Patents

Literature

213results about How to "Long electrode life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

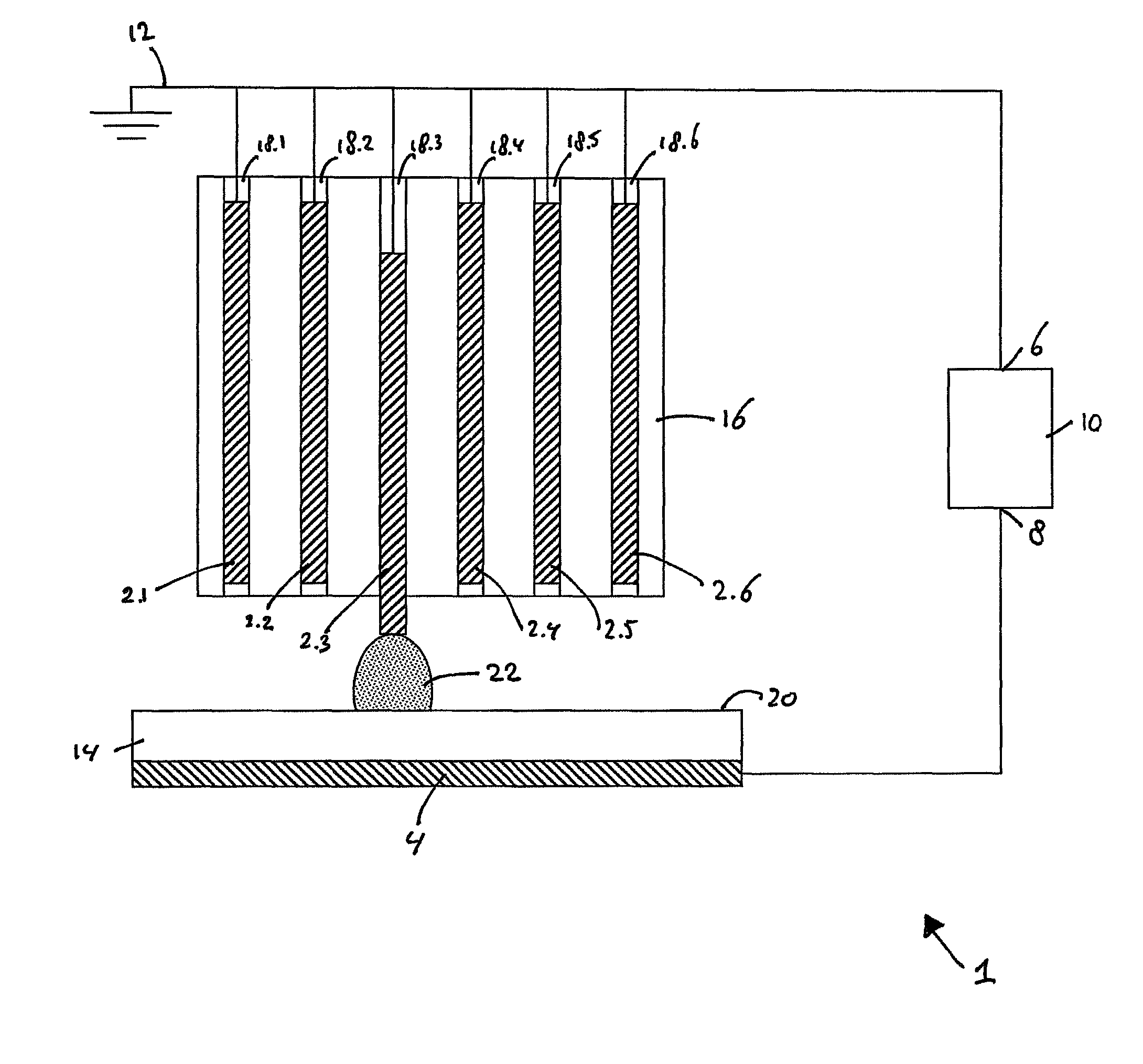

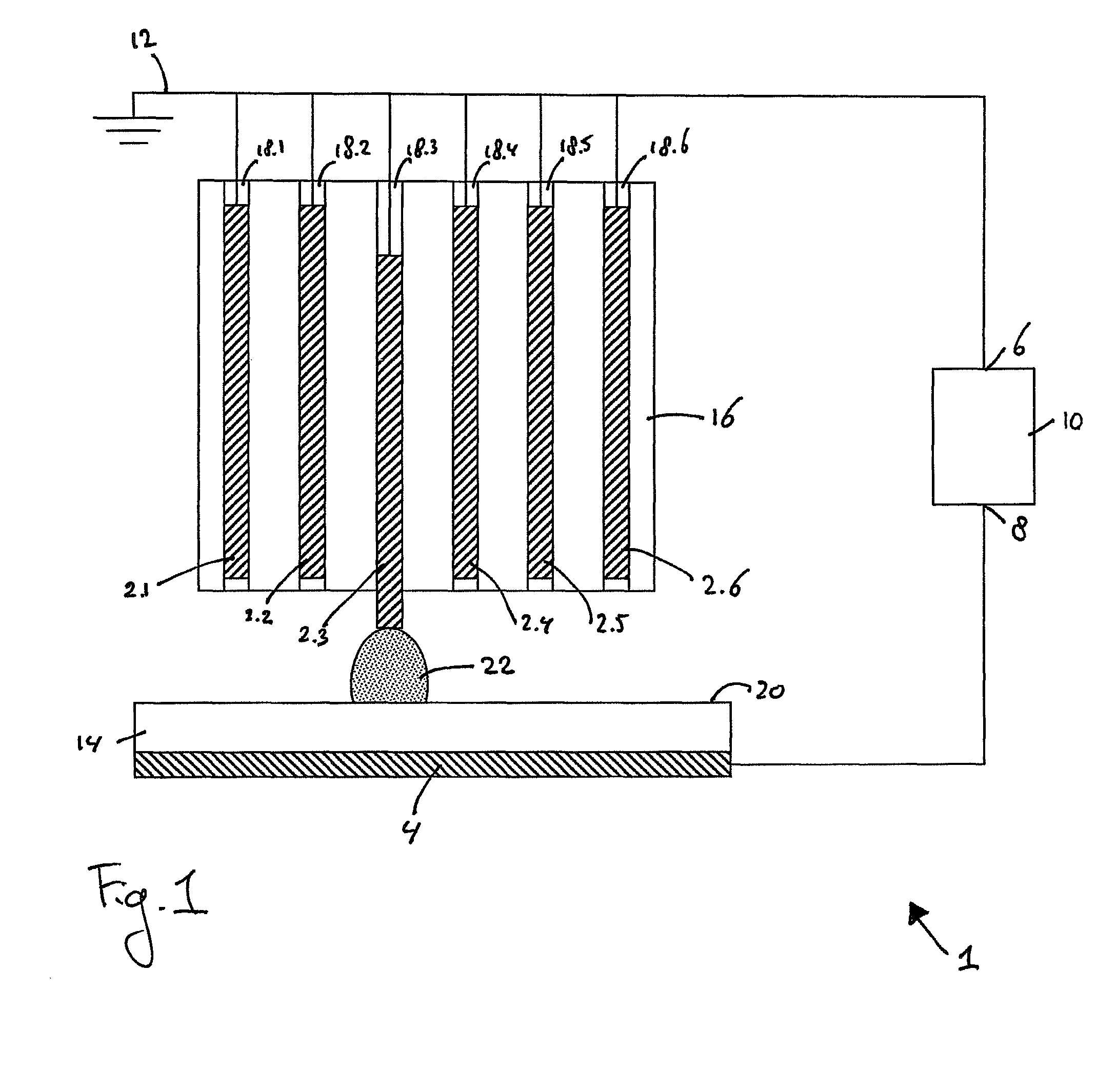

Device for generating a plasma discharge for patterning the surface of a substrate

InactiveUS8702902B2Easy to controlLong electrode lifeDecorative surface effectsSemiconductor/solid-state device manufacturingHigh pressureHigh voltage source

Device for generating a plasma discharge for patterning the surface of a substrate, comprising a first electrode having a first discharge portion and a second electrode having a second discharge portion, a high voltage source for generating a high voltage difference between the first and the second electrode, and positioning means for positioning the first electrode with respect to the substrate, wherein the positioning means are arranged for selectively positioning the first electrode with respect to the second electrode in a first position in which a distance between the first discharge portion and the second discharge portion is sufficiently small to support the plasma discharge at the high voltage difference, and in a second position in which the distance between the first discharge portion and the second discharge portion is sufficiently large to prevent plasma discharge at the high voltage difference.

Owner:VISION DYNAMICS HLDG

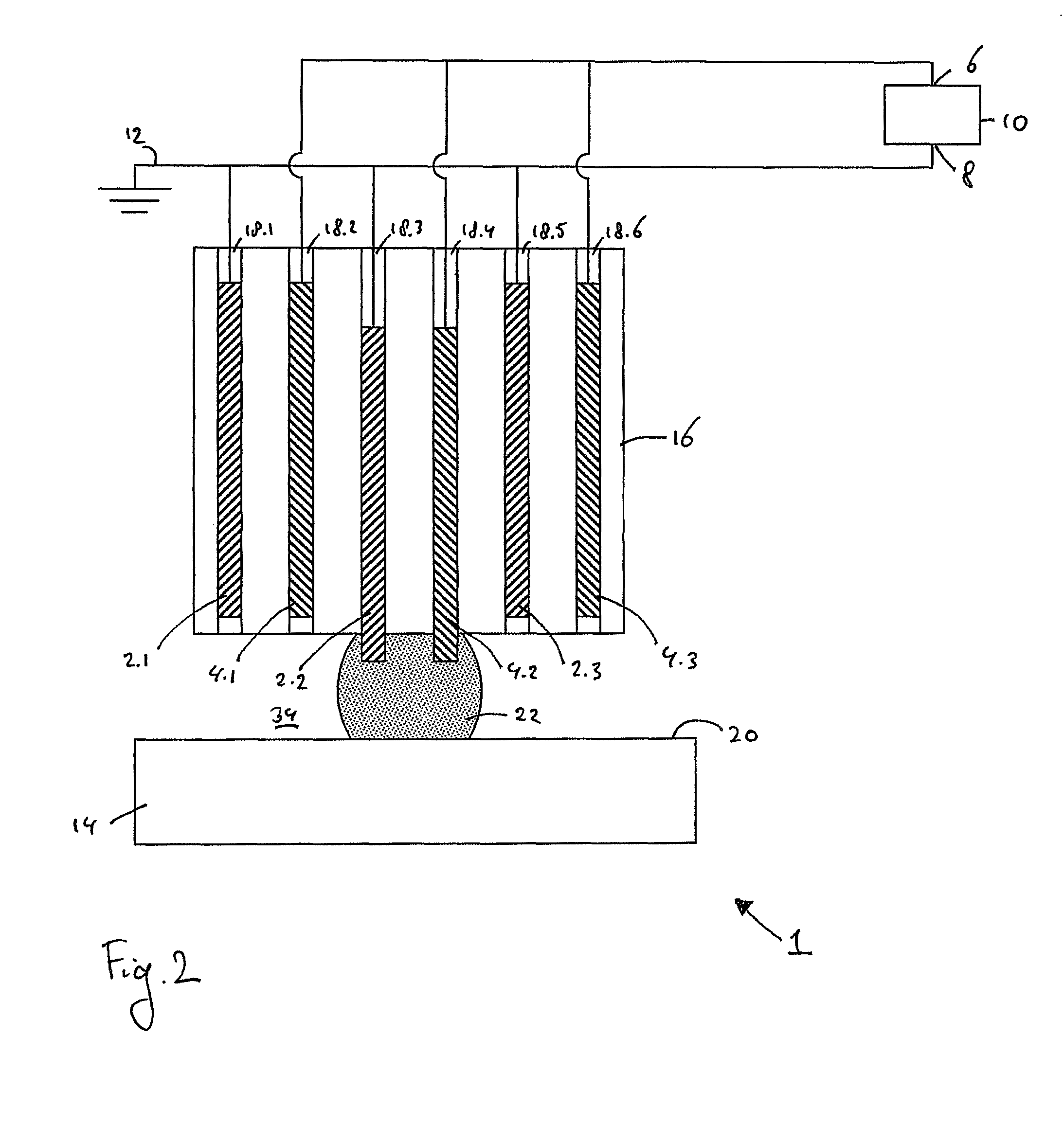

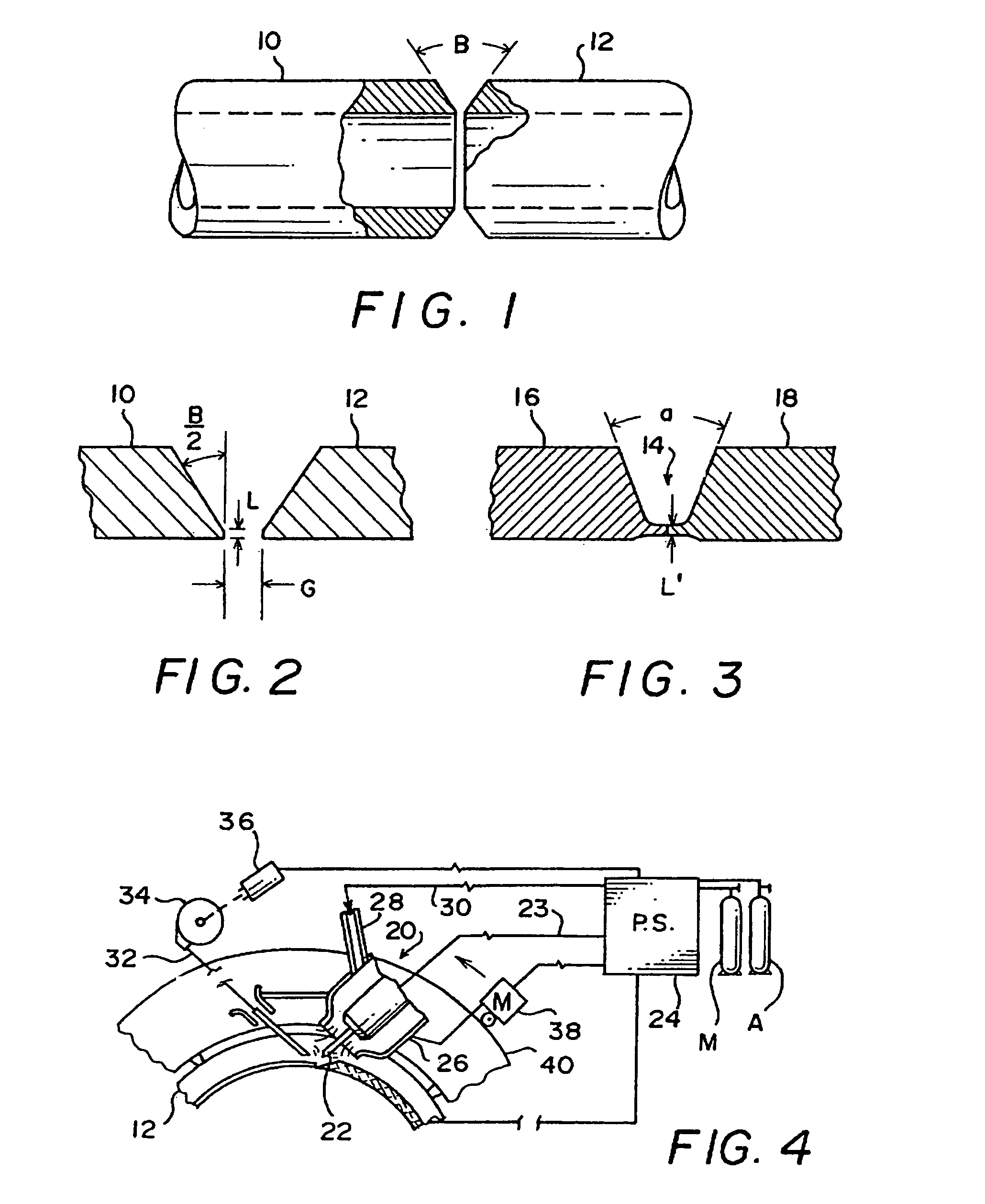

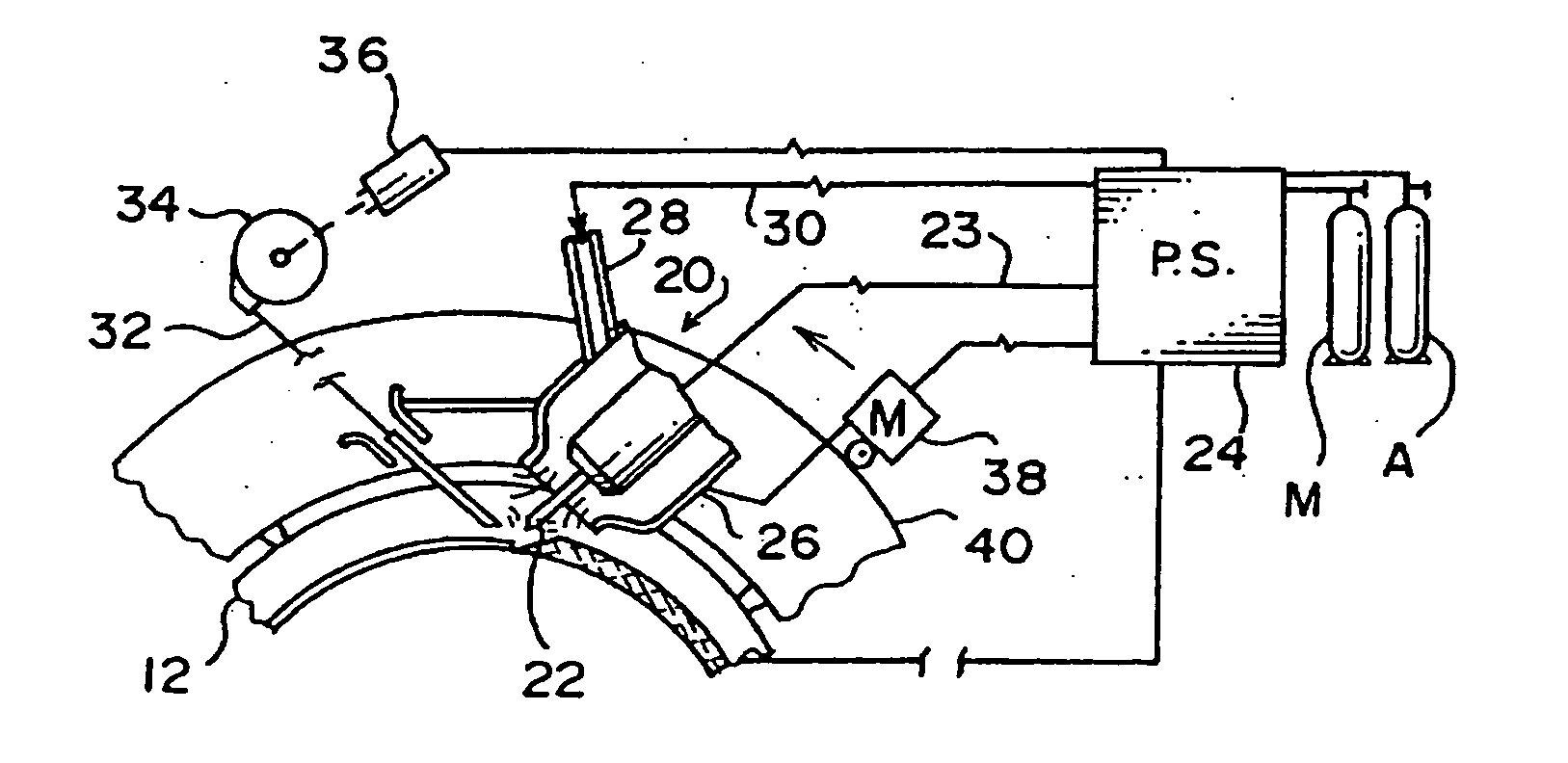

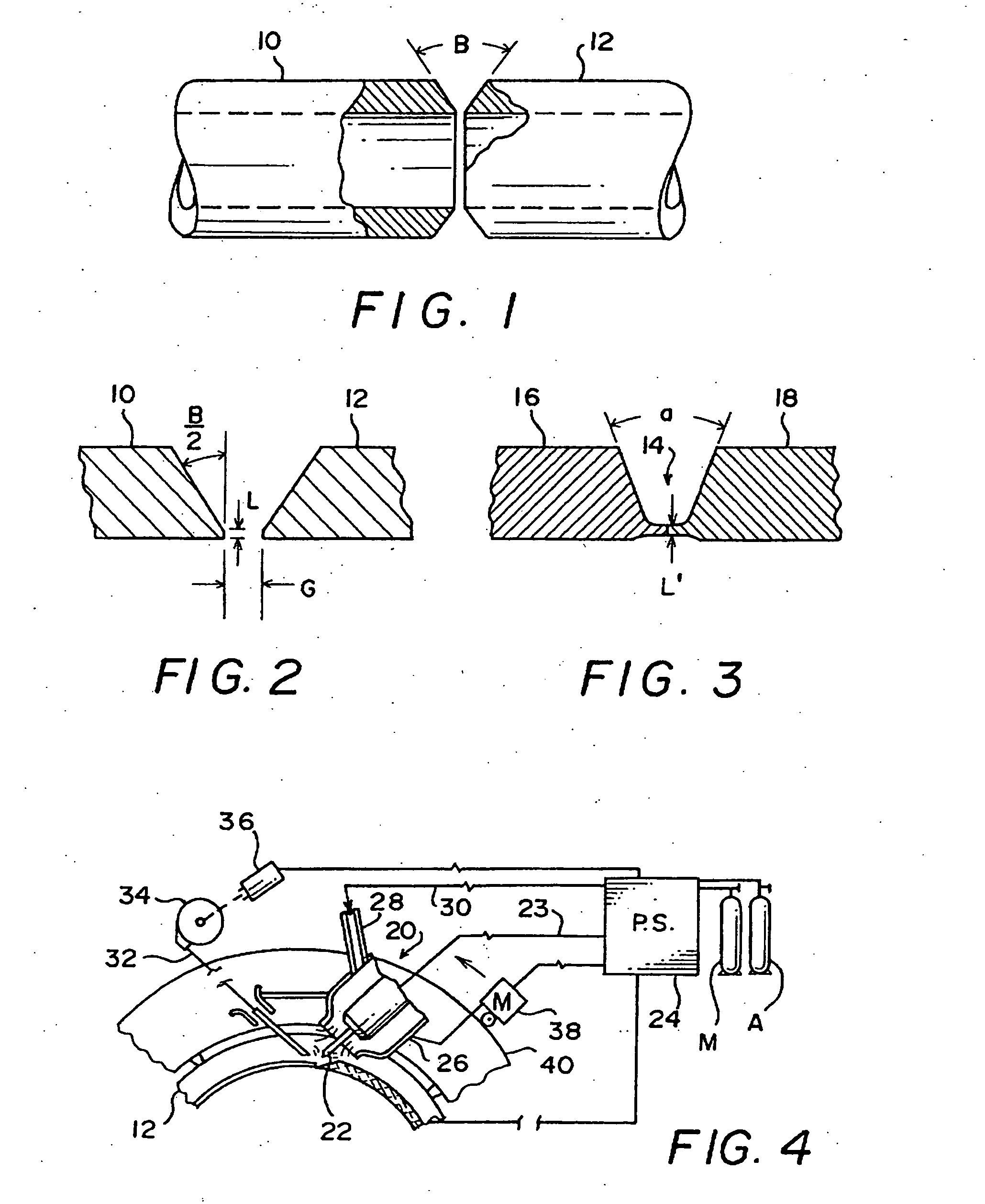

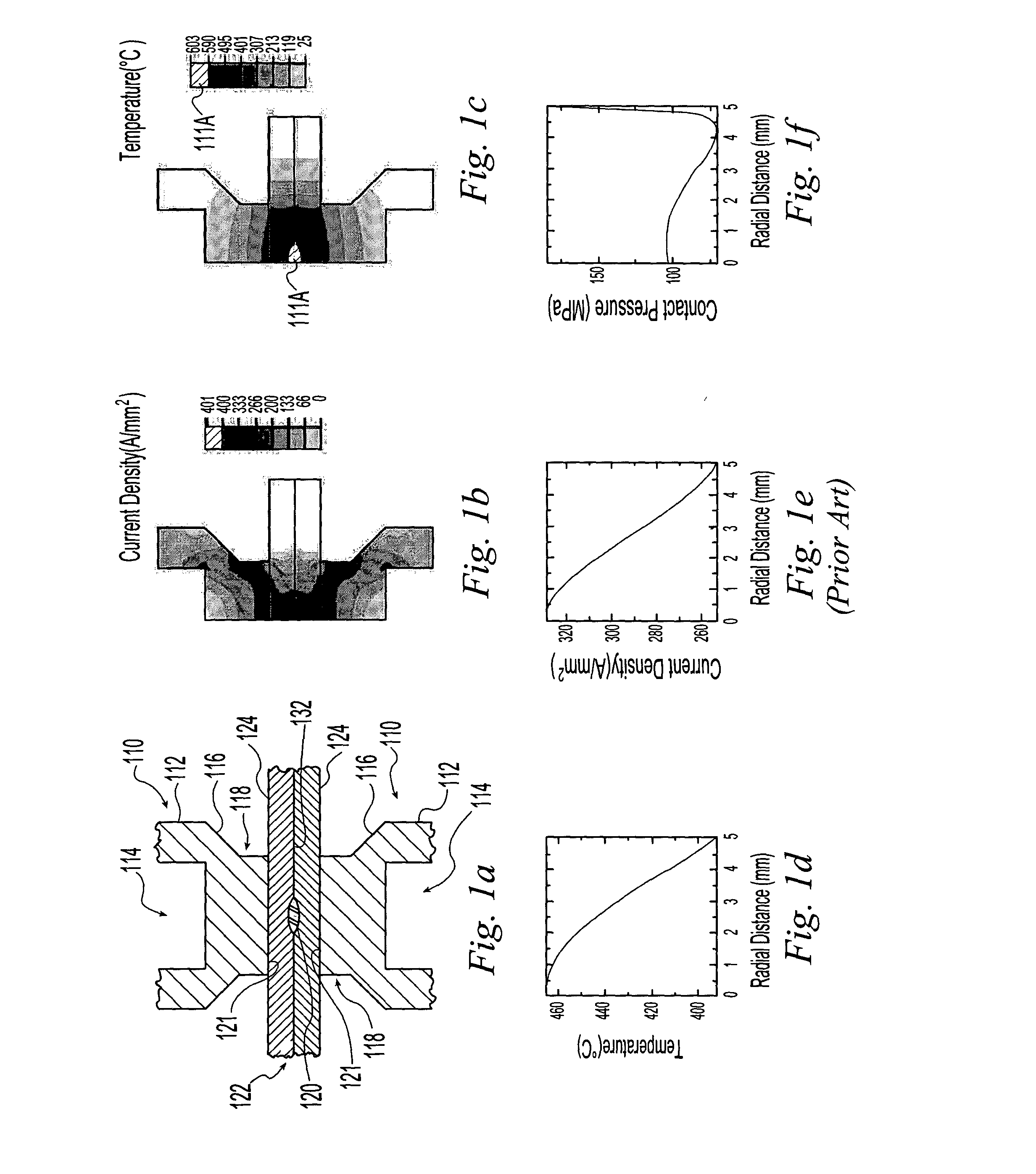

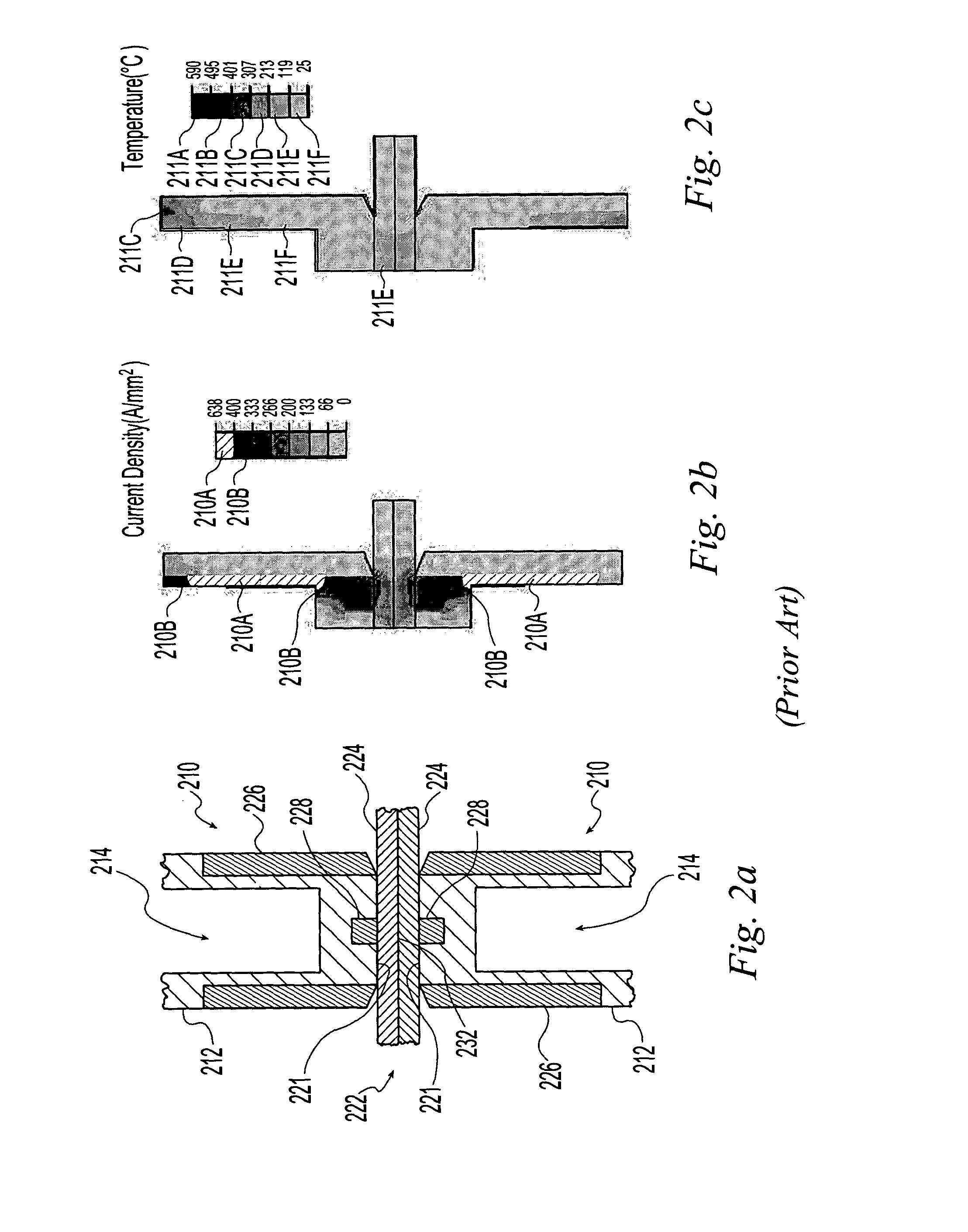

Process for welding

InactiveUS7170032B2Long electrode lifeEvacuating shieldingWelding/cutting media/materialsElastomerShielding gas

A welding process for non-stainless steel workpieces using GTAW equipment and hydrogen containing shield gas on a first root pass is improved by using a shield gas delivery system comprising hoses or conduits made of elastomeric material having a moisture permeability coefficient of less that 275, preferably less than 100, and using a tungsten electrode composition comprising at least tungsten and lanthanum oxide, and preferably tungsten, lanthanum oxide, yttrium oxide and zirconium oxide. Preventing moisture permeation through the elastomeric hoses delivering hydrogen containing shield gas eliminates expulsion of fused weld metal during second pass filler welding over the root pass weld. Electrode life is enhanced using the tungsten compounds.

Owner:JV IND CO LLC

Process for welding

InactiveUS20050109735A1Long electrode lifeEvacuating shieldingWelding/cutting media/materialsElastomerShielding gas

A welding process for non-stainless steel workpieces using GTAW equipment and hydrogen containing shield gas on a first root pass is improved by using a shield gas delivery system comprising hoses or conduits made of elastomeric material having a moisture permeability coefficient of less that 275, preferably less than 100, and using a tungsten electrode composition comprising at least tungsten and lanthanum oxide, and preferably tungsten, lanthanum oxide, yttrium oxide and zirconium oxide. Preventing moisture permeation through the elastomeric hoses delivering hydrogen containing shield gas eliminates expulsion of fused weld metal during second pass filler welding over the root pass weld. Electrode life is enhanced using the tungsten compounds.

