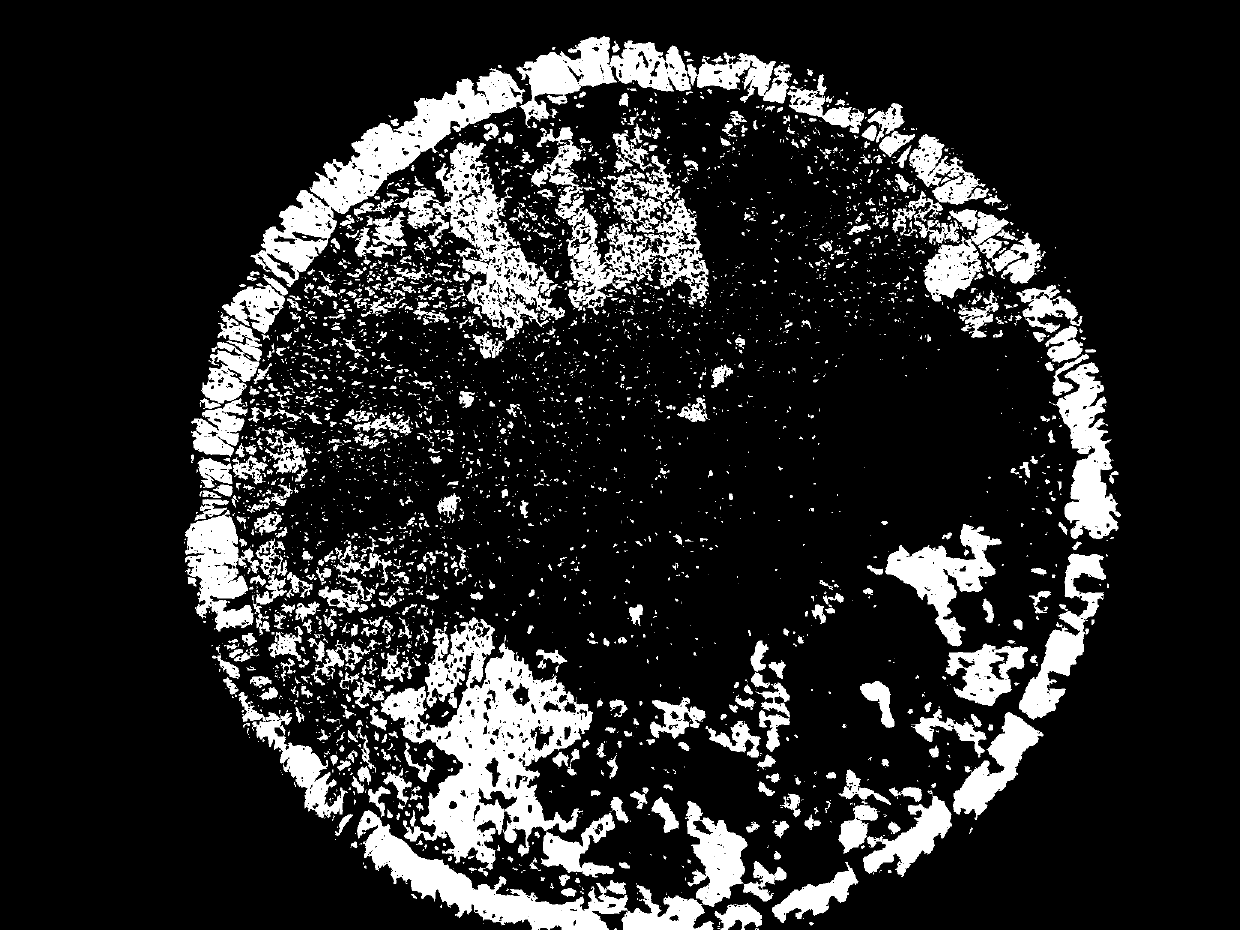

The invention relates to the field of metal material manufacturing technology, and specifically relates to a negative electrode material for a high intensity discharge lamp and a manufacturing method thereof. The negative electrode material comprises the following components: 1.5%-2.0% of thorium oxide, 0.0020%-0.0080% of potassium and 97%-98% of tungsten. Compared with a conventional negative electrode material, the negative electrode material provided by the invention has the following advantages that (1) thorium oxide particles of a thorium tungsten negative electrode even if 0.0020%-0.0080% of potassium is doped are fine and uniformly distributed; and (2) the thorium tungsten negative electrode contains a trace amount of potassium element, and by adopting the potassium-doped tungsten thorium negative electrode, the growth speed of crystal particles is slow, the tip shape of the electrode can be stably maintained, and the service life of the discharge lamp is prolonged.

