Patents

Literature

60results about How to "No brittle fracture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

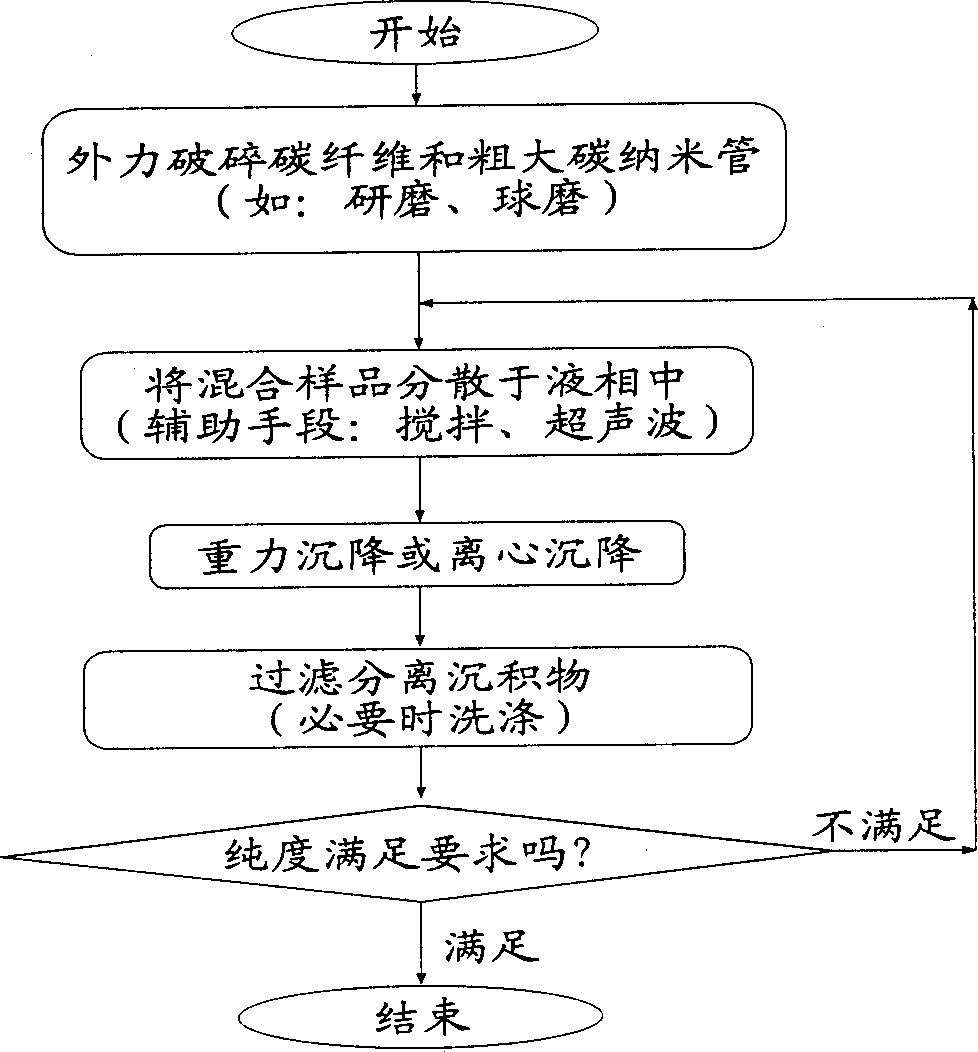

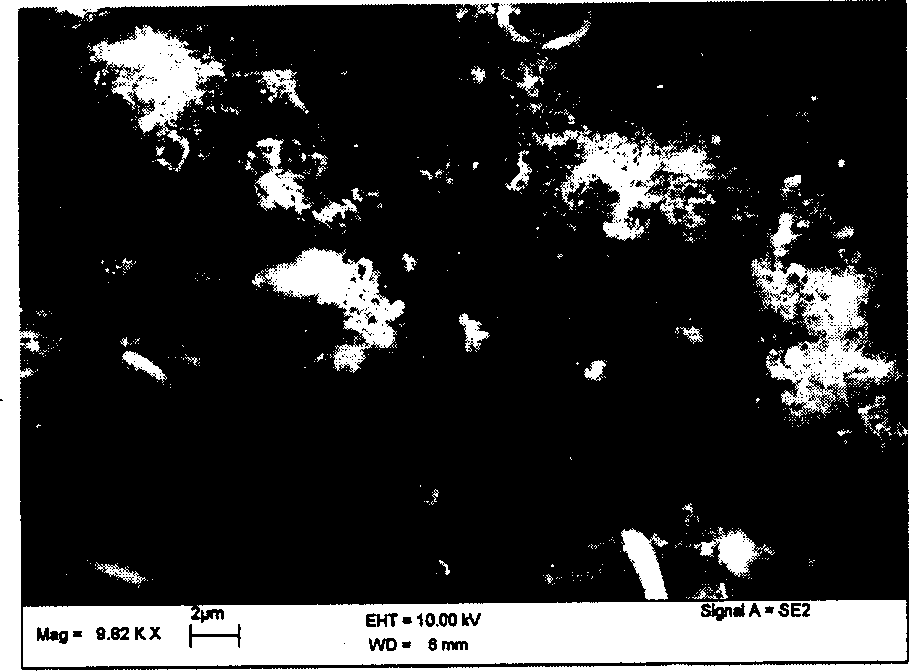

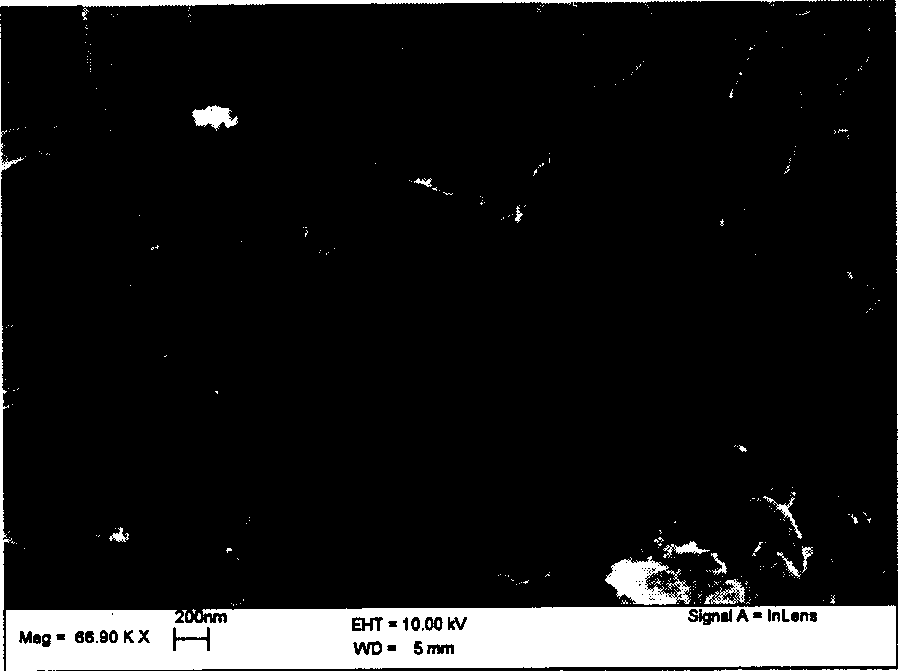

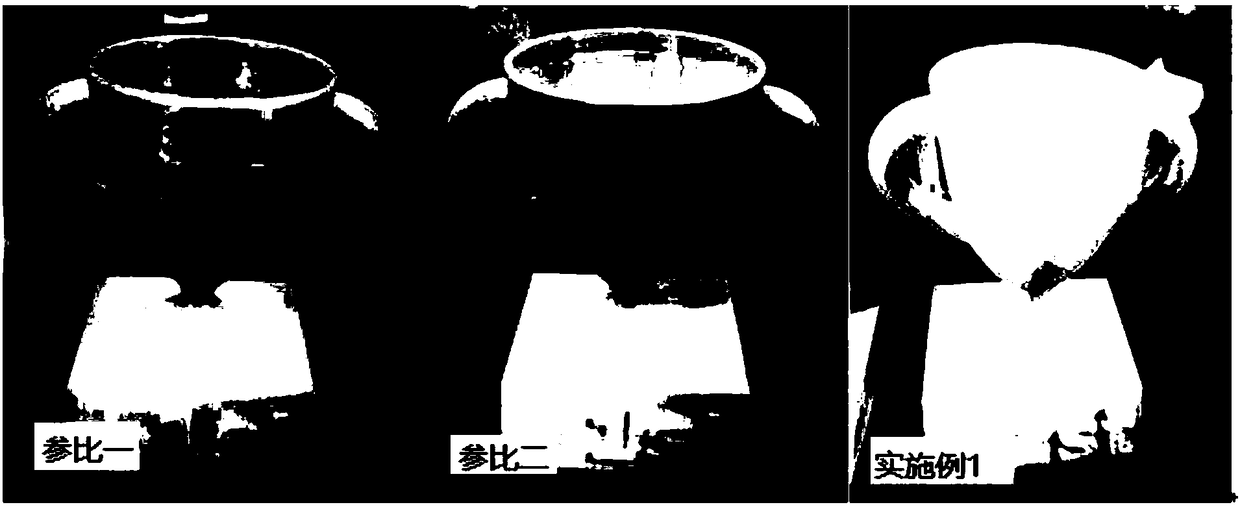

Method of utilizing external force to crush, wash and purify slender carbon nanotube

The present invention relates to one physical technological method of purifying slender carbon nanotube. The purifying process includes external force crushing, liquid phase dispersion, deposition, filtering and washing. By means of the characteristics of slender carbon nanotube, which is flexible, wear resistant and easy to flocculate and deposit in liquid phase, coarse carbon fiber and large carbon nanotube may be eliminated easily and nano carbon particle, fine amorphous carbon and other easy-to-suspend impurity may be eliminated. The said process has no damage to slender carbon nanotube and has high purification efficiency.