Owner:JV IND CO LLC

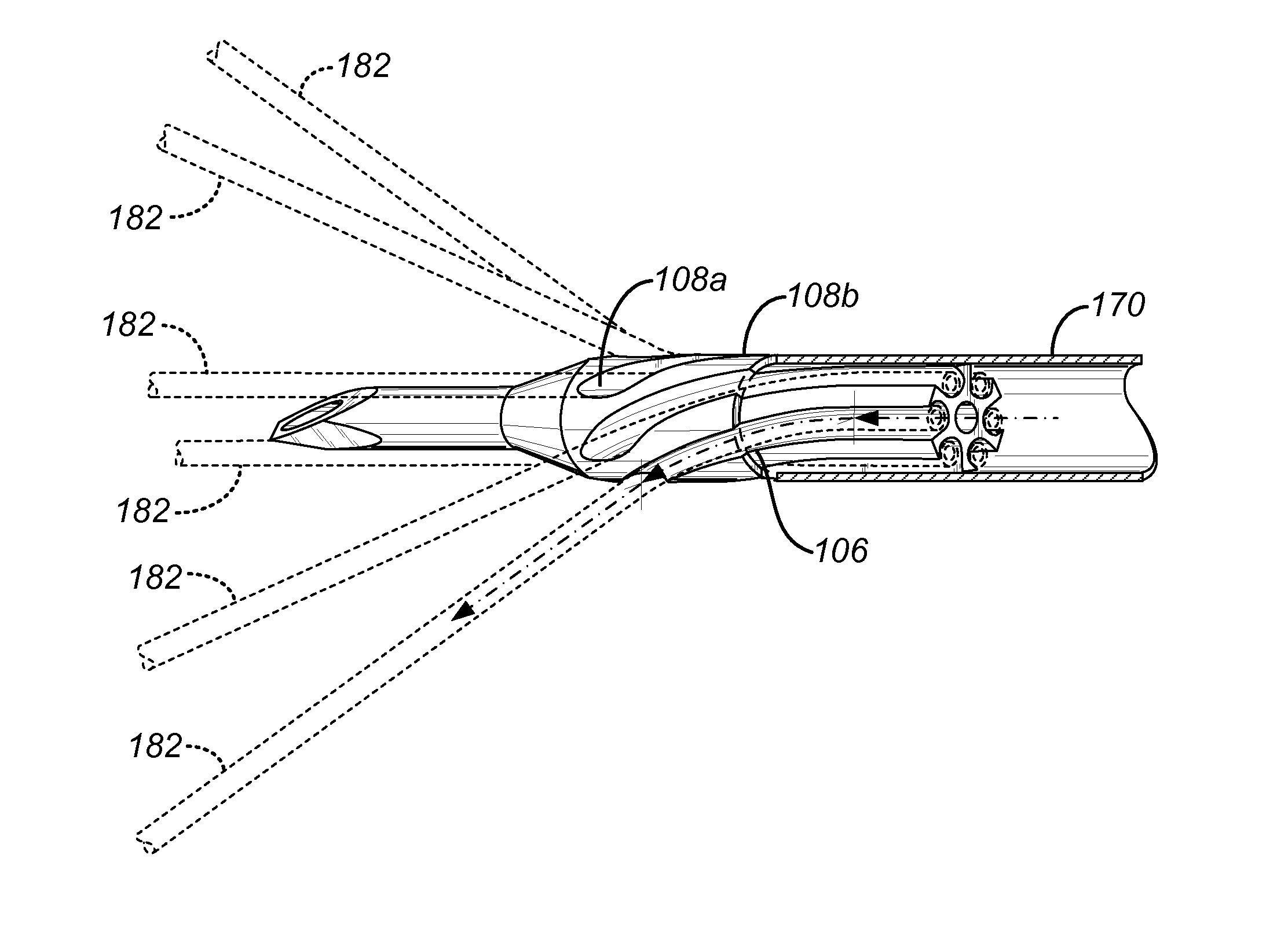

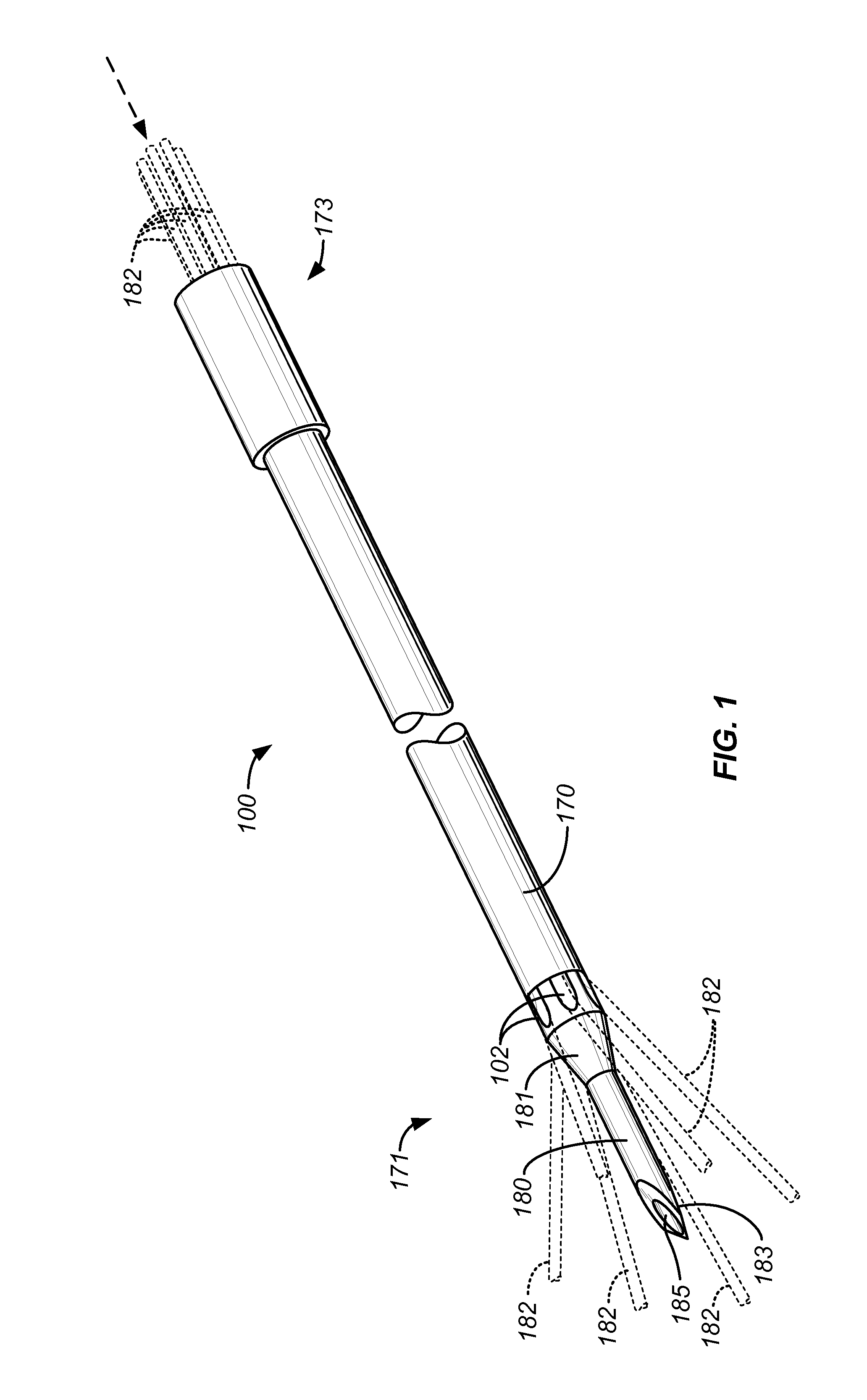

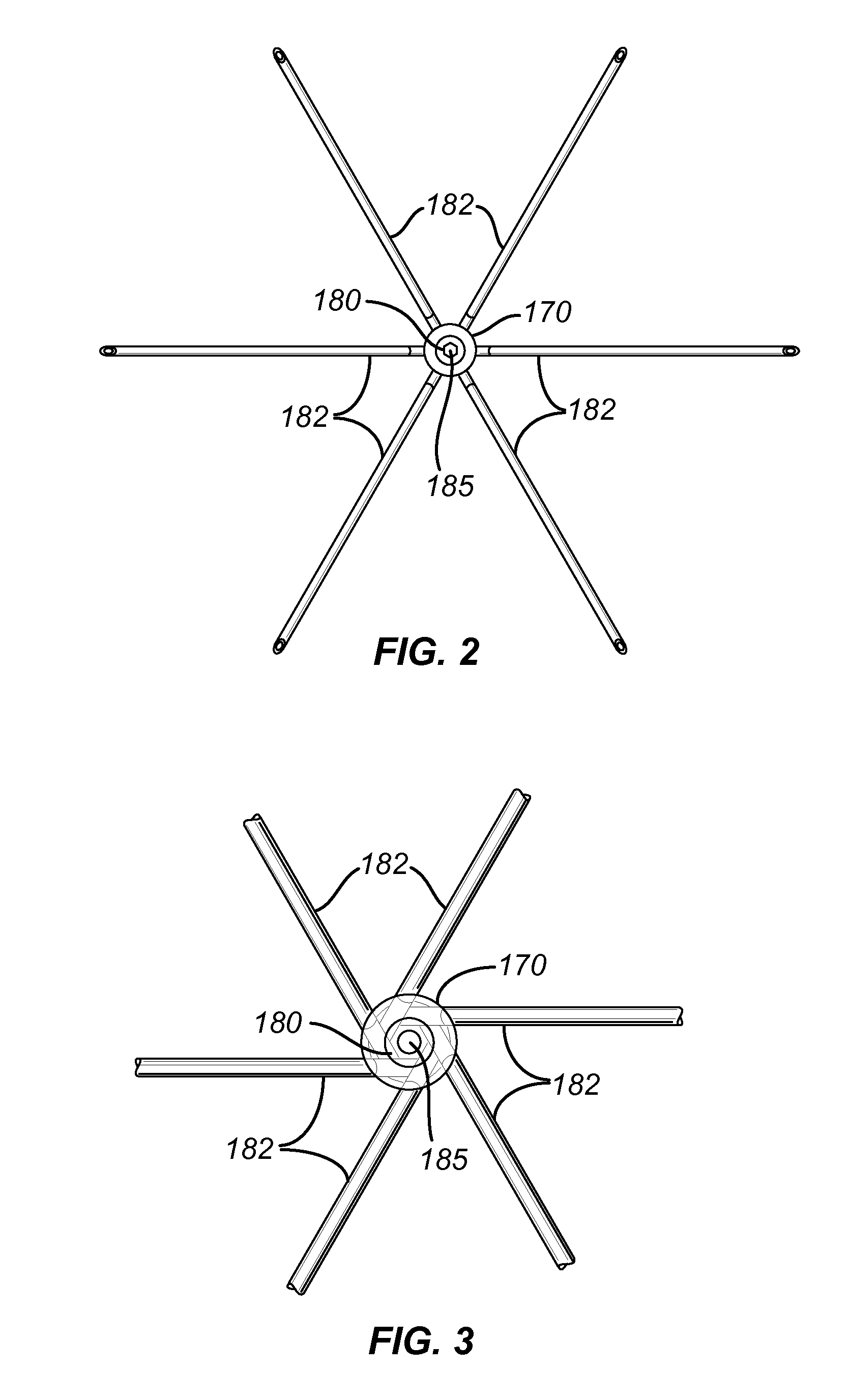

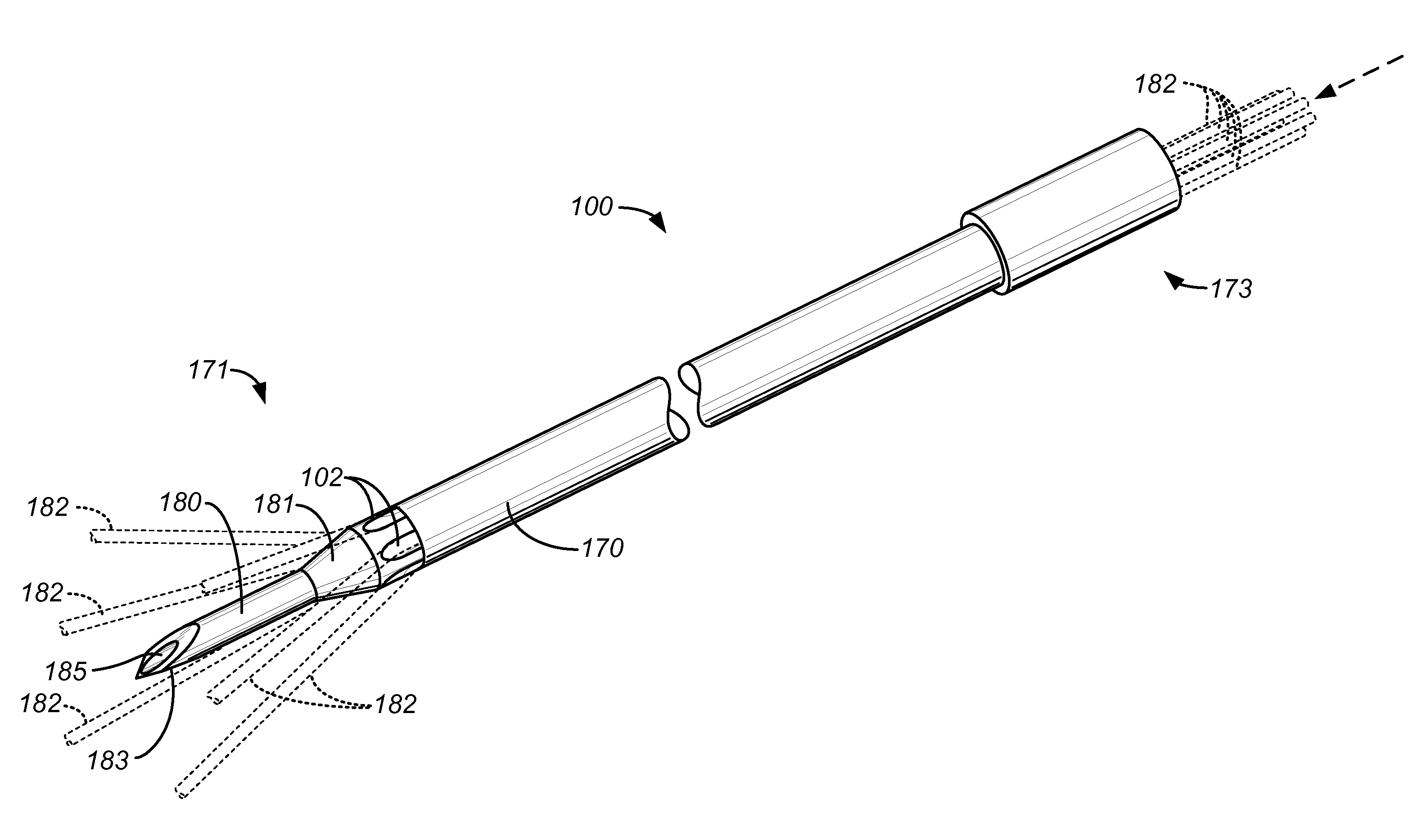

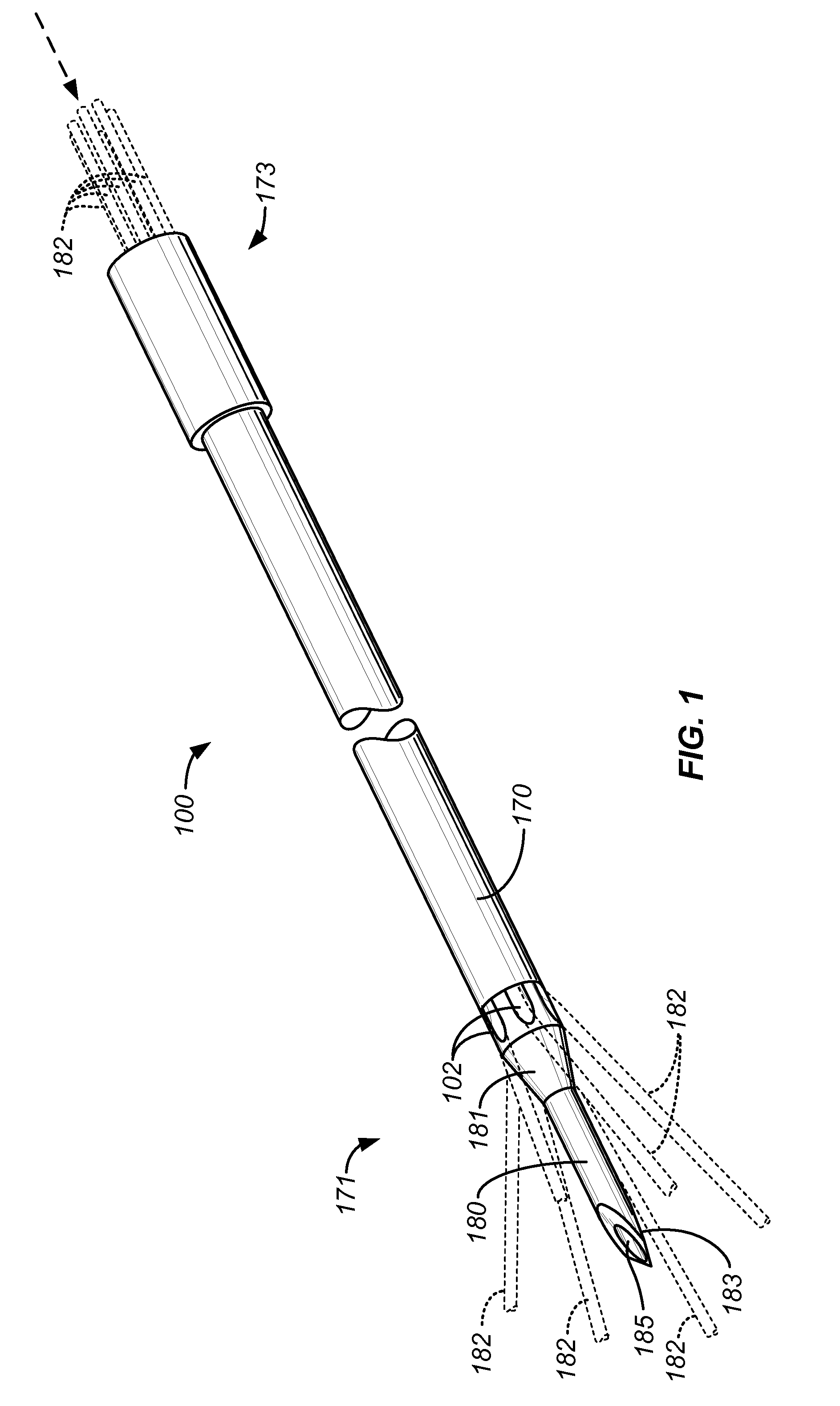

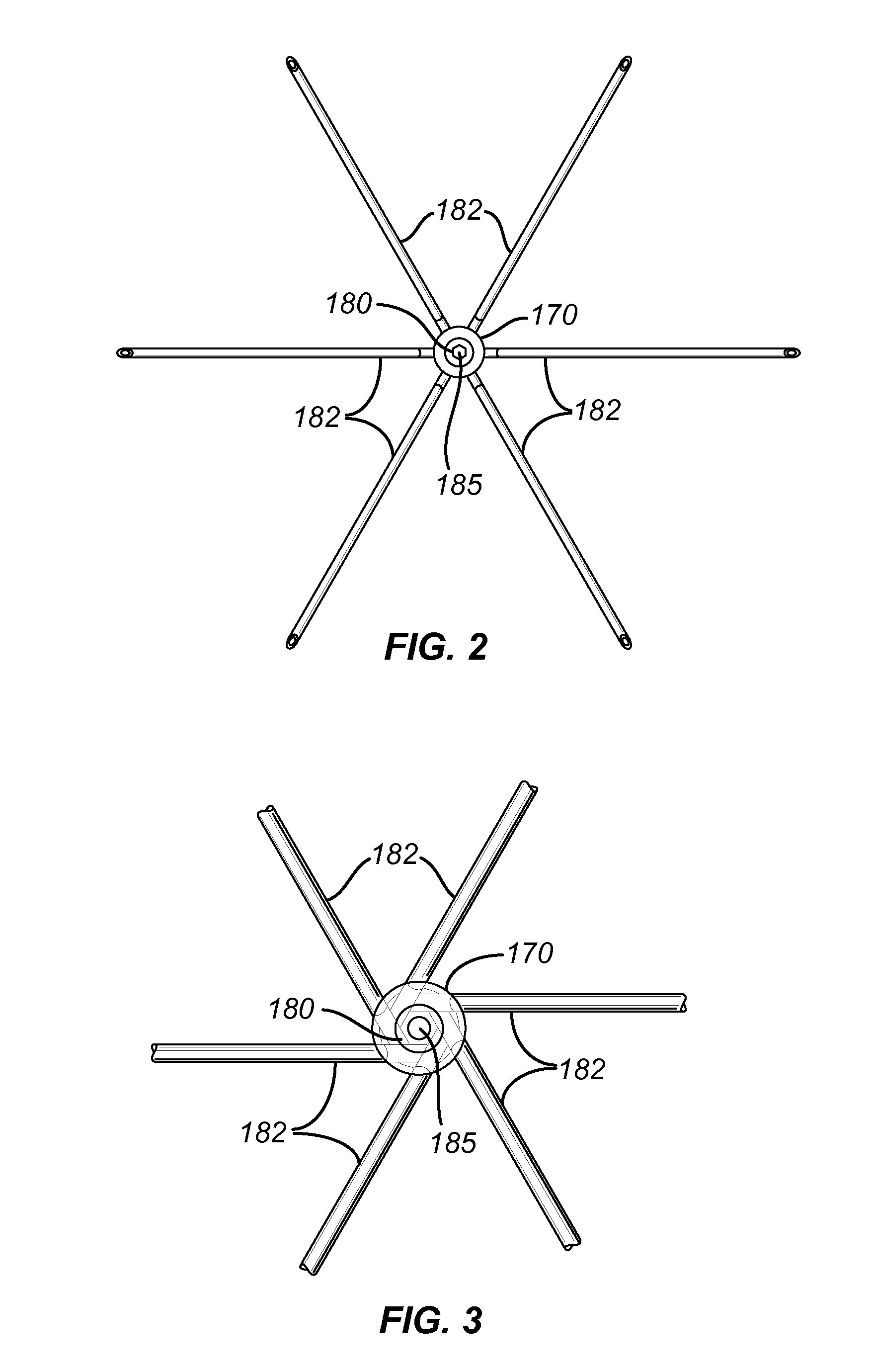

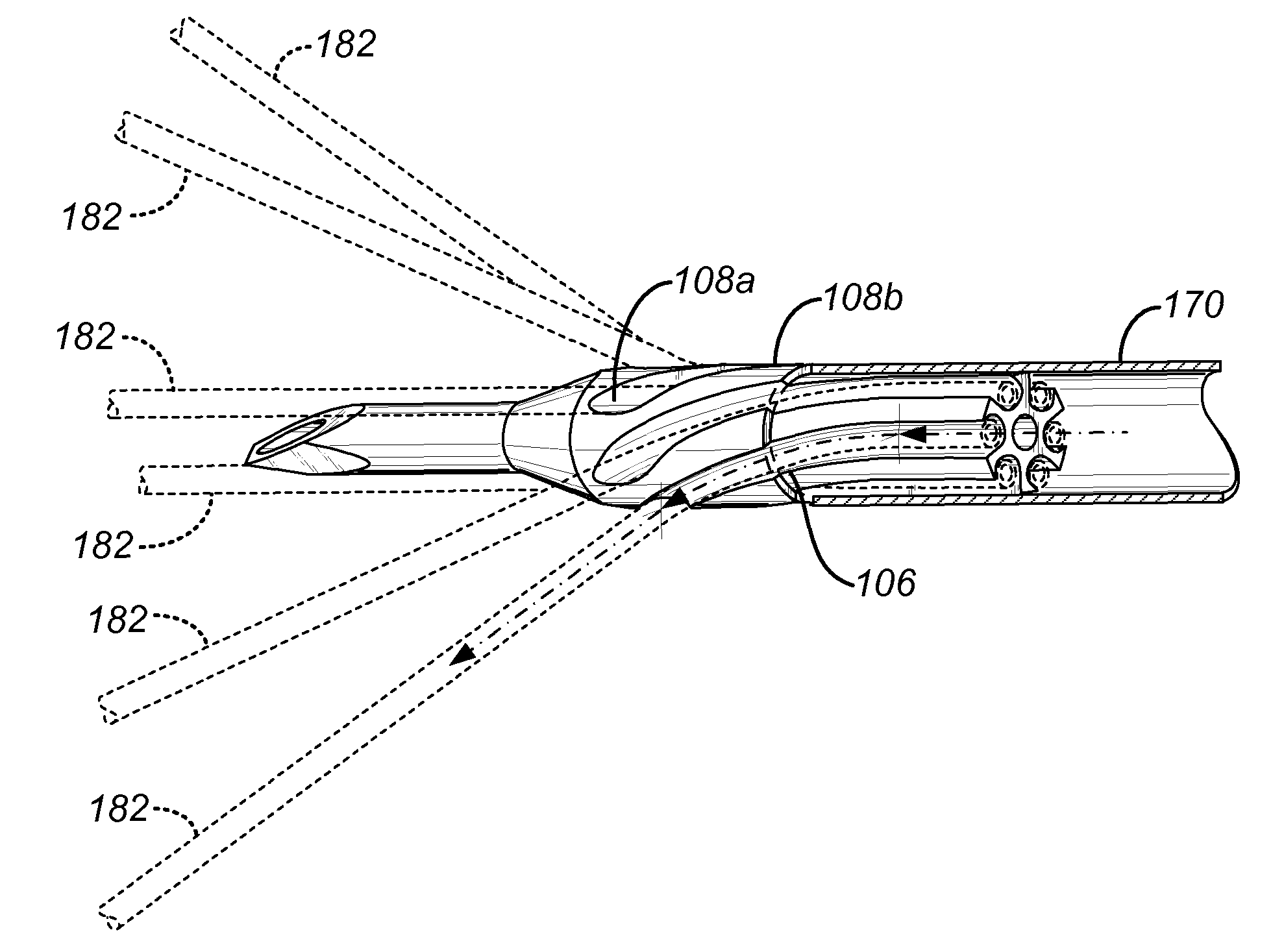

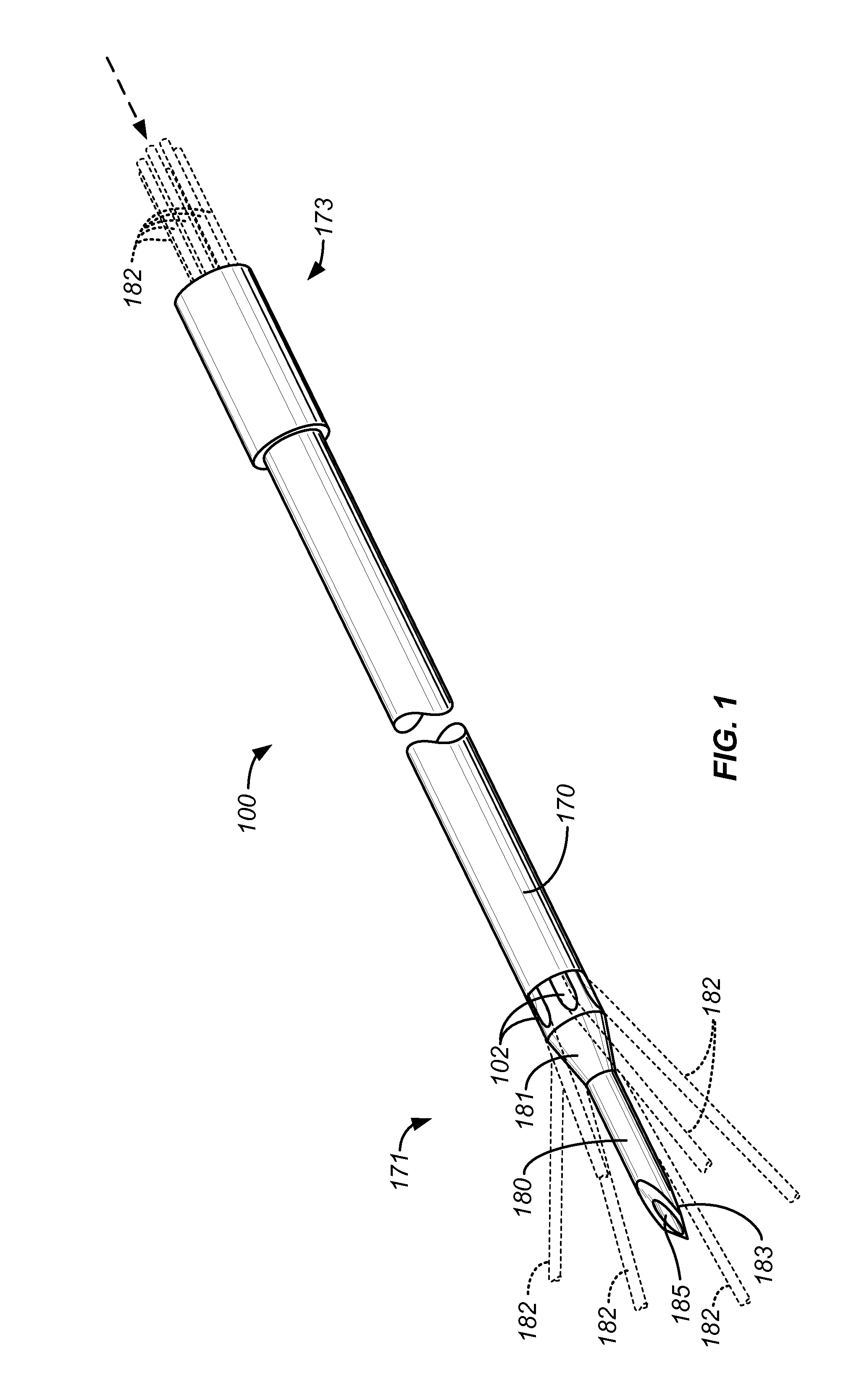

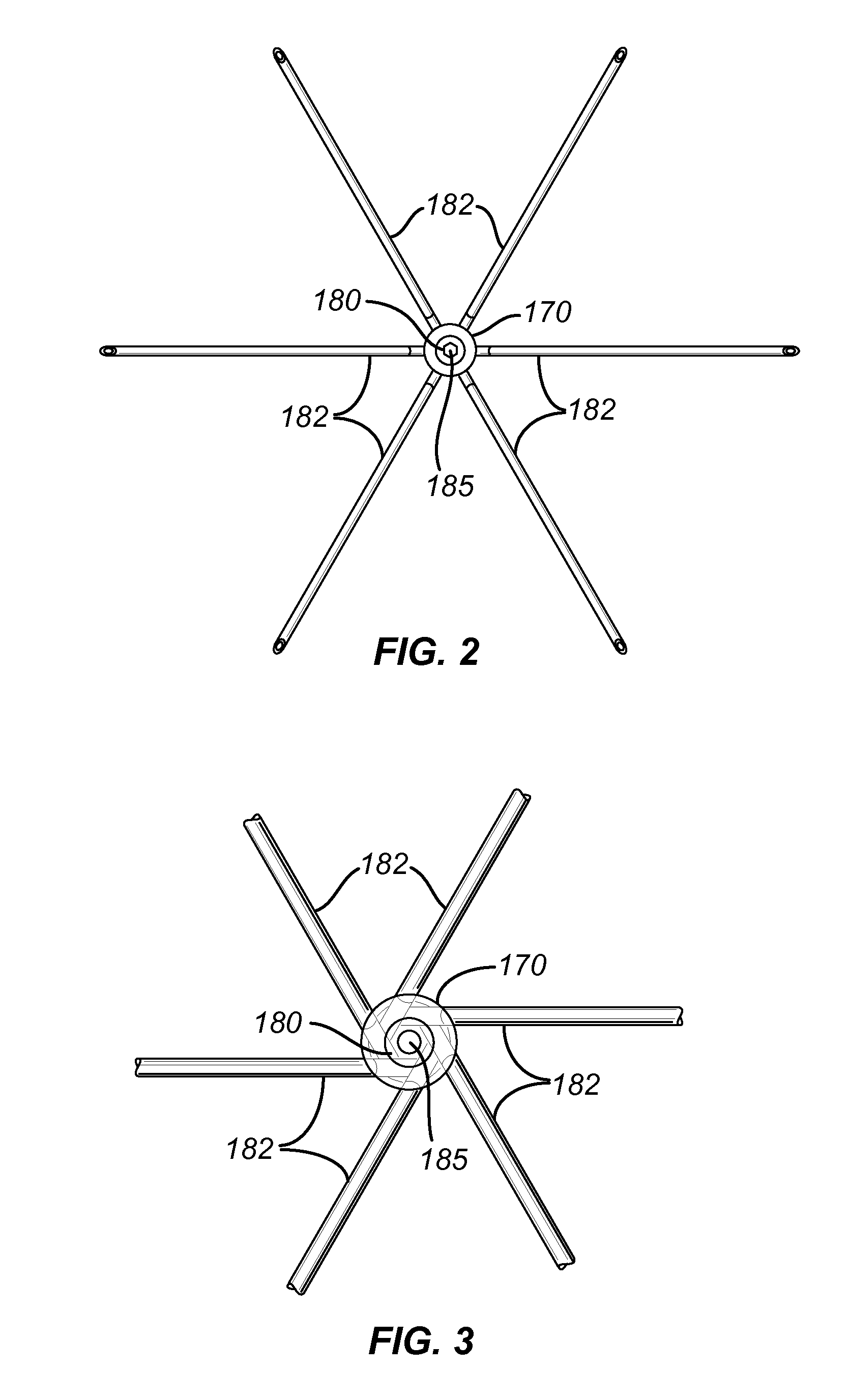

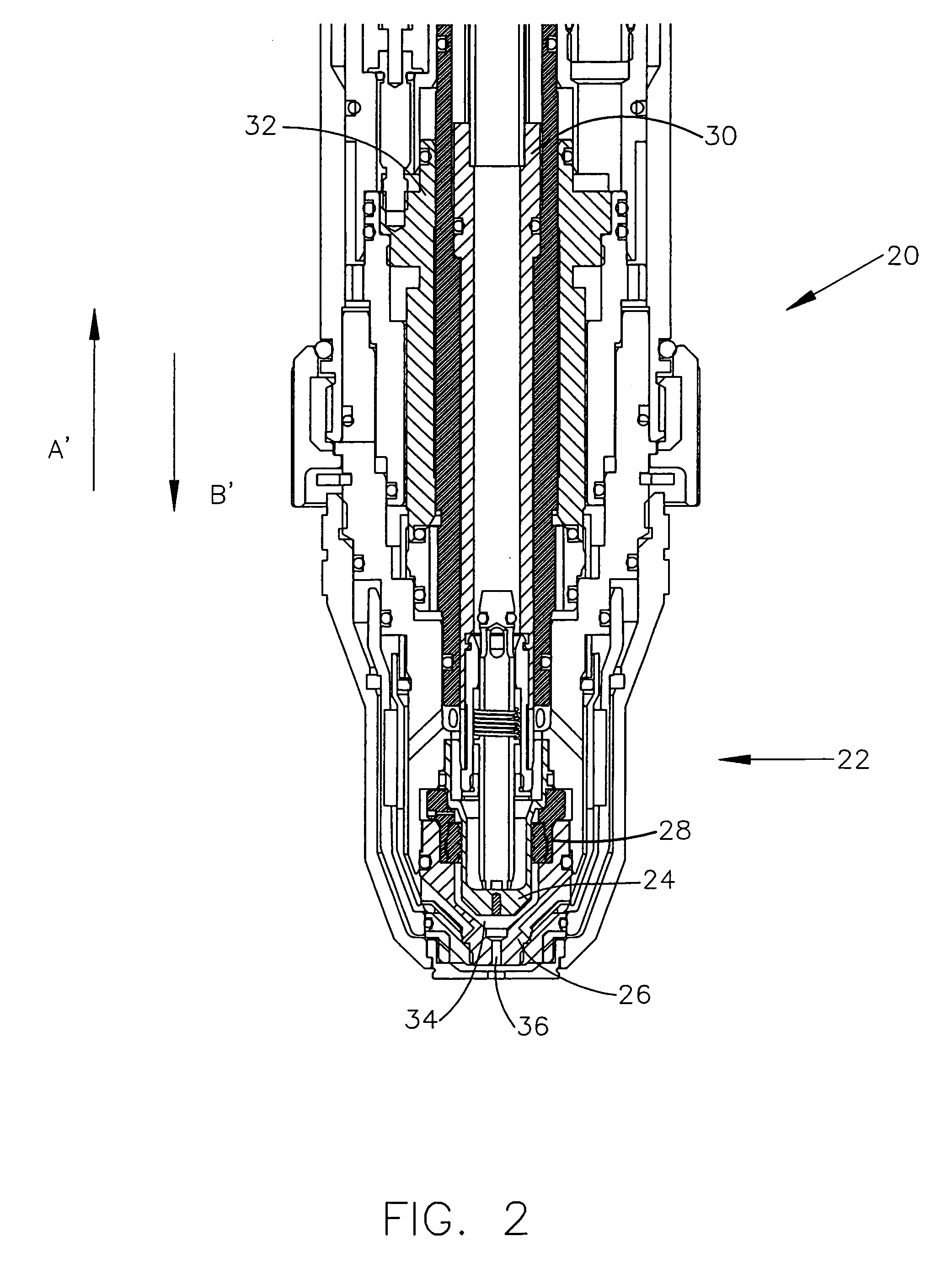

Needle and tine deployment mechanism

ActiveUS20100222677A1Improved and stabilized geometryEasy to take backUltrasonic/sonic/infrasonic diagnosticsSurgical needlesBiomedical engineeringNeedle electrode

A needle electrode deployment shaft includes a central member and a plurality of needle electrodes. The central member has a plurality of needle advancement channels formed therein. The needle electrodes are disposed within the advancement channels and each advancement channel terminates in a ramp portion which deflects the needles radially outwardly as they are axially advanced. The ramps may be spirally or acutely configured in order to increase the distance through which the needles may be bent as they are axially advanced. Additionally, the central member may have a radially reduced distal tip in order to decrease tissue insertion forces.

Owner:GYNESONICS

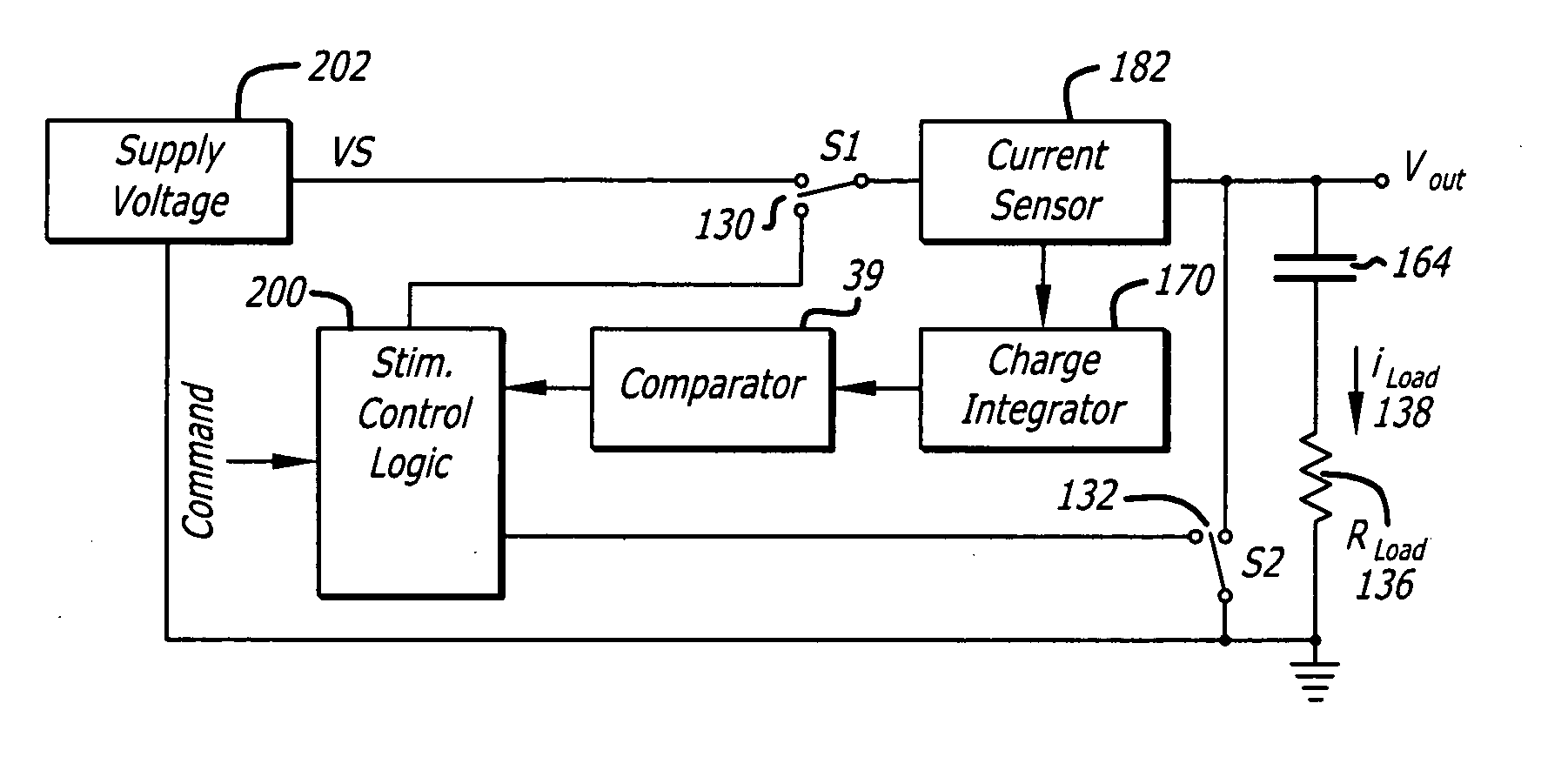

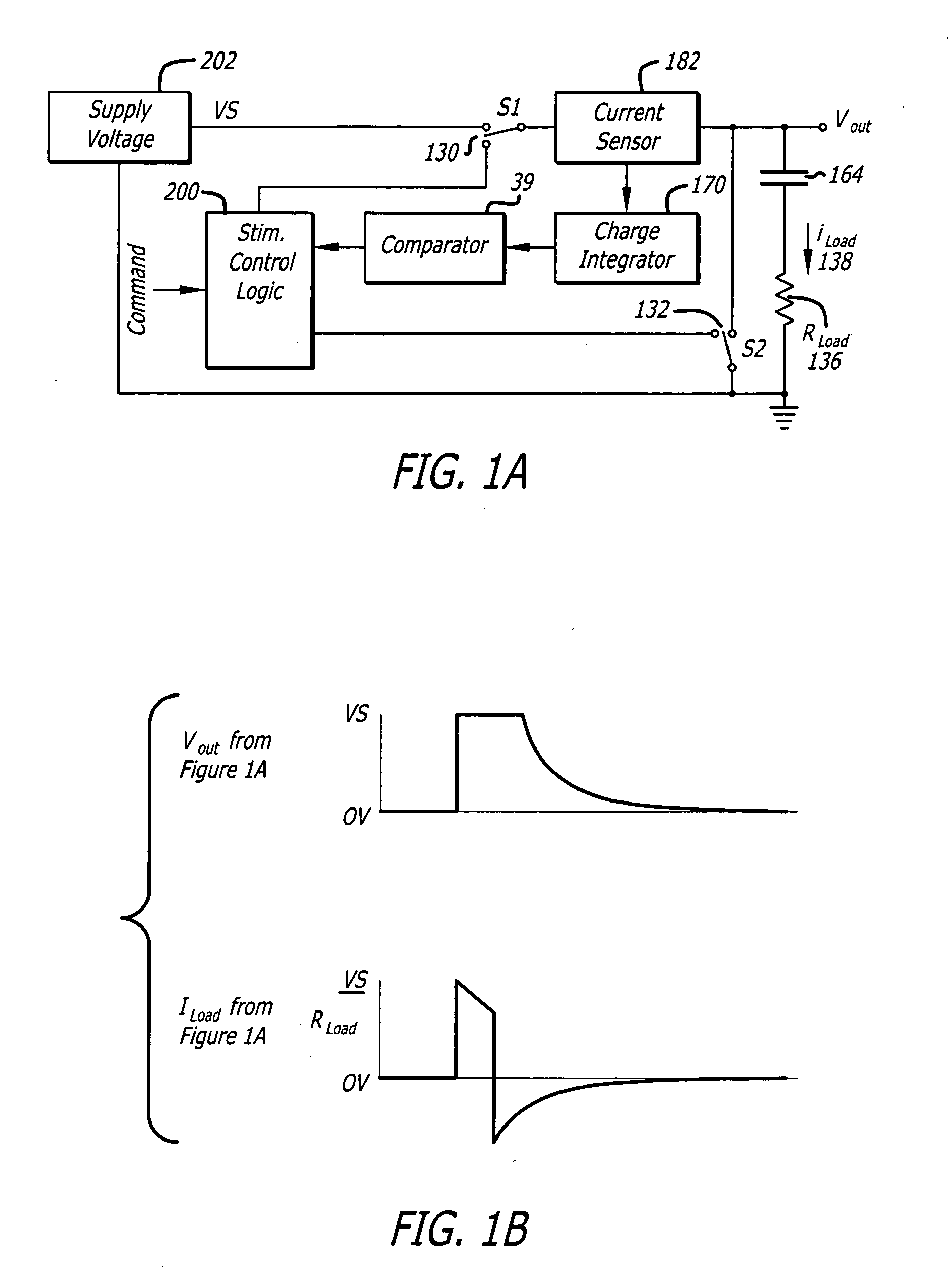

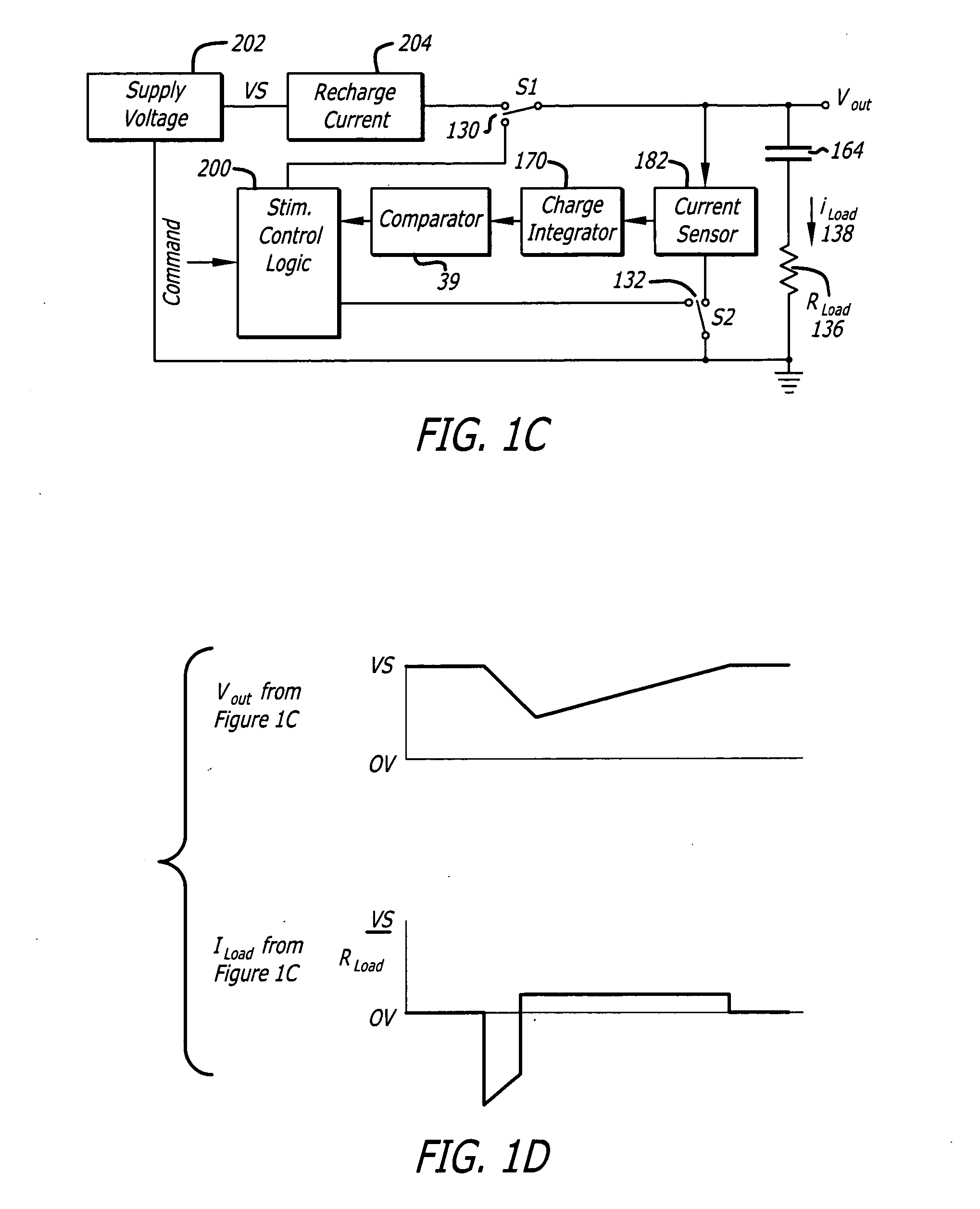

Charge-metered biomedical stimulator

InactiveUS20060004424A1Reduce and eliminate residual post-stimulation chargeProlonging electrode lifeHeart defibrillatorsImplantable neurostimulatorsStimulus strengthWide dynamic range

Disclosed are biomedical stimulators and systems that deliver stimulus power efficiently to electrodes and tissues, provide reliable control of stimulus efficacy over a wide dynamic range of available power and voltage, avoid damaging net direct current flow through tissue, minimize the amount of data that must be transmitted to specify a particular stimulus strength, and extend the range of received field strengths for which stimulators can function safely and reliably. These biomedical stimulators and systems provide reliable stimulation of known intensity by measuring charging currents and discharging predetermined quantities of charge.

Owner:UNIV OF SOUTHERN CALIFORNIA

Needle and tine deployment mechanism

ActiveUS20120310236A1Minimize residual strainResidual strain can be minimizedDiagnosticsSurgical needlesBiomedical engineeringNeedle electrode

