Protection method of lithium metal electrode

A lithium metal electrode, metal lithium technology, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problems of complex interface nano-modification process, limited to laboratory stage, no industrialization basis, etc., to improve the overall Effects of life and quality, improved stability and safety performance, improved cycle performance and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

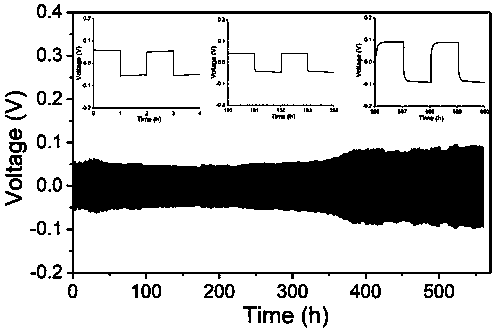

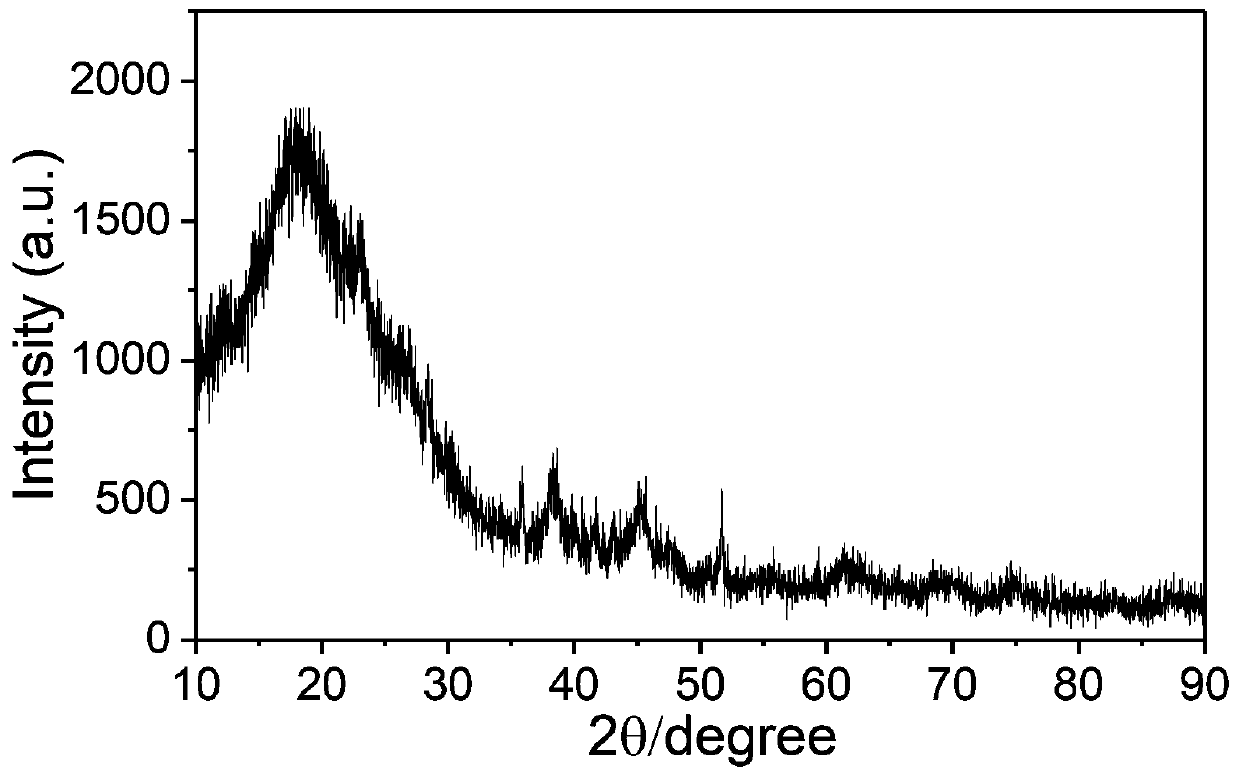

[0035] In this example, see Figure 1 ~ Figure 3 , a kind of protection method of lithium metal electrode, comprises the steps:

[0036] a. Weigh 53.6 mg of antimony trifluoride, pour it into a 20 milliliter glass bottle with a cap, and add 3 milliliters of propylene carbonate as a solvent with a pipette gun, stir to fully dissolve antimony trifluoride in propylene carbonate, Obtain antimony trifluoride solution for subsequent use;

[0037]b. Take a lithium sheet with a diameter of 15.6 mm, press it into a sheet with a thickness of 0.2 mm with a smooth cylinder, and then cut it into a disc with a diameter of 12 mm with a die, and set it aside;

[0038] c. pressing the lithium sheet in b on the stainless steel gasket, so that the lithium sheet and the stainless steel gasket are fully adhered and bonded;

[0039] d. put the lithium sheet processed in the c into the glass bottle used in the step a together with the stainless steel gasket, make the lithium sheet immersed in the ...

Embodiment 2

[0044] This embodiment is basically the same as Embodiment 1, especially in that:

[0045] In this example, see Figure 4 , a kind of protection method of lithium metal electrode, comprises the steps:

[0046] a. Weigh 107.2 mg of antimony trifluoride, pour it into a 20 milliliter glass bottle with a cap, and add 6 milliliters of propylene carbonate as a solvent with a pipette gun, stir to fully dissolve antimony trifluoride in propylene carbonate, Obtain antimony trifluoride solution for subsequent use;

[0047] b. Take a lithium sheet with a diameter of 15.6 mm, press it into a sheet with a thickness of 0.2 mm with a smooth cylinder, and then cut it into a disc with a diameter of 12 mm with a die, and set it aside;

[0048] c. pressing the lithium sheet in b on the stainless steel gasket, so that the lithium sheet and the stainless steel gasket are fully adhered and bonded;

[0049] d. put the lithium sheet processed in the c into the glass bottle used in the step a toget...

Embodiment 3

[0054] This embodiment is basically the same as the previous embodiment, and the special features are:

[0055] In this example, see Figure 5 , a kind of protection method of lithium metal electrode, comprises the steps:

[0056] a. Weigh 53.6 mg of antimony trifluoride, pour it into a 20 milliliter glass bottle with a cap, and add 3 milliliters of propylene carbonate as a solvent with a pipette gun, stir to fully dissolve antimony trifluoride in propylene carbonate, Obtain antimony trifluoride solution for subsequent use;

[0057] b. Take a lithium sheet with a diameter of 15.6 mm, press it into a sheet with a thickness of 0.2 mm with a smooth cylinder, and then cut it into a disc with a diameter of 12 mm with a die, and set it aside;

[0058] c. pressing the lithium sheet in b on the stainless steel gasket, so that the lithium sheet and the stainless steel gasket are fully adhered and bonded;

[0059] d. put the lithium sheet processed in the c into the glass bottle used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com