Owner:TSINGHUA UNIV

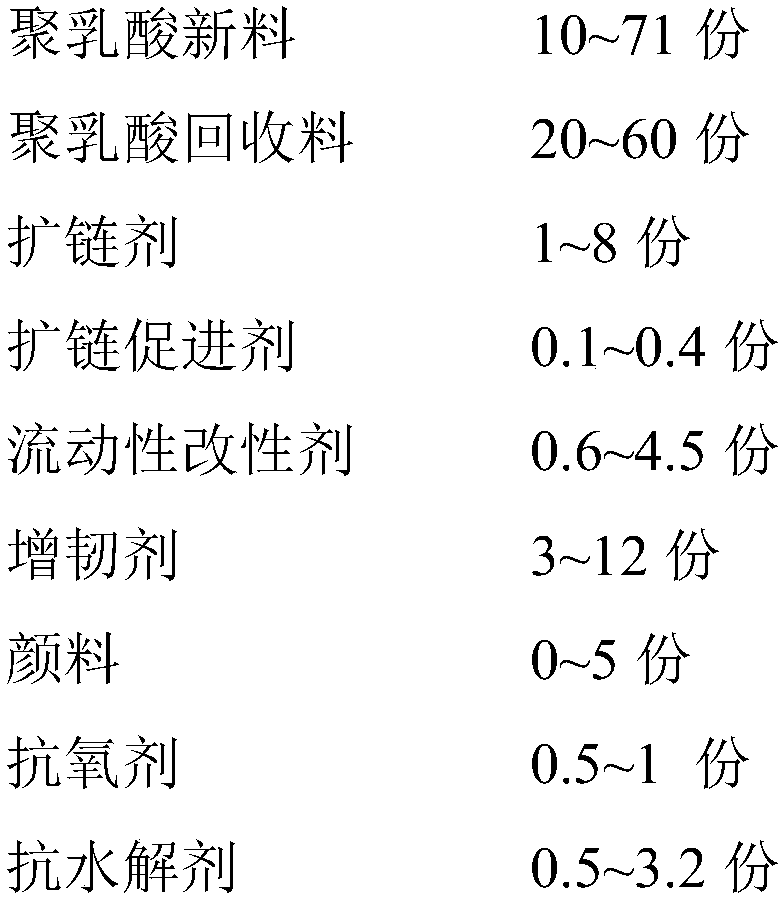

3D printing wire prepared from polylactic acid recycling material and preparation method

ActiveCN108410147AFlat surfaceNo brittle fractureAdditive manufacturing apparatusPolymer scienceAccelerant

The invention belongs to the field of preparation of macromolecular 3D printing wires, and discloses a 3D printing wire prepared from a polylactic acid recycling material and a preparation method. Forovercoming the shortcomings that the polylactic acid recycling material can be degraded after being subjected to several times of high-temperature extrusion processes, thus, the prepared 3D printingwires are high in brittleness, not high in tensile property, not smooth in surface and uneven in wire diameter, and a 3D model printed by the material deforms severely, has obvious interlayer concavemarks and is low in surface gloss, the polylactic acid recycling material is added with functional auxiliaries such as a chain extender, a chain extending accelerant, a flowable agent and a tougheningagent, the prepared wire is stable in diameter and smooth in surface, when printed by an FDM method, the material is extruded stably, and the prepared 3D printed device is smooth and flat in surfaceand does not deform.