A needle electrode deployment shaft includes a central member and a plurality of needle electrodes. The central member has a plurality of needle advancement channels formed therein. The needle electrodes are disposed within the advancement channels and each advancement channel terminates in a ramp portion which deflects the needles radially outwardly as they are axially advanced. The ramps may be spirally or acutely configured in order to increase the distance through which the needles may be bent as they are axially advanced. Additionally, the central member may have a radially reduced distal tip in order to decrease tissue insertion forces.

Owner:GYNESONICS

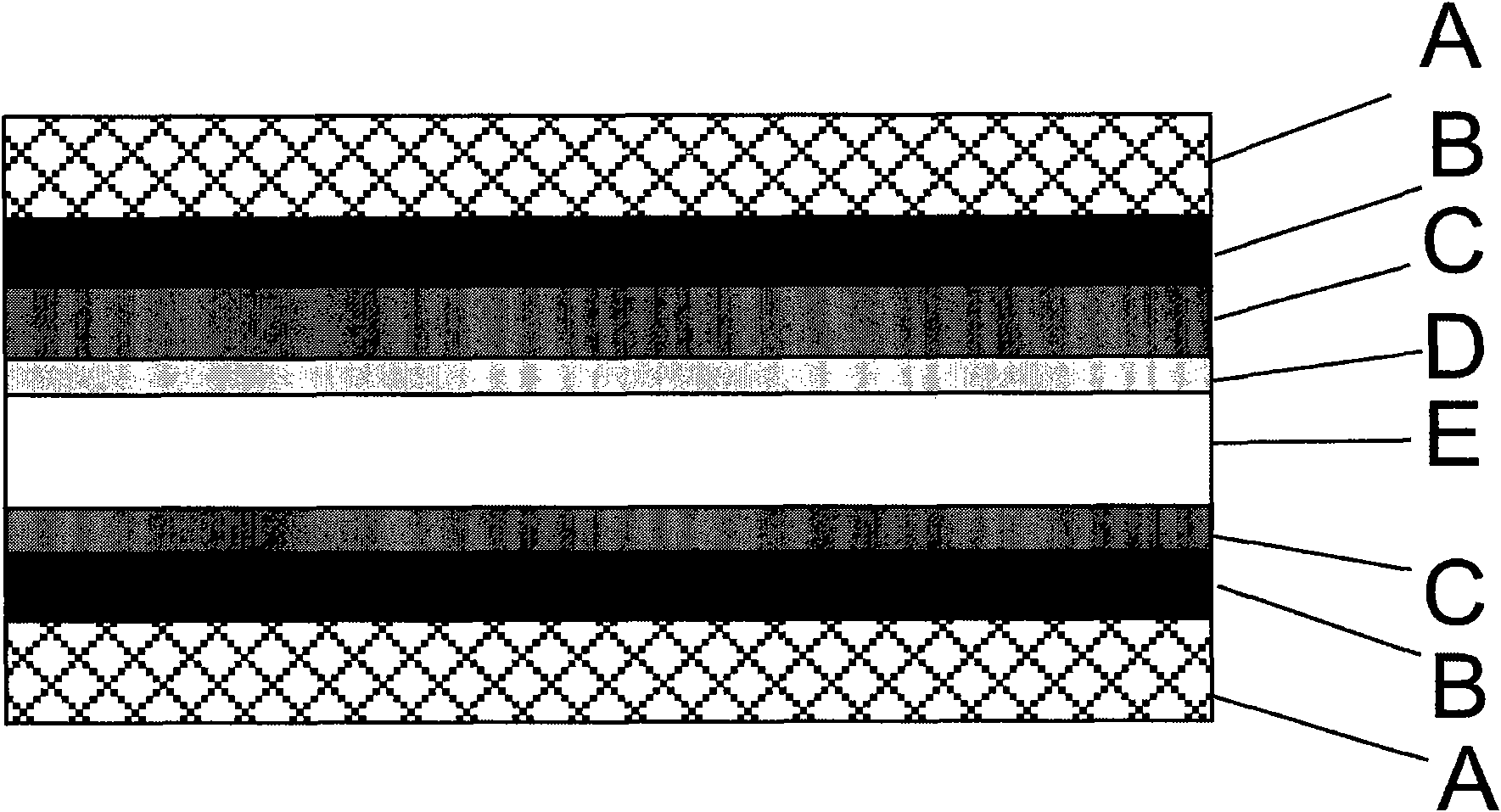

Novel ti-supported lead dioxide electric pole and preparation method thereof

InactiveCN101417831ALow costReduce internal stressWater/sewage treatment by sorptionAcid etchingLead dioxide

The invention relates to a novel titanium substrate lead dioxide electrode and a preparation method thereof, which belong to the field of water treatment technology application. The titanium substrate lead dioxide electrode adopts titanium material as a carrier; after the titanium substrate undergoes acid etching, pyrolytic process is adopted to plate a tin-stibium oxide bottom layer; alkaline solution is then used for electroplating an alpha-PbO2 intermediate layer; acidic composite electroplating solution is used for preparing a fluorine-containing beta-PbO2 surface layer doped with an active metal (such as bismuth, nickel, lanthanum, cerium and erbium) and a particle with high absorption performance (such as powdered activated carbon and chitosan), thus obtaining a novel titanium substrate lead dioxide electrode. The titanium substrate lead dioxide electrode prepared by the method has low cost and long service life. Using the electrode as an anode and applying certain applied voltage can realize efficient removal and mineralization to the organic contaminants in the water. With simple operation and convenient management, the method is applicable to small-scale and dispersible wastewater and feed water treatment.

Owner:BEIJING NORMAL UNIVERSITY

Needle and tine deployment mechanism

ActiveUS8262574B2Minimize residual strainResidual strain can be minimizedUltrasonic/sonic/infrasonic diagnosticsSurgical needlesBiomedical engineeringNeedle electrode

A needle electrode deployment shaft includes a central member and a plurality of needle electrodes. The central member has a plurality of needle advancement channels formed therein. The needle electrodes are disposed within the advancement channels and each advancement channel terminates in a ramp portion which deflects the needles radially outwardly as they are axially advanced. The ramps may be spirally or acutely configured in order to increase the distance through which the needles may be bent as they are axially advanced. Additionally, the central member may have a radially reduced distal tip in order to decrease tissue insertion forces.

