Internal recycle multi-dimensional electro-catalytic wastewater treating equipment

A technology of wastewater treatment and multi-dimensional electricity, which is applied in the direction of electrochemical water/sewage treatment, flotation water/sewage treatment, adsorption water/sewage treatment, etc. Mass efficiency, improve wastewater treatment effect, increase the effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

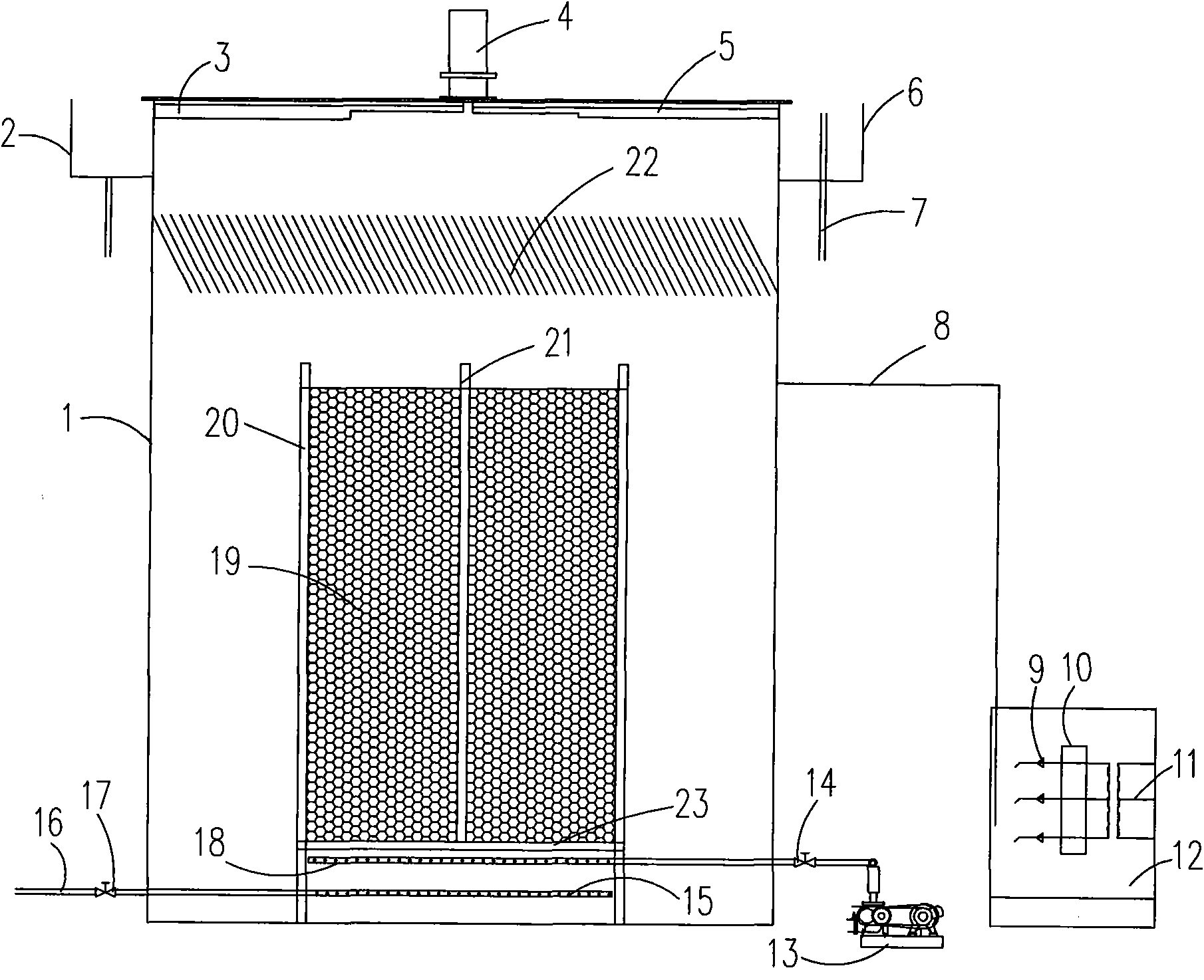

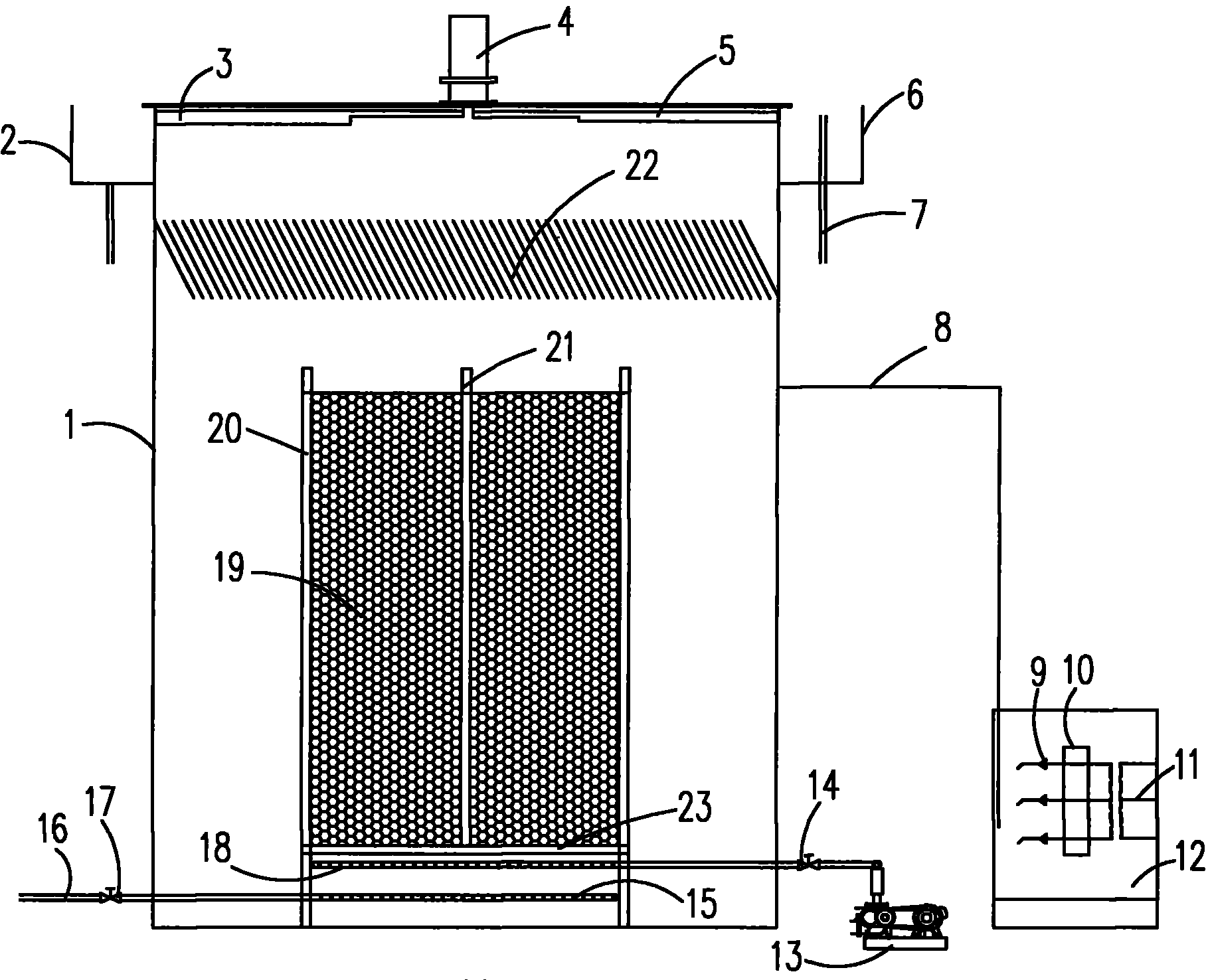

[0025] In this embodiment, a cylindrical body 1 is set, and in the cylindrical body 1, water inlet distribution pipes, aeration pipes, electrode reaction areas, rectification areas, water outlet areas, and scum collection areas are arranged sequentially from bottom to top. .

