Method for performing spot welding on Al-Zn hot-coated steel plate

A hot-dip aluminum and steel plate technology, applied in welding media, welding equipment, welding equipment and other directions, can solve the problems of high consumption cost of foil tape production, serious sticking phenomenon, low electrode life, etc., to achieve simple and convenient grinding work, Good electrode cooling conditions, improve the effect of electrode life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

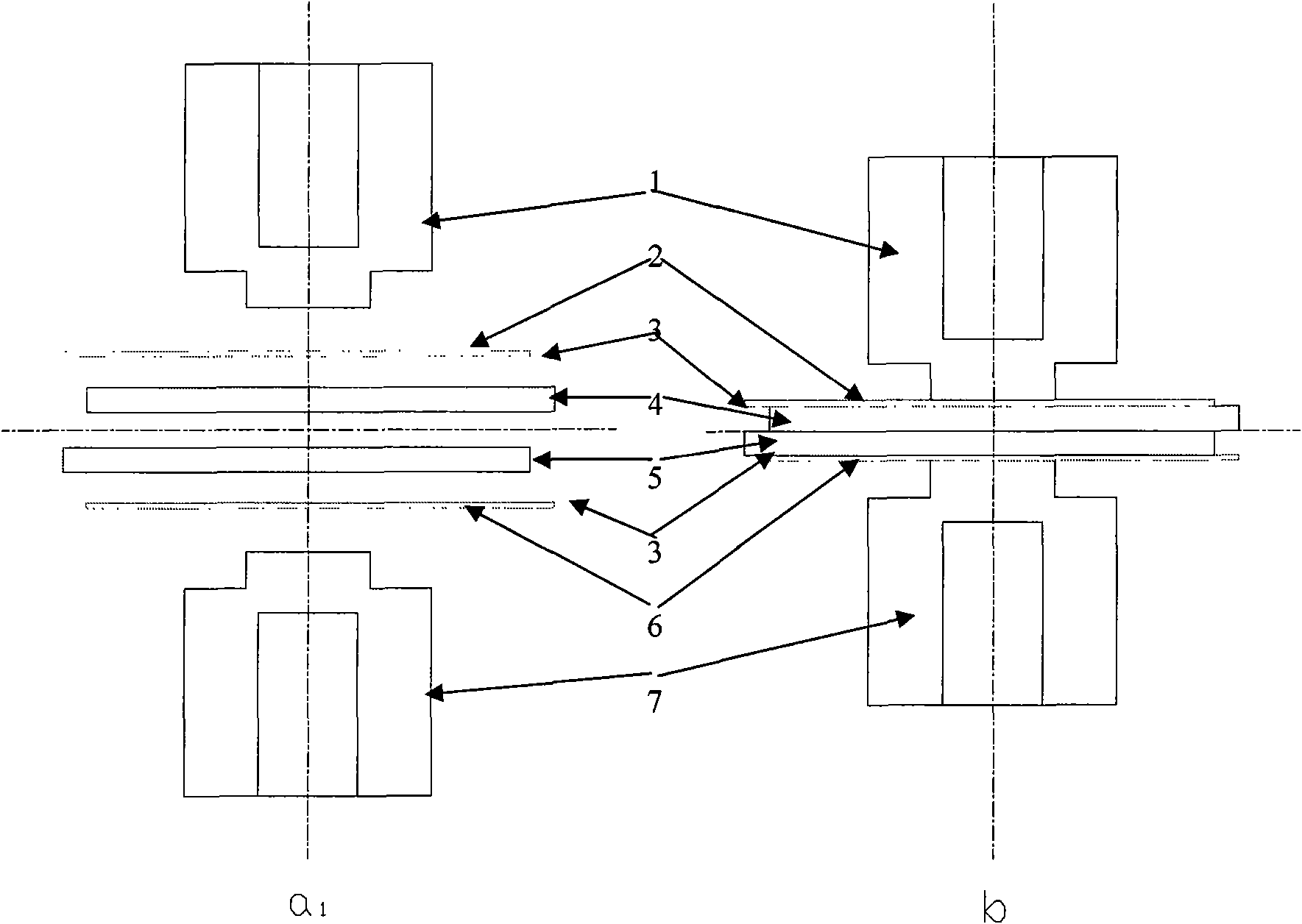

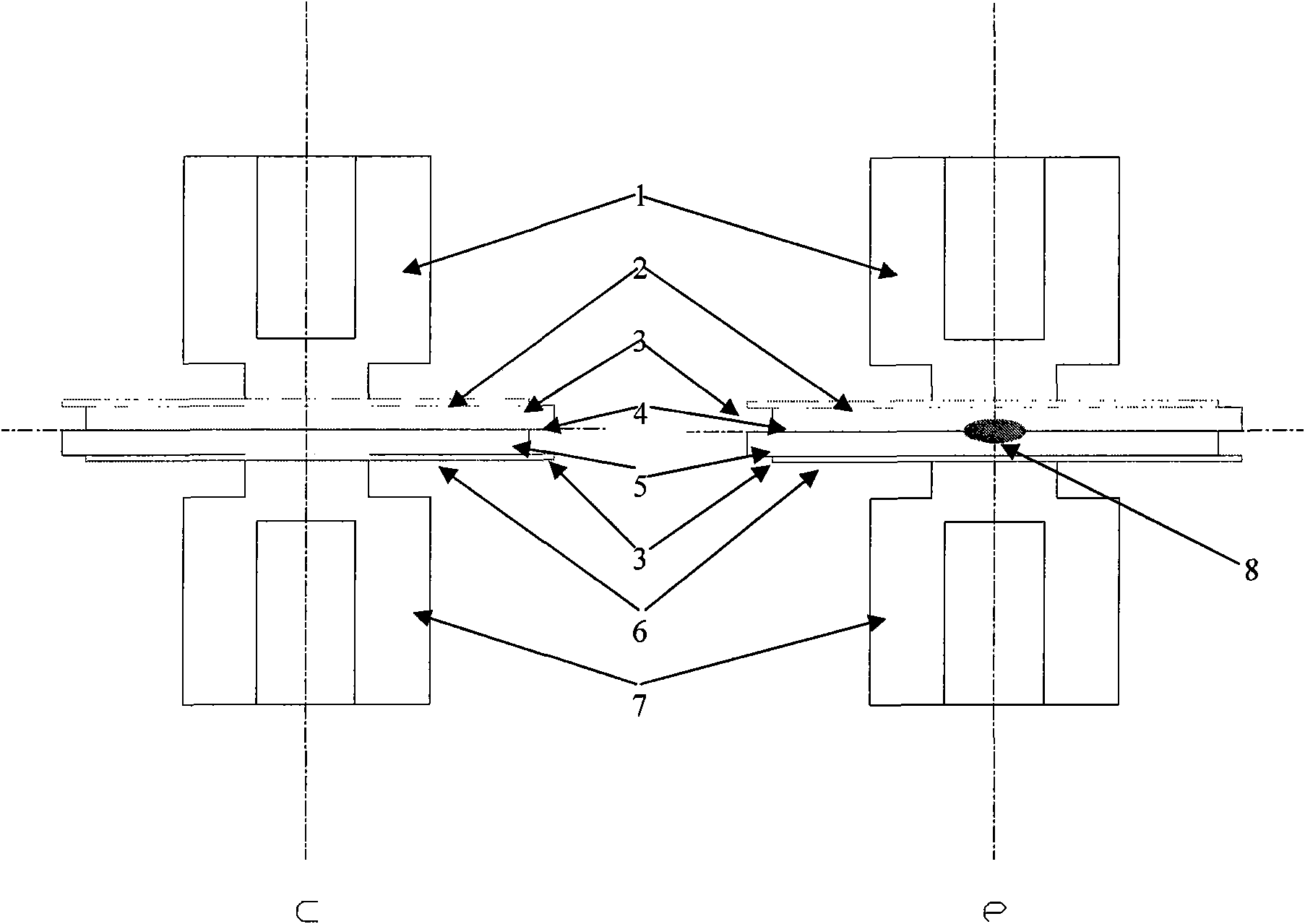

[0032] Such as Figure 8 Shown is a schematic diagram of the difference between the spot welding method A of the present invention and the ordinary spot welding method B. The upper and lower foil strips are inserted between the upper and lower