PbO2 electrode with long service life and high catalytic activity

A lead dioxide and electrode technology, which is applied in chemical instruments and methods, electrolytic inorganic material coating, water/sludge/sewage treatment, etc., can solve the problem of reducing the electrochemical stability and service life of electrodes, coating shedding, and substrate passivation And other problems, to achieve the effect of improving life, stable performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

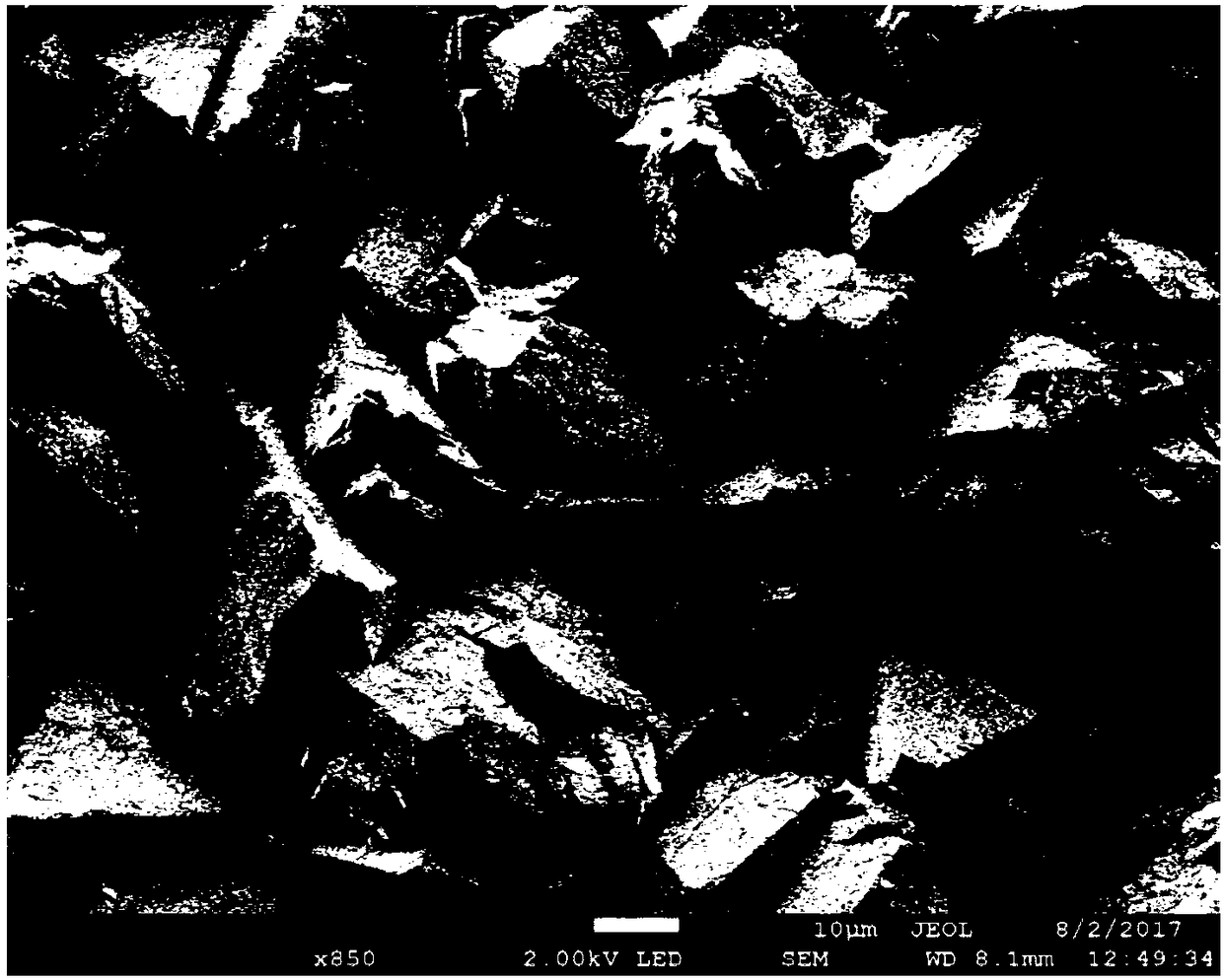

[0027] The titanium mesh was ultrasonically cleaned with acetone, ethanol, and deionized water for 15 minutes, and then air-dried naturally after taking it out. Then Ti / SnO was prepared on the surface of titanium mesh by coating thermal decomposition 2 -Sb bottom layer, the composition of the coating solution used is 5ml of n-butanol, 3ml of concentrated hydrochloric acid, 3g of tin tetrachloride, and 0.3g of antimony trichloride. When the coating solution is completely dissolved into a uniform and transparent state, dip the coating solution with a brush and apply it on the titanium mesh. Then place it in an electric constant temperature drying oven and dry it at 120°C for 15 minutes, then take it out and paint it again. After repeating this for 8 times, it was fired in a muffle furnace at 500°C for 2 hours.