Owner:威海多晶钨钼科技有限公司

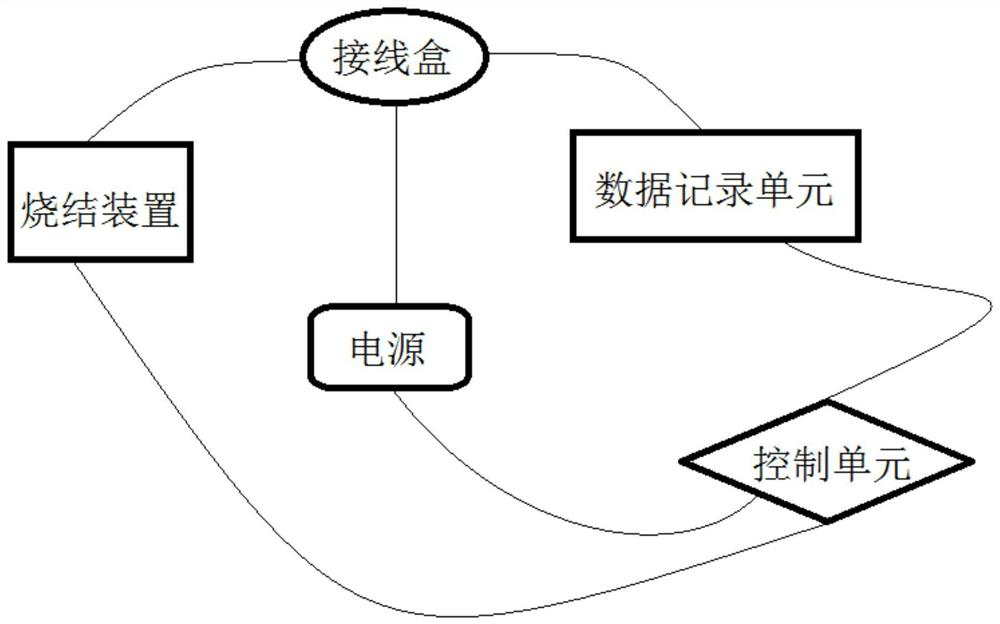

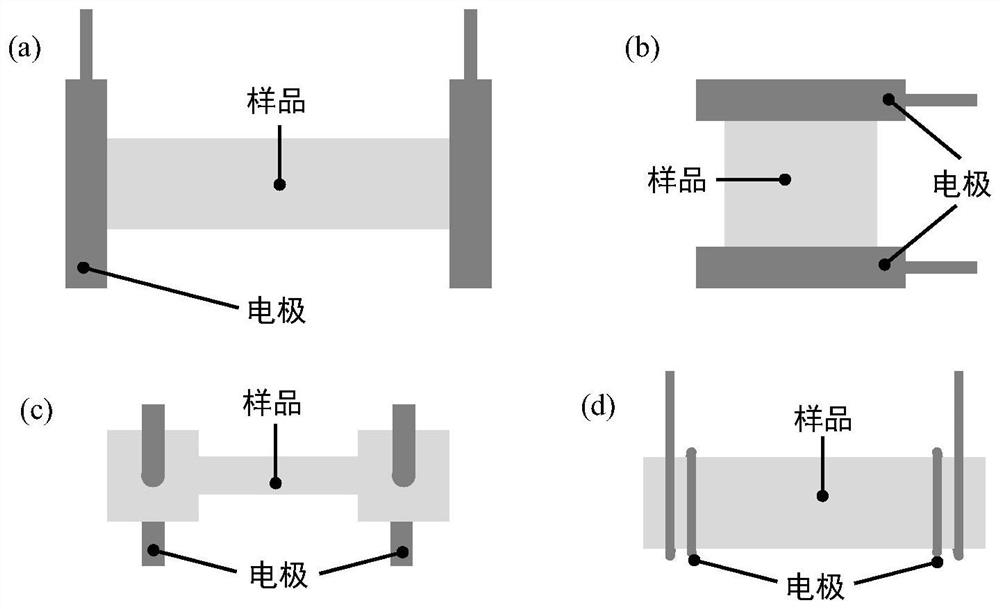

Oxide composite nuclear fuel pellet and preparation method thereof

InactiveCN112358308AHigh densityShorten sintering holding timeNuclear energy generationReactor fuel susbtancesUranium oxideThorium oxide

The invention provides a preparation method of an oxide composite nuclear fuel pellet, and belongs to the technical field of nuclear material preparation. The preparation method comprises the following steps: 1) preparing mixed powder: putting oxide nuclear fuel powder and filler powder into a ball-milling tank, adding zirconium dioxide grinding balls, mixing and carrying out ball milling; 2) compression molding: carrying out compression molding on the ball-milled mixed powder, and demolding to obtain an oxide composite nuclear fuel blank; 3) flash burning: electrifying the oxide composite nuclear fuel blank body, applying constant electric fields to two ends of the blank body, simultaneously raising the temperature, and carrying out flash burning when the flash burning temperature is met,wherein the current is a constant current of 0-700mA / mm < 2 >, the field intensity is 0-300V / cm, the flash burning temperature is 25-1000 DEG C, and the flash burning time is 0-600s; and after flashburning is completed, cooling and demolding and obtaining the oxide composite nuclear fuel pellet. According to the method, the constant direct-current electric field is applied to the two ends of theblank by utilizing a flash burning technology, so that the sintering temperature of uranium dioxide or thorium dioxide can be remarkably reduced, the sintering time is shortened and the density of the material is improved.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