Owner:GYNESONICS

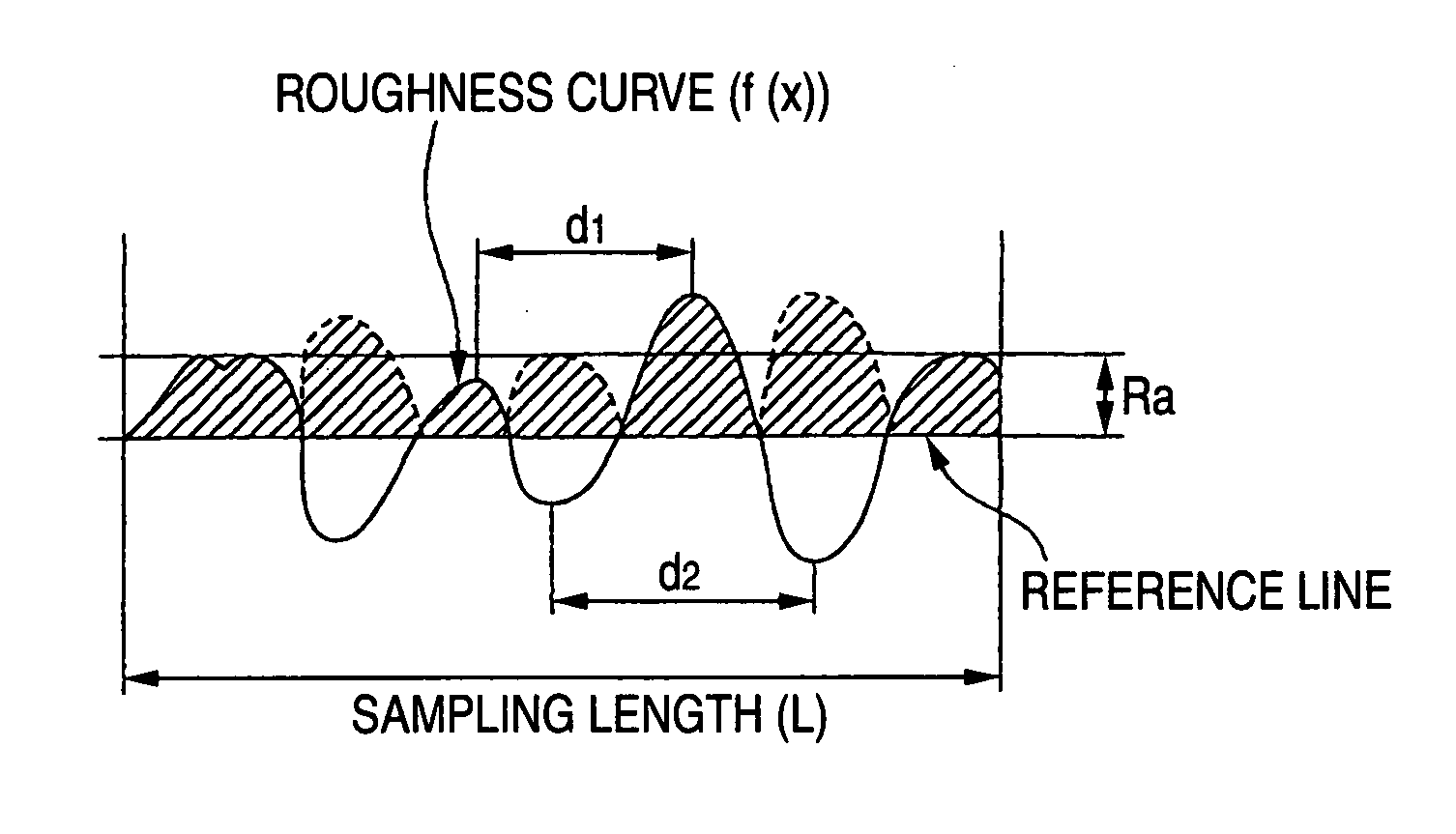

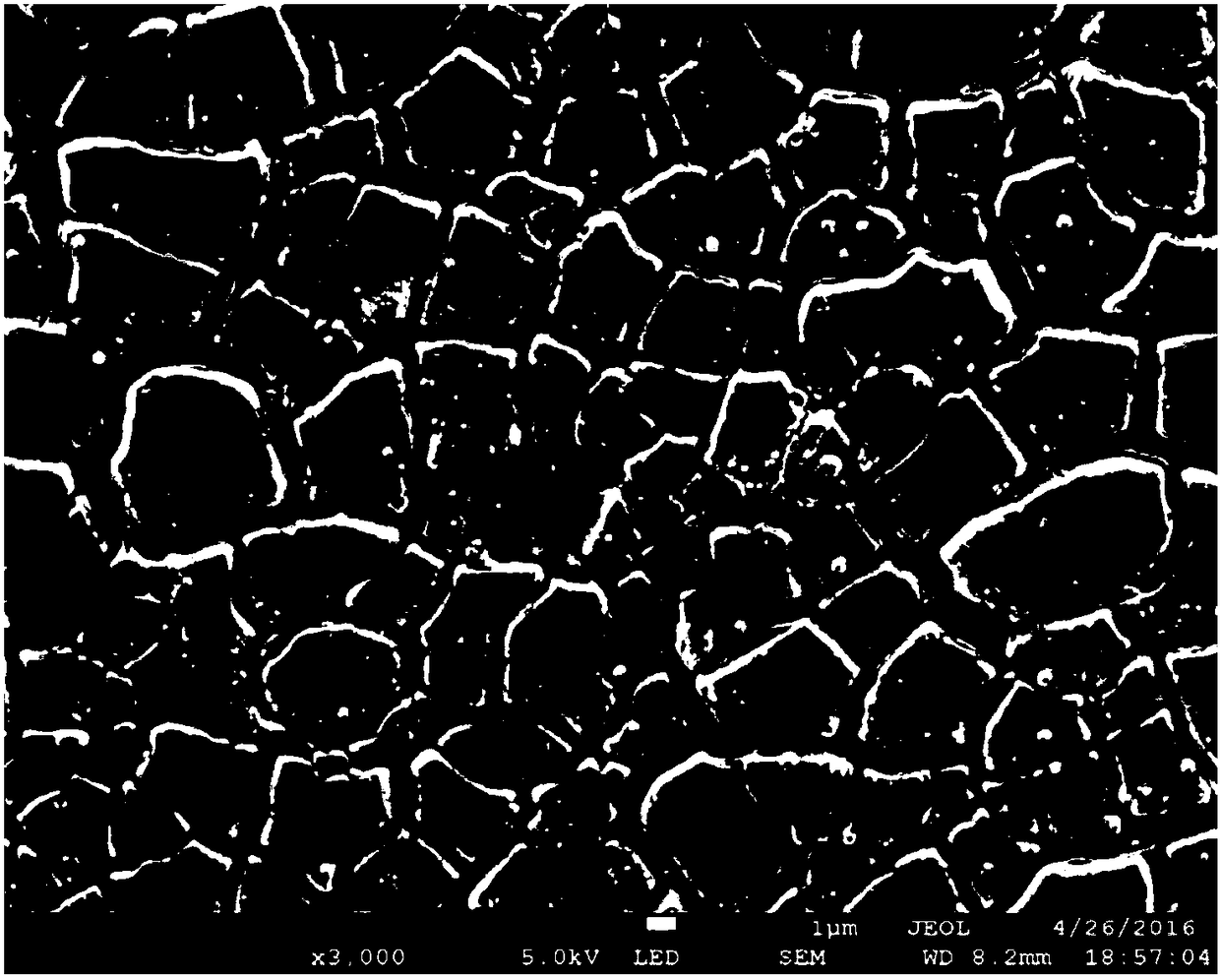

Electrode for electrolysis and process for producing the same

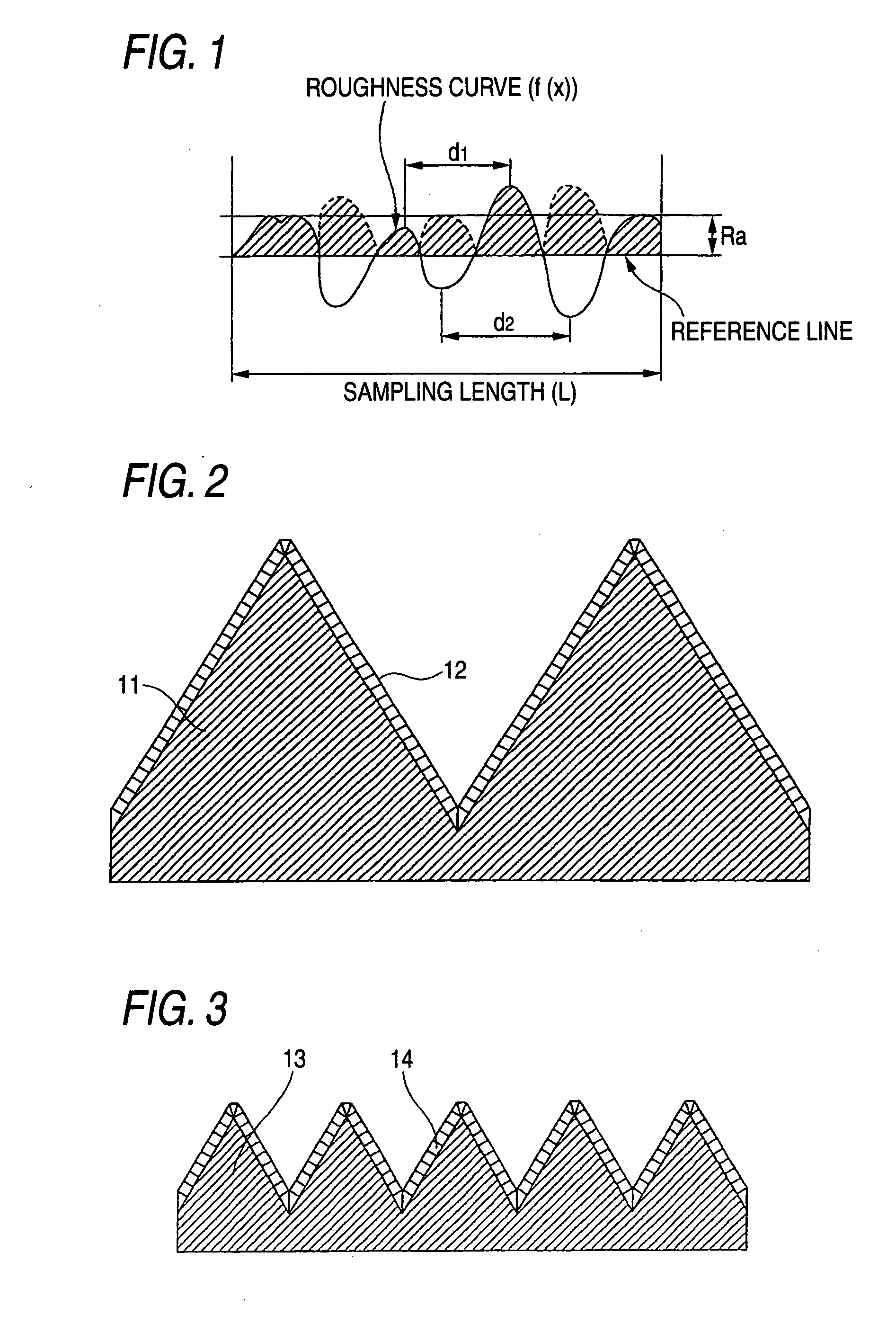

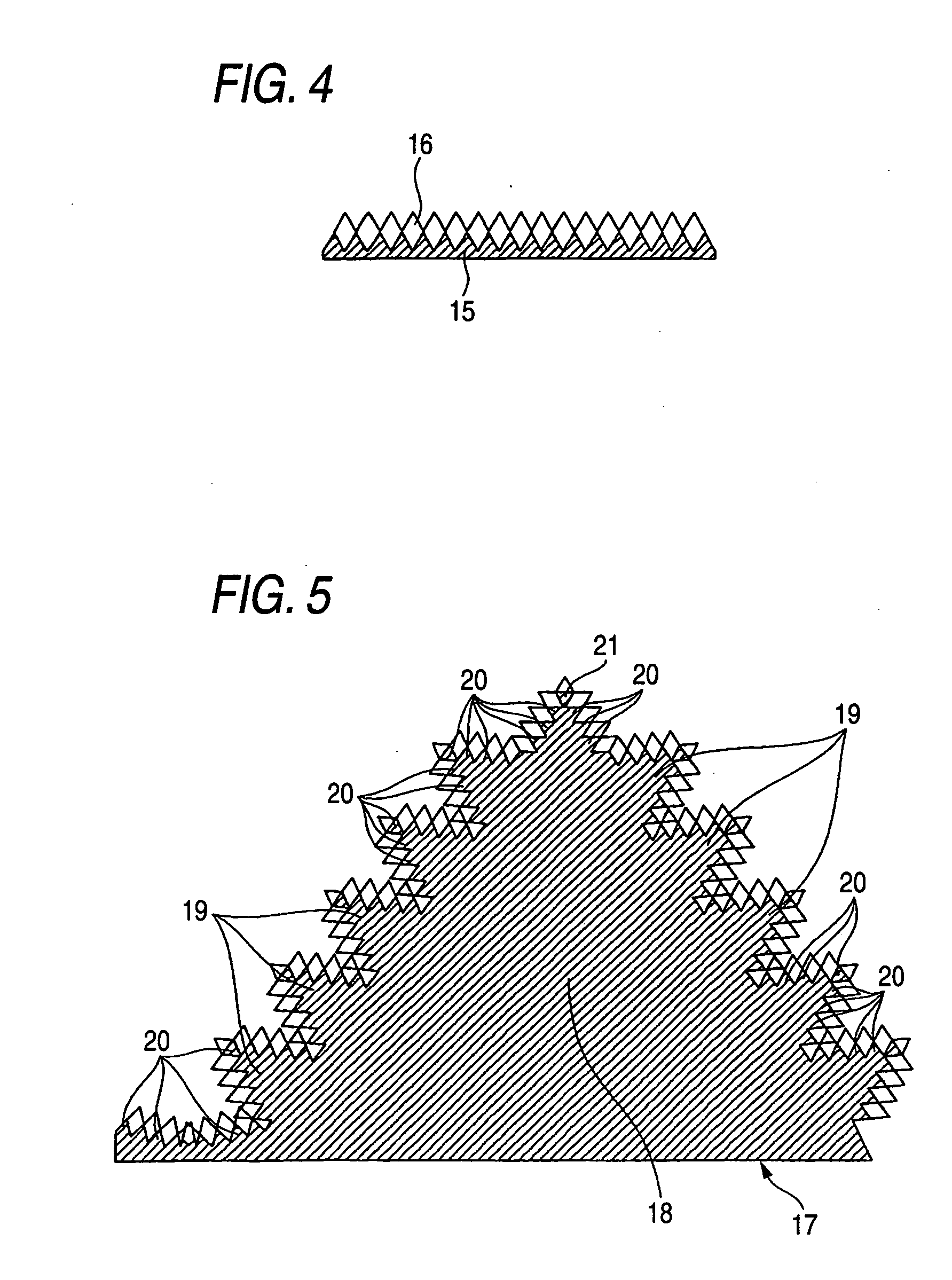

ActiveUS20070029190A1Increased durabilityIncrease surface areaMaterial nanotechnologyPolycrystalline material growthElectrolysisManufacturing technology

The present invention provides an electrode for electrolysis including: a conductive substrate; and a conductive diamond formed on a surface of the conductive substrate, the conductive substrate having at least one surface shape selected from the group consisting of: (a) a surface shape of a combination of an Ra of 100-1,000-μm and an RSm of 50-10,000 μm; (b) a surface shape of a combination of an Ra of 2.5-100 μm and an RSm of 1.5-800 μm, and (c) a surface shape of a combination of an Ra of 0.01-2 μm and an RSm of 0.005-250 μm, and a process for producing the electrode.

Owner:DE NORA PERMELEC LTD

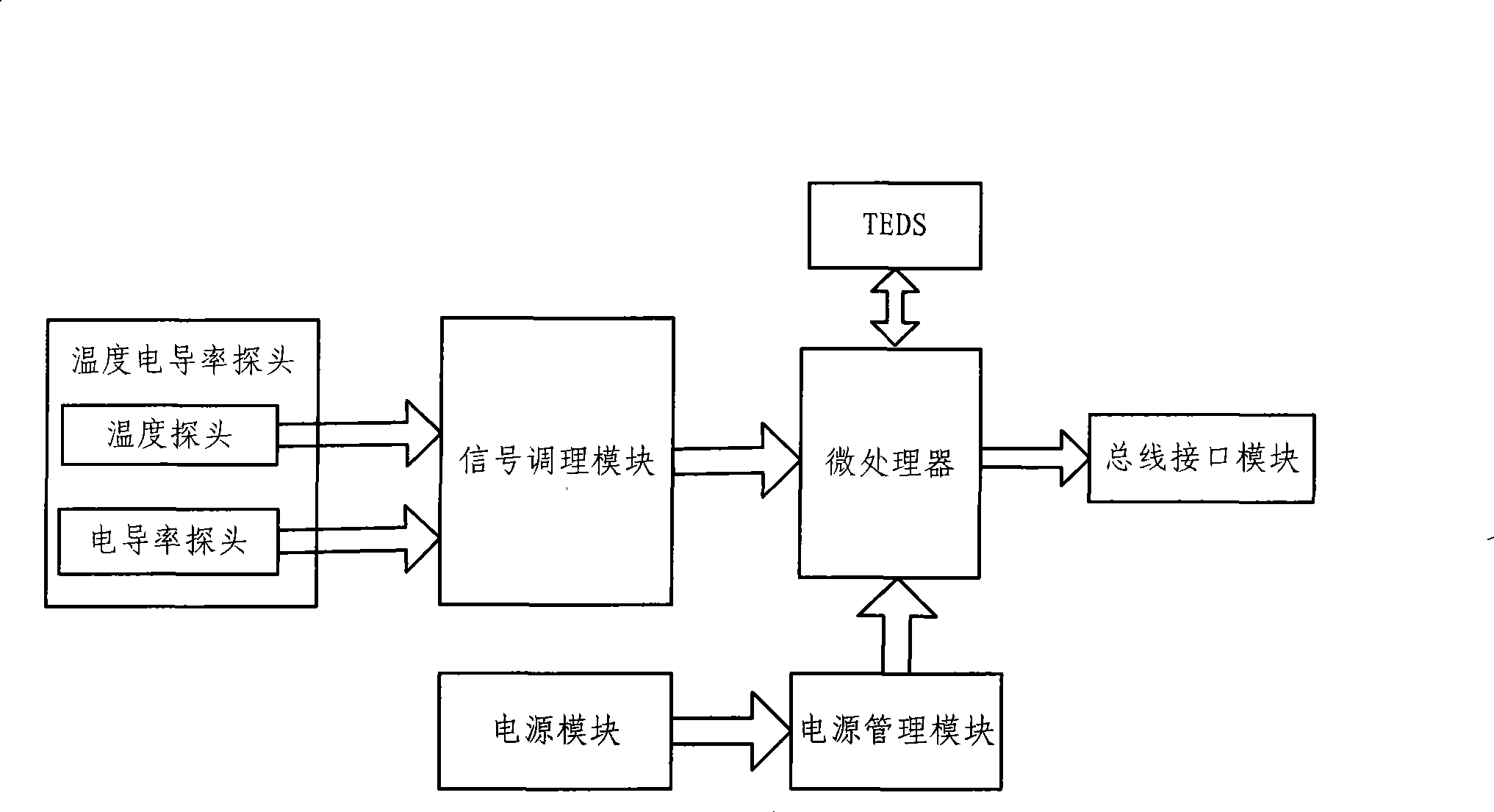

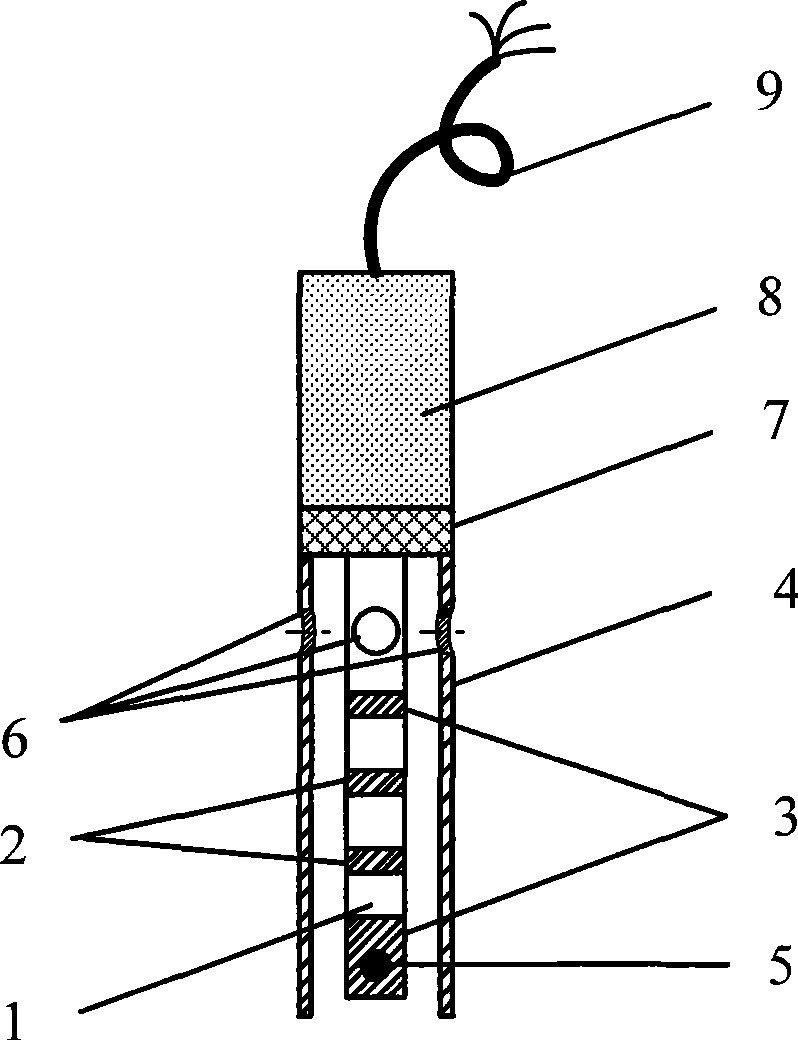

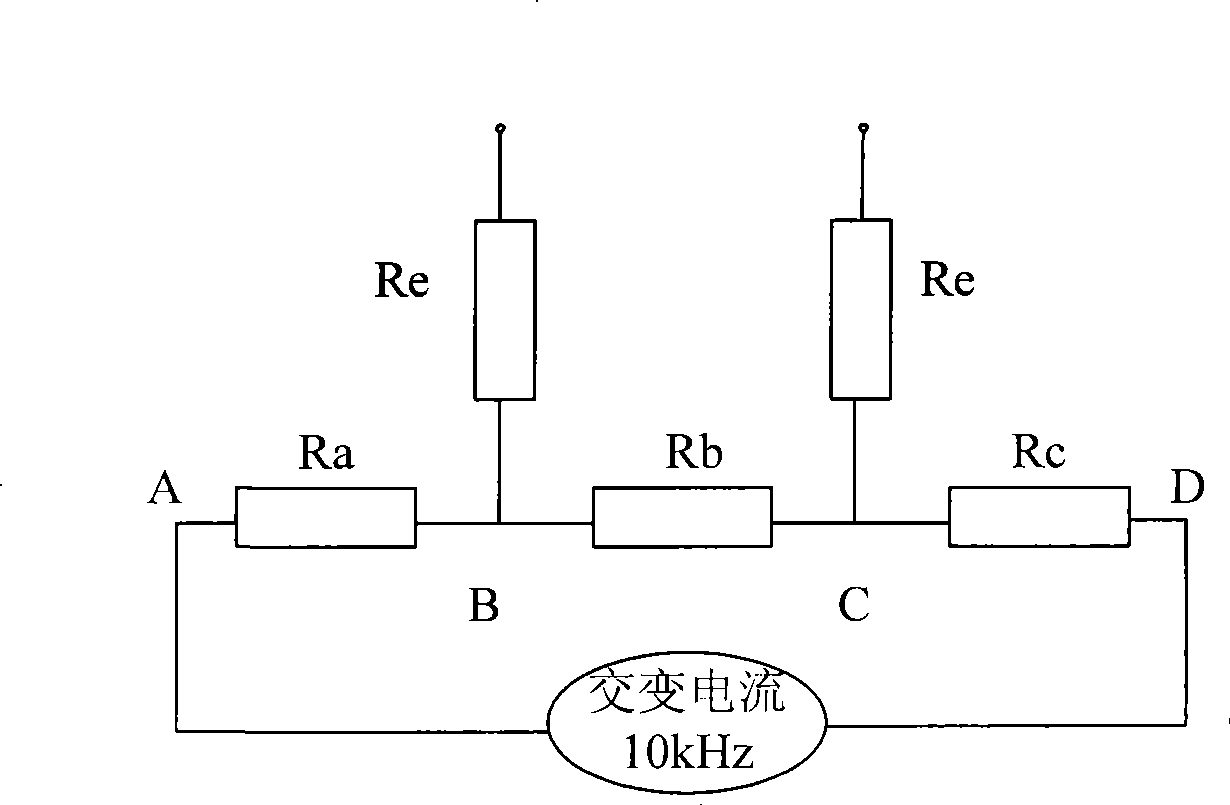

Water electric conductivity intelligent sensor

InactiveCN101398405AAvoid Electrode PolarizationLong electrode lifeMaterial analysis by electric/magnetic meansPlug and produceSmart transducer

The invention discloses an intelligent sensor for the electrical conductivity of water quality. The sensor comprises a temperature-conductivity probe used for sensing the temperature and the electrical conductivity of the water; a signal conditioning module which is connected with the temperature-conductivity probe, forms a sensing circuit with the temperature-conductivity probe and carries out filtering and amplification to an output signal; a microprocessor which is connected with the signal conditioning module, is used for digitizing the signal input by the signal conditioning module and adopts IEEE1451 standards to carry out the calibration and alignment of channels; a bus interface module which is connected with the microprocessor and is used for the functions of networking and plugging and playing; and a power module which supplies power to the circuits of all parts of the sensor under the control of the microprocessor and realizes the characteristic of low power consumption. The invention can eliminate the polarization effect of the probe, has pollution resistance, large measuring range and low price, and is characterized by the functions of self alignment and compensation, self diagnosis and plugging and playing and high integrity.

Owner:CHINA AGRI UNIV

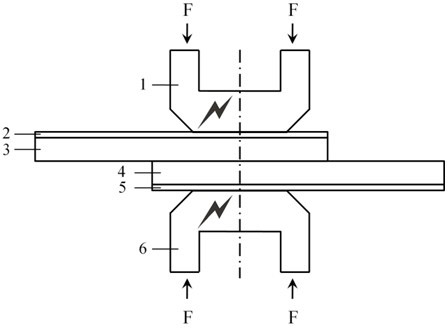

Method for performing spot welding on Al-Zn hot-coated steel plate

InactiveCN101961814ASolder joint appearance is goodQuality improvementWelding/cutting media/materialsWelding/soldering/cutting articlesPlanar electrodePower flow

The invention provides a method for performing spot welding on an Al-Zn hot-coated steel plate. In the method, a foil belt is arranged between a copper electrode and an Al-Zn hot-coated steel plate workpiece; a step type large-contact planar electrode is adopted, a two-section welding current mode is adopted; and the two-section welding current adopts a constant current control mode, so that the foil belt is not adhered to the workpiece and the electrode and each welding spot has fine appearance and stable quality. The copper electrode is only contacted with a non-tinplated surface of the foil plate, so the method solves the problem that the electrode is alloyed by a zinc aluminium coating fundamentally, prolongs the service life and improves the welding spot quality of a spot-welding electrode of the zinc aluminium plated steel plate, prolongs the service life of the electrode and has favorable popularization and application prospects.

Owner:BAOSHAN IRON & STEEL CO LTD +1

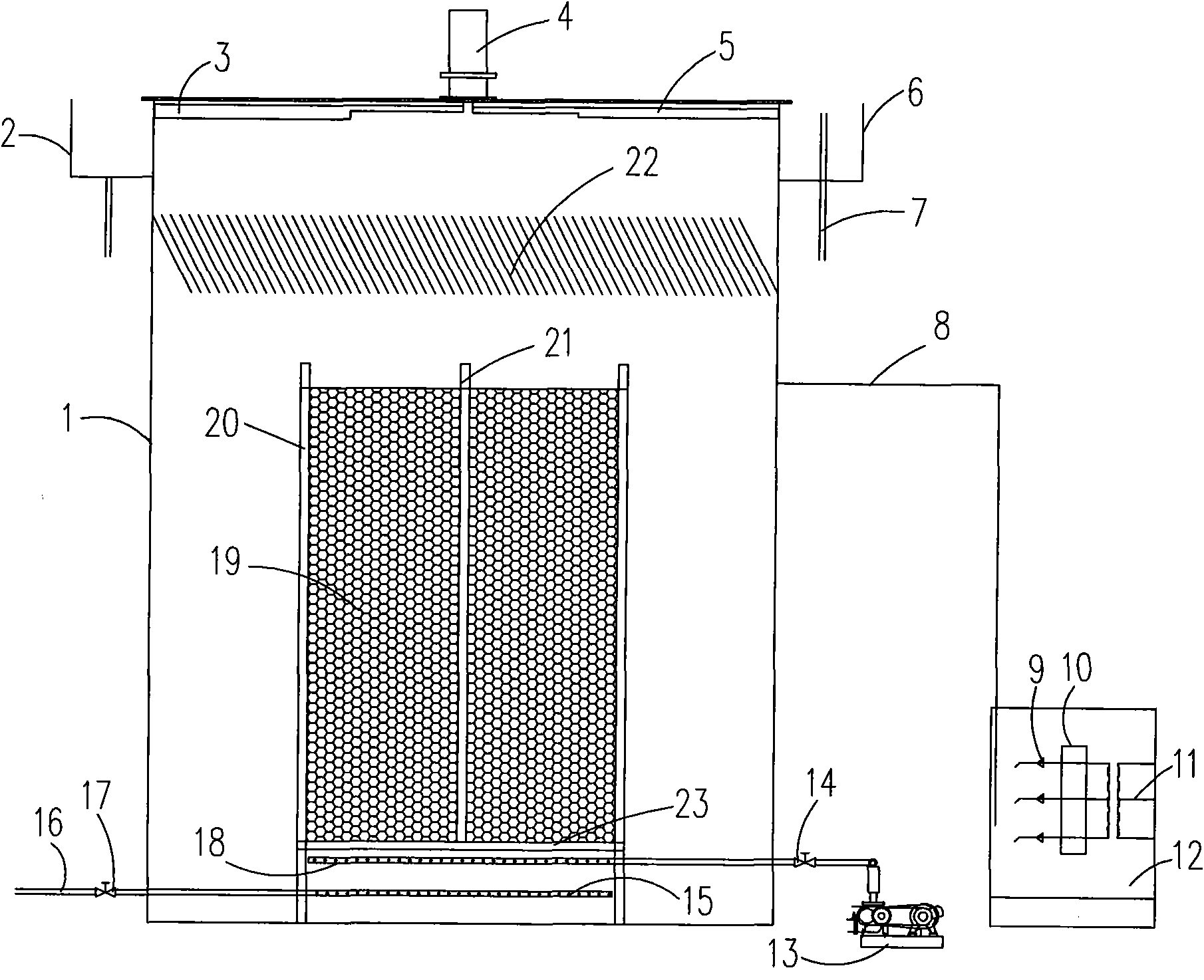

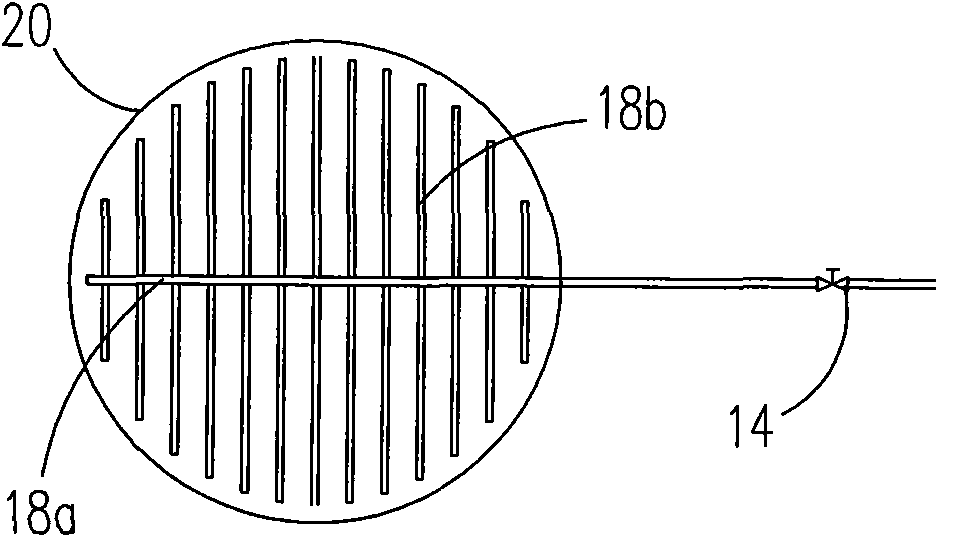

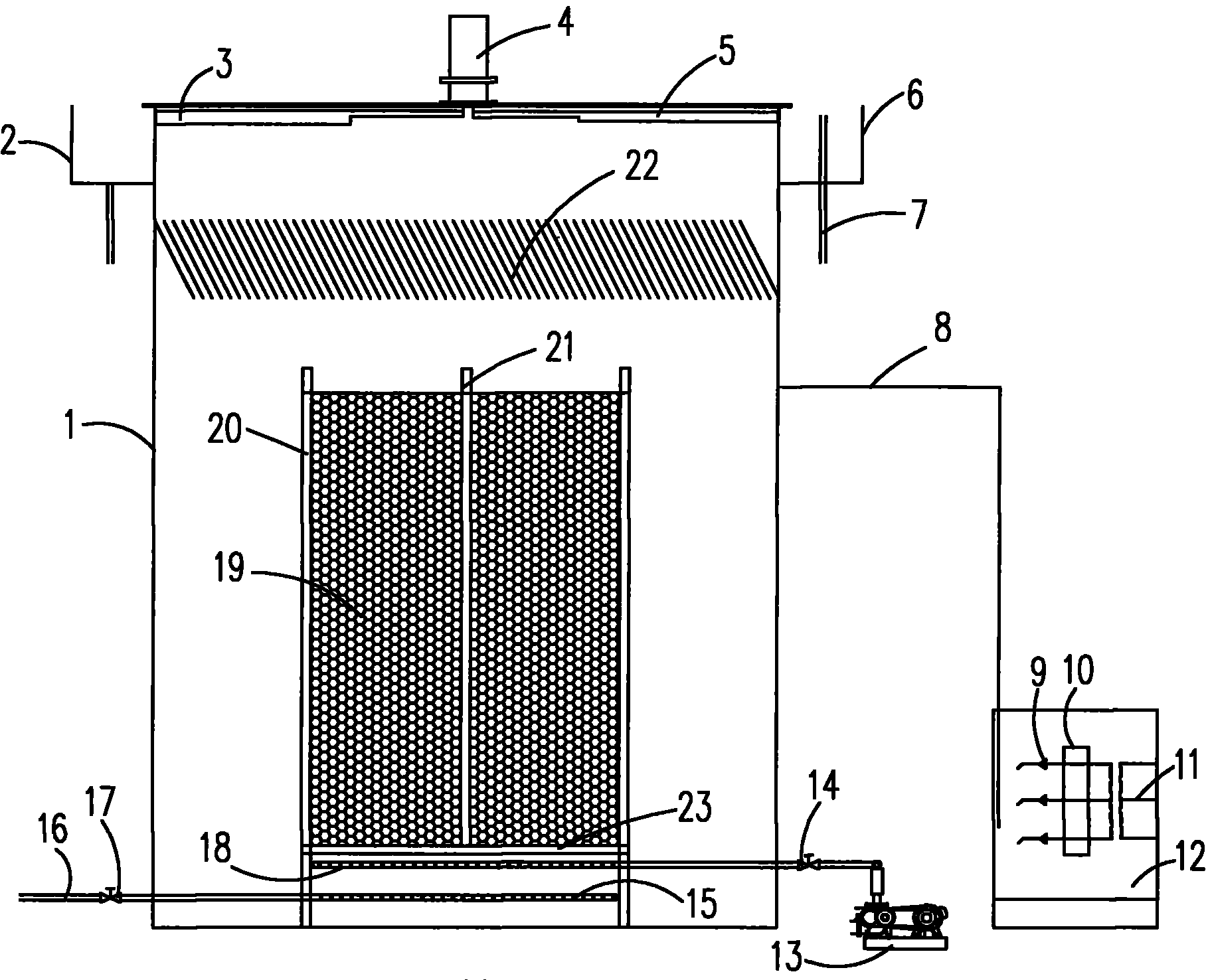

Internal recycle multi-dimensional electro-catalytic wastewater treating equipment

InactiveCN101863533AEasy to handleReduce energy consumptionWater/sewage treatment by electrochemical methodsWater/sewage treatment by sorptionElectricityCatalytic oxidation

The invention discloses internal recycle multi-dimensional electro-catalytic wastewater treating equipment, which is characterized in that the wastewater treating equipment is provided with a cylindrical device which is internally provided with an inflow water distribution pipe, an aerator pipe, an electrode reaction region, a rectifying region, a water outlet region and a scum collecting region from bottom to top. The wastewater treating equipment of the invention integrates the electro-catalytic oxidation and air floating functions into a whole with good treating effect, low energy consumption and long electrode life.

