Membrane electrode of long-life fuel cell with porous adsorption layer and preparation method thereof

A fuel cell membrane and porous adsorption technology, which is applied in the direction of fuel cells, battery electrodes, fuel cell components, etc., can solve the problems that proton exchange membranes hinder the life of fuel cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

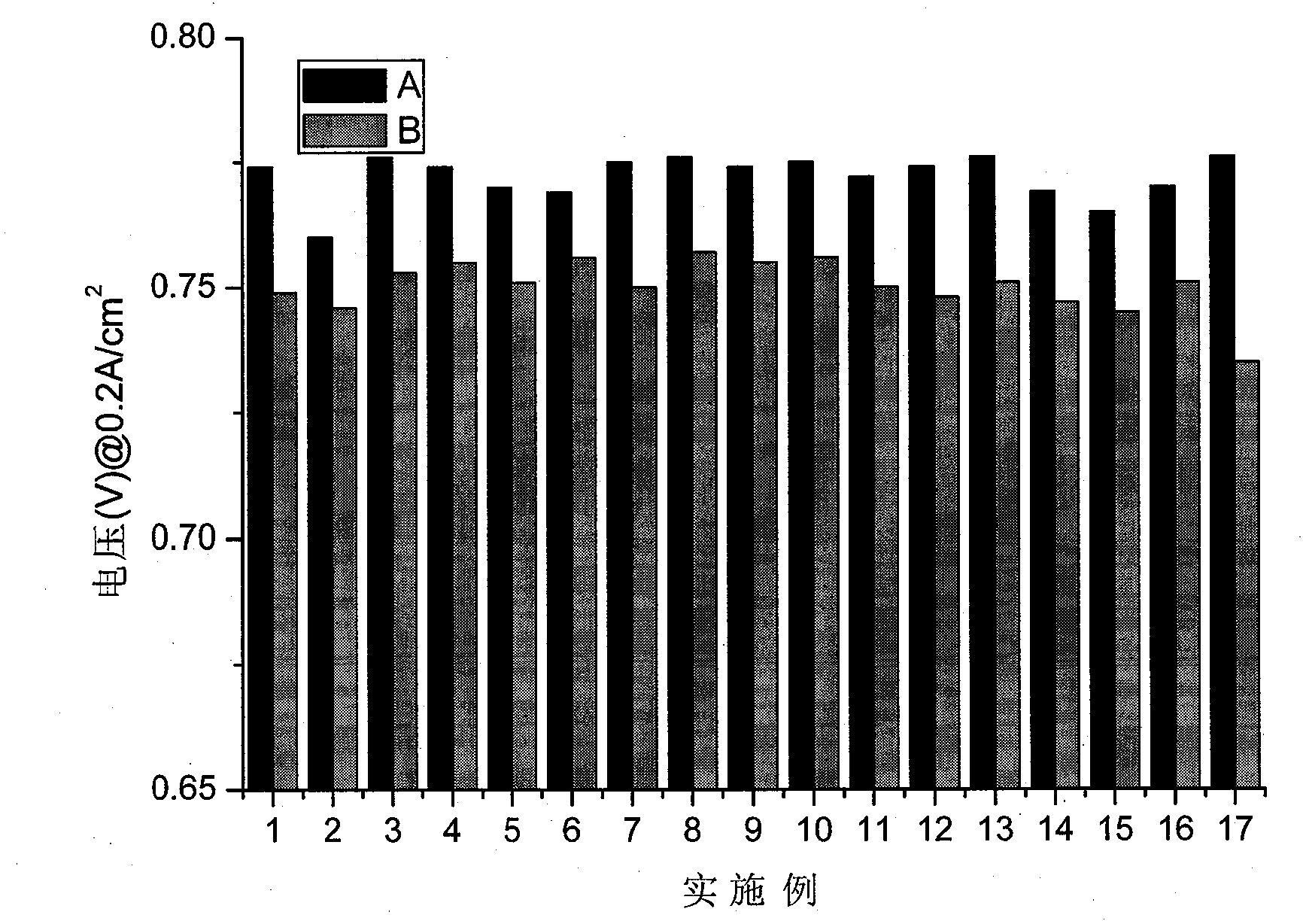

Examples

Embodiment 1

[0036] The preparation of a long-life fuel cell membrane electrode with a porous adsorption layer comprises the following steps:

[0037] 1. Preparation of palygorskite slurry

[0038] Get 3g palygorskite and 20ml 5wt% perfluorosulfonic acid proton exchange resin solution ( DuPont Company), and mixed with 50ml 5% ethanol / deionized aqueous solution, stirred at high speed for 1 hour, and ultrasonically dispersed for 20 minutes;

[0039] 2. Preparation of palygorskite adsorption layer

[0040] Coat the palygorskite slurry on the surface of the gas diffusion layer electrode and dry it at 100°C for 10 hours. The average thickness of the dry coating is about 4 μm;

[0041] 3. Pretreatment of the gas diffusion layer

[0042] The gas diffusion layer (Toray carbon paper) was impregnated with polytetrafluoroethylene hydrophobic agent (PTFE) for 10 minutes, and calcined at 350°C for 30 minutes, the content of polytetrafluoroethylene hydrophobic agent was 30wt%, and then, on one side ...

Embodiment 2

[0050] The preparation of a long-life fuel cell membrane electrode with a porous adsorption layer comprises the following steps:

[0051] 1. Preparation of sepiolite slurry

[0052] Mix 2g sepiolite and 8ml 5wt% The solution was mixed with 30ml deionized water solution, stirred at high speed for 0.5 hours, and ultrasonically dispersed for 10-15 minutes;

[0053] 2. Preparation of sepiolite adsorption layer

[0054] Same as Example 1, except that the average thickness of the dry coating is about 3 μm;

[0055] 3. Pretreatment of the gas diffusion layer

[0056] Immerse Toray carbon paper in polytetrafluoroethylene hydrophobizing agent for 5 minutes, and calcined at 350°C for 20 minutes, the content of polytetrafluoroethylene hydrophobizing agent is 20wt%, and then coat a layer of polytetrafluoroethylene on one side. A composite material layer composed of vinyl fluoride and conductive carbon black particles, wherein the content of polytetrafluoroethylene is 30wt%, which is ...

Embodiment 3

[0064] The preparation of a long-life fuel cell membrane electrode with a porous adsorption layer comprises the following steps:

[0065] 1. Preparation of silica gel slurry

[0066] Mix 4.0g of silica gel and 90ml of 5wt% Flemion polymer with 200ml of isopropanol solution, stir at high speed for 0.5 hours, and ultrasonically disperse for 15 minutes;

[0067] 2. Preparation of silica gel adsorption layer

[0068] Coat the silica gel slurry on both sides of NRE 212CS and dry it at 100°C for 20 hours. The average thickness of the dry coating is about 4 μm;

[0069] 3. Pretreatment of the gas diffusion layer

[0070] Same as embodiment 2;

[0071] 4. Preparation of gas diffusion layer electrodes

[0072] 1g of 40wt% Pt / C catalyst (produced by Johnson Matthey) was dispersed in 1ml of isopropanol solution, while adding 10ml of 5wt% The resin solution is fully dispersed under vacuum conditions to prepare a catalyst slurry, which is coated on one side of the pretreated gas diff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com