Hydrocracking catalyst carrier and preparation method thereof

A catalyst carrier and hydrocracking technology, which is applied in the direction of catalyst carrier, physical/chemical process catalyst, molecular sieve catalyst, etc., can solve the problems affecting the framework structure of molecular sieve, low catalytic activity of catalyst, and reduction of crystallinity of molecular sieve, etc., to overcome energy High consumption, high catalytic activity and isomerization ability, and the effect of improving product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the used β molecular sieve of hydrocracking catalyst carrier of the present invention specifically comprises the following steps:

[0037] (1) Contact the original powder of β molecular sieve with normal pressure and dynamic water vapor, the contact temperature is 500~650℃, and the time is 5~10 hours;

[0038] (2) Contacting the product obtained in step (1) with ammonium fluorosilicate, then filtering, washing with water and drying to obtain β molecular sieve.

[0039] In step (1), the method of contacting the original powder of β molecular sieve with normal pressure and dynamic water vapor is preferably to place the original powder of β molecular sieve in a container, then introduce water vapor from one end of the container, and pass through the original powder of β molecular sieve from The other end of the container is drained. In order to make the molecular sieve treatment more uniform, it is best to place the molecular sieve in a rotating ...

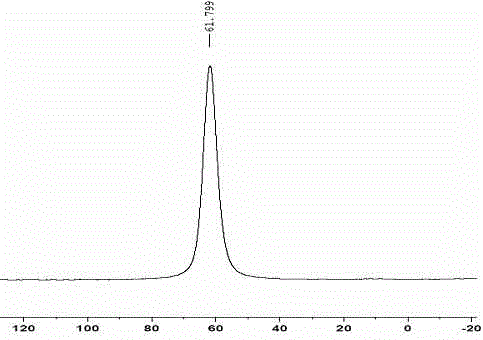

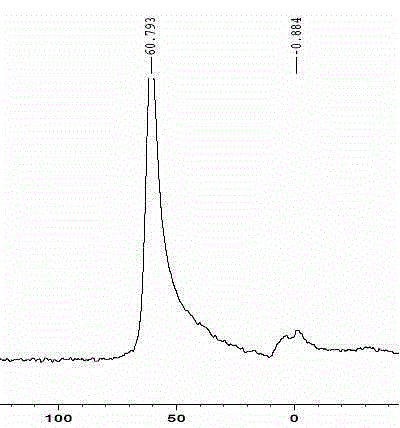

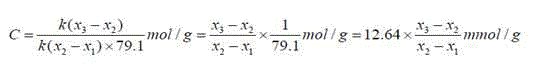

Embodiment 1

[0064] Take the original powder of β molecular sieve (synthesized by hydrothermal method using tetraethylammonium hydroxide as template agent, the weight content of the template agent in the original powder of β molecular sieve is about 11.8%, provided by Sinopec Catalyst Fushun Branch), its chemical SiO 2 / Al 2 o 3 The molar ratio is 25.5, Na 2 O content is 2.45wt%, in its skeleton structure, through 29 Si MAS NMR spectrum, the distribution of silicon atoms in different coordination states is obtained as follows: Si (4Al) is 7.6%, Si (3Al) is 30.6%, Si (2Al) is 32.3%, Si (1Al) is 21.0% %, Si (0Al) is 8.5%. Take 1000g of the above-mentioned β molecular sieve raw powder, put it into a tube furnace, adopt the method of temperature program (heating rate is 100°C / hour), and start to introduce 100wt% water vapor when the temperature of the tube furnace rises to 300°C, water vapor The flow rate is 50L / hour, the tube furnace is heated to 550°C, and the constant temperature time ...

Embodiment 2

[0066] Get the former powder of β molecular sieve with embodiment 1. Take 1000g of the above-mentioned molecular sieve, put it into a tube furnace, adopt the method of temperature program (heating rate: 100°C / hour), and start to introduce 100wt% water vapor when the temperature of the tube furnace rises to 300°C, the flow rate of water vapor is 70L / hour, the tube furnace is heated to 600°C, and the constant temperature time is 8 hours. The obtained molecular sieve number is BS-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com