Tungsten electrode material and thermal electron emission current measurement device

A technology of emission current and measurement device, which is applied in the field of thermionic emission current measurement device, can solve the problem that thermionic emission current density cannot be measured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

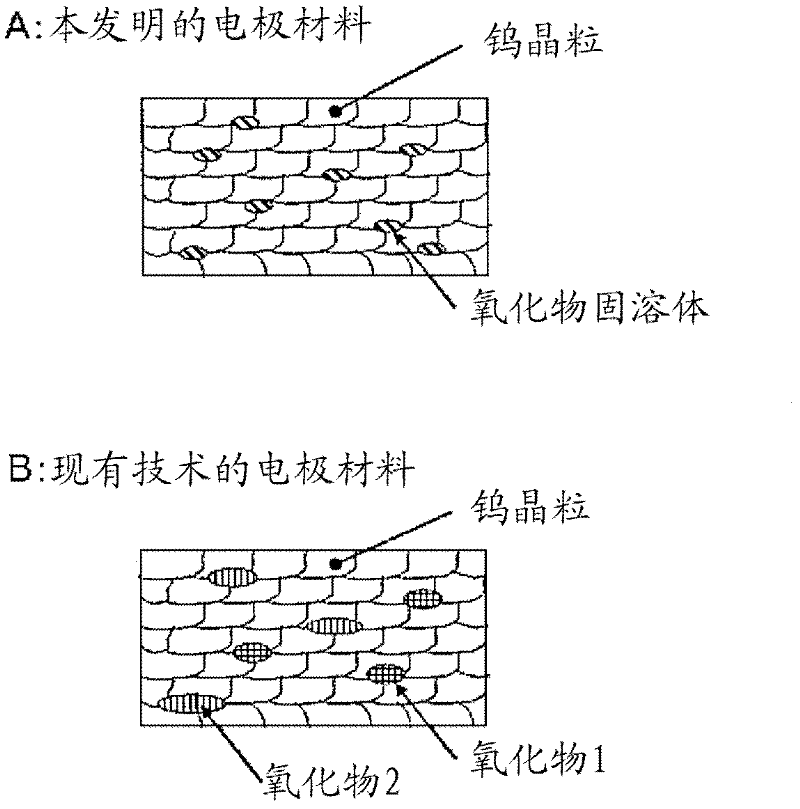

Method used

Image

Examples

Embodiment 1

[0270] [Example 1] The mass ratio of Zr chloride to La chloride (manufactured by Aldrich, purity 99.9% by mass) is specified so that ZrO 2 95 mol% and La 2 o 3 These chlorides were dissolved in water to adjust the concentration to 0.2 mol / L to 5 mol%. While stirring the obtained aqueous solution, 2 mol / L ammonia water was added dropwise to the aqueous solution. Add dropwise until the pH of the aqueous solution is 8 to obtain hydroxide precipitates of Zr and La.

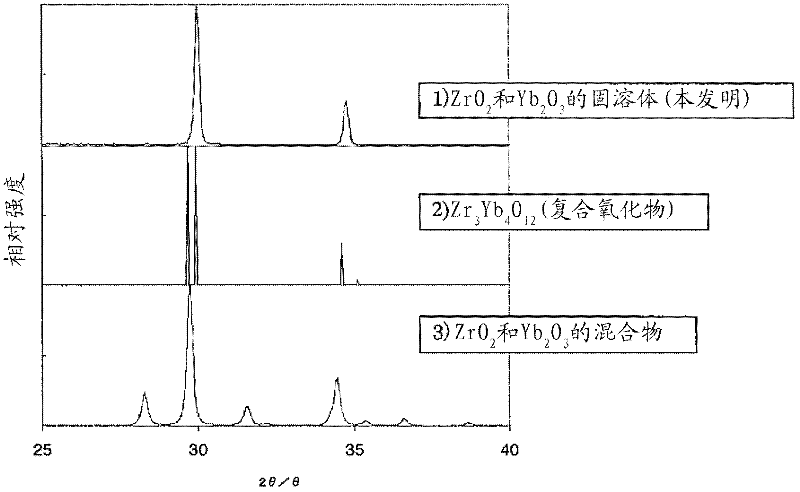

[0271] Next, dry the hydroxide precipitate at 200° C., and roast the dried hydroxide precipitate at 1000° C. in the air to obtain an oxide solid solution powder. By X-ray diffraction, it was confirmed that the powder was ZrO 2 with La 2 o 3 solid solution powder. The particle size of the obtained oxide solid solution is approximately 1-10 μm.