Owner:HEFEI UNIV OF TECH

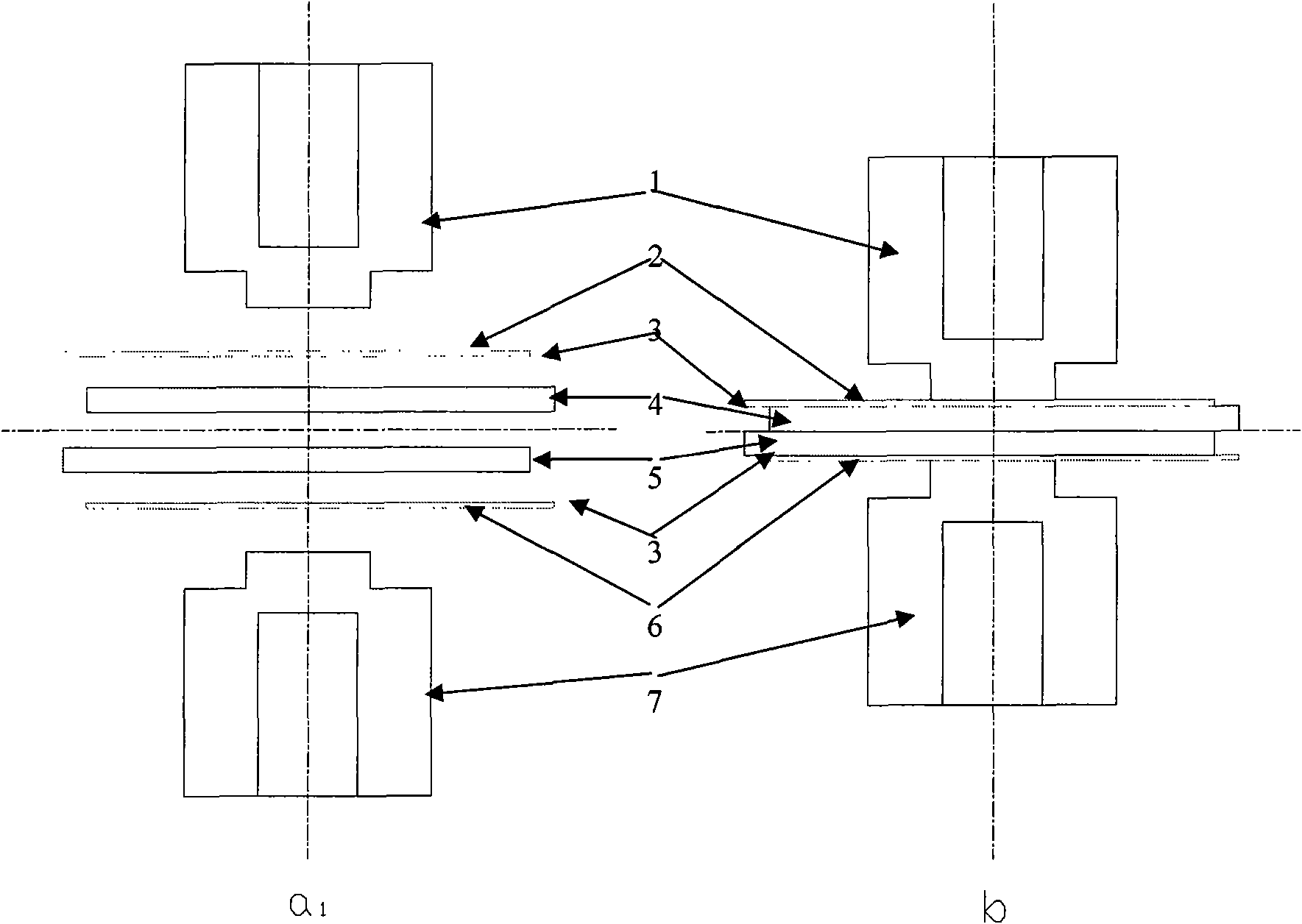

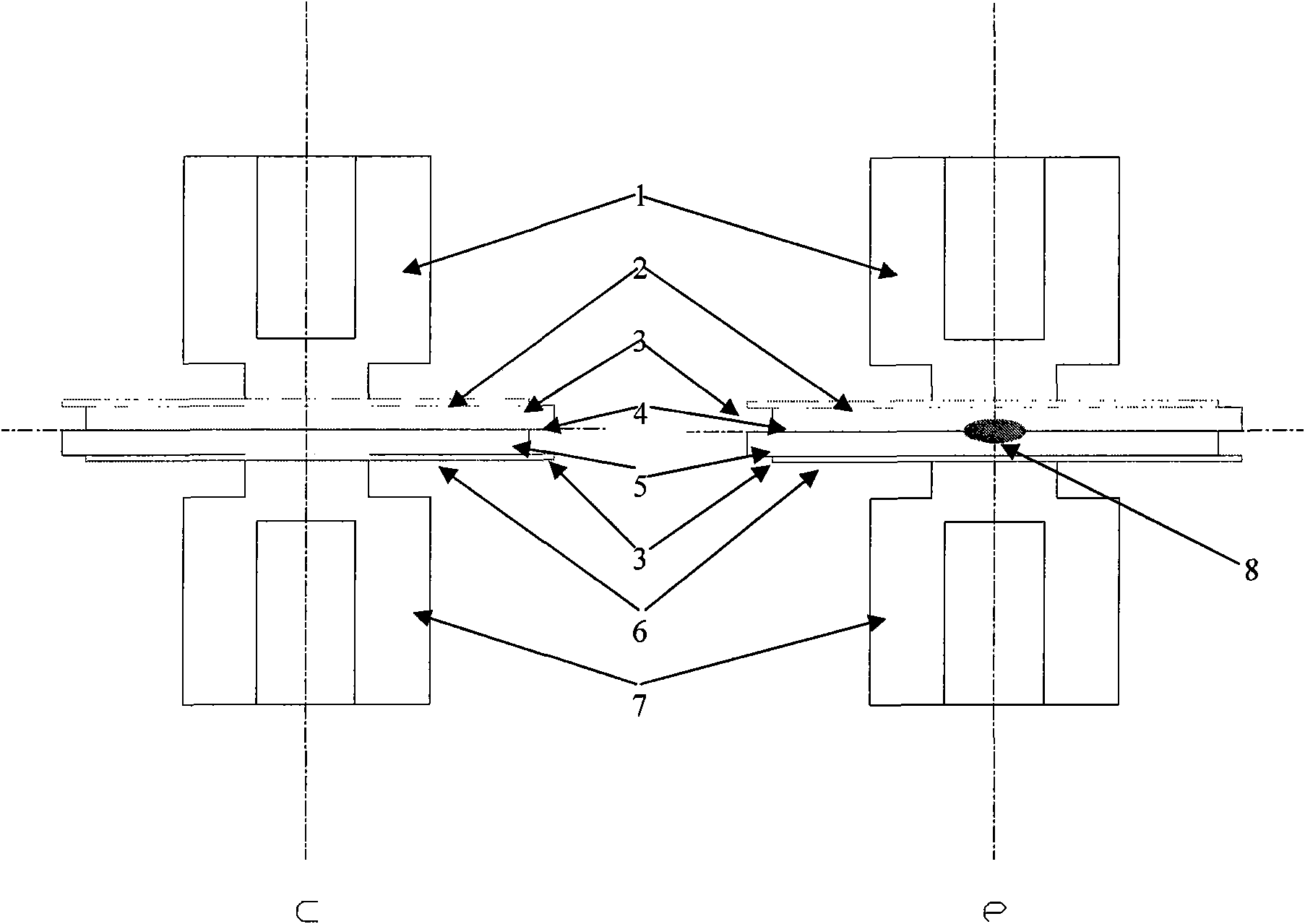

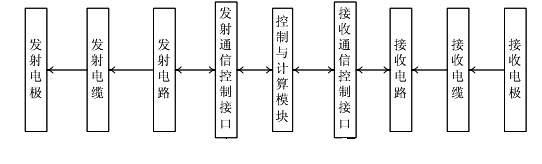

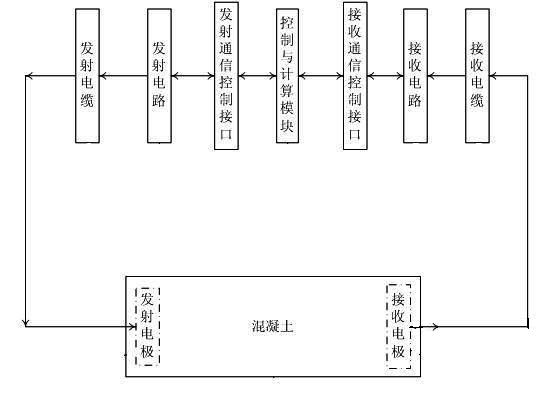

Concrete crack detector with reinforcing bar as electrode

InactiveCN102692431AReal-time forecastReal-time awarenessMaterial impedanceCommunication controlRebar

The invention discloses a concrete crack detector with a reinforcing bar as an electrode. A reinforcing bar emission electrode and a reinforcing bar receiving electrode are embedded in concrete, wherein the emission electrode is connected with an emission circuit through an emission cable; a signal transmitted by the emission circuit is sent out from the concrete through the emission electrode; the receiving electrode is connected with a receiving circuit through a receiving cable; and the receiving circuit is used for amplifying and filtering a signal received by the receiving electrode. An output signal of the emission circuit is connected to a control and computation module through an emission communication control interface, and two-way communication control is performed between the control and computation module and the emission circuit. An output signal of the receiving circuit is connected to the control and computation module through a receiving communication control interface, and two-way communication control is performed between the control and computation module and the receiving circuit. As the reinforcing bar is used as the electrode, the original construction features and stress features of the concrete do not change, a construction process and a construction method have no need to change, and the electrode and the concrete structure have the same service life. The concrete crack detector with the reinforcing bar as the electrode has the advantages of simplicity in design, convenience for construction, low cost and long service life.

Owner:SICHUAN UNIV

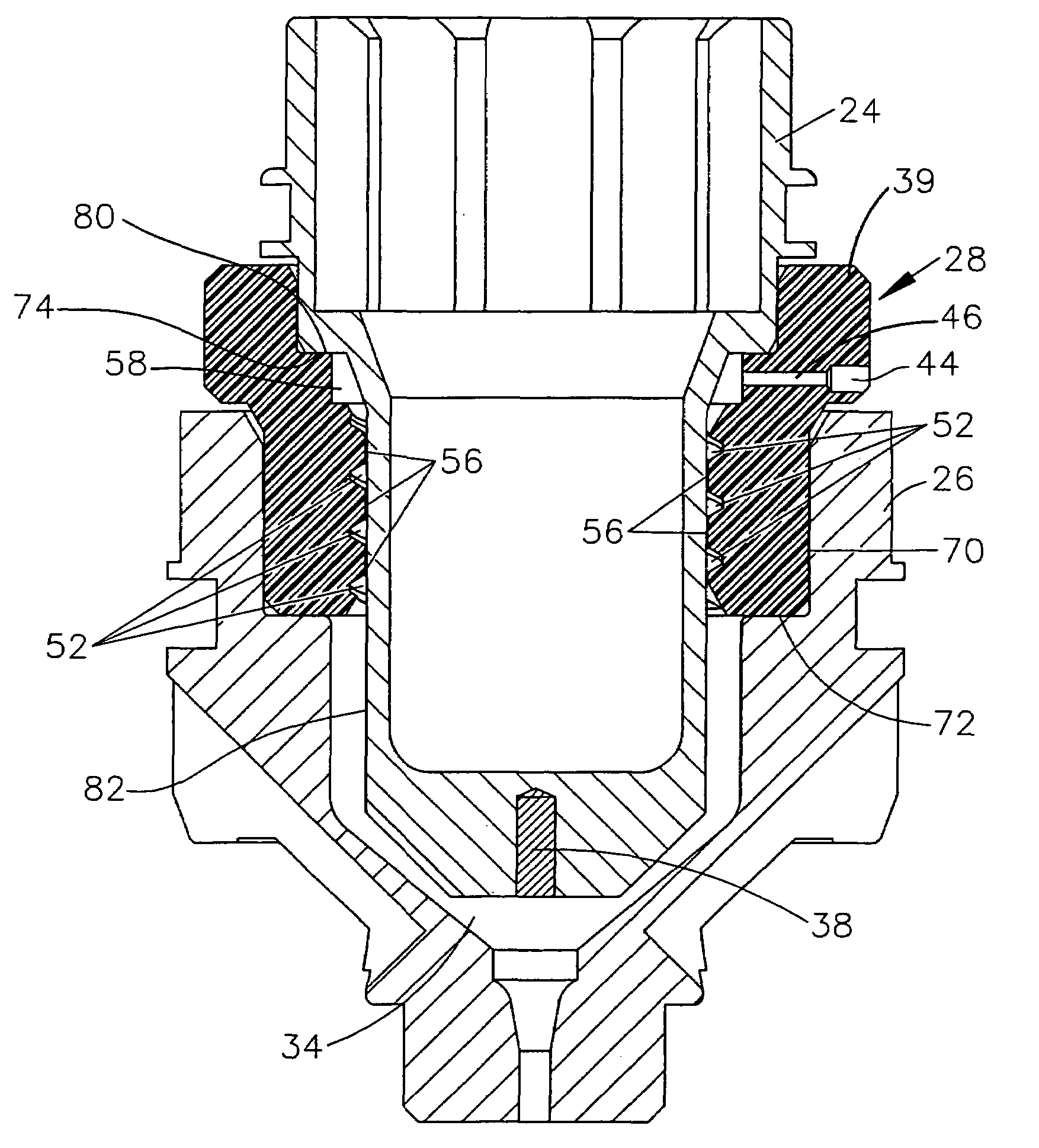

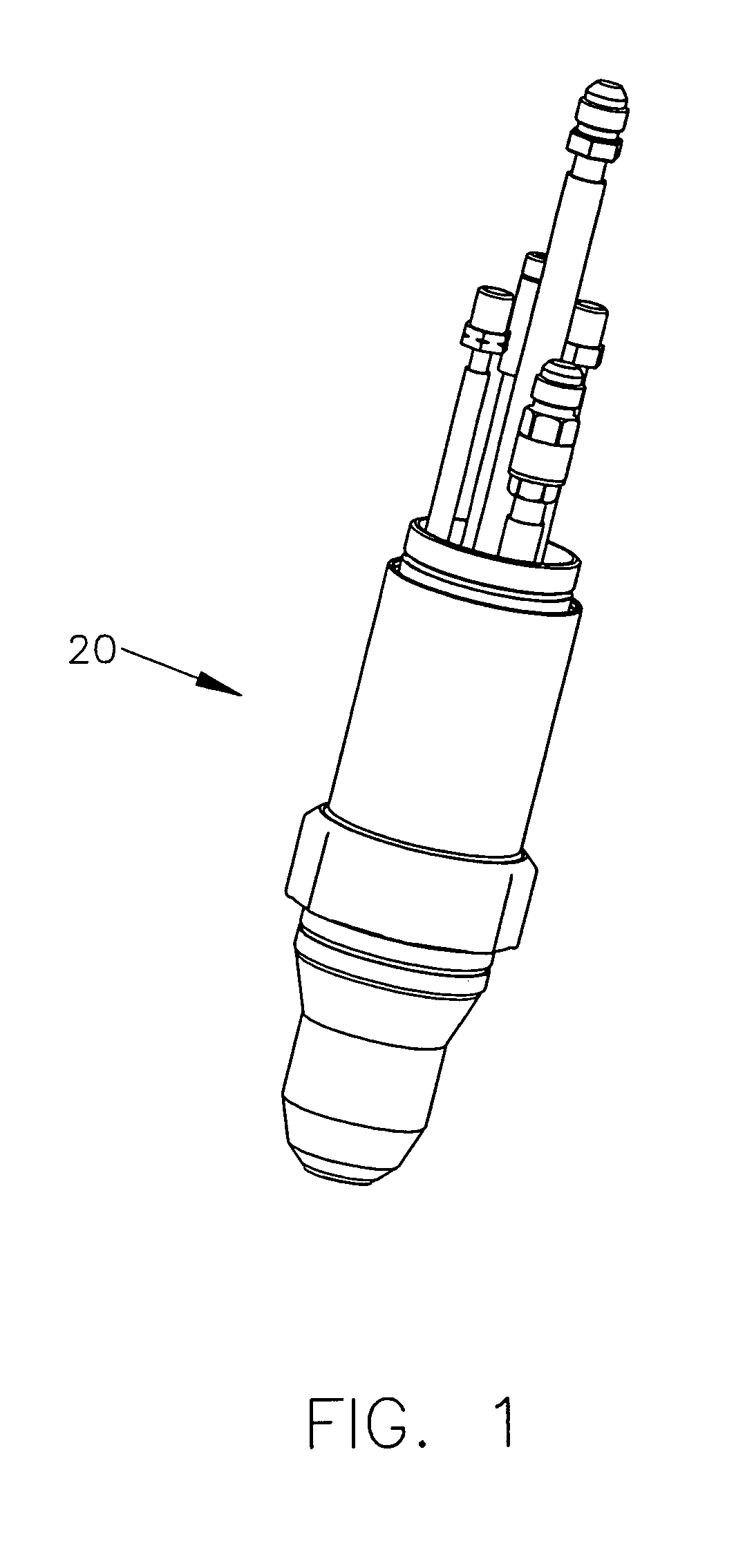

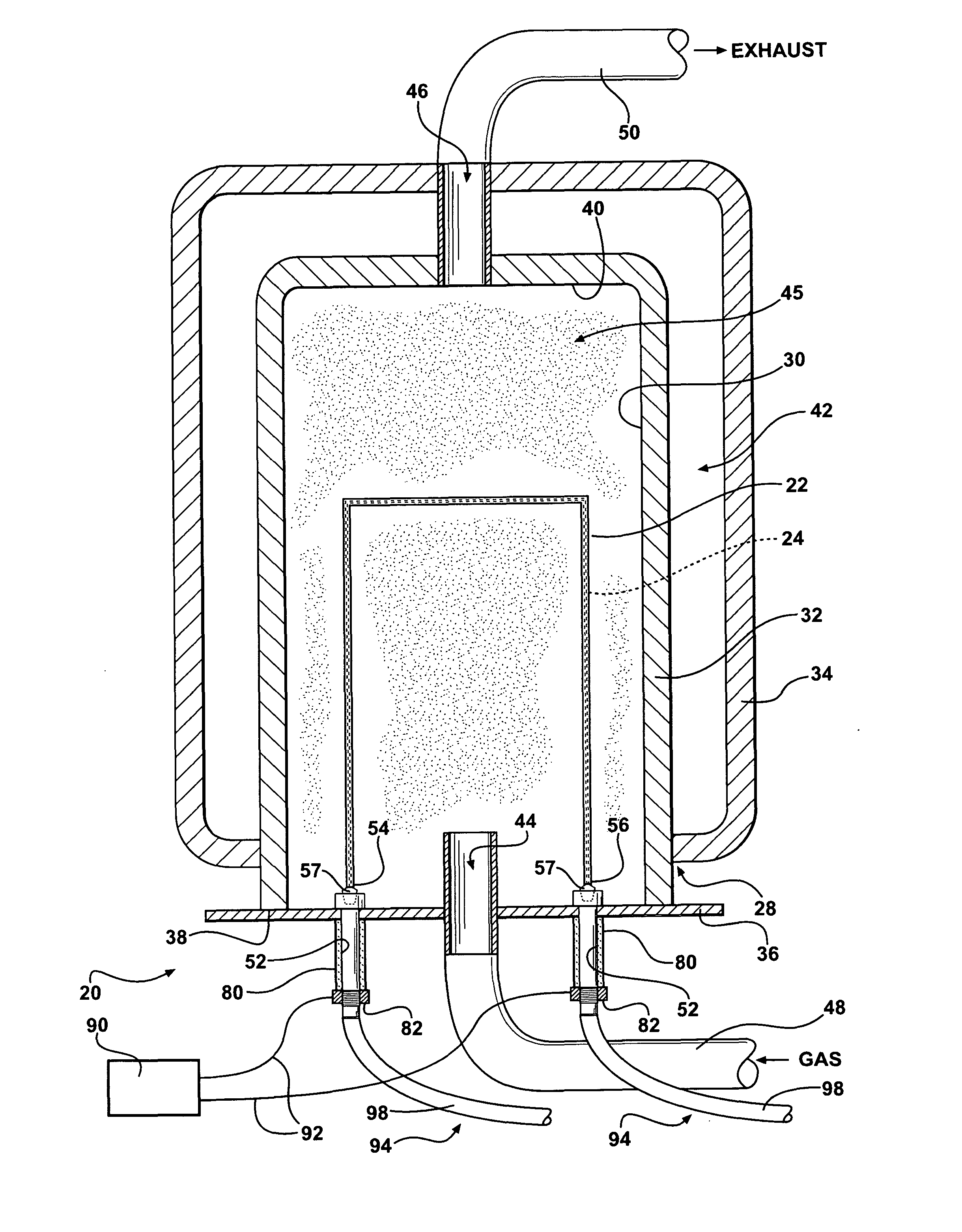

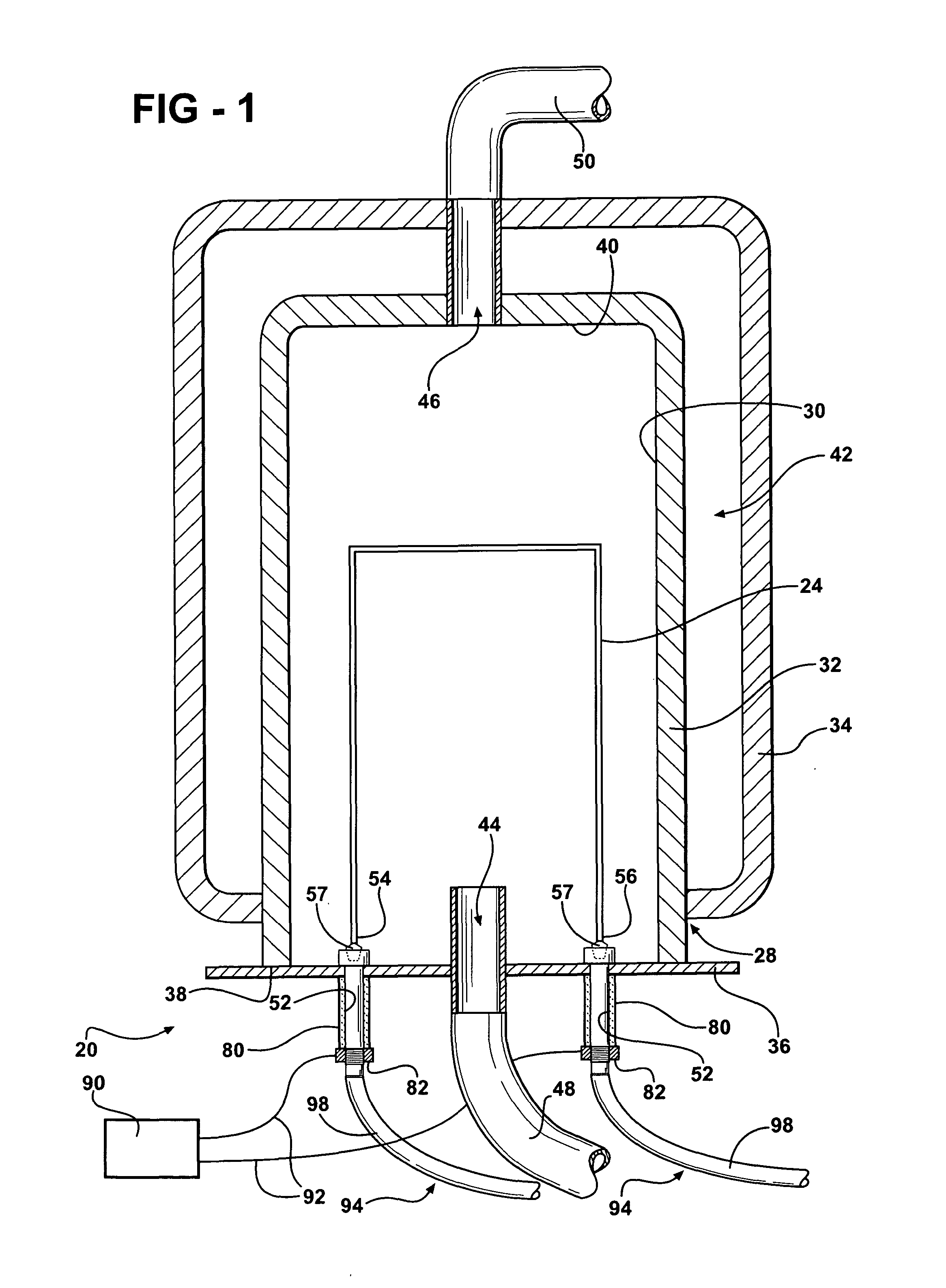

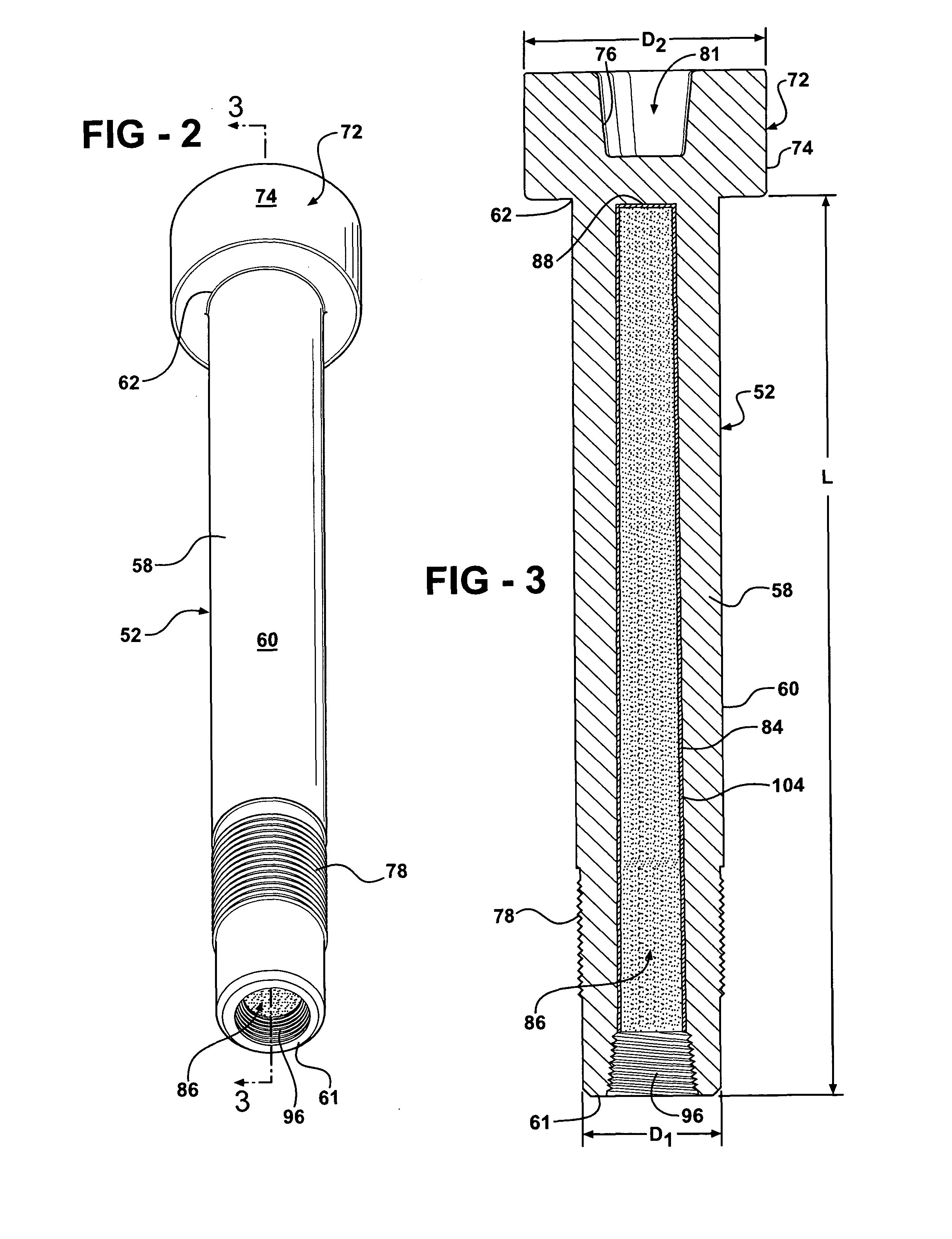

Plasma gas distributor with integral metering and flow passageways

ActiveUS7126080B1Long electrode lifeReduce the amount requiredArc welding apparatusPlasma welding apparatusEngineeringTorch

A gas distributor for use in a plasma arc torch is provided that has at least one plasma gas passageway formed conjointly with a metering passageway, and at least one helical gas passageway formed along an interior portion of the gas distributor, wherein the helical gas passageway is in fluid communication with the plasma gas passageway and the metering passageway. The combination of the metering passageway and the helical gas passageway provides for a metered flow rate and a controlled swirling flow of plasma gas within the plasma arc chamber, respectively, which functions to reduce the amount of molten emissive insert that is ejected from within an electrode at arc shut off, thereby resulting in an increased life of the consumable electrode.

Owner:VICTOR EQUIP

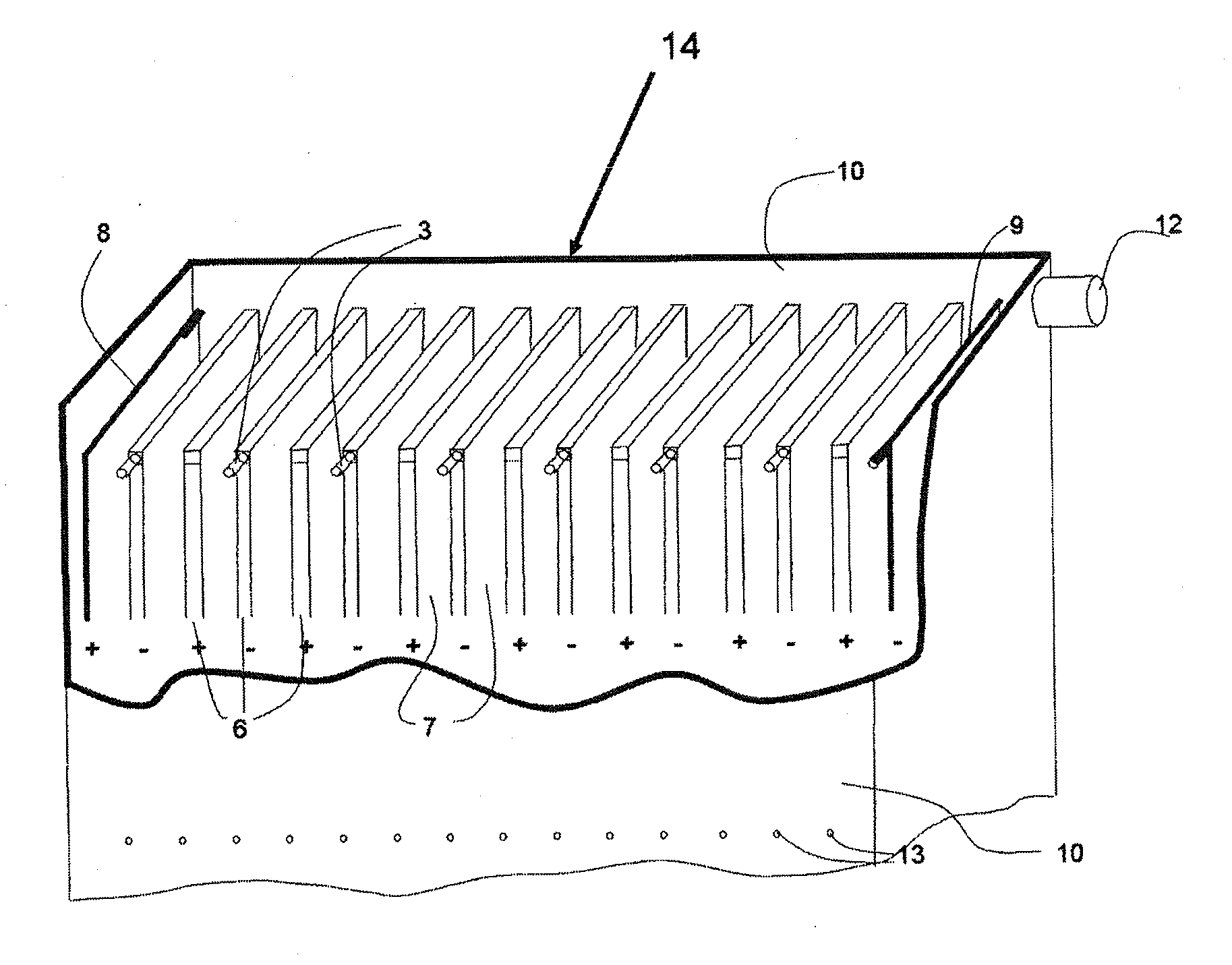

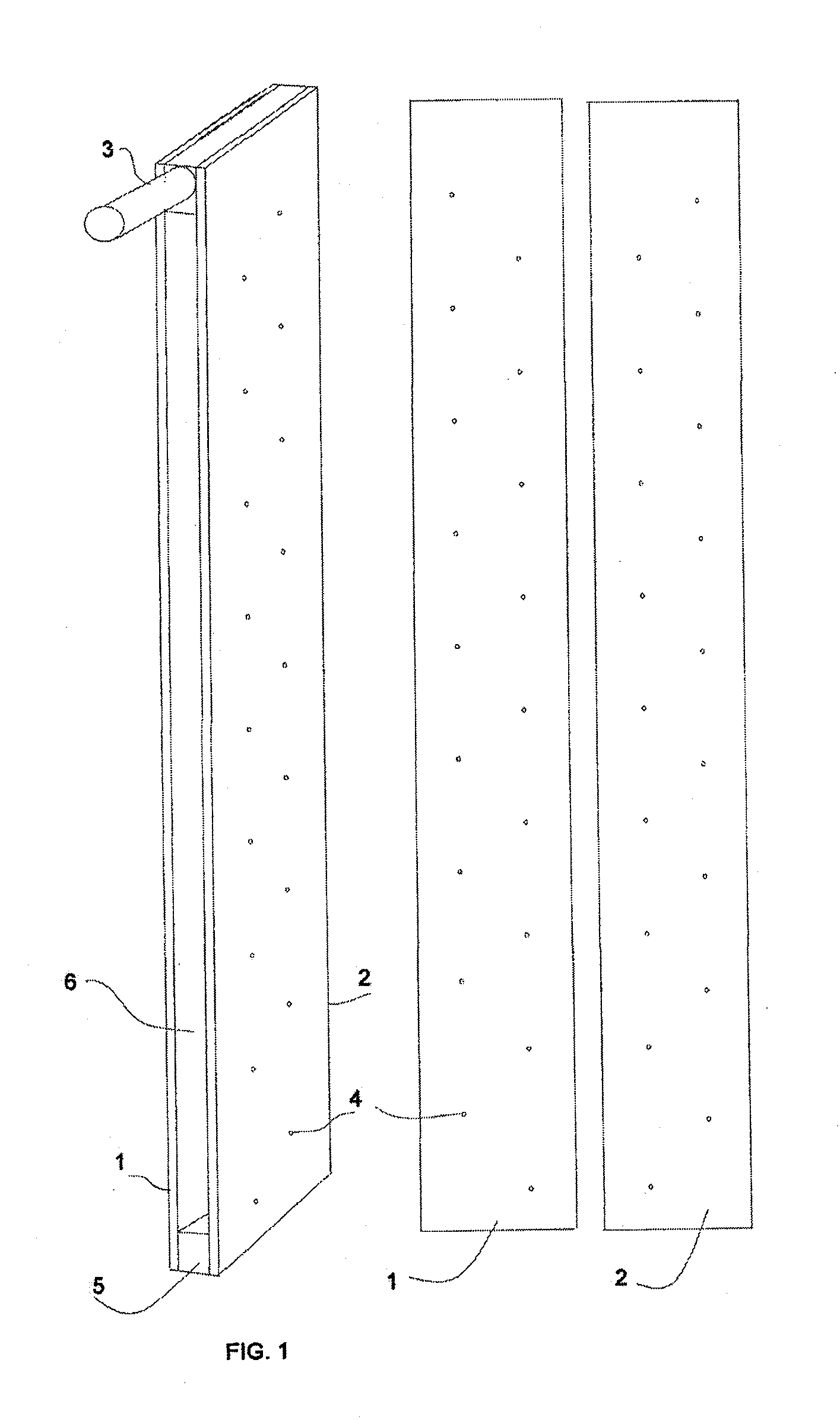

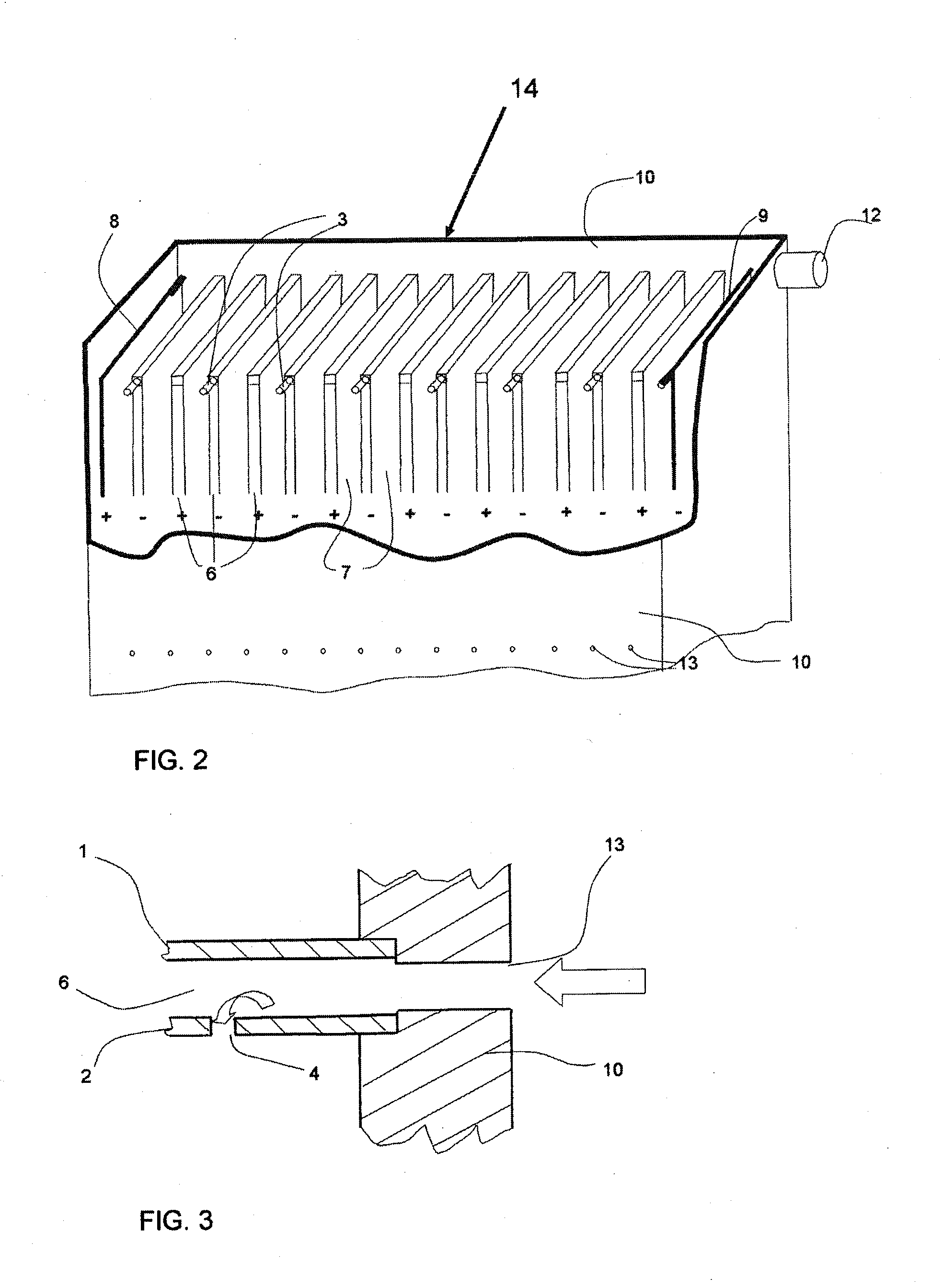

Method and apparatus for electrochemical treatment of contaminated water or wastewater