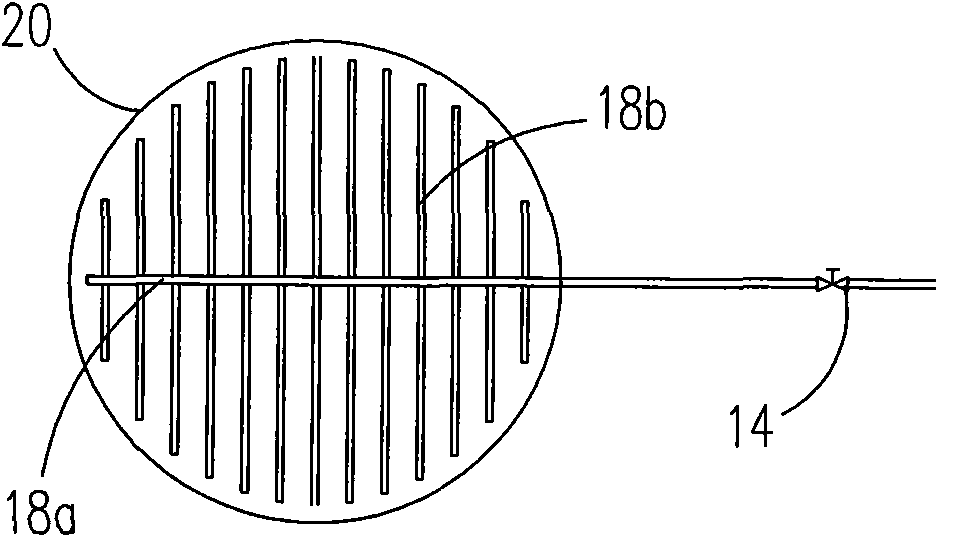

[0026] see figure 1 , the electrode reaction zone is a cylindrical cavity formed by a cylindrical anode 20, a rod-shaped cathode 21 is set on the central axis of the cylindrical cavity, the particle electrode 19 is filled in the cylindrical cavity, and is located in the cylindrical cavity The porous support plate 23 at the bottom supports and forms a fixed bed of particle electrodes. In this embodiment, the cathode uses a graphite rod or stainless steel rod, the anode uses a titanium plate coated with a catalyst, and the catalyst coating can be made of SnO 2 , Ru-Ir, Ir-Ta, Pt and other materials, the particle electrode uses granular activated carbon with a particle size of 3-5mm, and the body can be m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com