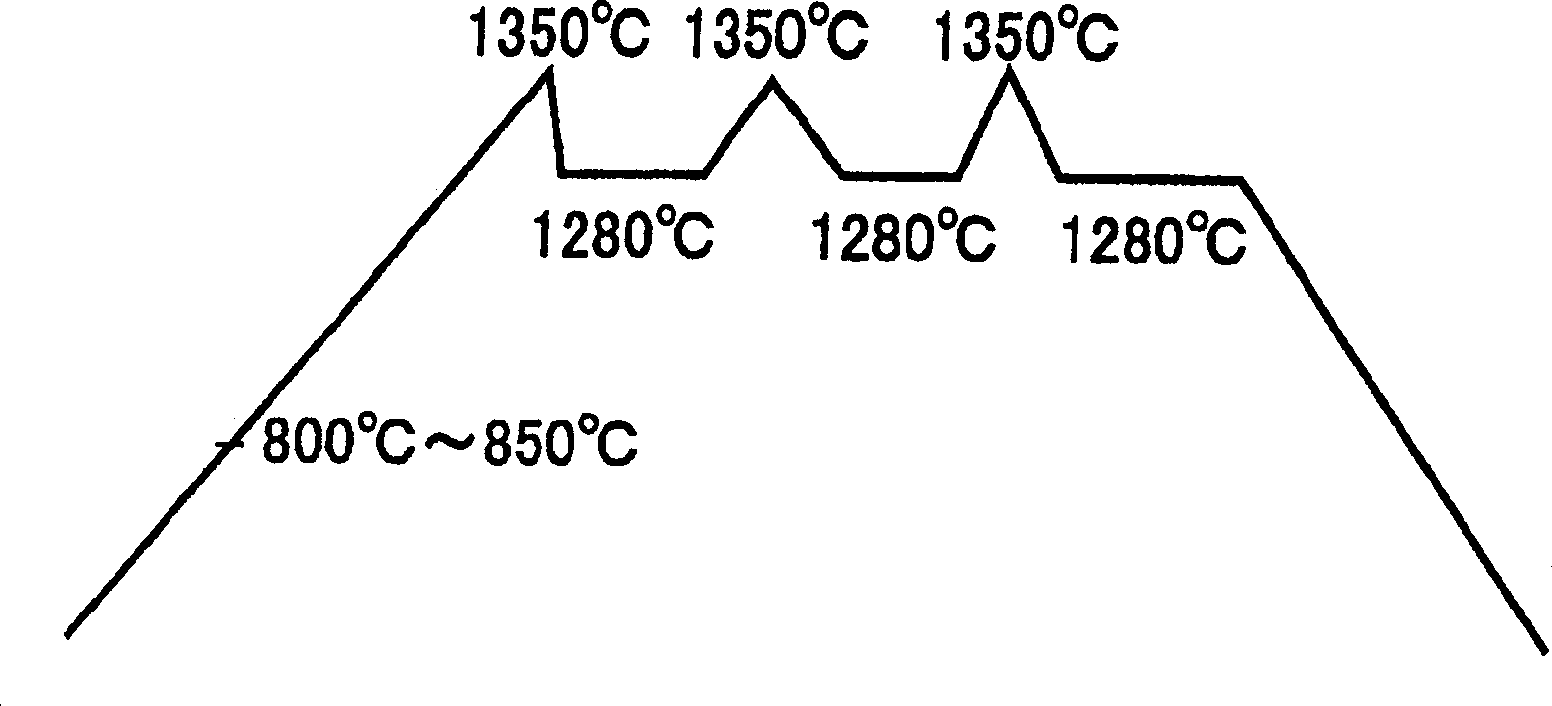

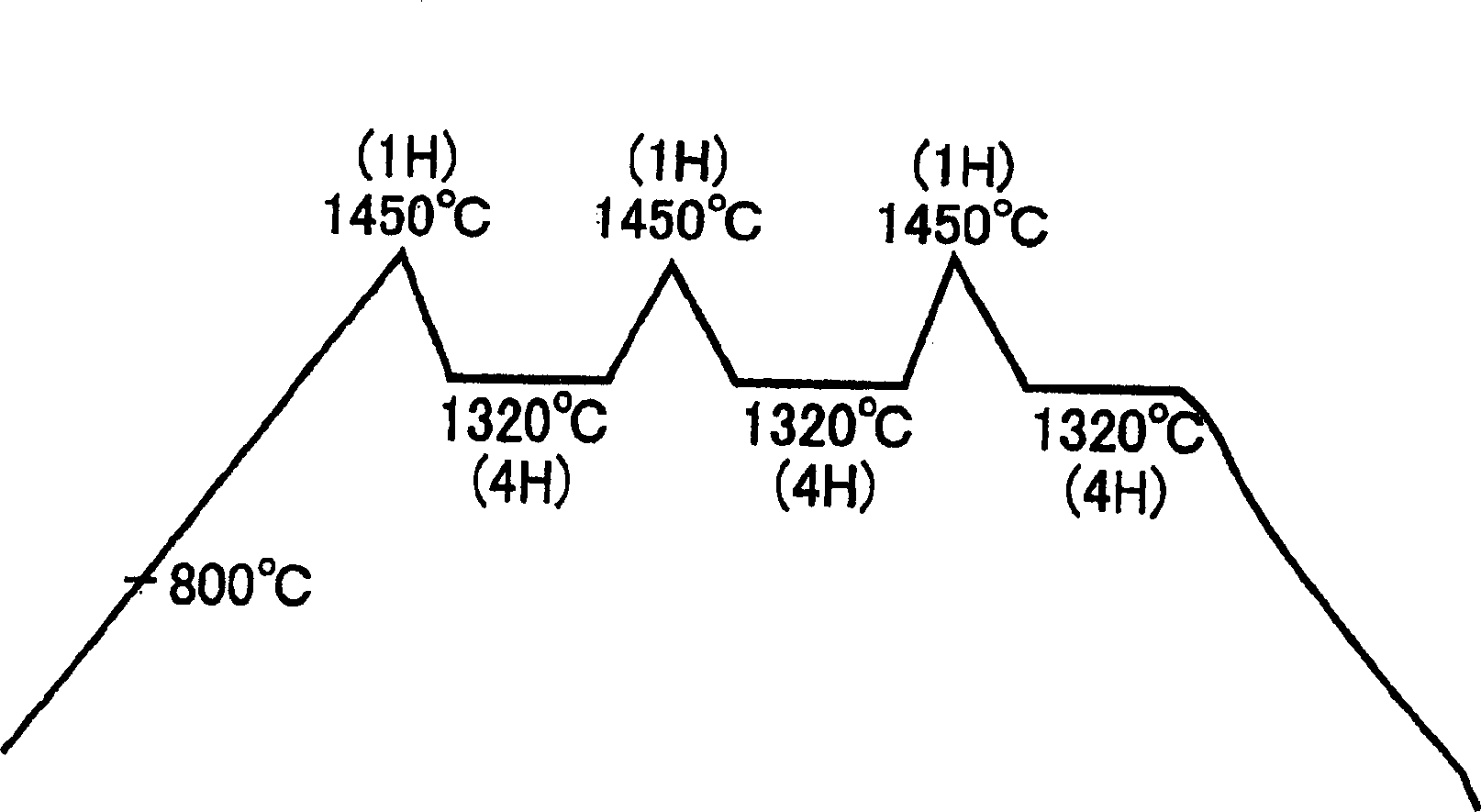

Preparation method of intermediate-frequency sintering thorium-tungsten billets

ActiveCN105328178AGood pressure processing performanceImprove performanceTransportation and packagingMetal-working apparatusRare-earth elementThorium oxide

The invention discloses a preparation method of intermediate-frequency sintering thorium-tungsten billets. The method comprises the steps that thorium-tungsten powder doped with rare earth element oxides is prepared, and the Fisher particle size of the thorium-tungsten powder is 1.2-2.2 micrometers; the thorium-tungsten powder doped with the rare earth element oxides includes, by mass, 0.1-1.5% of the rare earth element oxides and 0.8-2.3% of thorium oxides; the thorium-tungsten powder is mixed to be even, and green thorium-tungsten billets are formed by pressing; and the green thorium-tungsten billets are placed into an intermediate-frequency sintering furnace for intermediate-frequency sintering, the sintering temperature is 2300-2500 DEG C, the temperature is kept constant for 1-4 h, and then the thorium-tungsten billets are obtained. The density of the obtained thorium-tungsten billets is 17.4-18.5 g / cm<3>, the pressure processing performance is good, and the thorium-tungsten billets can be used for further processing thorium-tungsten electrodes of different diameters and with