InactiveUS20120298526A1More strengthSimple constructionCellsElectrostatic separationContaminated waterElectrochemistry

An apparatus for electrochemical treatment of contaminated water or wastewater comprises a container or tank having an inlet and an outlet and a feed pump for the water to be treated, connected to the inlet for supplying the water through the inlet to the container or tank. Parallel pairs of electrode plates are situated in vertical position in the container or tank and form parallel vertical passages therebetween for the water to be treated. In the pairs of electrode plate at least one electrode plate comprises holes connected to a feed pump for an auxiliary medium. Said pairs of electrode plates are positioned between the inlet and outlet in the container or tank such that in at least part of the flow route between the inlet and outlet the water passes upwards in the vertical passages. The feed pump for the water to be treated and / or the feed pump for the auxiliary medium is a pulsating feed pump.

Owner:ATLANTIS LIFE SYST

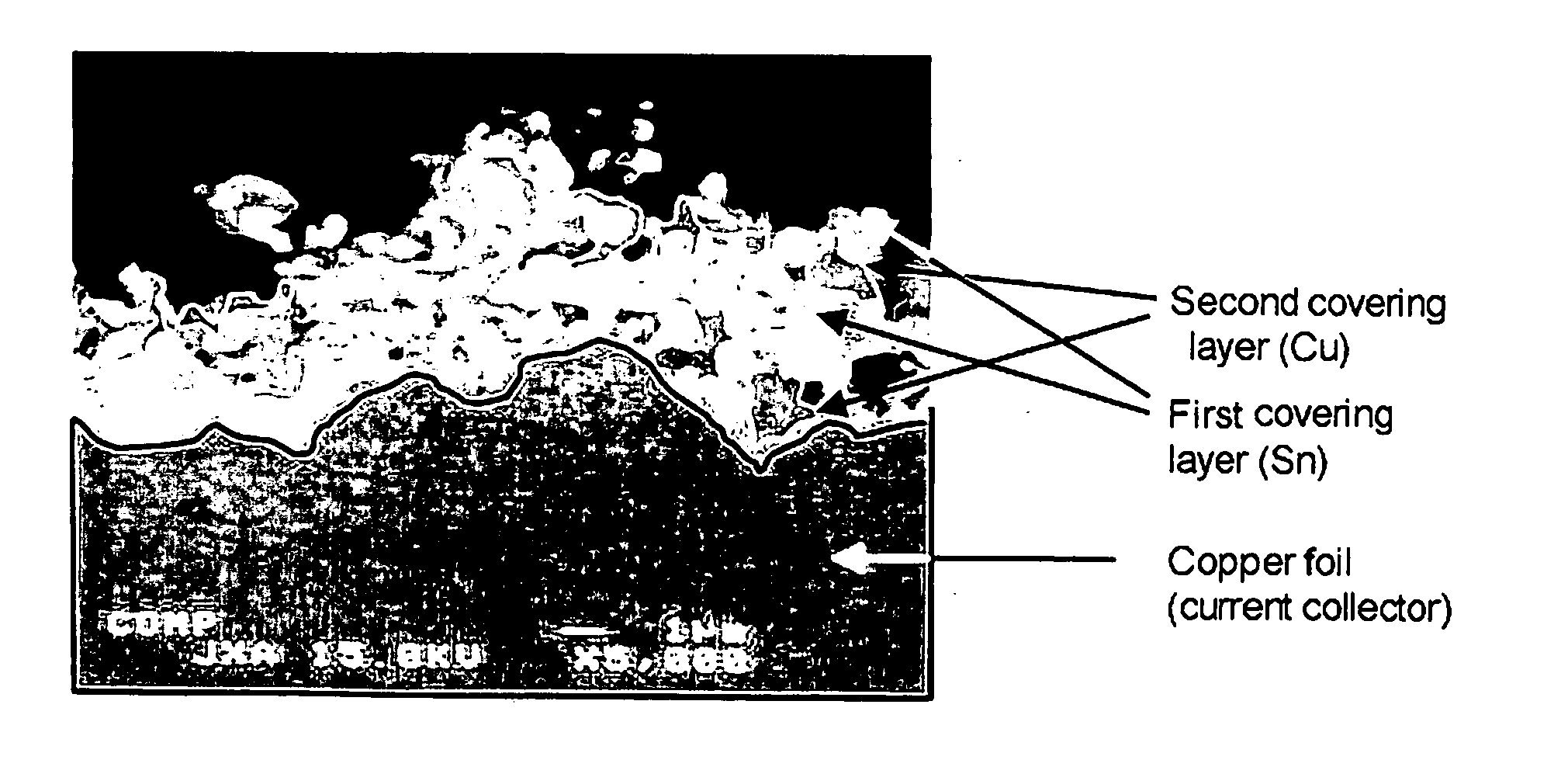

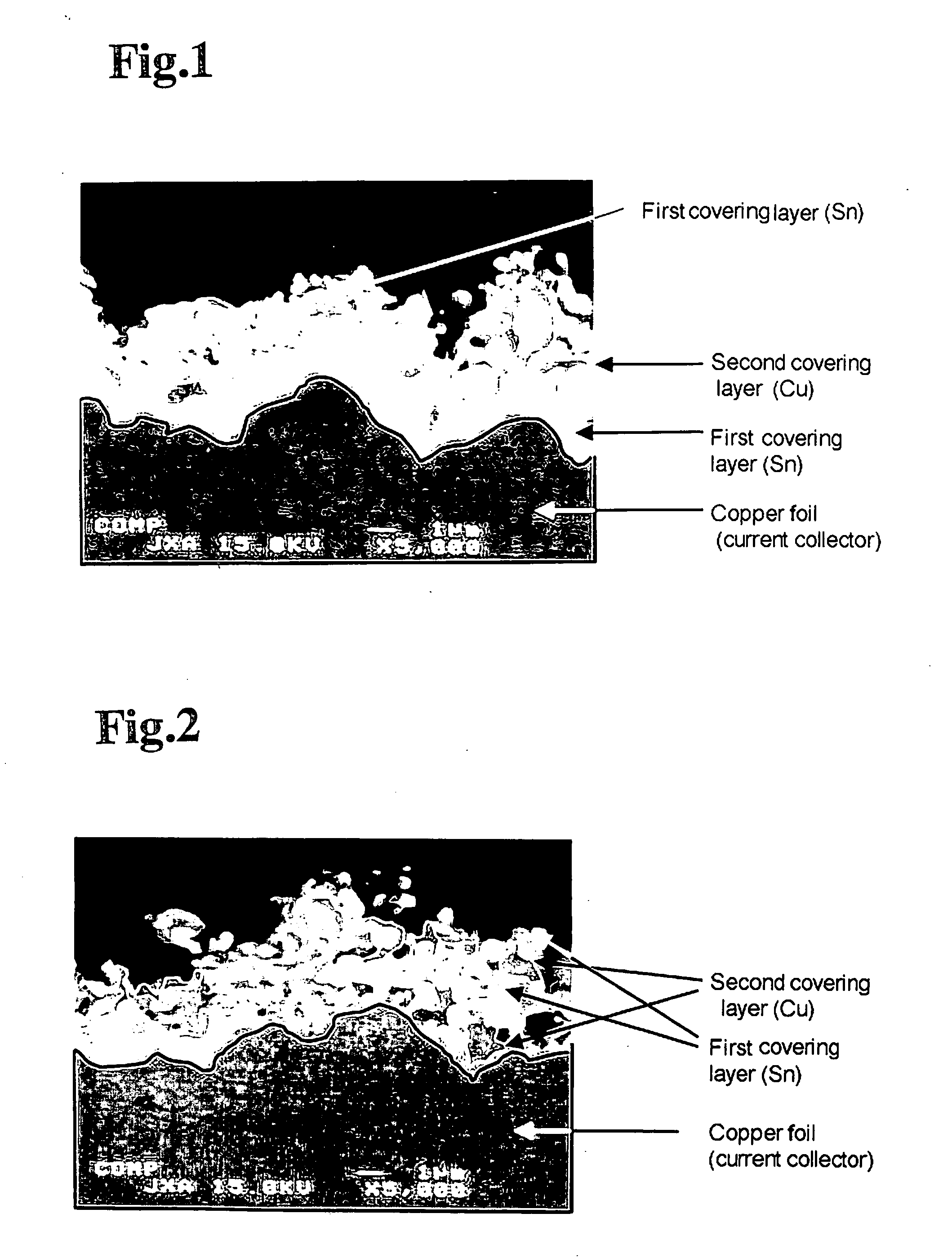

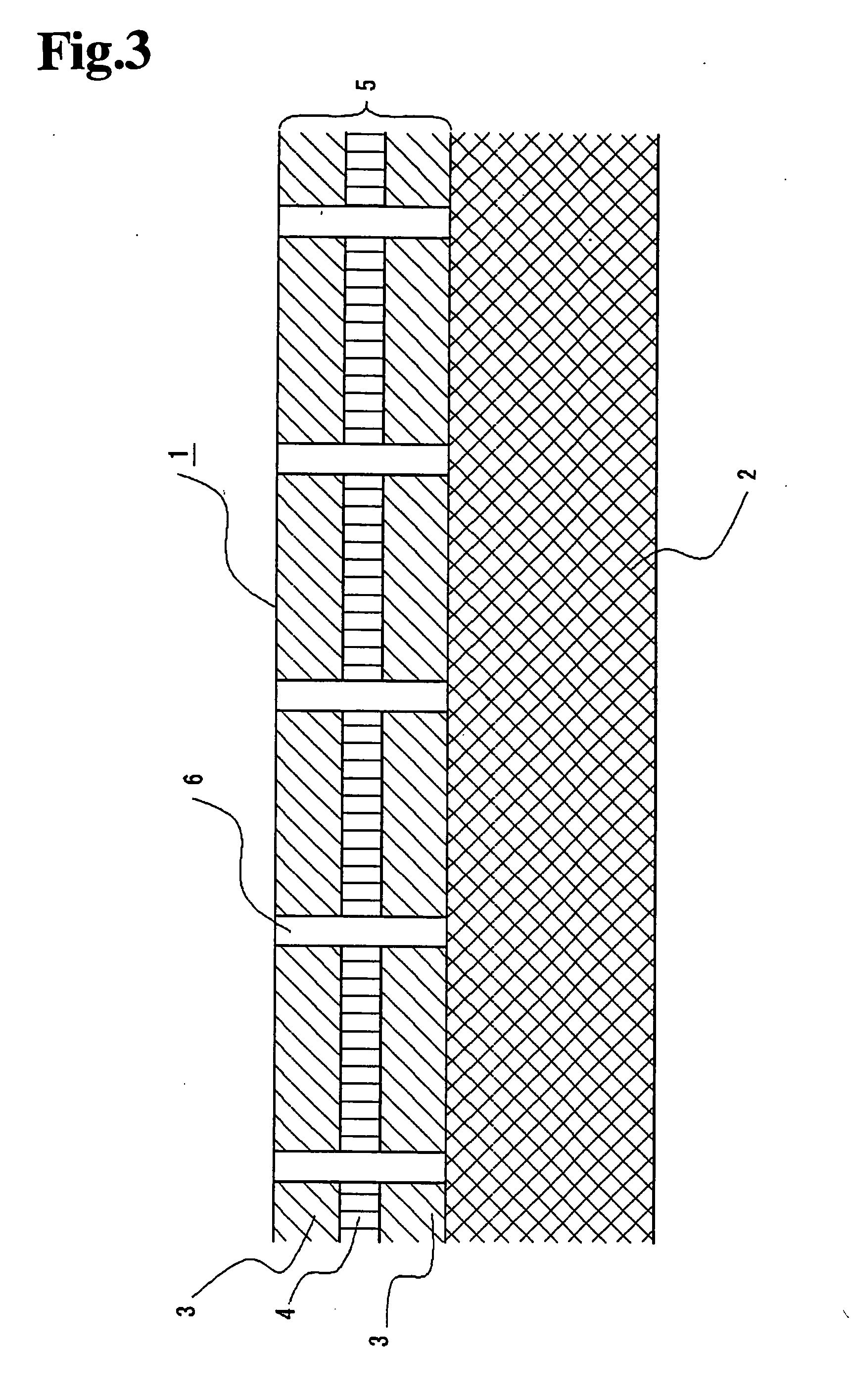

Negative electrode for non-aqueous electrolyte secondary cell and method for manufacture thereof, and non-aqueous electrolyte secondary cell

InactiveUS20050175900A1Long electrode lifeIncrease volumeElectrode rolling/calenderingElectrochemical processing of electrodesLithium compoundCopper

An anode for a nonaqueous secondary battery comprising a current collector having formed thereon a first covering layer containing tin, a tin alloy, aluminum or an aluminum alloy and a second covering layer containing a metal having low capability of forming a lithium compound in that order. The anode may have an additional first covering layer formed on the second covering layer. A covering layer containing a copper etc. may be formed as an uppermost layer. Each layer can be formed by heat treating to get desired property. As heat treatment can be done in a short time, it has a great cost merit.

Owner:MITSUI MINING & SMELTING CO LTD

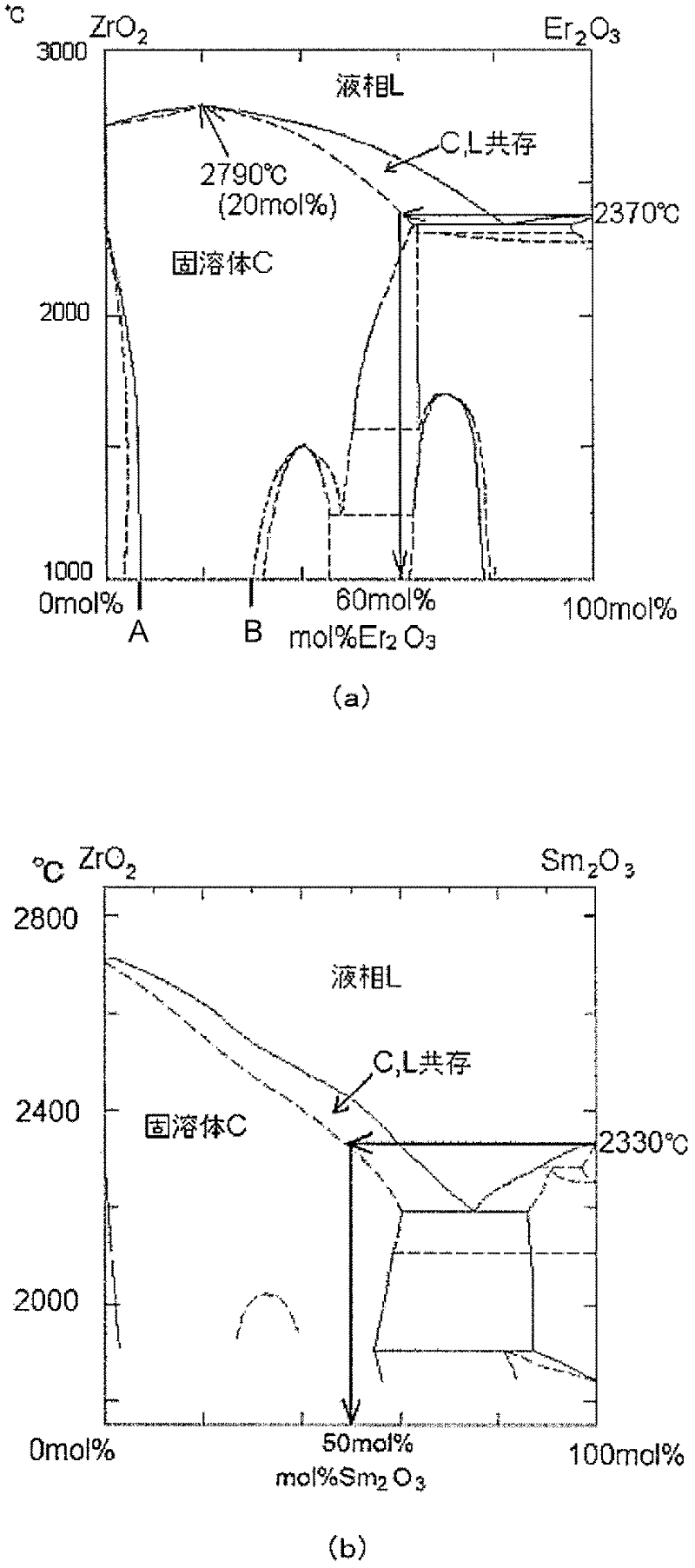

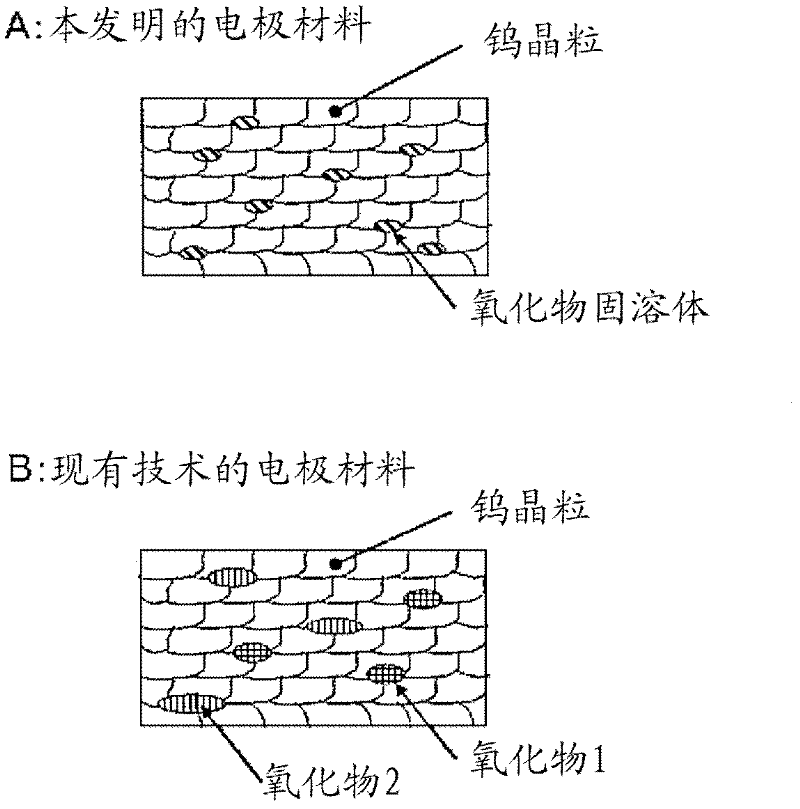

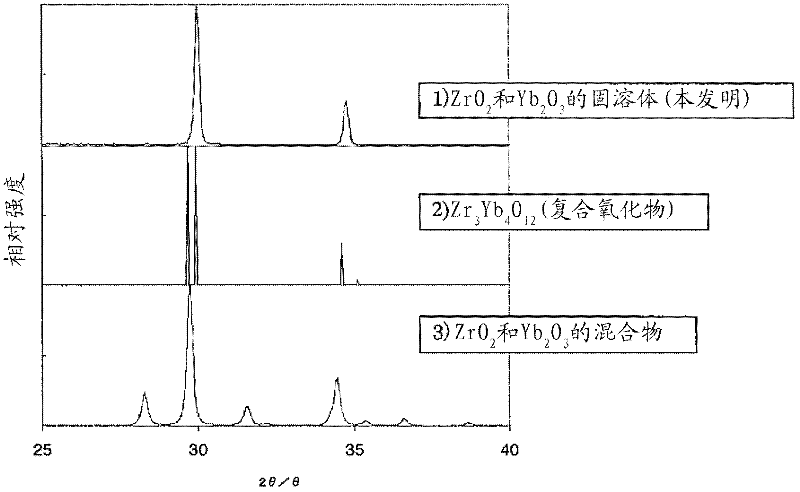

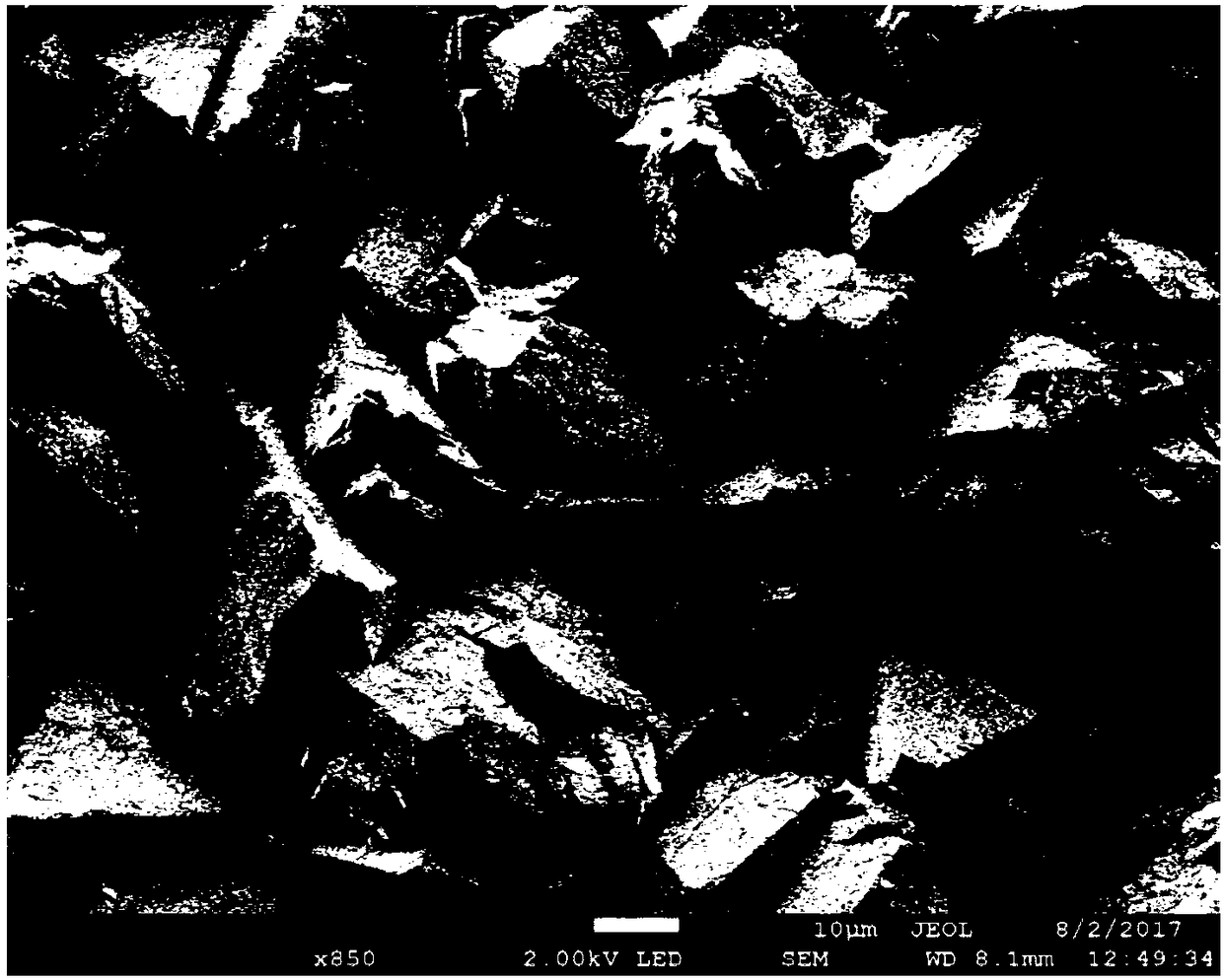

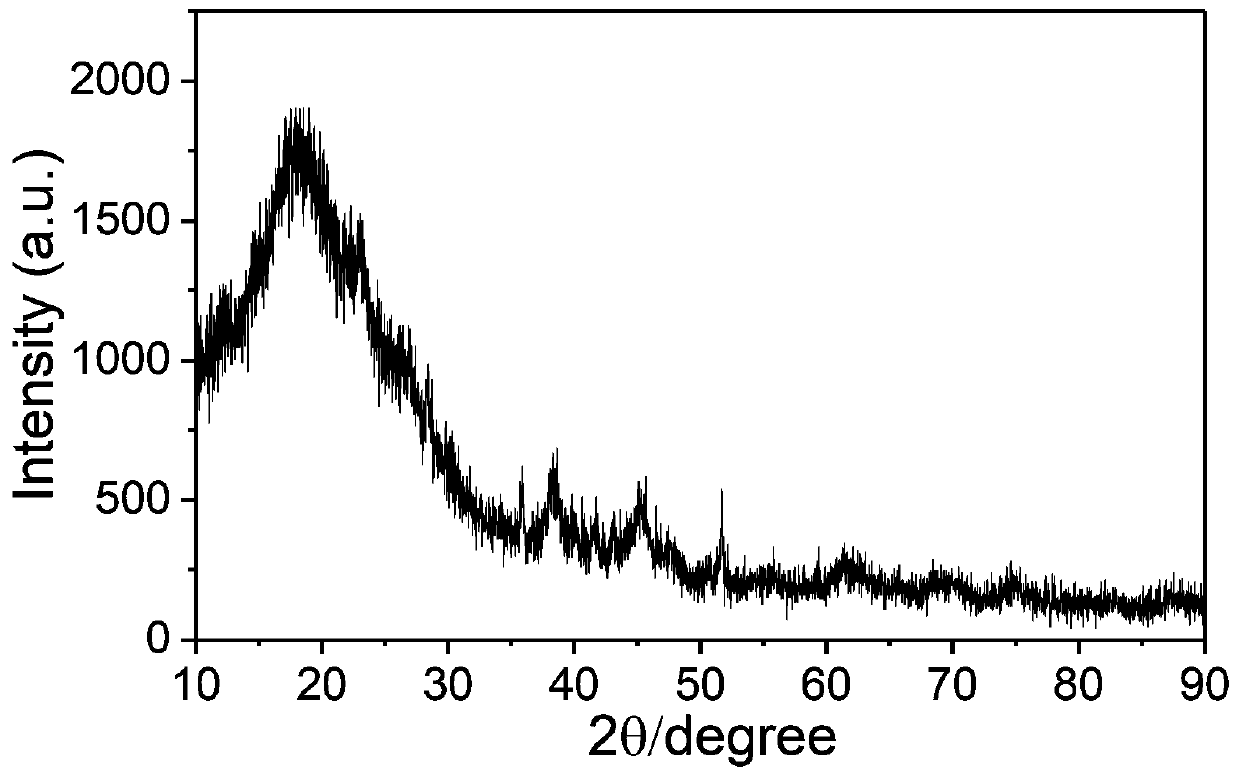

Tungsten electrode material and thermal electron emission current measurement device

InactiveCN102246260ALong electrode lifeAccurate evaluation of electrode characteristicsOxide conductorsDischarge tube/lamp detailsMeasurement devicePower flow

Provided is a tungsten electrode material which uses a material to replace thorium oxide so as to improve the electrode service life as compared to the conventional technique. The tungsten electrode material has a tungsten base and oxide particles dispersed in the tungsten base. The oxide particles are prepared as an oxide solid solution containing in a solid solved state: a Zr oxide and / or a Hf oxide and an oxide of at least one rare earth selected from a group consisting of Sc, Y, La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu.