Owner:SOUTH CHINA INST OF COLLABORATIVE INNOVATION

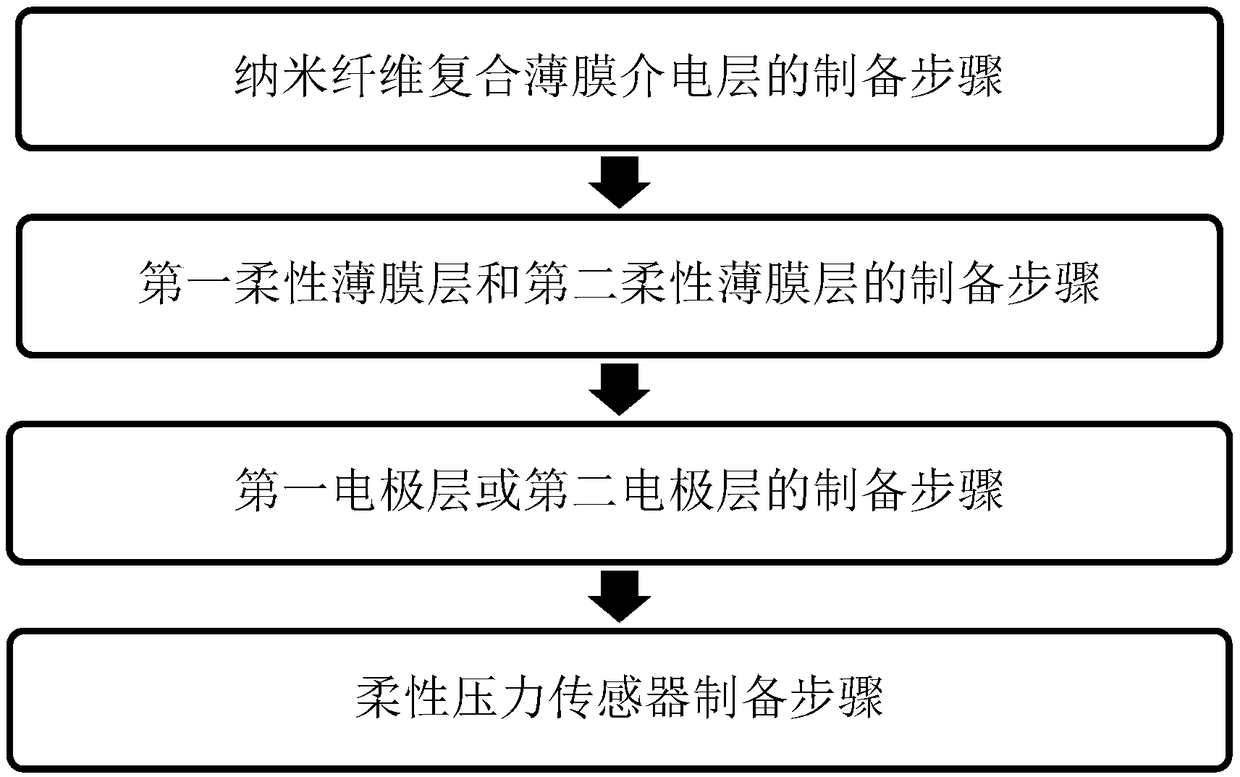

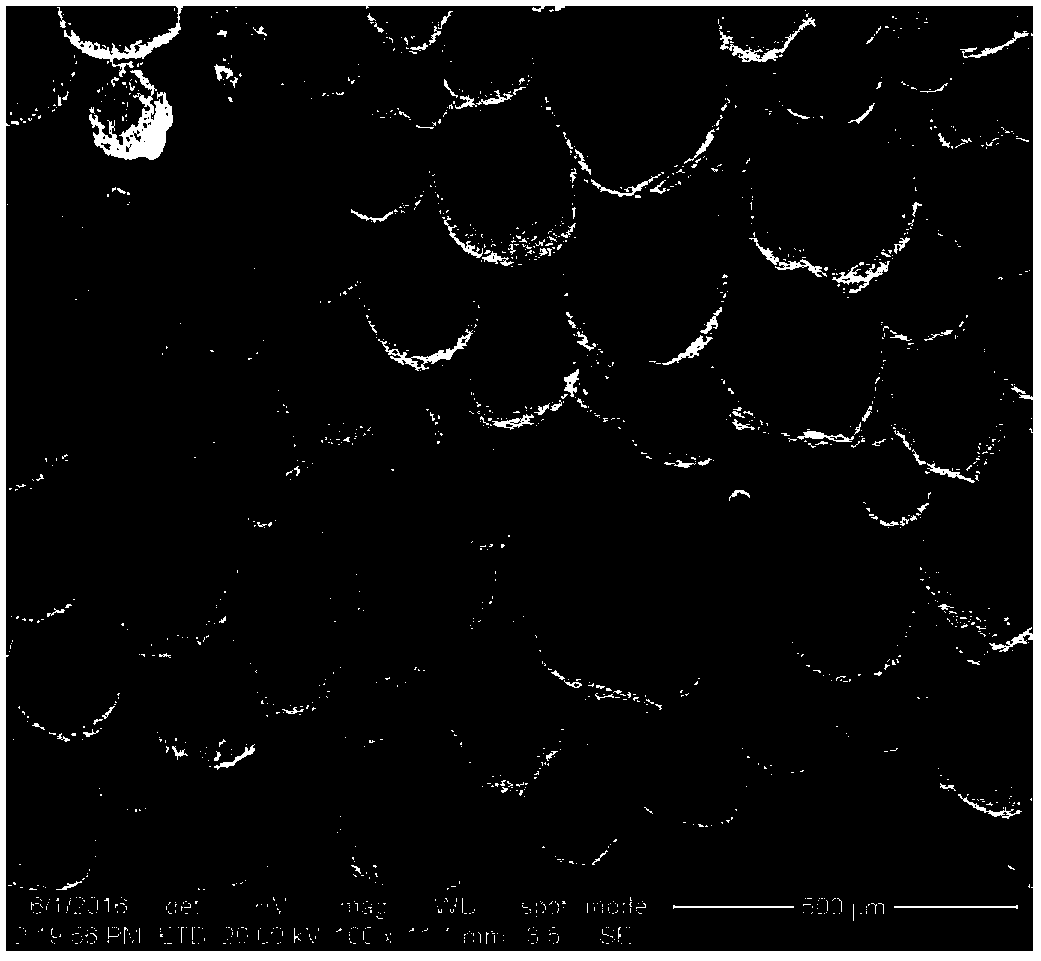

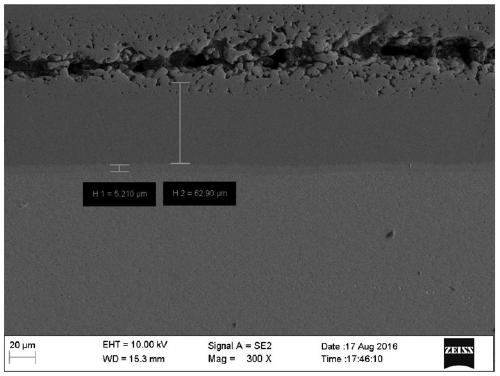

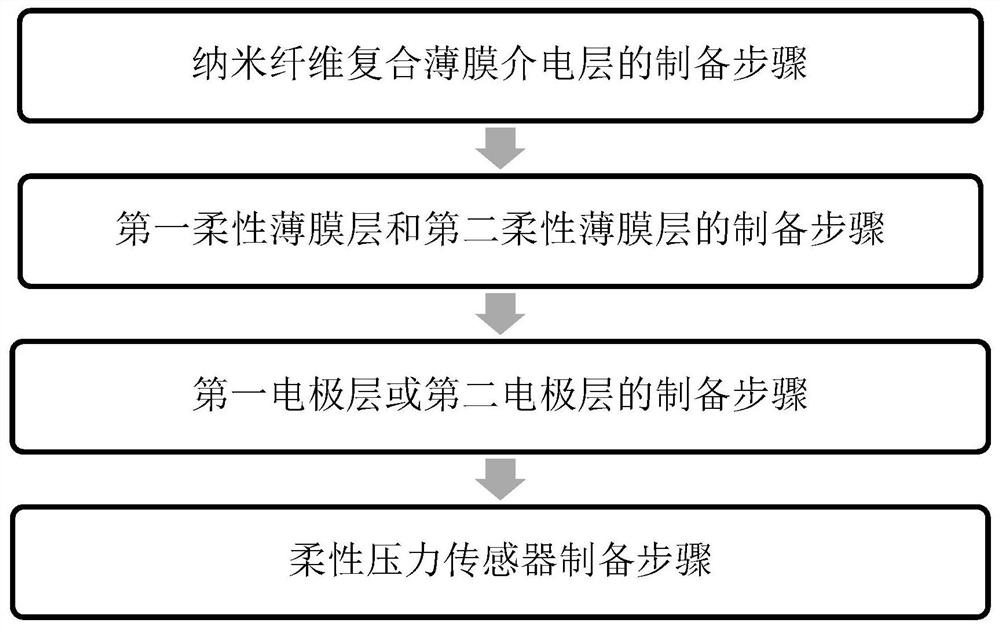

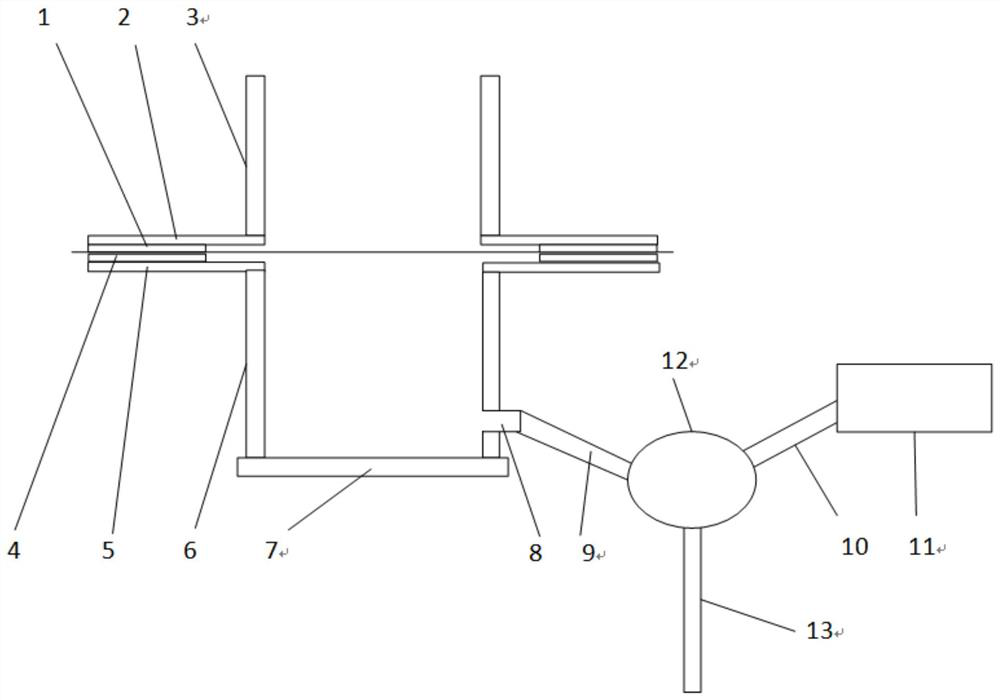

Flexible pressure sensor using graphene as electrode material and preparation method thereof

ActiveCN109341902AStrong bending resistanceNo brittle fractureFluid pressure measurement by electric/magnetic elementsForce measurementFiberNanofiber

Provided is a flexible pressure sensor using graphene as the electrode material. Two outer flexible film layers are doped PCL electrospun films with graphene micro-sheets of which the average radial size is higher than 5-10 microns. Two electrode layers are conductive ink containing graphene micro-sheets with large radial size and nano-silver particles with minimal agglomeration. A dielectric layer is electrospun from nano-fibers. A preparation method for preparing the flexible pressure sensor and a special preparation device are further provided.

