Thorium tungsten wire used for winding microwave oven magnetron and manufacturing method of thorium tungsten wire

A manufacturing method and magnetron technology, applied in the field of metal material manufacturing, can solve the problems of low creep resistance, easy brittle fracture, fast growth rate, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

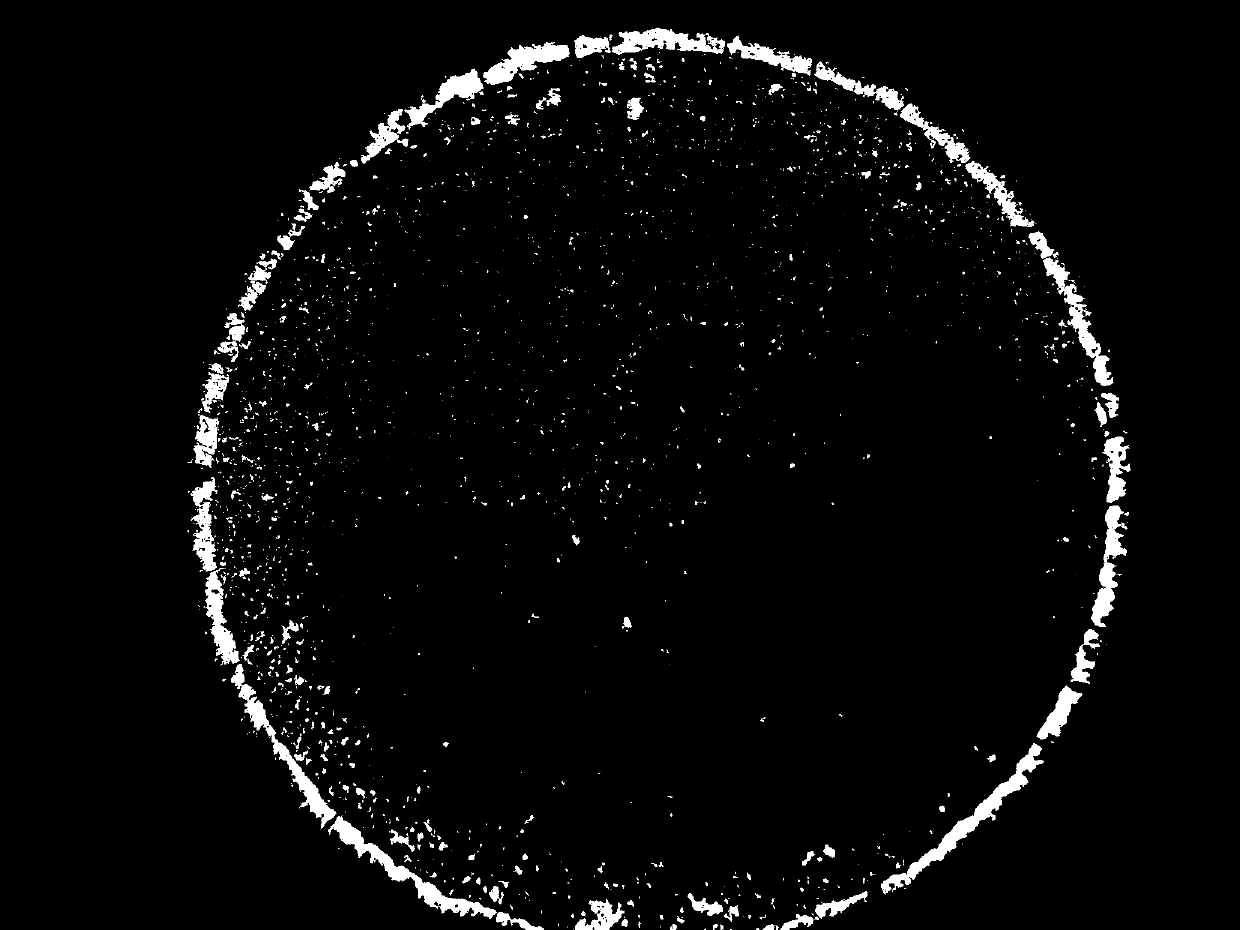

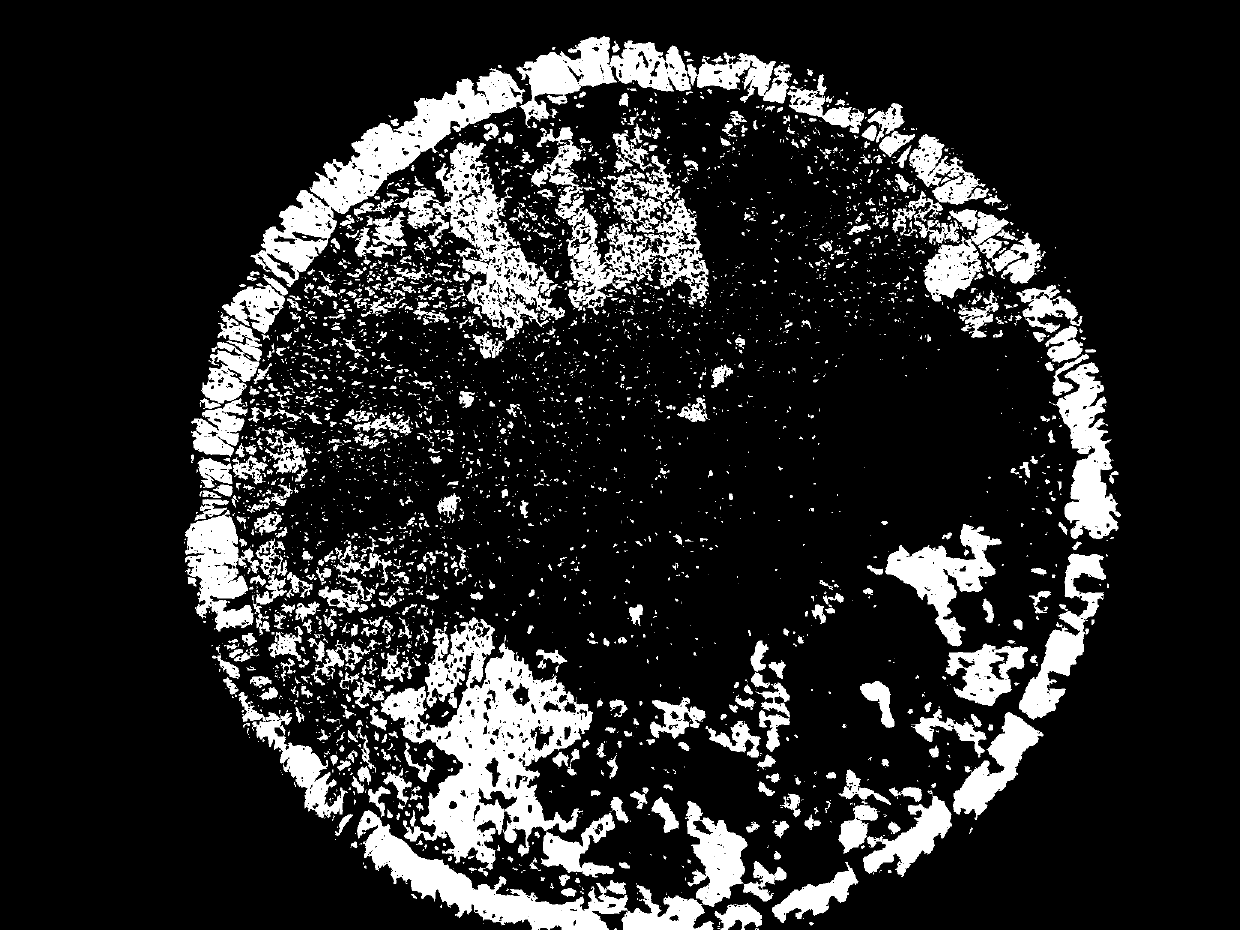

Image

Examples

Embodiment 1

[0025] A method for manufacturing a thoriated tungsten wire for winding a microwave oven magnetron, comprising the following steps:

[0026] Step 1: Doping, mix and dry thorium nitrate solution, potassium nitrate solution, aluminum silicate solution and blue tungsten powder in the doping pot, and then send it to the reduction furnace.

[0027] Step 2: Reduction. The reduction furnace adopts a 5-stage temperature-controlled reduction process. The temperatures of the 4 stages are 550°C, 750°C, 850°C, and 950°C. / boat, the reducing atmosphere is hydrogen, and the flow rate of hydrogen is 3-5m 3 / h, reducing to obtain thoriated tungsten powder containing trace potassium elements, the powder particle size range is 1.3-1.5μm,

[0028] Step 3: High-energy ball milling, put the thoriated tungsten powder into a ball mill tank with polyurethane lining for high-energy ball milling for 3-5 hours, the ball milling medium is tungsten balls, the ball-to-material ratio is 5:1,

[0029] Ste...

Embodiment 2

[0037] A method for manufacturing a thoriated tungsten wire for winding a microwave oven magnetron, comprising the following steps:

[0038] Step 1: Doping, mix and dry the thorium nitrate solution, potassium nitrate solution, aluminum silicate solution and blue tungsten powder in the doping pot, then send them to the reduction furnace.

[0039] Step 2: Reduction, use 5-stage temperature-controlled reduction process to reduce the raw materials in the furnace, the 5-stage temperature is 550°C, 650°C, 750°C, 850°C, 950°C, and the holding time of each stage is 60-80min , the loading capacity is 300-350g / boat, the reducing atmosphere is hydrogen, and the flow rate of hydrogen is 3-5m 3 / h, reducing to obtain thoriated tungsten powder containing trace potassium elements, the powder fineness range is 1.3-1.5μm,

[0040] Step 3: High-energy ball milling, put the thoriated tungsten powder obtained in step 2 into a ball mill tank with polyurethane lining for high-energy ball milling f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com