Owner:ALLIED MATERIAL

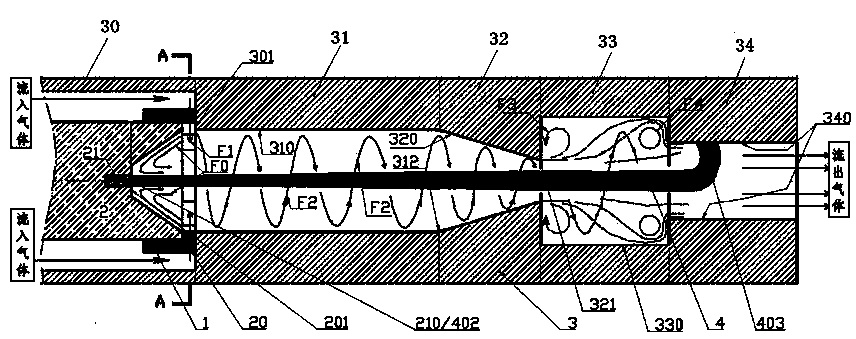

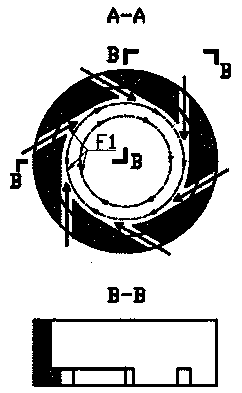

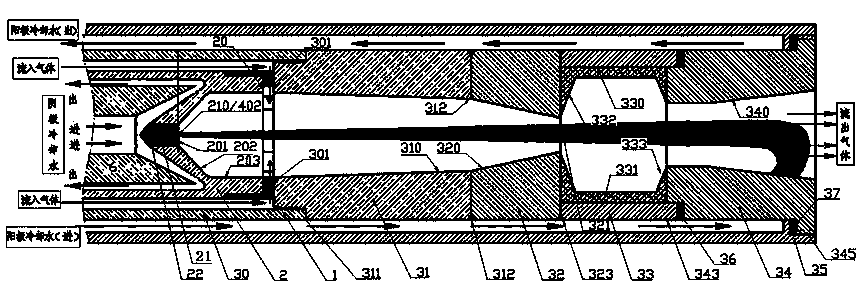

Arc plasma torch having arc channel with abnormal diameter

ActiveCN103354695AIncrease arc voltageIncrease arc powerPlasma techniqueStraight tubeMaterials science

Provided by the invention is an arc plasma torch having an arc channel with an abnormal diameter. The arc plasma torch comprises an anode, a cathode, and an annular gas whirlcone. The anode is a circular tube with an abnormal inner bore diameter; the cathode is arranged in the inner bore of the anode circular tube; the gas whirlcone is arranged between the cathod front end and the anode; and the gas whirlcone, the cathode, and the inner bore of the anode circular tube are arranged coaxially. One end, provided with the cathode, of the anode circular tube serves as a gas inflow end and the other end serves as a gas outflow end; the anode circular tube is successively divided into a gas lead-in segment, a straight tube segment or reducing segment, a contraction segment, a groove segment and a nozzle segment; inner bores of the straight tube segment or reducing segment, the contraction segment, the groove segment and the nozzle segment of the anode circular tube forms an anode arc channel. And a tangential air flow channel is arranged at an annular wall of the gas whirlcone and is used for guiding gas into the inner bore of the gas whirlcone to generate an eddy air flow. According to the invention, the provided an arc plasma torch with the simple structure enables the arc power, the electrode life, and the energy utilization rate to be substantially improved.

Owner:ANHUI TENGLONG ELECTRIC

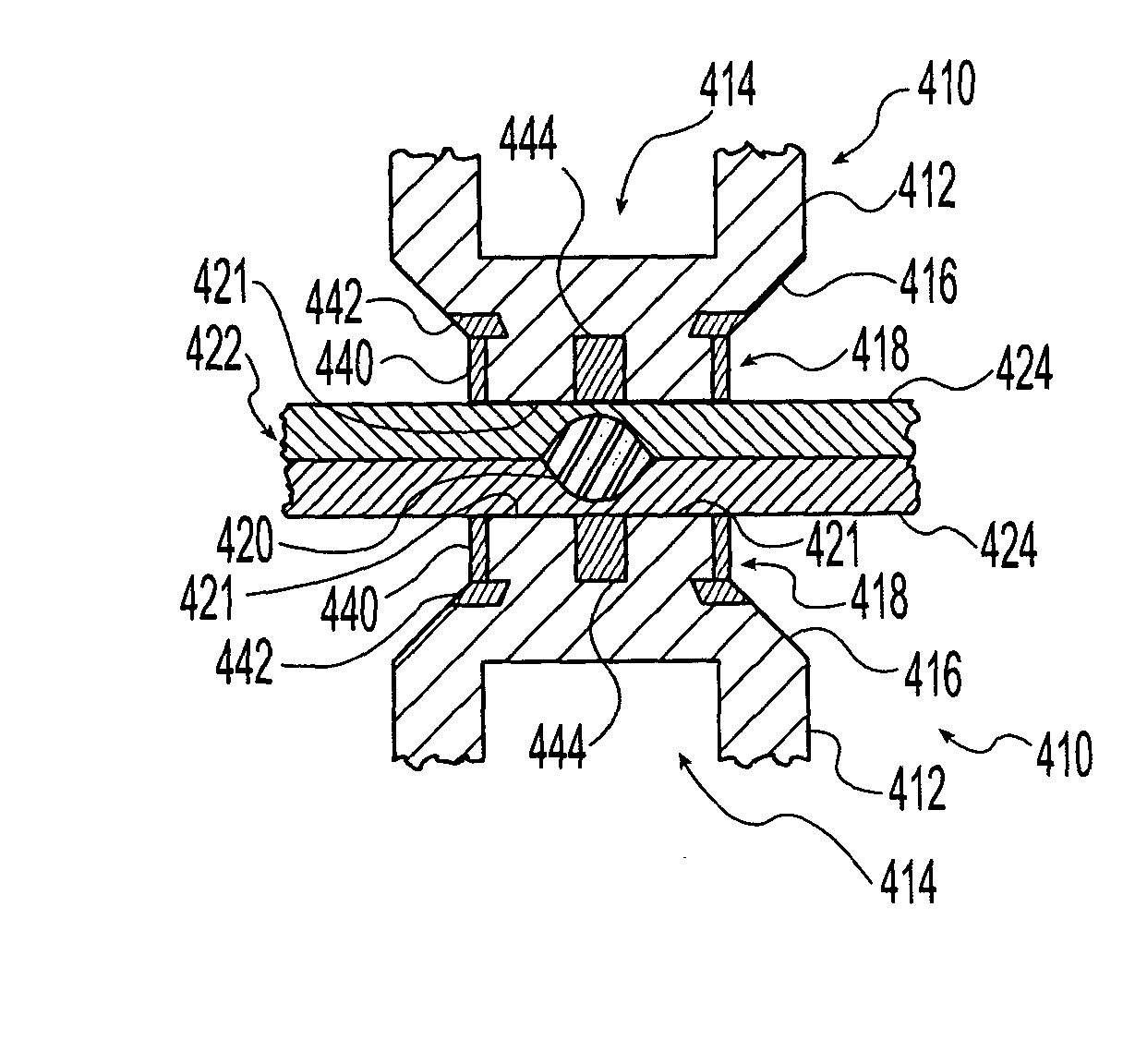

Resistance spot welding electrode

InactiveUS20050029234A1Easy to weldLong electrode lifeOhmic-resistance electrodesWelding/cutting media/materialsElectrical resistance and conductanceEngineering

A composite resistance spot welding electrode is disclosed which comprises a co-axial annular neck ring, a co-axial insert, a co-axial annular sleeve, or combinations there of. The electrode provides improved nugget formation and longer electrode life.

Owner:BATTELLE MEMORIAL INST

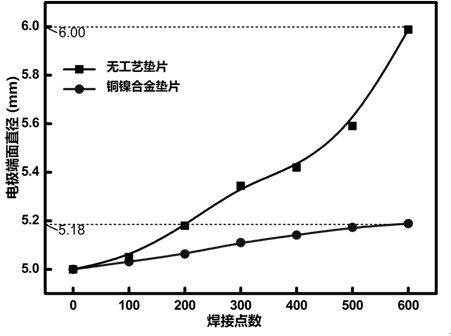

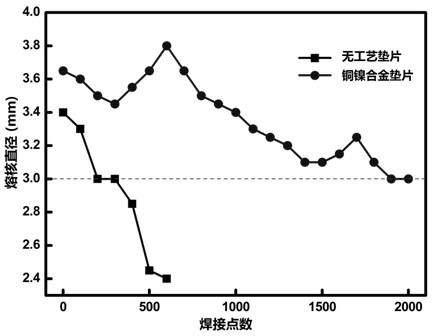

Method for prolonging service life of resistance spot welding electrode of galvanized thin steel plate

InactiveCN102672332AReduce end temperatureReduce wearResistance welding apparatusPower flowNickel alloy

The invention relates to a method for prolonging the service life of a resistance spot welding electrode of a galvanized thin steel plate; when the galvanized thin steel plate is connected by resistance spot welding, an upper layer Cu-Ni alloy process gasket is inserted between a top electrode and an upper layer galvanized steel plate to be welded, and a lower layer Cu-Ni alloy process gasket is inserted between a lower electrode and a lower layer galvanized steel plate to be welded; each Cu-Ni alloy process gasket comprises the following components by mass percent: 40-45% of Ni, 1-1.5% of Mn and the balance of Cu, and respectively has the resistivity within the range of 0.45-0.51 and the thickness within the range of 0.05-0.2mm. The method can effectively reduce the temperature of the end surface of the electrode, and reduces the abrasion of the electrode, thus prolonging the service life of the electrode; the Cu-Ni alloy process gaskets hardly have alloying reaction with electrode material, so that the abrasion is further reduced; the formation and growth of spot welding nugget can be promoted by the self resistance heat of the Cu-Ni alloy process gaskets, so that the quality of a spot-welded joint can be improved, and the current needed by welding is reduced, and the energy consumption is lowered.

Owner:SHANGHAI JIAO TONG UNIV +1

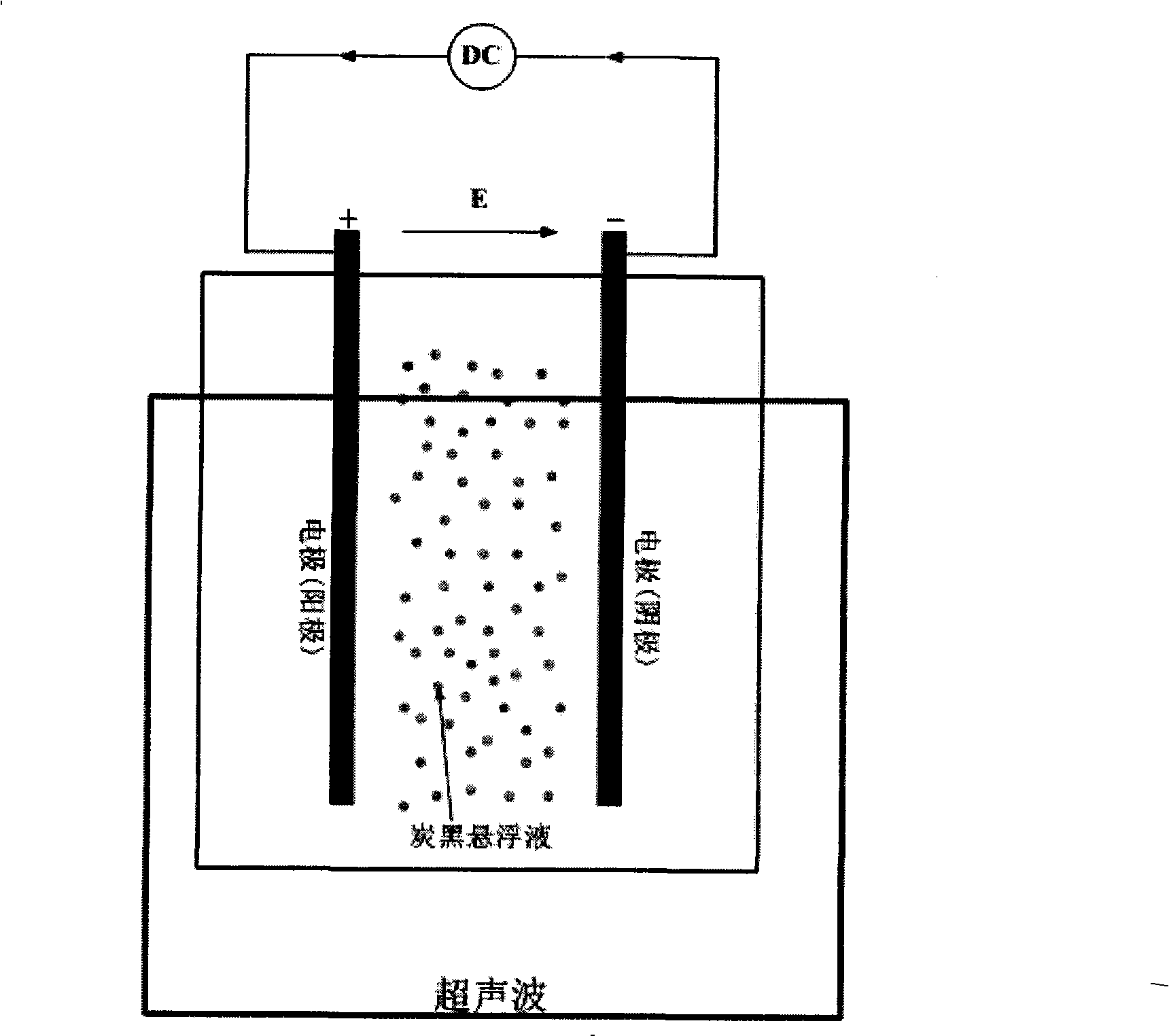

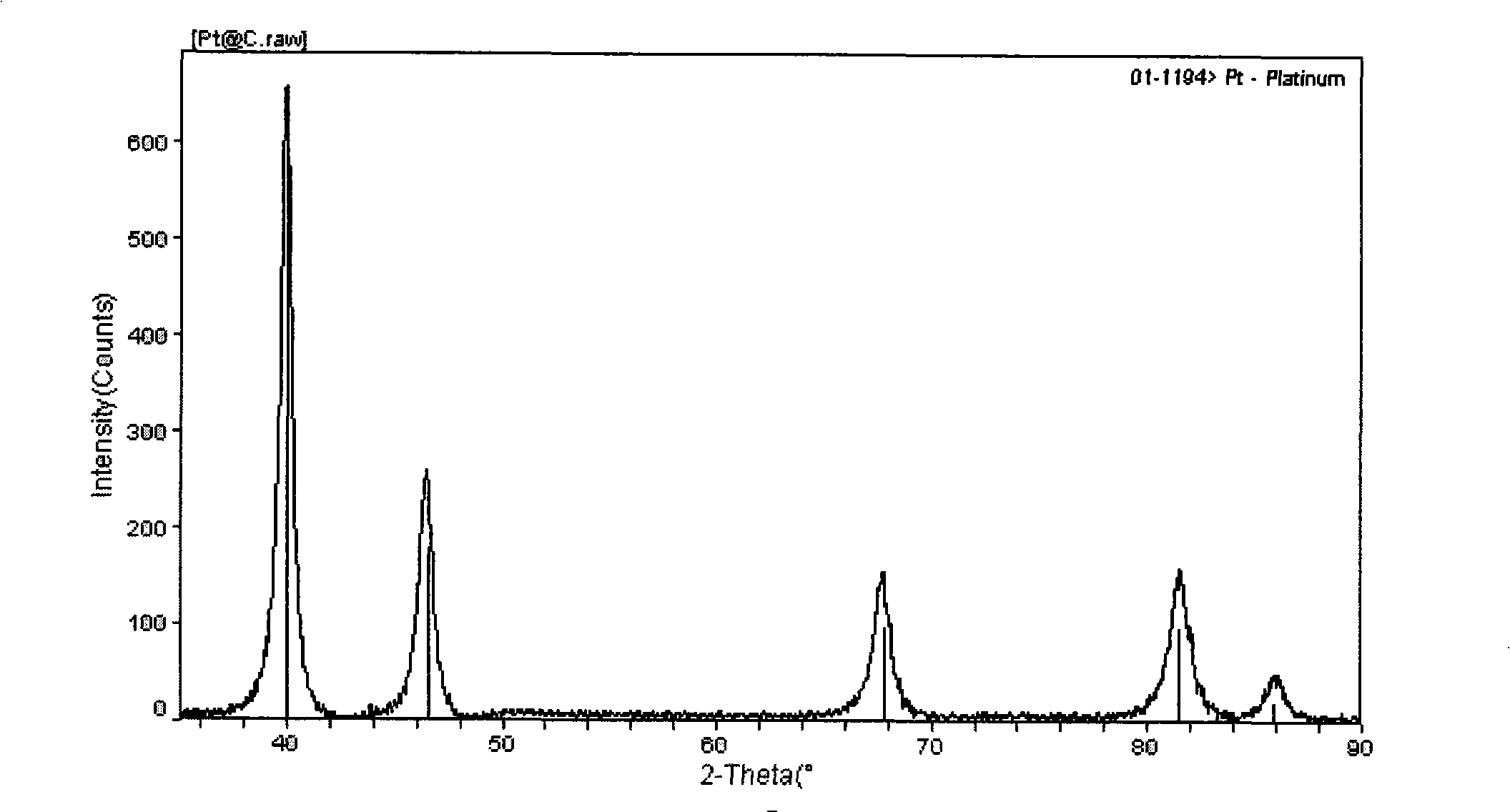

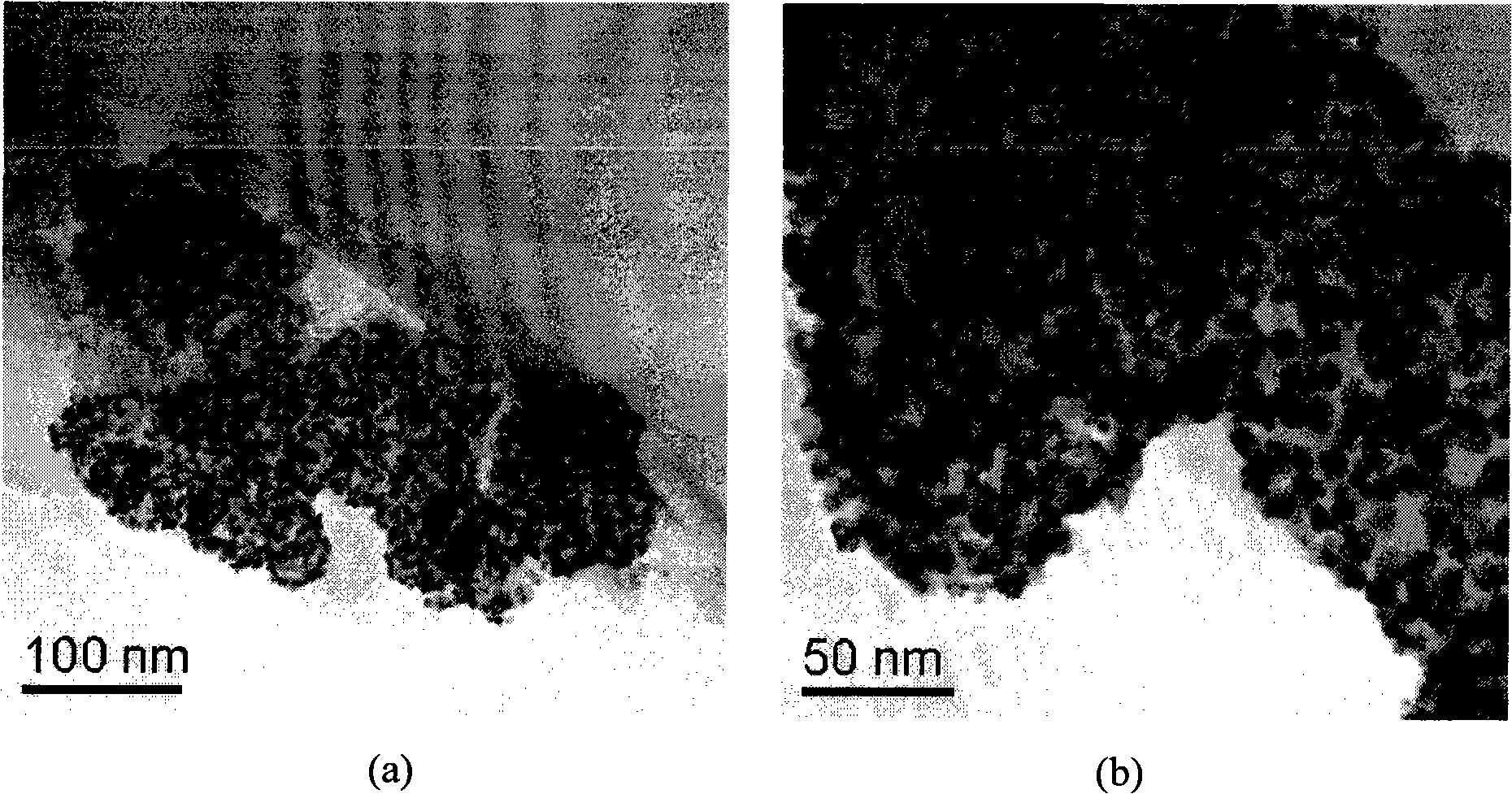

Method for preparing supported type nano Pt(Pt-M)/carrier catalyst

InactiveCN101352683AReduce manufacturing costLong electrode lifeCell electrodesMetal/metal-oxides/metal-hydroxide catalystsChemistryVolt-ampere

The invention relates to a preparation method of a load-typed nanometer Pt (Pt-M) / carrier catalyst, which comprises that a carrier is uniformly dispersed in a chloroplatinic acid solution to obtain an electrolyte which is then infused to a ultrasound-imposed double-platinum-electrode electrolysis bath for electrodeposition, so as to obtain a catalyst suspension of a nanometer Pt (Pt-M) catalyst which is uniformly loaded on the carrier and then separated to obtain the load-typed nanometer Pt (Pt-M) / carrier catalyst. The preparation method loads the nanometer Pt (Pt-M) on the carrier directly, thus avoiding the defects of high-temperature reduction or use of reducers for preparation of other methods; the preparation method does not require to conduct separate activation or modification treatment to the carrier and has the advantages of simple process and catalyst with adjustable size, low cost and no environmental pollution, thus being a universal method easy for industrialized massive production. By determining with cyclic volt-ampere curves, in terms of performance, 40 percent load-typed nanometer Pt / C catalyst prepared by the invention is superior to similar products produced by the worldwide advanced Johnson Matthey Company.

Owner:NANJING UNIV

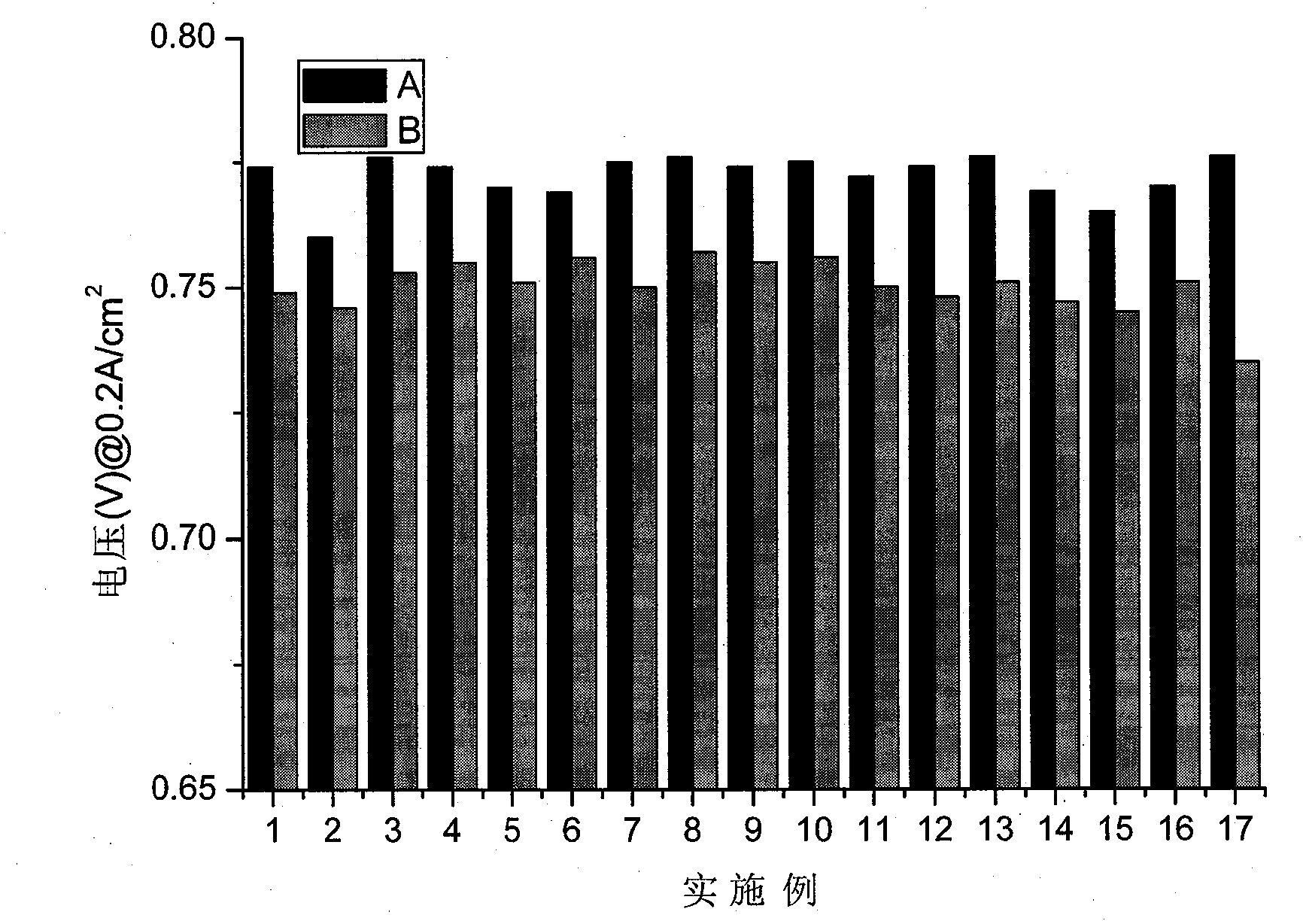

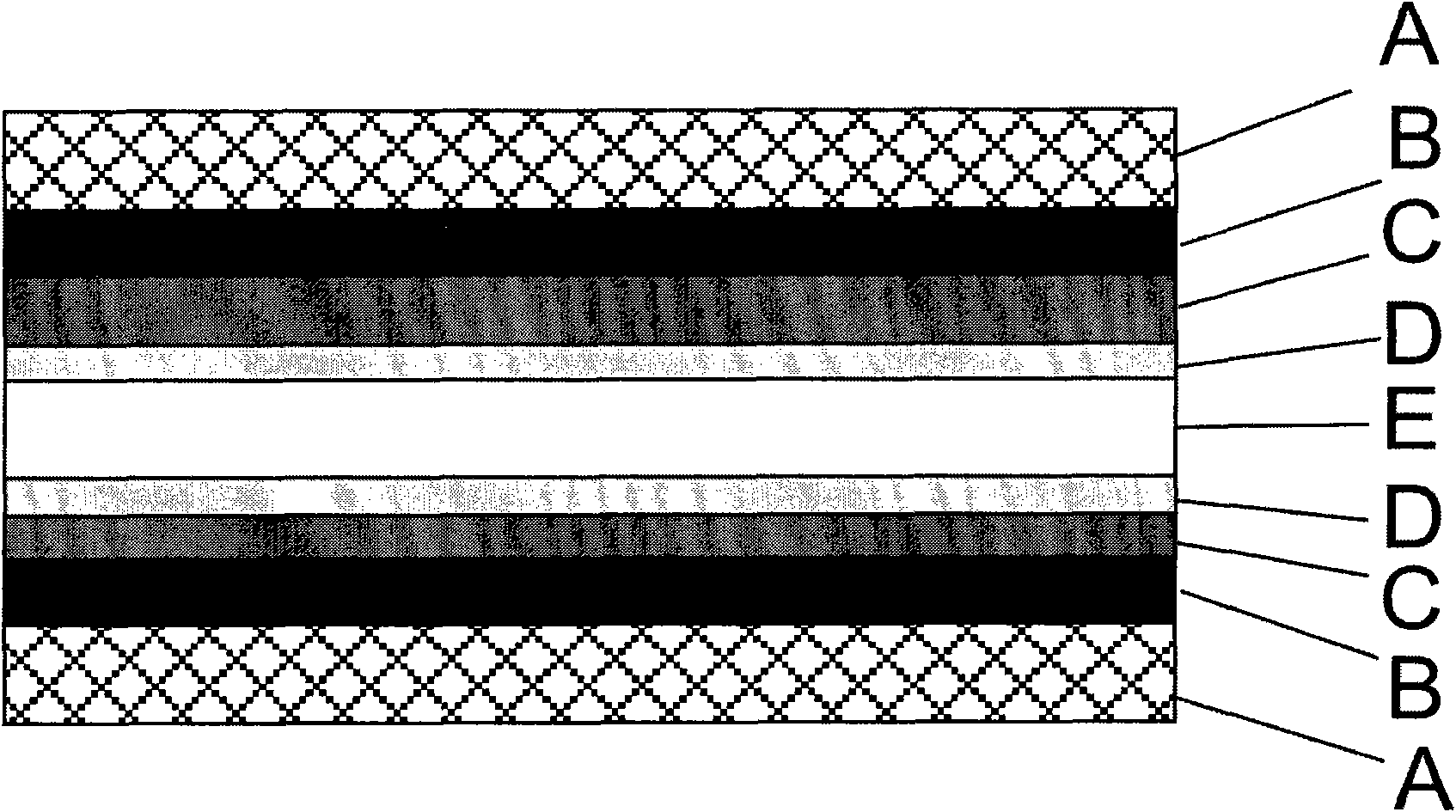

Membrane electrode of long-life fuel cell with porous adsorption layer and preparation method thereof

InactiveCN101853943ALong electrode lifeInhibit migrationCell electrodesFinal product manufactureFiberSorbent

The invention provides a membrane electrode of a long-life fuel cell with a porous adsorption layer and a preparation method thereof. The membrane electrode is characterized in that a porous siliceous adsorption layer is additionally arranged between a catalyst layer and a proton exchange membrane and is used for multi-layer adsorption (e.g. surface adsorption, shallow adsorption and deep absorption) or interception of metal particles or ions moving or diffusing into the membrane so as to block the metal particles or ions against movement towards the membrane side or into the membrane, thereby prolonging the service life of the membrane electrode of the fuel cell. The porous siliceous adsorption layer is prepared with a porous siliceous material paligorskite-sepiolite mineral fiber, zeolite molecular sieve, montmorillonite, diatomaceous earth or silica gel and Nafion proton exchange resin. The preparation method of the porous siliceous adsorption layer comprises the following steps: preparation of the slurry of the porous material, preparation of the porous adsorption layer, pretreatment of the gas diffusion layer, preparation of the electrode of the gas diffusion layer, preparation of the chip of the fuel cell and preparation of the membrane electrode.

Owner:WUHAN UNIV OF TECH

PbO2 electrode with long service life and high catalytic activity

ActiveCN108217852AExtend your lifeReduce catalytic activityElectrolytic inorganic material coatingWater/sewage treatment using germicide/oligodynamic-processAdhesion forceElectricity

A PbO2 electrode with long service life and high catalytic activity is prepared with SnO2-Sb2O3 as a base layer, alpha-PbO2 as a medium layer, and beta-PbO2 as a surface active layer. The PbO2 in theinvention is compact and uniform and has small particles and large specific surface area; meanwhile, the surface active layer has excellent adhesion force and is not liable to fall off; the surface ofthe PbO2 electrode is smooth and firm and is anti-acid / alkali-corrosion, has high catalytic activity and long service life. In addition, a preparation method is simple in conditions and low in cost;the product has stable performance and is suitable for industrial production, can be widely applied to the field of sewage treatment with electrically catalytic oxidization, and has extensive market prospect.