Owner:国宏中晶集团有限公司

Airfield runway pavement layer prepared from high-toughness impact-resistant cement-based composite material

InactiveCN103265247AImprove toughnessImprove impact resistanceSolid waste managementRepair materialRoad surface

The invention discloses an airfield runway pavement layer prepared from a high-toughness impact-resistant cement-based composite material. The airfield runway pavement layer prepared from the high-toughness impact-resistant cement-based composite material comprises a first ingredient and a second ingredient. The first ingredient comprises 22 to 45wt% of cement, 15 to 33wt% of waste, 20 to 33wt% of sand, 13 to 20wt% of water, 2 to 6wt% of a polymer emulsion, 0.2 to 1.0wt% of a water reducer, 0.5 to 1.0wt% of an antifoaming agent and 0.2 to 0.6wt% of a curing agent. The second ingredient comprises fibers, wherein the use amount of the fibers is 0.5 to 5wt% of the total amount of the cement, the waste and the sand. The high-toughness impact-resistant cement-based composite material has the advantages of ultrahigh toughness, good anti-permeability, good wear resistance, good impact resistance and green environmental protection performances. The airfield runway pavement layer prepared from the high-toughness impact-resistant cement-based composite material satisfies airfield runway concrete material performance requirements, and has greatly improved fracture resistance, anti-permeability and impact resistance. The high-toughness impact-resistant cement-based composite material can be used as a repair material of a bridge floor and a road pavement.

Owner:CHINA UNIV OF PETROLEUM (BEIJING) +1

Preparation method for environment-friendly TPU

InactiveCN108997557AImprove insulation effectImprove flame retardant performancePolyesterDistillation

The invention relates to a preparation method for an environmentally-friendly TPU. The preparation method comprises the following steps: mixing polyether polyol with polyester polyol, carrying out pressure-reduced distillation to remove moisture therein, then adding hexamethyldiisocyanate, and carrying out a reaction at 37 DEG C under nitrogen protection for 40-45 min to obtain a prepolymer A; adding a catalyst into the prepolymer A, carrying out a reaction at 45-48 DEG C for 20-15 min, then adding a composite additive, carrying out stirring treatment for 40-50 min so as to obtain a prepolymerB; and adding a chain extender into the prepolymer B, carrying out a reaction at 70-72 DEG C for 55-70 min to obtain a polyurethane elastomer. The TPU of the invention has good processing properties,and is not significantly reduced in performance during molding process, free of toxicity to environment and human beings and improved in environmental safety.