the excellent welding performance, so that the thorium-tungsten billets have the good performance, the production efficiency is improved, energy consumption and hydrogen consumption are lowered, and the production cost is reduced.

Owner:BGRIMM ADVANCED MATERIALS SCI & TECH

Catalyst oxide for changing quality of fossil fuel

InactiveCN1611296ACombustion-air/fuel-air treatmentCatalyst activation/preparationRheniumCombustion chamber

Owner:满超

High-strength gray cast iron, casting and preparation method of high-strength gray cast iron

The invention discloses high-strength gray cast iron, a casting and a preparation method of the high-strength gray cast iron. The preparation method comprises steps as follows: 1), pig iron, scrap steel, foundry returns, antimony oxide, silicon carbide, nickel oxide, thorium oxide and a carburant are preheated at the temperature of 1,200-1,300 DEG C; 2), the preheated raw materials are molten at the temperature of 1,460-1,470 DEG C to prepare molten iron; 3), silicon iron, a silicon-calcium inoculant and a silicon-strontium inoculant are added to the molten iron and are stirred to prepare inoculated molten iron; 4), high carbon ferromanganese at the temperature of 1,490-1,510 DEG C is added to the inoculated molten iron and stirred to prepare the high-strength gray cast ion. The casting prepared from the high-strength gray cast iron has excellent mechanical performance.

