Method for preparing supported type nano Pt(Pt-M)/carrier catalyst

A catalyst and supported technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the difficult control of metal particle agglomeration, decreased catalytic activity, Problems such as the growth of metal particles can achieve the effects of adjustable catalyst size, prolonging electrode life, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

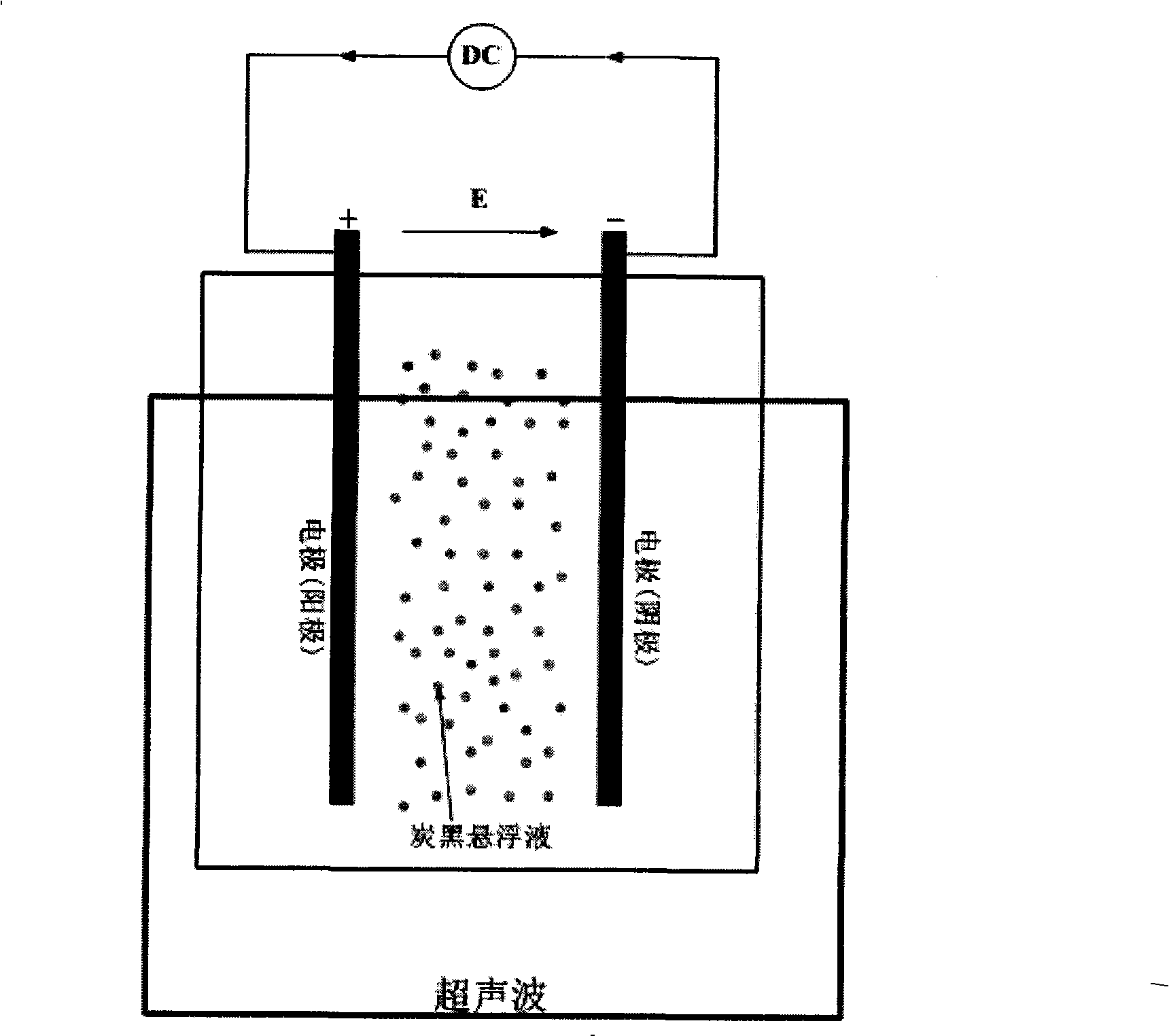

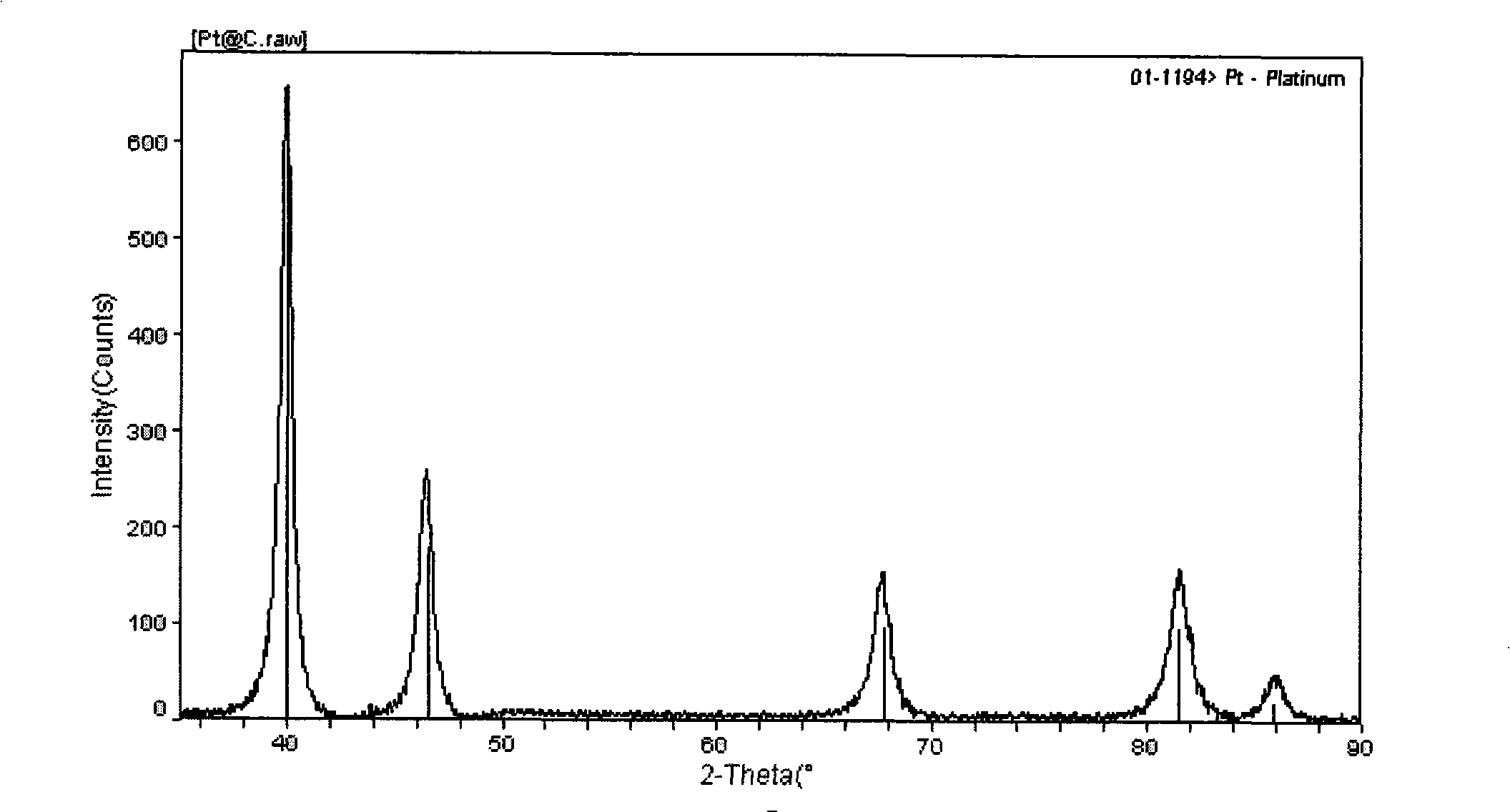

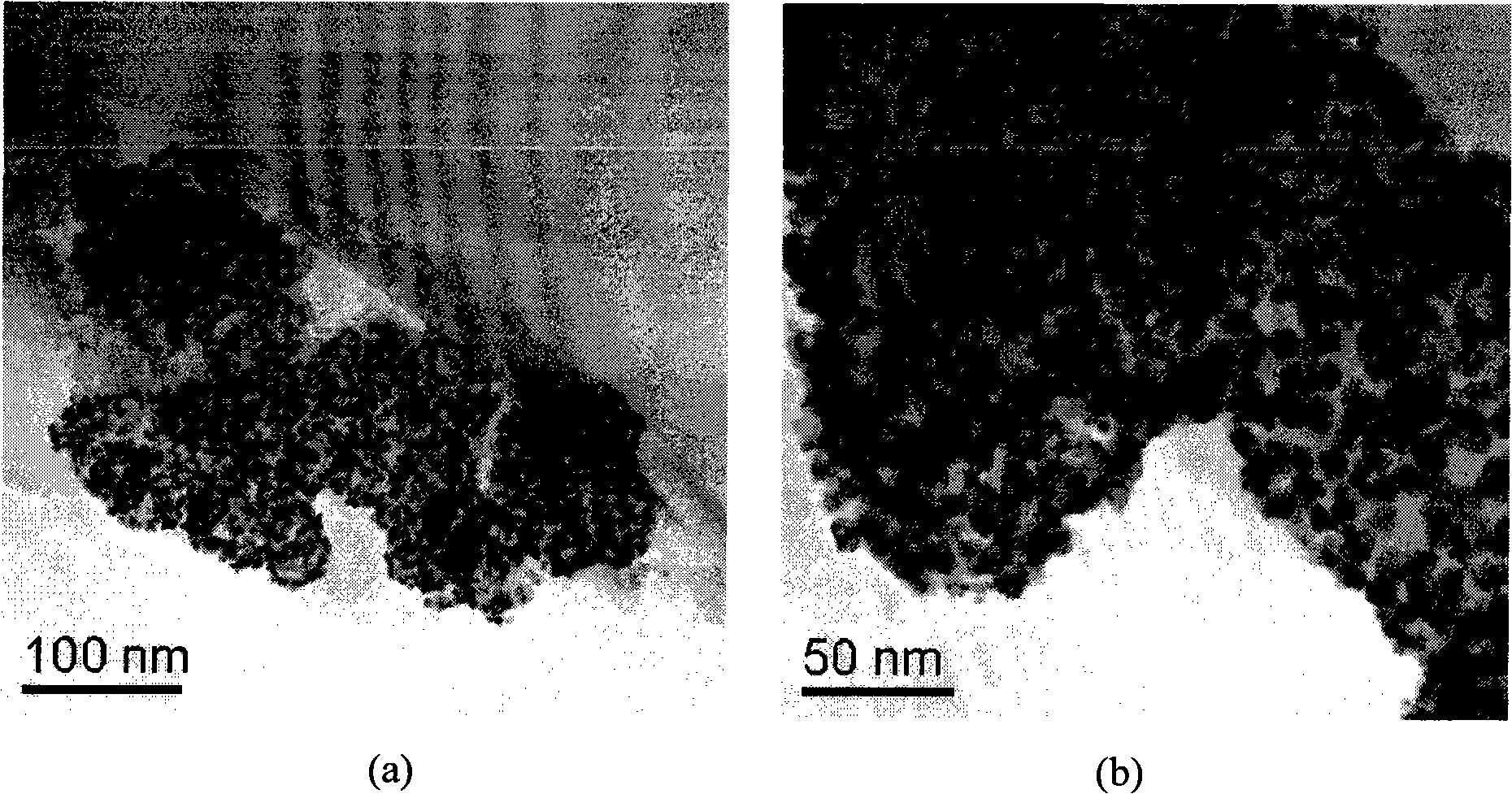

[0017] The present invention uses deionized water to prepare concentration ≥ 10 -8 mol L -1 The chloroplatinic acid solution, the carrier is uniformly dispersed in the prepared chloroplatinic acid solution by ultrasonic waves to obtain a suspension, and then the suspension is adjusted to an appropriate pH value with acid, ranging from 0.1 to 7.0, to obtain the electrodeposition ultrasonic The suspension, that is, the electrolyte, in which the amount of carrier added can be adjusted according to the concentration of the required electrolyte and the electrodeposition time; the prepared electrolyte is injected into the double platinum electrode electrolytic cell with ultrasonic application, and the current density during electrolysis Range: 1mA / cm 2 ~1000mA / cm 2 ;Electrolysis time: 1 ~ 6000min Under the continuous action of direct current, the bulk Pt (Pt-M) can be directly converted into nano-Pt (Pt-M) particles, and nano-Pt (Pt-M) uniformly loaded on the carrier can be obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com