Owner:界首永恩机电科技有限公司

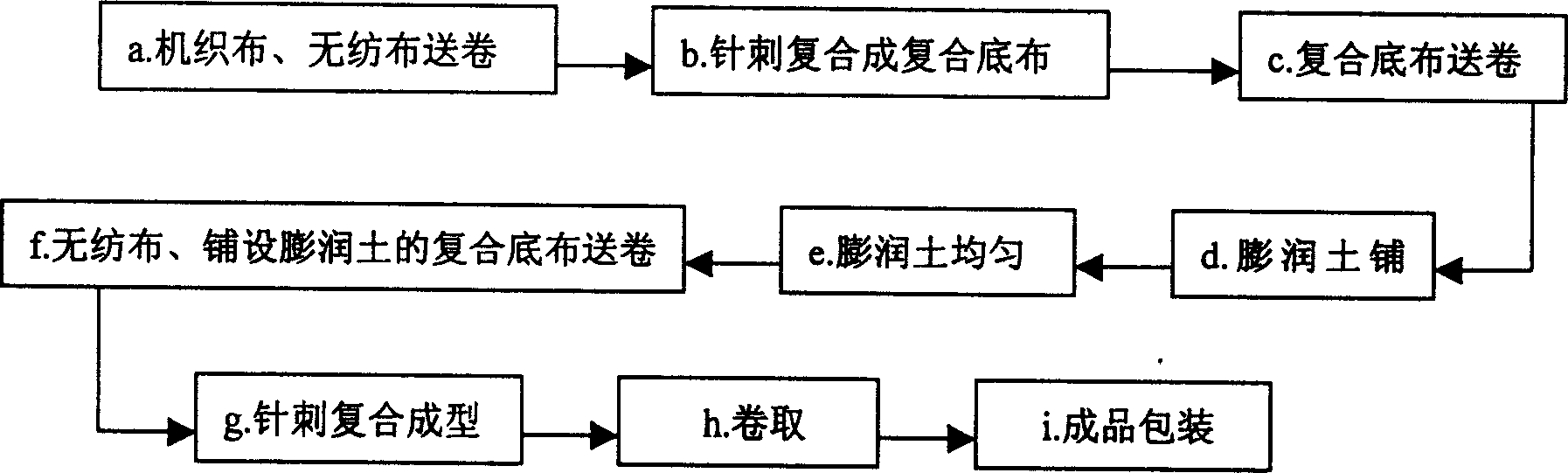

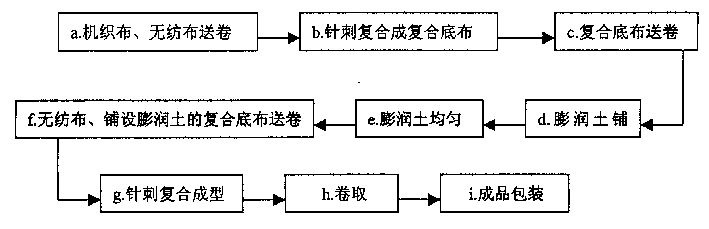

Method for fabricating composite geomaterial in wide size

Owner:SHANGHAI NEW TECHTEXTILES

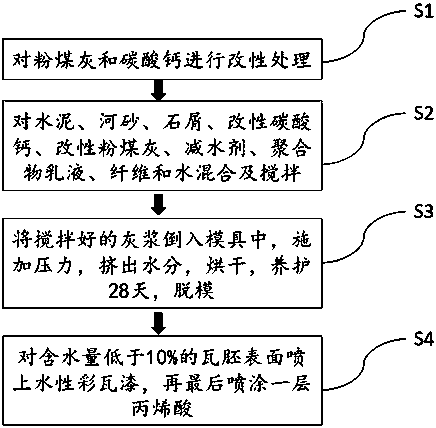

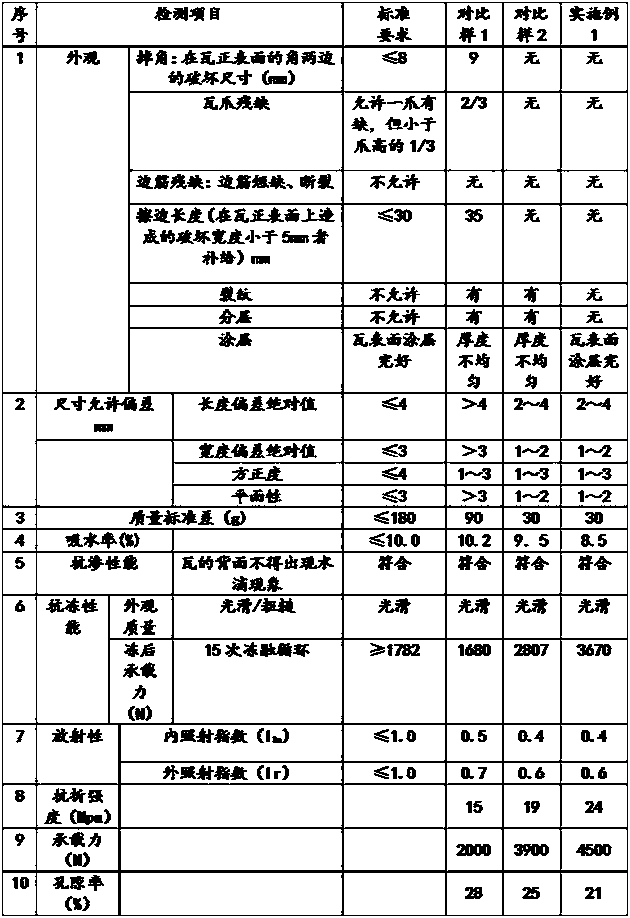

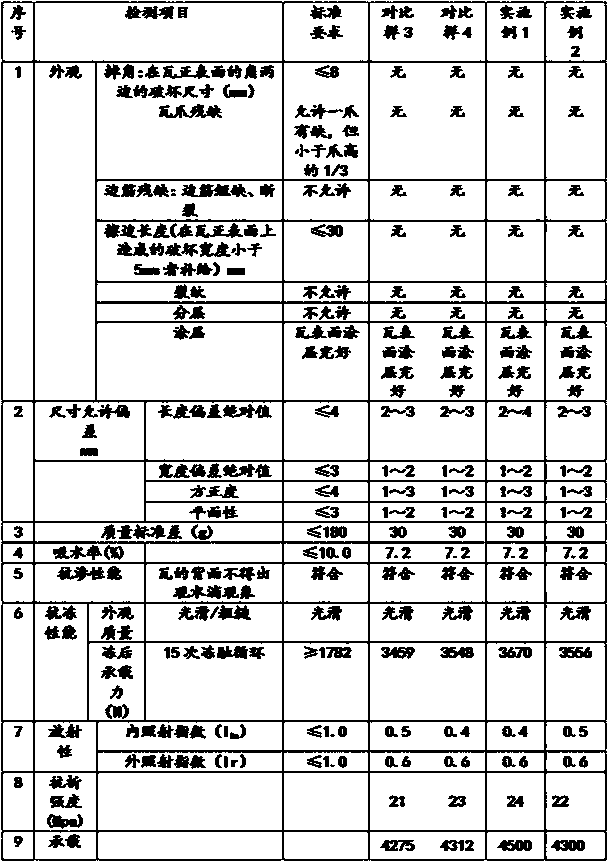

Durable concrete colored tile

ActiveCN107935490AImprove bending resistanceHigh compressive strengthSolid waste managementFiberLacquer

The invention provides a durable concrete colored tile and a preparation method thereof. The durable concrete colored tile comprises the following raw materials in parts by mass: 40 to 80 parts of cement, 20 to 60 parts of modified fly ash, 10 to 30 parts of modified calcium carbonate, 20 to 60 parts of fine sand, 10 to 40 parts of stone chips, 18 to 55 parts of water, 4 to 16 parts of a polymer emulsion, 1 to 6 parts of fiber, 0.1 to 1 part of a water reducing agent, 1 to 5 parts of color tile paint and 1 to 5 parts of a sealant. The durable concrete colored tile provided by the invention hasgood mechanical properties and impermeability, has high bearing capacity after freezing, does not generate color-fading and color-losing phenomenons in 5 years, and is free of cracks on a coating.

