Method for separation and purification of thorium

An extraction and extraction technology, which is applied in the field of purifying thorium by solvent extraction, can solve the problems of large acid consumption and TBP consumption, and achieve the effects of improving purity, reducing consumption and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

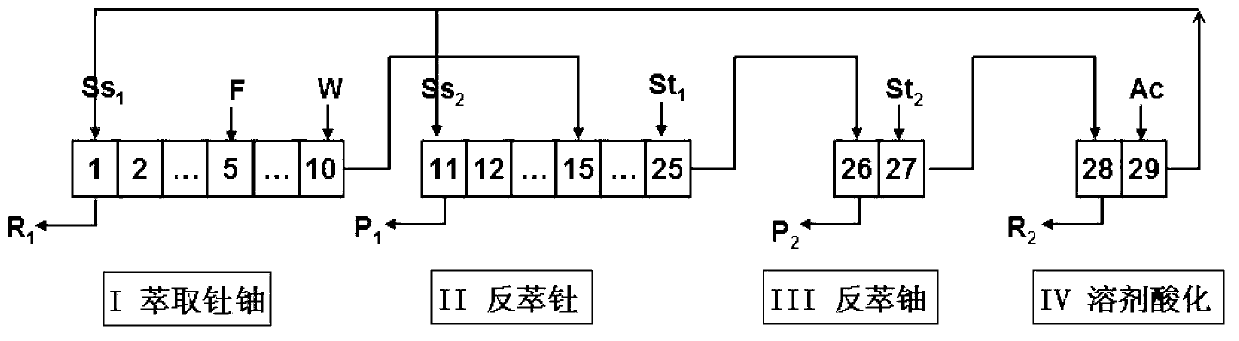

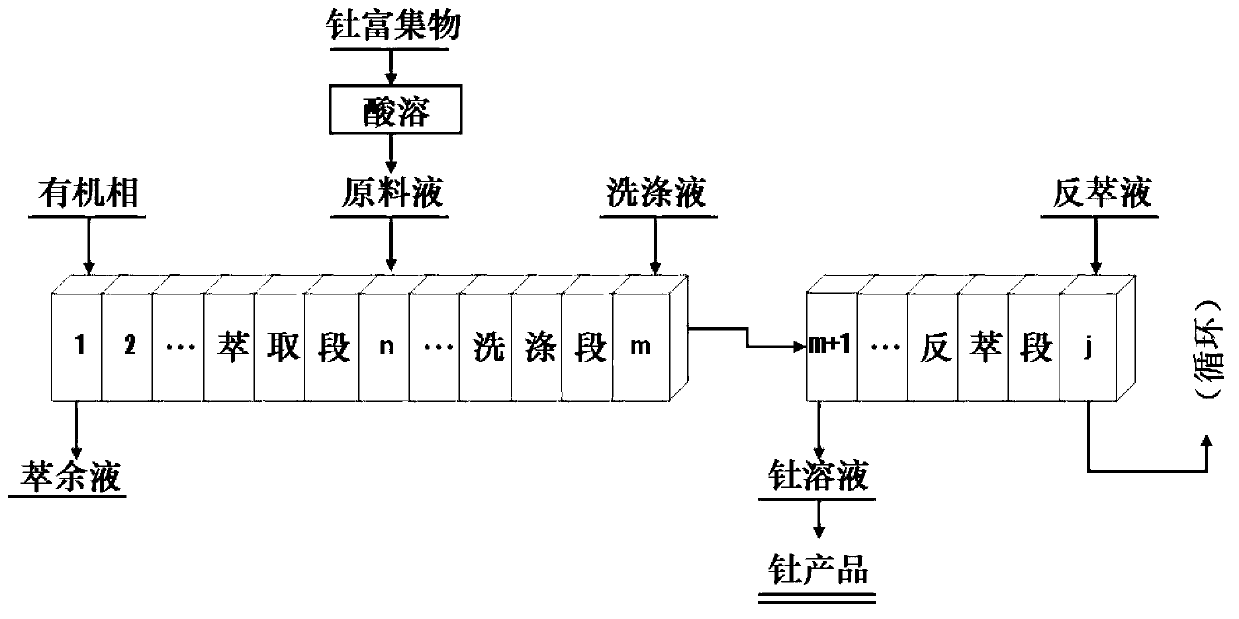

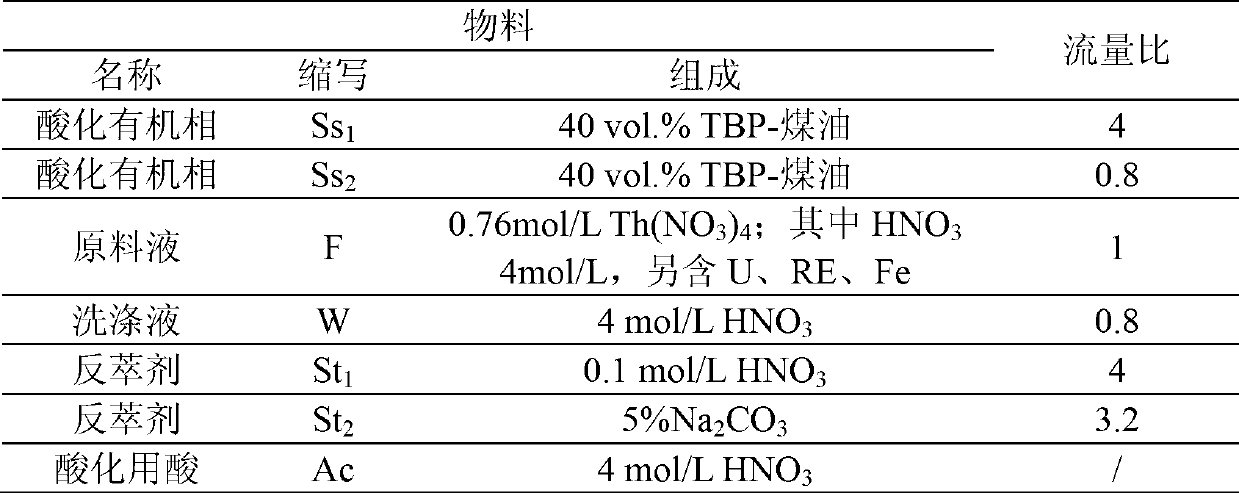

Method used

Image

Examples

Embodiment 1

[0054] Prepare the raw material solution: take the aqueous thorium oxalate recovered from the production process of bastnaesite in Panxi, Sichuan, dry it at 150°C, and burn it at 520°C for 1 hour to obtain 80g of thorium oxide. Thorium oxide was dissolved with nitric acid until complete. Appropriately dilute and filter to obtain the raw material solution required for extraction. After analysis, the composition of the raw material liquid is: Th(NO 3 ) 4 =1.50mol / L; where HNO 3 =2.50mol / L. The weight percent of thorium is: ThO 2 95.36%, the main impurity is rare earth. The content of uranium is less than 0.002%.

[0055] Prepare the organic phase: take 800mL of industrial 2-ethylhexylphosphonic acid bis(2-ethylhexyl) ester (P503) extractant and dissolve it in 260 solvent oil, and dilute to 2000mL, at this time the volume concentration of the extractant 40%.

[0056] Fractional distillation extraction: The whole extraction process uses a mixed clarification extraction tan...

Embodiment 2

[0058] Preparation of raw material solution: Take concentrated thorium nitrate and dissolve it by heating with 2.5mol / L nitric acid. Let stand to cool completely, dilute appropriately and filter to obtain 1.0L raw material solution. After analysis, the composition of the raw material