Owner:WUHU GUODING MACHINERY MFG

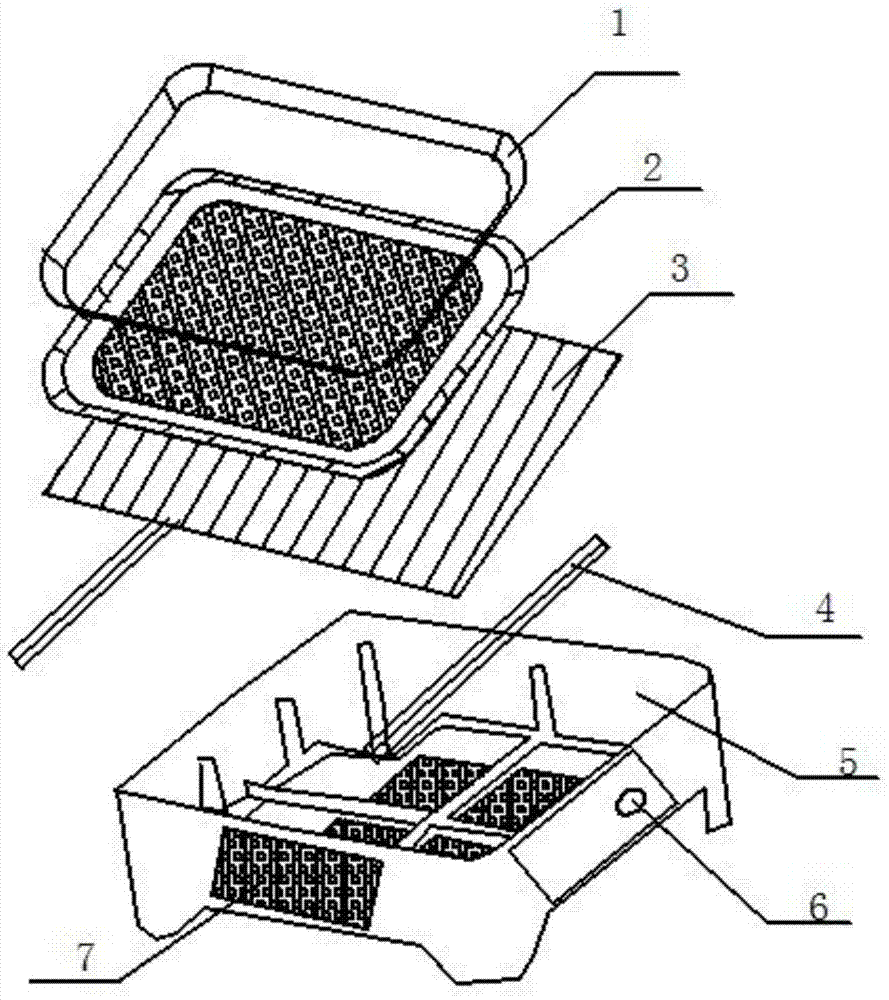

Energy-saving type foot warmer

InactiveCN104515178AGuaranteed fire resistanceReduce heat lossLighting and heating apparatusElectric heating systemThorium oxideEngineering

The invention discloses an energy-saving type foot warmer. The energy-saving type foot warmer comprises a decoration cover, a pedal plate, a heating body, a supporting device and a base. The heating body is arranged on the periphery of the pedal plate, and the decoration cover is arranged on the periphery of the pedal plate. The supporting device is placed below the pedal plate, and the decoration cover, the pedal plate, the heating body and the supporting device are fixedly connected in sequence through a fastener and then are arranged in the base. A heat insulating layer is arranged on the inner side of the base, and a coating is arranged on the heat insulating layer. The coating is at least one kind of oxide powder or a mixture of two or more kinds of oxide powder of aluminum oxide, lanthanum oxide, beryllium oxide, calcium oxide, zirconium oxide, uranium oxide, magnesium oxide, cerium oxide, thorium oxide, silicon dioxide and titanium dioxide. A high-radiation coating is smeared on the lower end of the heating body. The energy-saving type foot warmer is low in powder, environmentally-friendly, free of open fire, safe in use, easy to maintain, convenient to clean and waterproof and saves energy.