Owner:CHONGQING UNIV

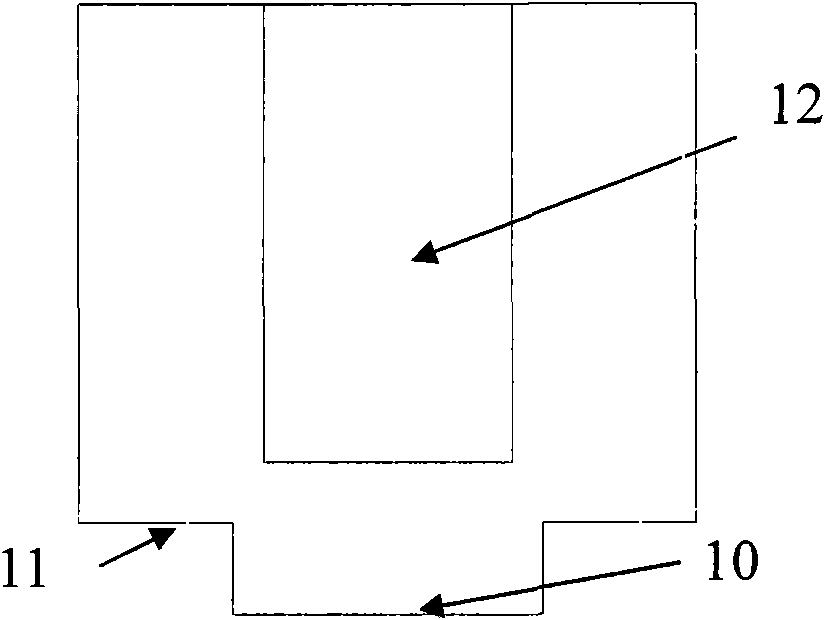

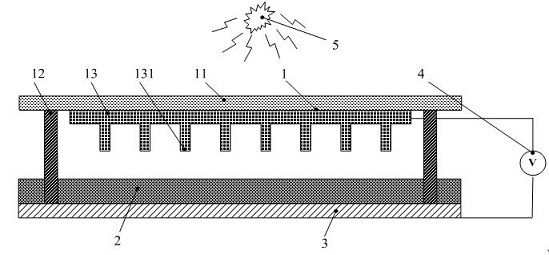

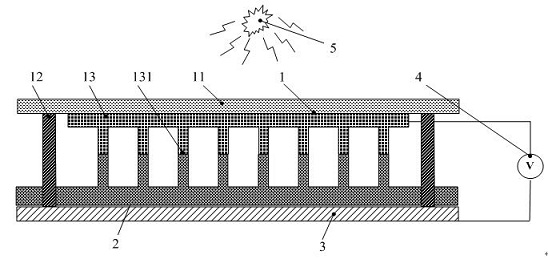

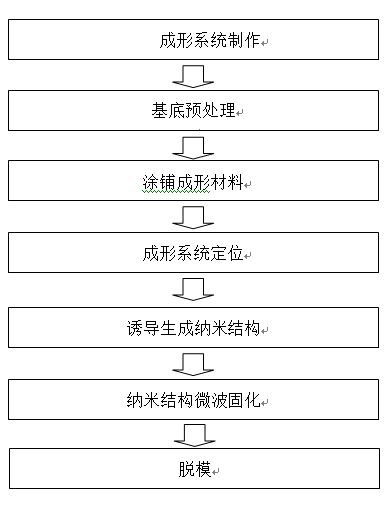

Apparatus and method for graphically producing nano structures by way of electrode induction and microwave curing

The invention relates to an apparatus and a method for graphically producing nano structures by way of electrode induction and microwave curing. The apparatus comprises a molding system, a molding material, a substrate, a nano structure induction system and a microwave curing system. The method for producing nano structures based on the apparatus includes the following steps: (1) the fabrication of the molding system; (2) the preprocessing of the substrate; (3) the coating of the molding material; (4) the positioning of the molding system; (5) the inductive production of a nano structure; (6)the microwave curing of the nano structure; and (7) demolding. The invention is characterized by simple structure, low cost, high productivity, long electrode service life, high pattern precision andthe like, and can efficiently produce nano structures less than 100 nanometers at low cost.

Owner:SHANDONG UNIV

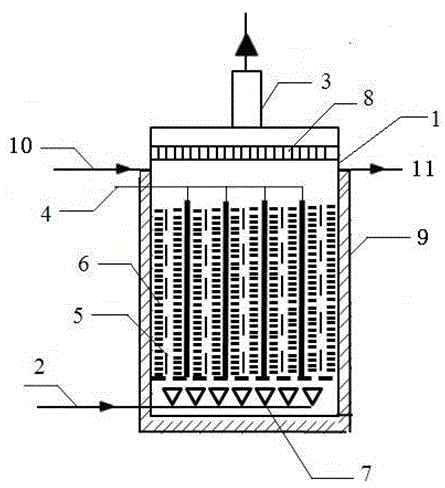

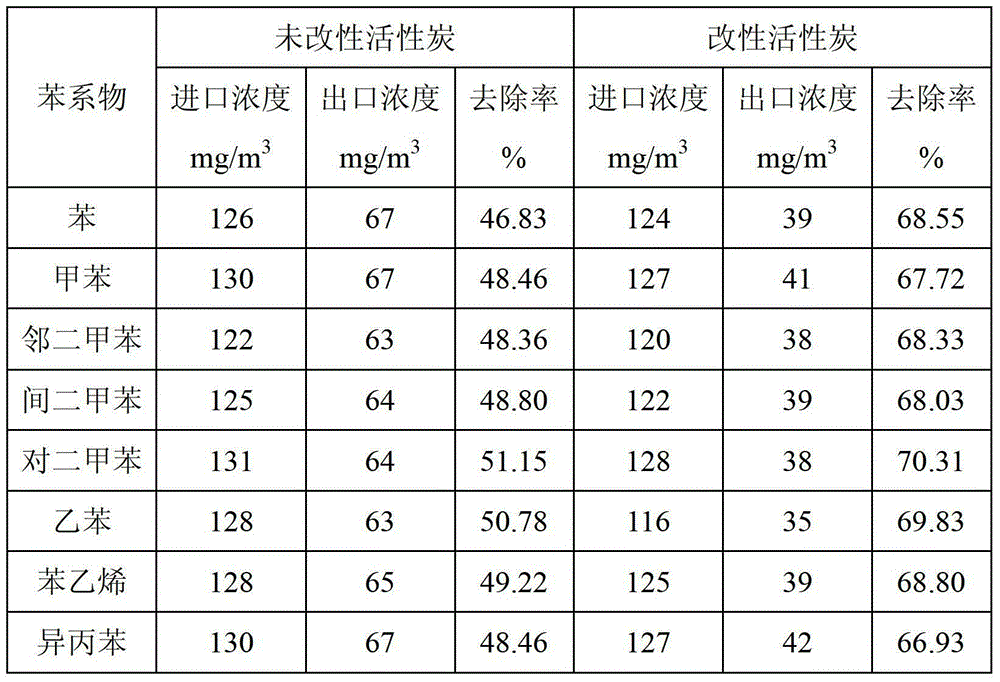

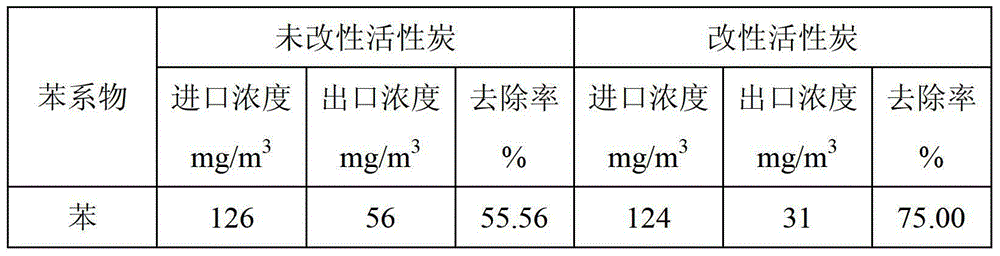

Apparatus for oxidization treatment of benzene-containing exhaust gas through coupling of particle swarm electrode adsorption with electro-catalysis

The invention discloses an apparatus for the oxidization treatment of a benzene-containing exhaust gas through the coupling of particle swarm electrode adsorption with electro-catalysis. The apparatus comprises a cylinder and an electrolytic reactor; a gas inlet and a gas outlet are arranged at two ends of the cylinder respectively; the electrolytic reactor is arranged in the cylinder; the electrolytic reactor comprises a plurality of unit reactors; each of the unit reactors comprises a positive-electrode conductive plate and a negative-electrode conductive plate which are arranged in parallel; and particle swarm electrodes are filled between the positive-electrode conductive plate and the negative-electrode conductive plate. The apparatus can effectively improve the treatment effect of the benzene organic pollutant-containing exhaust gas, allows the organic waste to be instantly degraded after absorbed by the surfaces of the particle swarm electrodes, realizes the integration of the adsorption and degradation of the organic exhaust gas, has a high treatment efficiency and has no secondary pollution. The apparatus has the advantages of small size, low equipment cost, simple operation, low running and using cost, realization of the equipment with a proper amount of the unit reactors according to the exhaust gas amount and the treatment requirements, economy and high efficiency.

Owner:JIANGSU PROVINCIAL ACAD OF ENVIRONMENTAL SCI

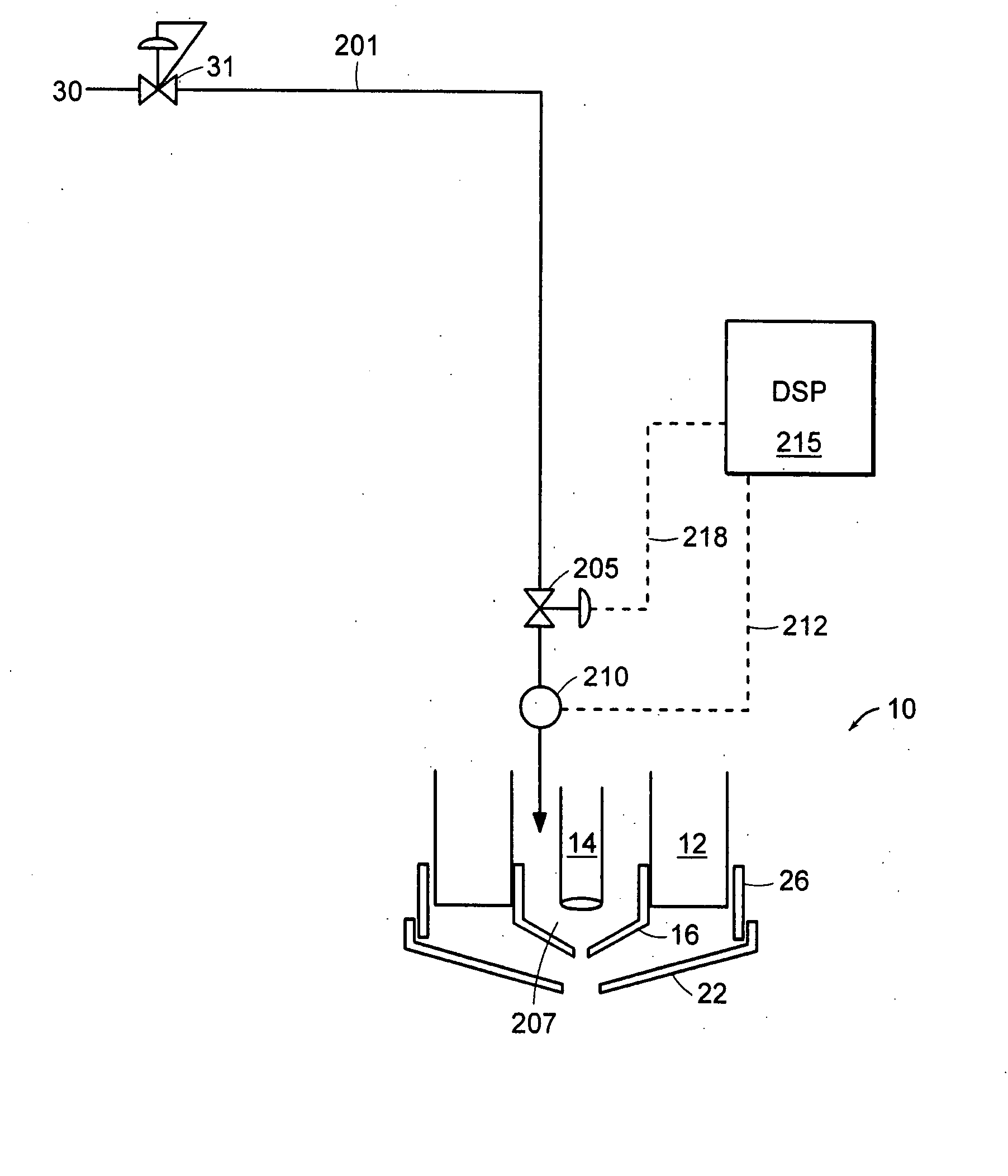

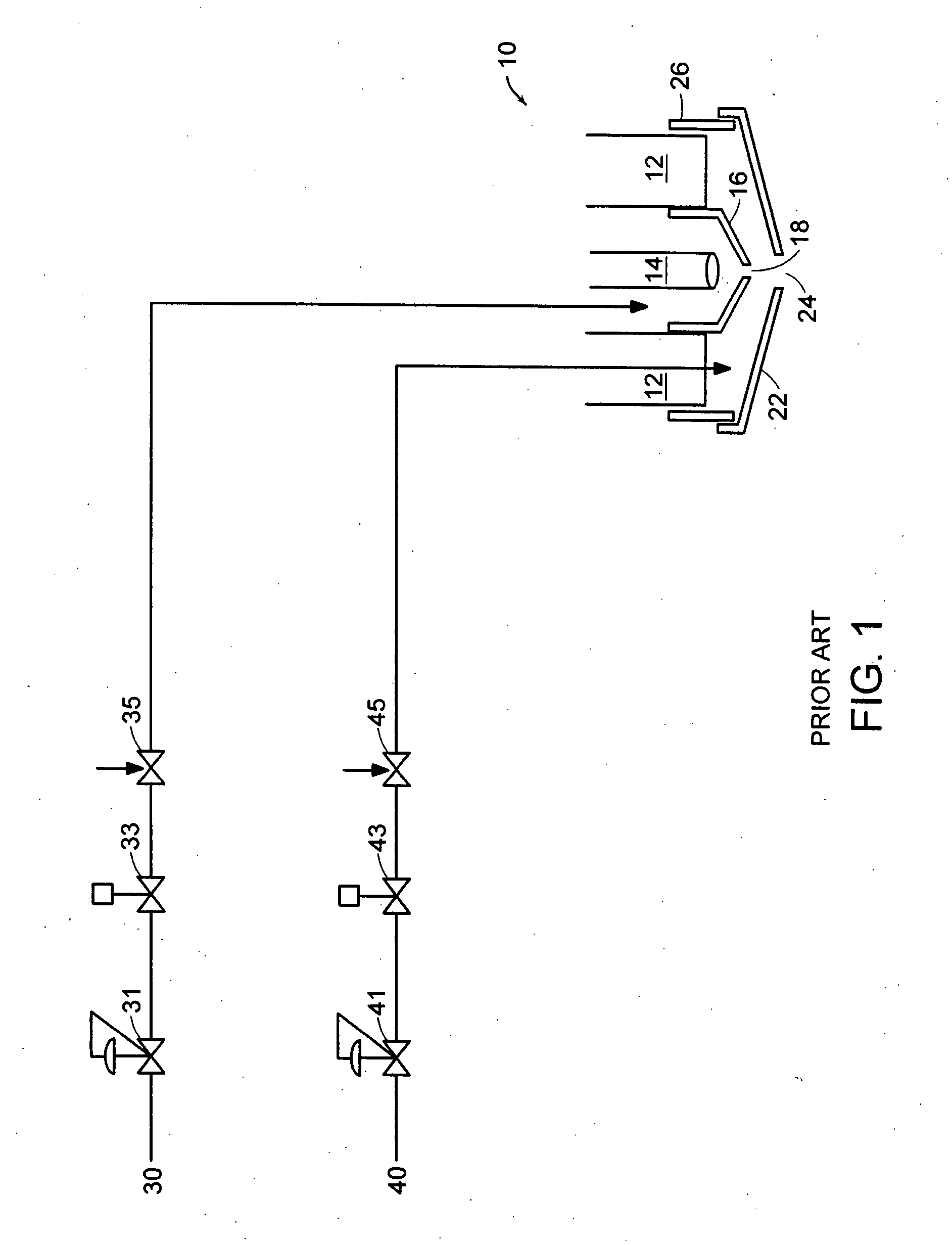

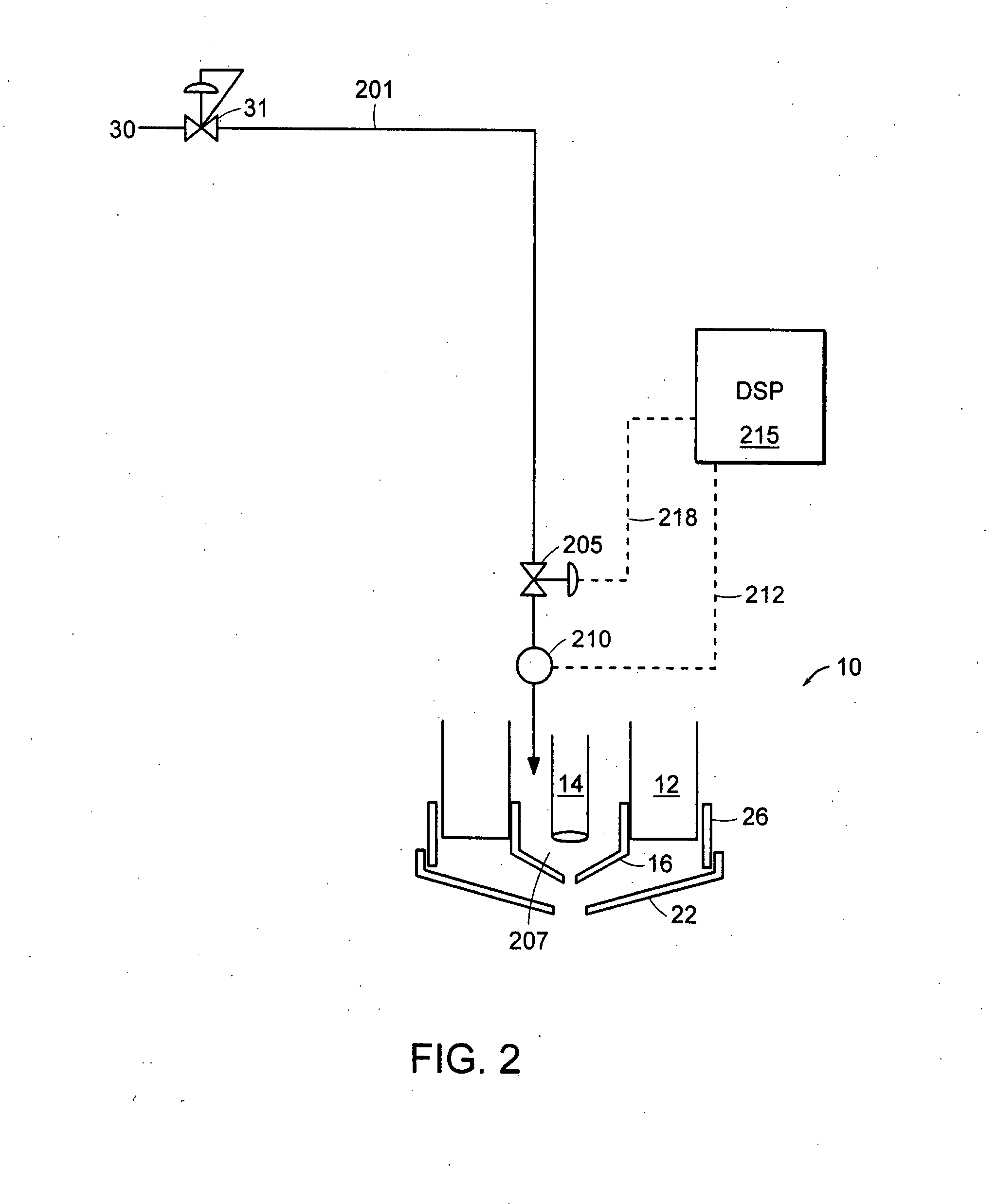

Method and apparatus for automatic gas control for a plasma arc torch

ActiveUS20080006614A1Prolong lifeShorten cycle timeArc welding apparatusPlasma welding apparatusProportional controlSolenoid valve

Owner:HYPERTHERM INC

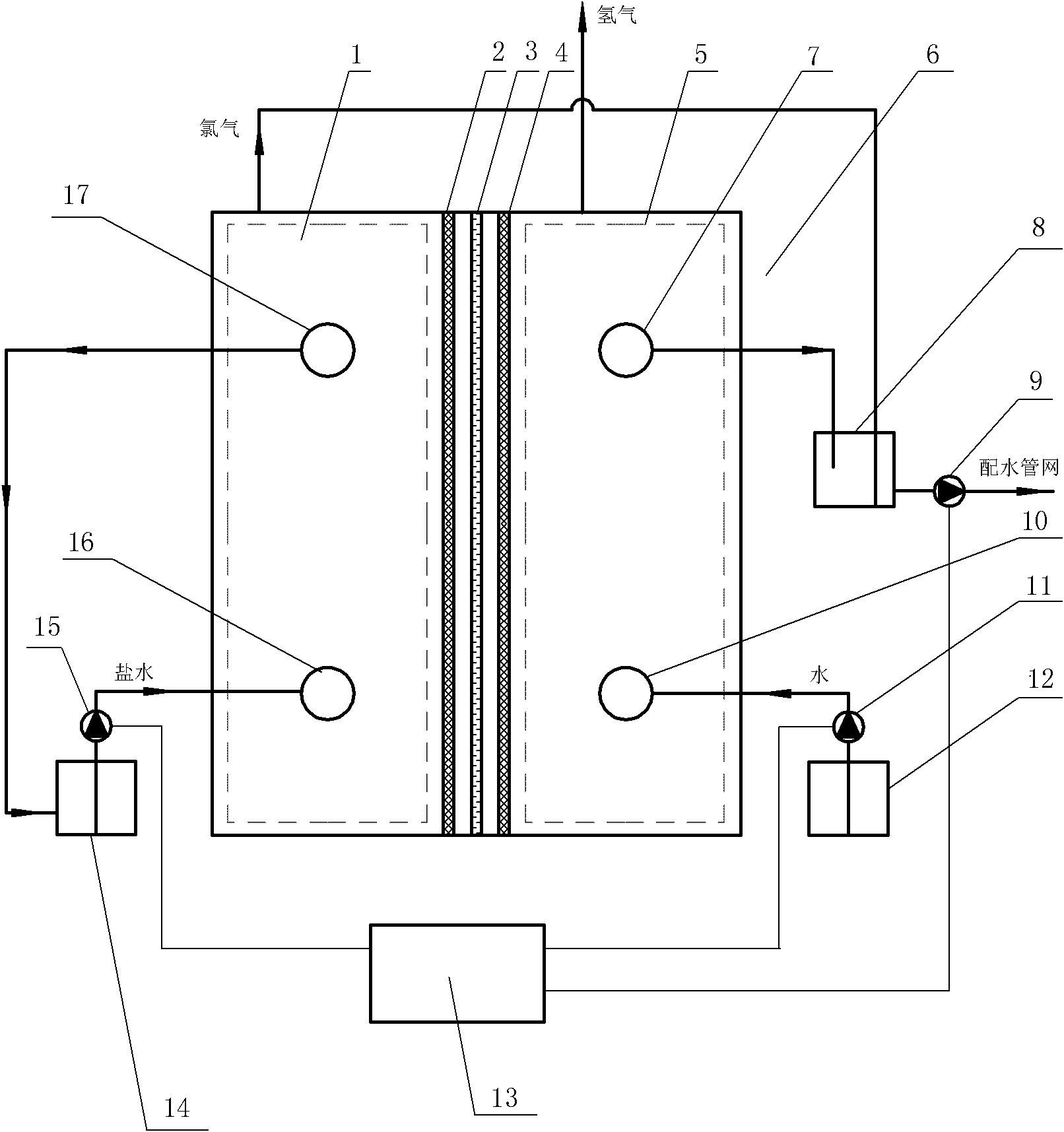

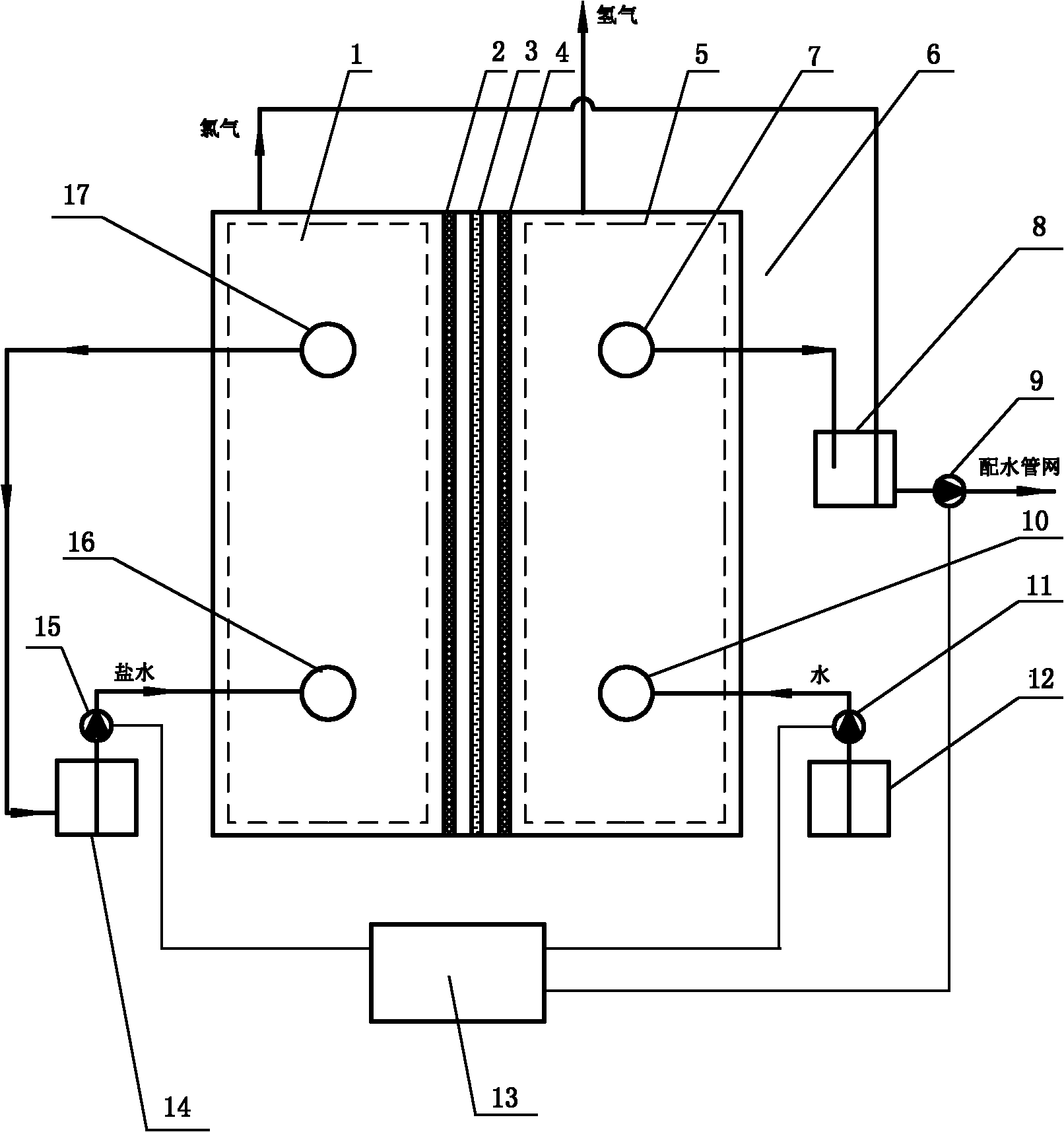

Preparing system and method of sodium hypochlorite

InactiveCN102465311AIncrease available chlorine concentrationQuality improvementDiaphragmsHigh concentrationPollution

The invention relates to a preparing system of sodium hypochlorite, which comprises an electrolytic cell, an anode, a cathode, a saline water cycling injection box, a reaction chamber, a cation film and a water inlet tank, wherein the electrolytic cell is divided into an anode chamber and a cathode chamber through the anode and the cathode; the cation film is arranged between the anode and the cathode; a saline water outlet and a saline water inlet are respectively arranged on the upper end and the lower end of the cathode chamber; and the upper end of the cathode chamber is provided with a water outlet, and the lower end of the cathode chamber is provided with a water inlet. The saline water cycling injection box is connected with the saline water inlet through a metering pump and a pipeline, the saline water outlet is connected with the saline water cycling injection box thorough a pipeline, and chlorine generated by the anode chamber is led into the reaction chamber through a pipeline; and the water inlet tank is connected with the water inlet through a water inlet pump and a pipeline, hydrogen generated by the cathode chamber is discharged through a pipeline, and the water outlet is connected with the reaction chamber through a pipeline. The invention also relates to a method for preparing the sodium hypochlorite through the system. The system and the method have the advantages of low operating cost, high concentration of generated available chlorine, long service life of electrodes, no pollution, and the like.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

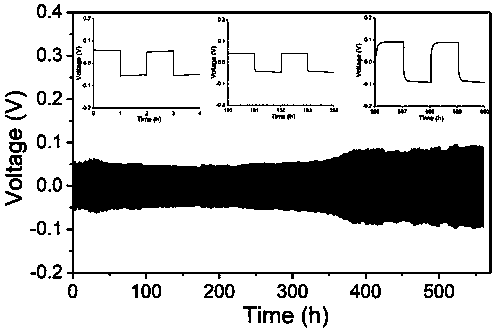

Protection method of lithium metal electrode

ActiveCN110071284AUniform prolapseUniform depositionNegative electrodesSecondary cellsLithium metalAlloy

The invention discloses a protection method of a lithium metal electrode. By use of a simple alloyage method, antimony trifluoride is utilized to form an artificial protective film on the surface of alithium cathode, so that polarization of the lithium cathode can be effectively lowered, and generation of dendritic crystals can be suppressed. According to the method, antimony trifluoride and lithium are mainly utilized for a reaction to generate the dense artificial protective film, wherein antimony trifluoride is dissolved in propylene carbonate to prepare a uniform solution first, pretreatment is performed on the surface of a lithium wafer to remove oxidized lithium on the surface, the lithium wafer is cut into a round wafer, the round wafer is immersed in the antimony trifluoride solution for a reaction to obtain a treated lithium electrode, and finally a symmetric battery is obtained through assembling. Through a low-concentration long-time reaction, a dense alloy layer can be generated on the surface of lithium metal. Through the method, the polarization of the lithium metal cathode is fully lowered, circulation stability is good, generation of lithium dendritic crystals is effectively suppressed, and the stable lithium metal cathode is obtained; and when the lithium metal cathode is applied to a lithium battery, the circulation performance and safety performance of the lithium battery can be improved, and potential commercial application value is obtained.

Owner:SHANGHAI UNIV

Electrocatalytic particle electrode material for treating high-concentration organic wastewater and preparation process thereof

InactiveCN103553188AImprove current efficiencyImprove stabilityWater/sewage treatment using germicide/oligodynamic-processHigh concentrationWastewater

The invention discloses an electrocatalytic particle electrode material for treating high-concentration organic wastewater and a preparation process thereof. The process comprises the steps of adding AgNO3 into isopropanol so as to obtain a solution A, adding treated Al2O3 into the solution A, filtering to obtain particles B and a microemulsion X, and washing by using ethanol so as to obtain particles D; adding the particles D into the X, and filtering to obtain particles F; preparing solutions B1, B2, B3, B4, B5, C, D, E and F from Ce(NO3) 2, MnCl2 and SnCl4; treating the particles F by sequentially using the solutions B1, B2, B3, B4 and B5, so as to obtain particles I; adding the particles I into the solution C, filtering, then, washing by using ethanol, and drying, so as to obtain particles K; adding the particles K into the solution D, filtering, then, washing by using ethanol, and drying, so as to obtain particles M; adding the particles M into the solution E, filtering, then, washing by using ethanol, and drying, so as to obtain particles O; adding the particles O into the solution F, filtering, then, washing by using ethanol, drying, and roasting for 4 hours at the temperature of 500 DEG C, thereby obtaining the electrocatalytic particle electrode material for treating the high-concentration organic wastewater.

Owner:BEIJING NORMAL UNIVERSITY

Manufacturing Apparatus For Depositing A Material And An Electrode For Use Therein

InactiveUS20110036292A1Maintain thermal conductivitySlow foulingOhmic-resistance electrodesPlasma welding apparatusDeposition temperaturePower flow

The present invention relates to a manufacturing apparatus for deposition of a material on a carrier body and an electrode for use with the manufacturing apparatus. Typically, the carrier body has a first end and a second end spaced from each other. A socket is disposed at each of the end of the carrier body. The apparatus includes a housing that defines a chamber. At least one electrode is disposed through the housing for receiving the socket. The electrode includes an interior surface that defines a channel. The electrode heats the carrier body to a necessary deposition temperature by direct passage of electrical current to the carrier body. A coolant is in fluid communication with the channel of the electrode for reducing the temperature of the electrode. A channel coating is disposed in the interior surface of the electrode for preventing loss of heat transfer between the coolant and the interior surface.

Owner:HEMLOCK SEMICONDUCTOR CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com