liquid is: Th(NO 3 ) 4 =1.50mol / L; where HNO 3 =2.52mol / L. The weight percent of thorium is: ThO 2 99.27%, the weight ratio of some rare earth impurities are: La 2 o 3 0.2%, CeO 2 0.45%, Pr 4 o 6 0.01%, Nd 2 o 3 0.03%, Y 2 o 3 0.008%. The content of uranium is less than 0.002%.

[0059] Preparation of organic phase: same as in Example 1.

[0060] Fractional distillation extraction: The whole extraction process uses a separating funnel to simulate fractional distillation extraction, and the number of extraction stages is adjusted to 6 stages of extraction, 6 stages of washing and 6 stages of back extraction. The washing solution is 2.5mol / L nitric acid, and the acid used for strippi...

Embodiment 3

[0062] Preparation of raw material solution: take the hydrous thorium hydroxide concentrate recovered in the production process of Baotou mixed rare earth mine, dry and burn to obtain anhydrous thorium oxide. Nitric acid dissolves. A small amount of solid hydroxylamine hydrochloride was added to reduce the iron. Dilute and filter to prepare raw material solution. After analysis, the composition of the raw material liquid is: Th(NO 3 ) 4 =1.45mol / L; where HNO 3 =2.50mol / L. The weight percent of thorium is: ThO 2 90.5%, the main impurity is rare earth. The content of uranium is less than 0.002%.

[0063] Preparation of organic phase: Take industrial P503 extractant and dissolve it in 260 solvent oil to reach a volume concentration of 38%. Pre-saturated with 2.5mol / L nitric acid once.

[0064]Fractional distillation extraction: The whole extraction process uses a mixed clarification extraction tank for fractional distillation extraction, and the extraction stages are 6-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| rate of recovery | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com