[0028] Continue to deposit a layer of α-PbO on the surface of the electrode by electrodeposition 2 middle layer. The electrodeposition solution used is 0.1mol / L of P...

Embodiment 2

[0037] Similar to Example 1, the same method is adopted to obtain a layer coated with bottom layer and α-PbO 2 The electrode in the middle layer, and then obtain β-PbO on the surface of the electrode by electrochemical deposition 2Surface active layer, the electrodeposition solution used is 0.5mol / L Pb(NO 3 ) 2 , 0.05mol / L HBO 3 , 0.1g / LNaF, 50mg / L graphene oxide (GO), 20mg / L nano-SiC; the current density used is 20mA / cm 2 . The temperature is 60°C, and electrodeposition is performed for 1 hour, and a new type of lead dioxide composite electrode can be obtained.

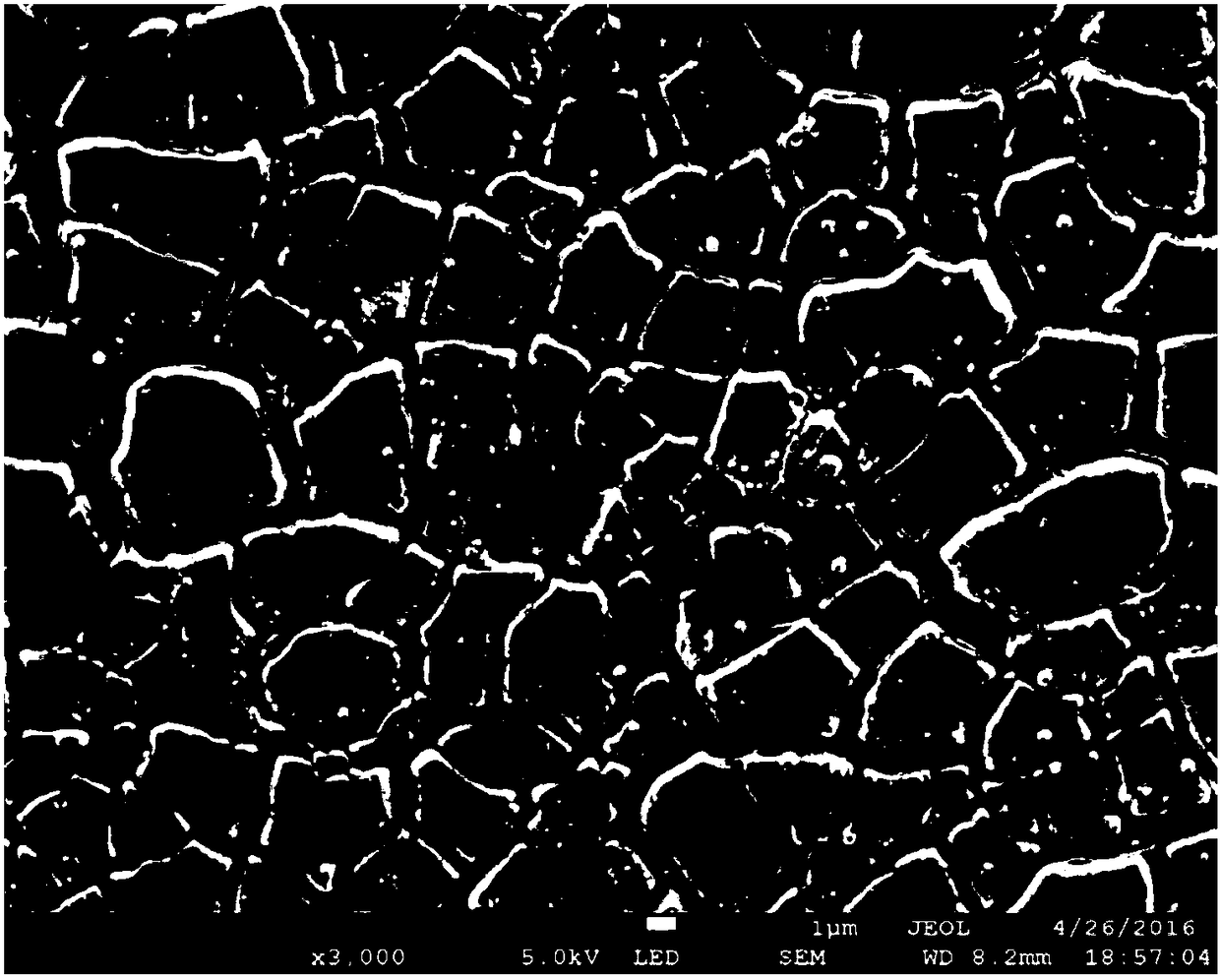

[0038] The surface morphology and catalytic performance of the electrode were analyzed and characterized by scanning electron microscope (SEM) and ultraviolet spectrophotometer. Such as Figure 4 As shown, it can be seen that the β-PbO on the surface of the composite electrode doped with nano-silicon carbide and graphene oxide obtained by electrodeposition 2 The particles are uniform and dense, and the particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com