Owner:NINGXIA QIKAI ENERGY SAVING EQUIP

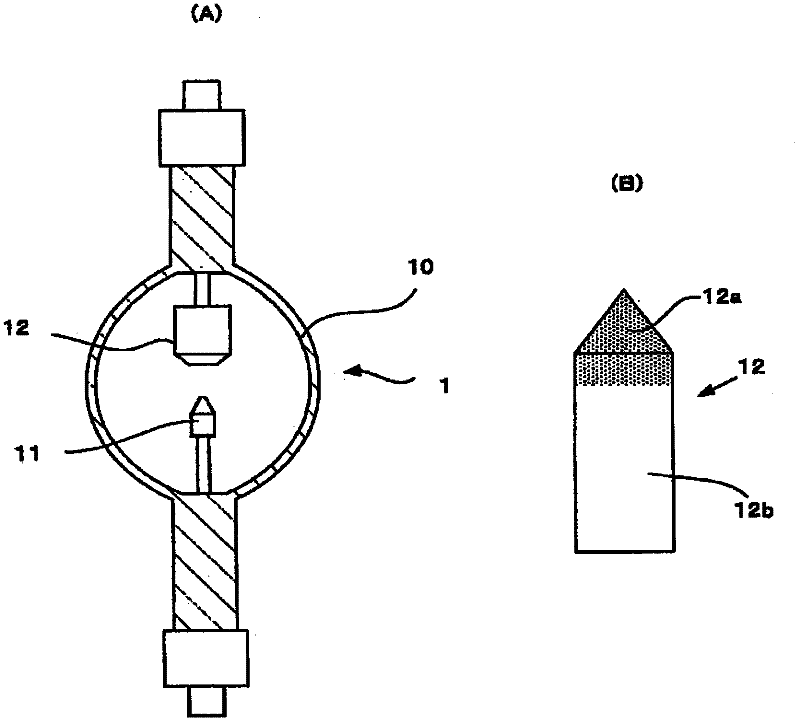

Short arc type discharge lamp

ActiveUS20120001541A1Long flicker durabilityHigh-pressure discharge lampsSolid cathode detailsThorium oxideOptoelectronics

A short arc type discharge lamp wherein a cathode and an anode are arranged opposite to each other in an interior of a light emitting tube and said cathode comprises a main part made from tungsten and a tip end part made from thoriated tungsten, wherein thorium oxide particles having been peripherally coated with thorium are contained in the tip end part of said cathode.

Owner:USHIO DENKI KK

Thorium tungsten wire used for winding microwave oven magnetron and manufacturing method of thorium tungsten wire

ActiveCN103346054AIncrease in crystal defectsSuppress coarseningTransit-tube cathodesCold cathode manufactureMicrowave ovenThorium oxide

The invention belongs to the technical field of metal material manufacturing, and particularly relates to a thorium tungsten wire used for winding a microwave oven magnetron and a manufacturing method of the thorium tungsten wire. The thorium tungsten wire is characterized by comprising 0.5-1.5% of thorium oxide, 0.0020-0.0080% of potassium and 97-98% of tungsten. Compared with the prior art, the thorium tungsten wire and the manufacturing method have the advantages that (1) according to the thorium tungsten wire, though 0.0020-0.0080% of the potassium is added, thorium oxide particles are still fine and uniform; (2) the thorium tungsten wire contains microelement potassium in content, after coils of the microwave oven magnetron wound through the thorium tungsten wire are carbonized at a high temperature, crystal grains cannot grow larger easily, organization stability is maintained, and the situation that the microwave oven magnetron cannot break due to shaking in the packaging and delivery transportation processes after being produced is guaranteed.