[0272] Next, the above-mentioned ZrO powder is mixed with ordinary tungsten powder having a purity of 99.9% by mass or more and an average particle diameter of about 4 ...

Embodiment 2

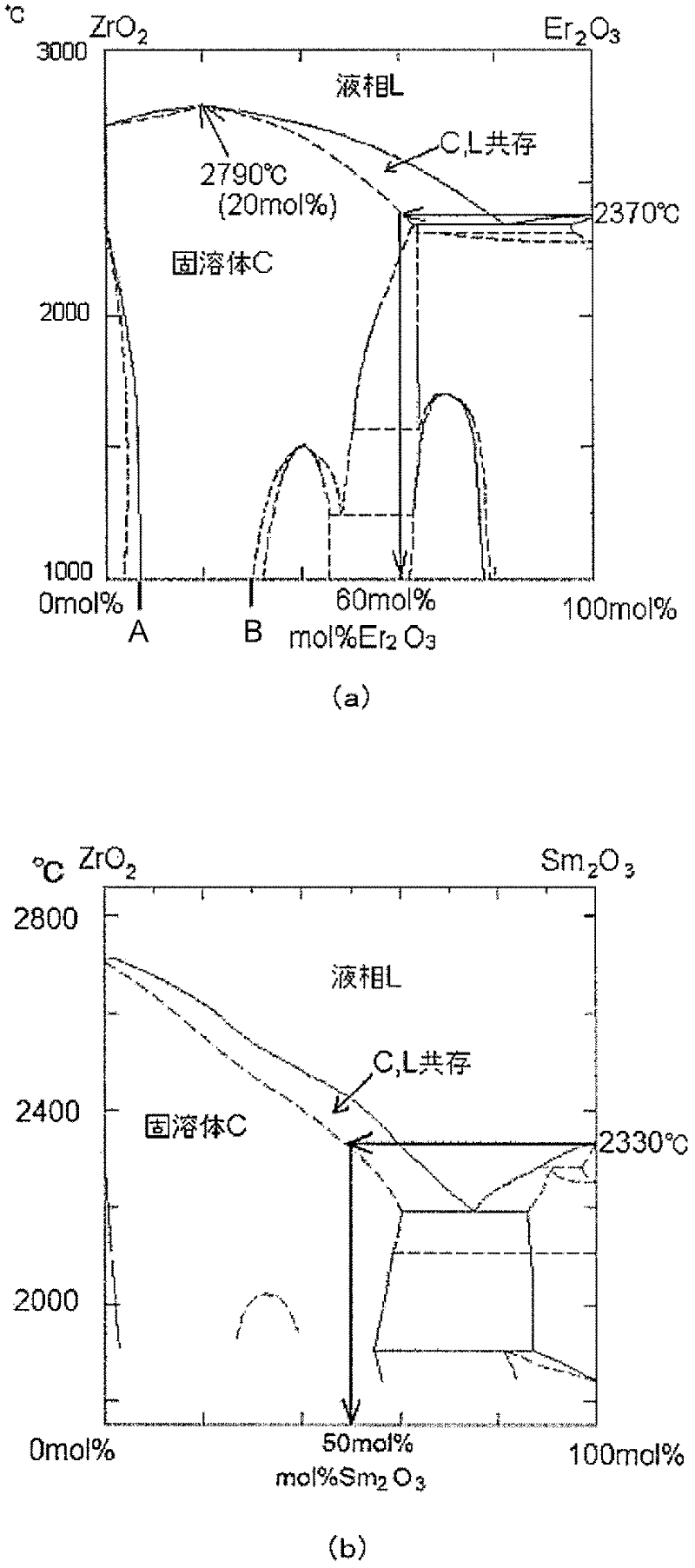

[0274] [Example 2] Use ZrO 2 -Sm 2 o 3 20 mol% oxide solid solution, in addition to making tungsten electrode material by the manufacturing process of embodiment 1.

Embodiment 3

[0275] [embodiment 3] make ZrO by the manufacture process of embodiment 1 2 with Er 2 o 3 solid solution oxides. Specifically, ZrO is mixed with ordinary tungsten powder with a purity of 99.9% by mass or more and an average particle size of about 4 μm (measured by the Fsss (Fisher) method). 2 -Er 2 o 3Oxide solid solution (relative to 78 mol% ZrO 2 , 22 mol% Er in solid solution 2 o 3 )powder.

[0276] Secondly, after molding the tungsten powder, it was heated in a hydrogen atmosphere at 1200°C for 1 hour, and then sintered in a hydrogen atmosphere at 2500°C to 3000°C for 1 hour to produce a rod-shaped tungsten electrode material with a cross-section of 25mm×25mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com