electrodes and the upper and lower workpieces. It is worth noting that the foil strips in the present invention are single-sided Tin-plated steel sheet (such as Figure 4 shown) and the tinned surface is in contact with the workpiece, while the non-tinned surface is in contact with the copper electrode, which separates the direct contact between the copper electrode and the aluminum-zinc coating of the workpiece, avoiding the prerequisites for alloying aluminum, zinc and copper . Such as figure 1 , figure 2 shown.

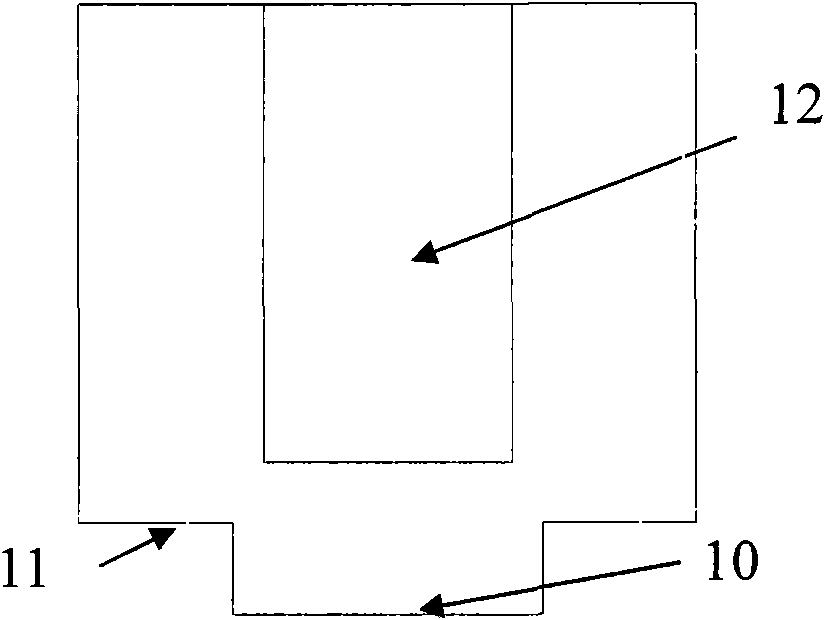

[0033] In addition, in order to realize the stability of the subsequent welding process and the practical operation is simple, this method uses a step-type spot welding electrode such as image 3 shown, and with the two...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com