Arc plasma torch having arc channel with abnormal diameter

An arc plasma and channel diameter technology, applied in the direction of plasma, electrical components, etc., can solve the problems of simple structure, high thermal efficiency, difficult to obtain power, etc., and achieve the effect of simple structure, increasing arc power, and increasing arc voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

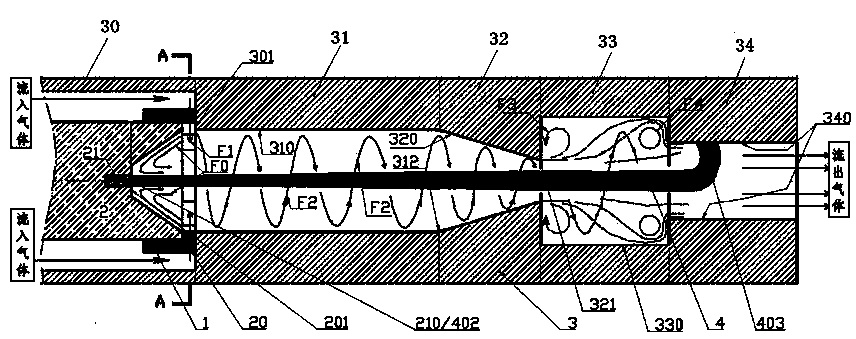

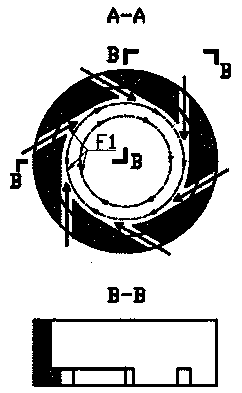

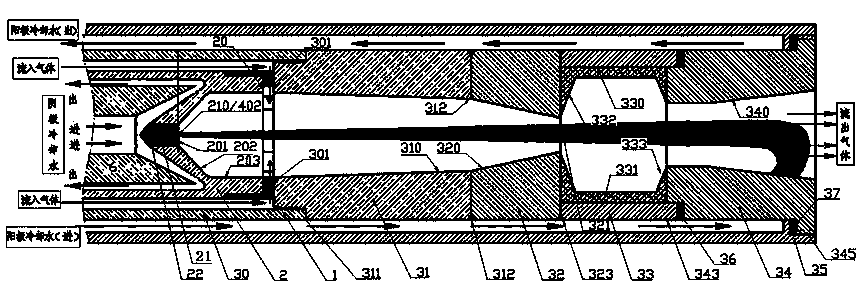

[0031] see image 3, an arc plasma torch with a profiled arc channel diameter, comprising a gas swirler 1, a cathode 2 and a group of anode assemblies 3. The anode assembly 3 is composed of inner cylinders 30, 31, 32, 33, 34 and an outer tube 35. The anode inner cylinder is a circular tube with a variable inner hole diameter. One end of the anode inner cylinder is the gas inflow end, and the other end is the Heated gas outlet. Water cooling is passed between the outside of the anode inner cylinder and the anode outer tube, image 3 Shown is the cooling channel with angular entry and exit distribution.

[0032] According to the change of the diameter of the inner hole of the anode inner cylinder, the anode inner cylinder can be sequentially divided into sections from the gas inflow end to the gas outflow end: a gas introduction section 30, a straight pipe section 31 with a constant inner hole diameter ( figure 1 ) or the tapered section 31 where the diameter of the inner hol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com