Owner:威海多晶钨钼科技有限公司

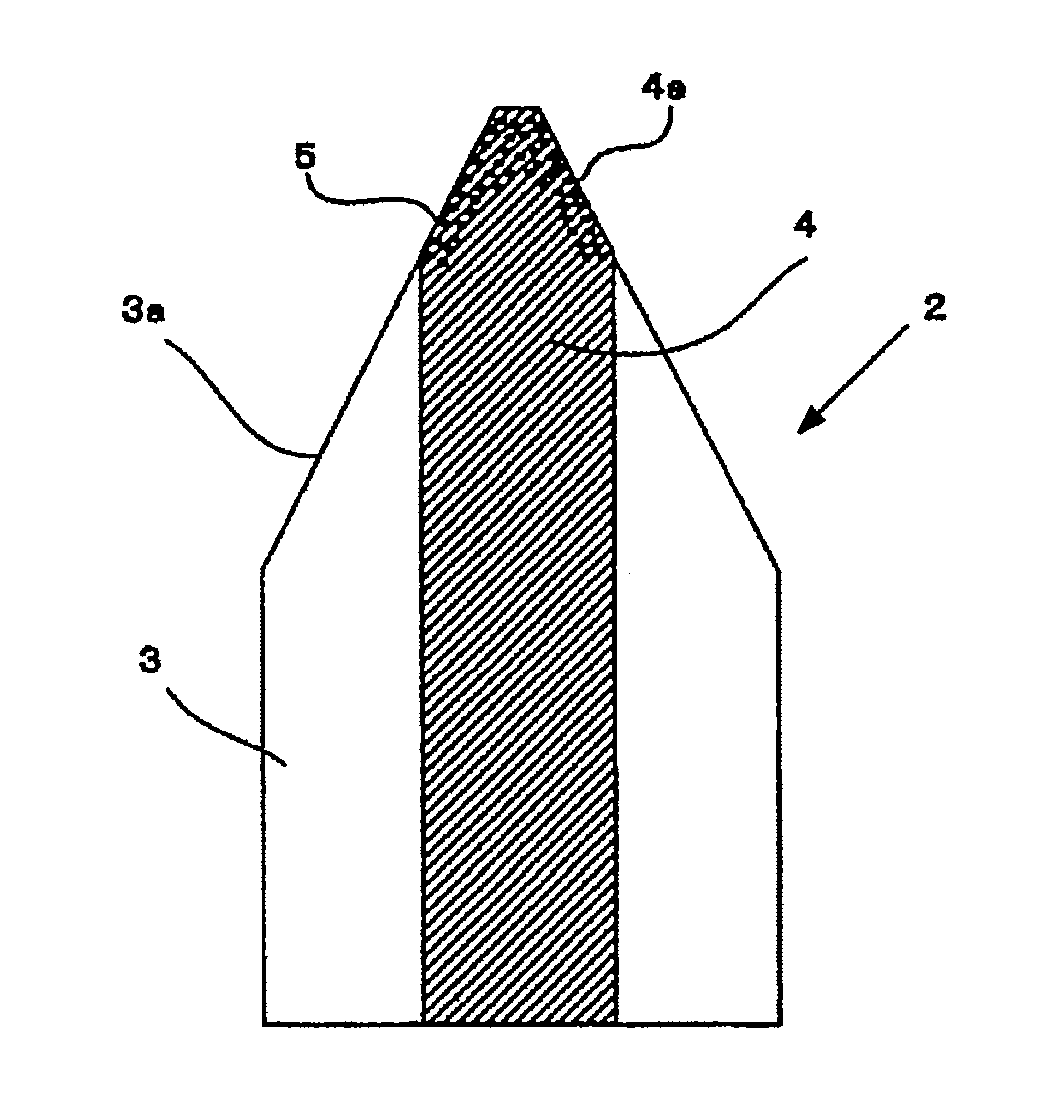

Discharge lamp

ActiveCN101236880AIncrease brightnessHigh-pressure discharge lampsGas discharge lamp detailsGas-discharge lampThorium oxide

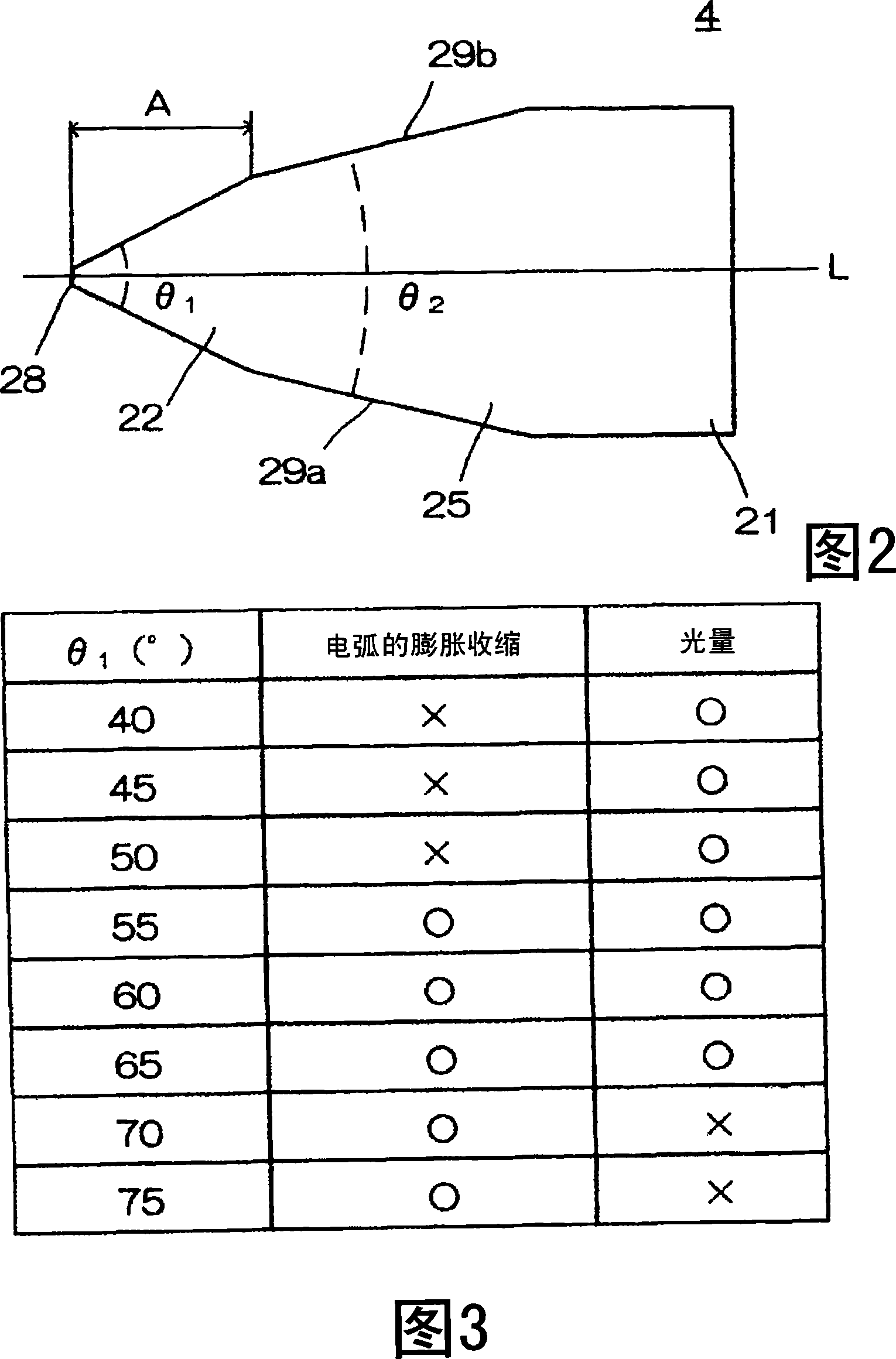

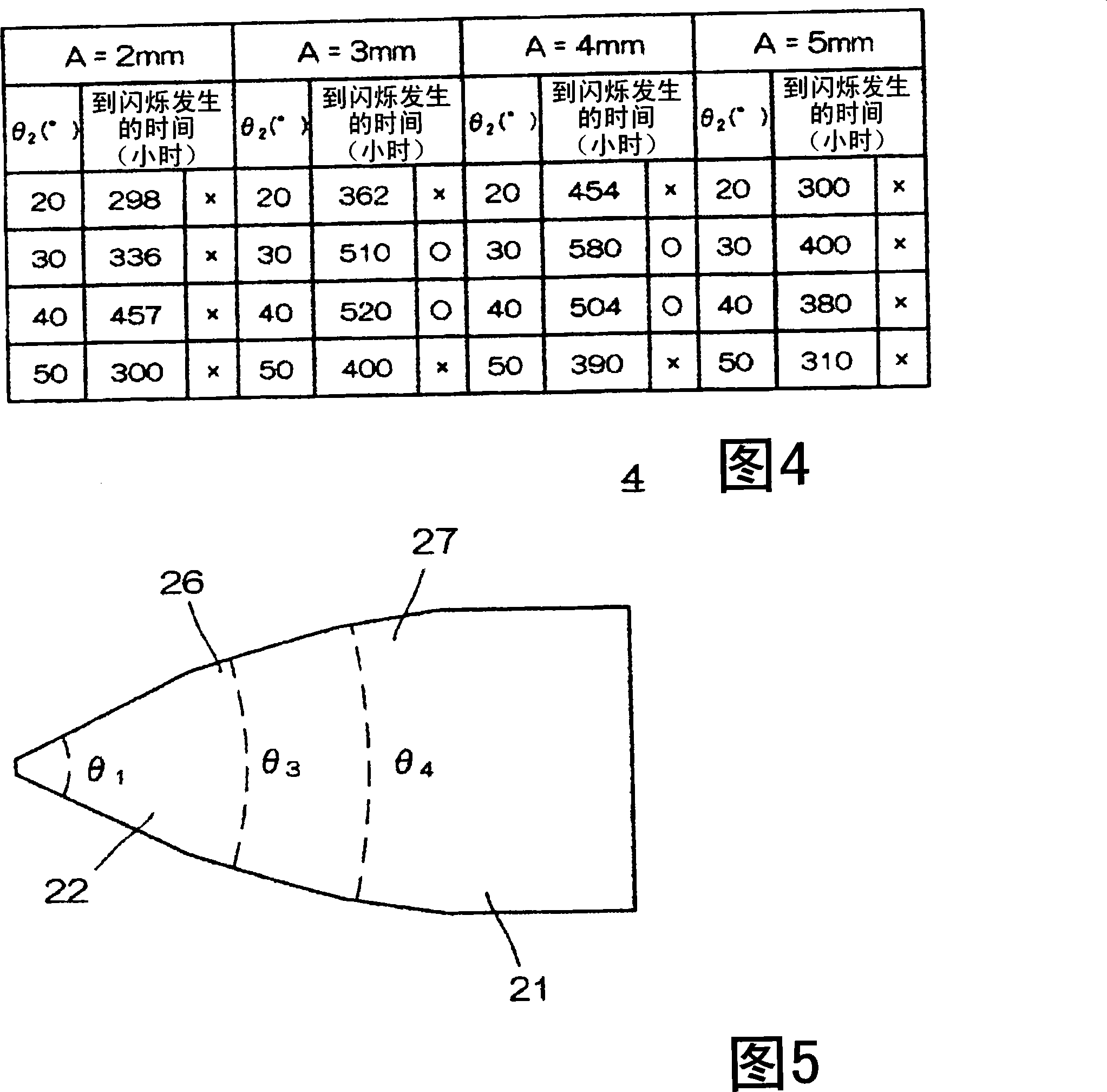

A discharge lamp includes a cathode and an anode which face each other in an arc tube, wherein the cathode is made of tungsten in which thorium oxide is doped. The cathode has a cylindrical body portion, a tip portion having a cone shape, and a middle portion formed between the body portion and the tip portion, wherein an angle θ1 of the tip portion is set to a range of 55 degrees≰θ1≰65 degrees, and an angle θ2 formed by side faces of the middle portion is smaller than that of the tip portion.

Owner:USHIO DENKI KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com