Owner:广东鸿业管桩有限公司

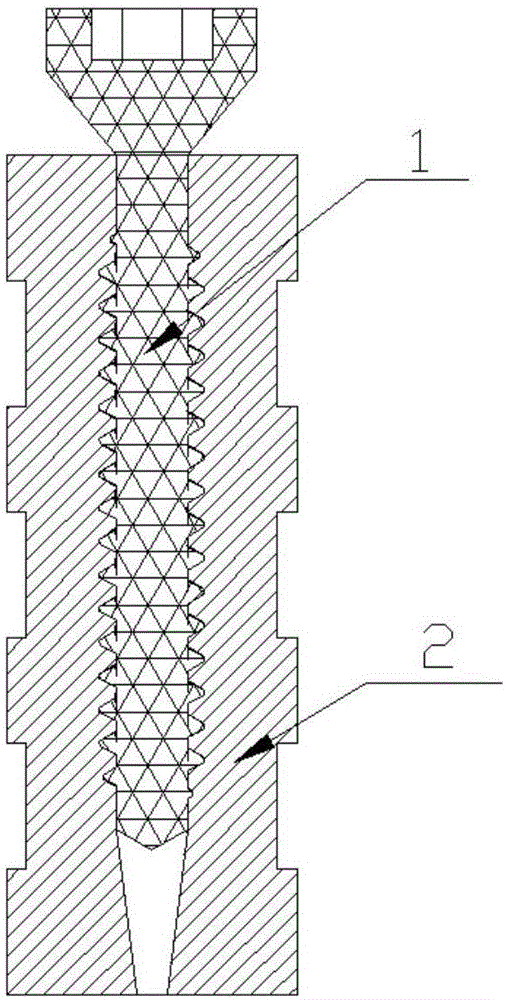

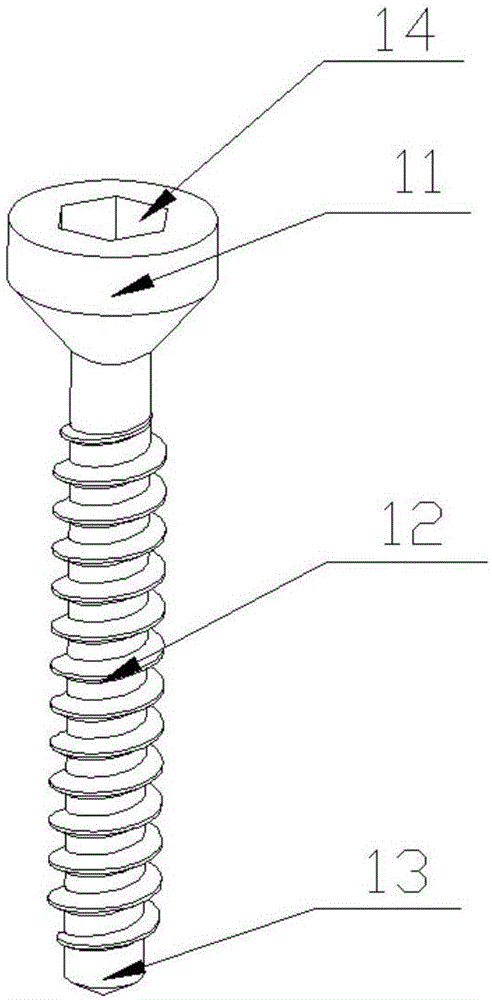

Bone screw covered with soft material

InactiveCN106420024APrevent rotationEffectively fixedInternal osteosythesisFastenersInterference fitRound table

The invention provides a bone screw assembly covered with soft material. The bone screw assembly comprises a bone nail body and outer covering soft material body; the outer covering soft material body is provided with a cavity in the center; the cavity is an inverted round table cavity; smooth parts and protruding sawtooth parts are arranged at the outer covering soft material body with equal intervals and one smooth part is arranged between two protruding sawtooth parts, wherein the number of the protruding sawtooth parts is n and the number of the smooth parts is n-1. The bone screw comprises outer layer soft material and an inner layer rigid screw; during the process of implanting, interference fit is formed to firmly fix the bone screw and affected parts; smooth parts and protruding sawtooth parts are arranged at the outer covering soft material body with equal intervals so as to guarantee that the bone screw assembly will not rotate at will and broken bones can be firmly fixed.

Owner:SUZHOU SEEMINE NEBULA BIOTECH CO

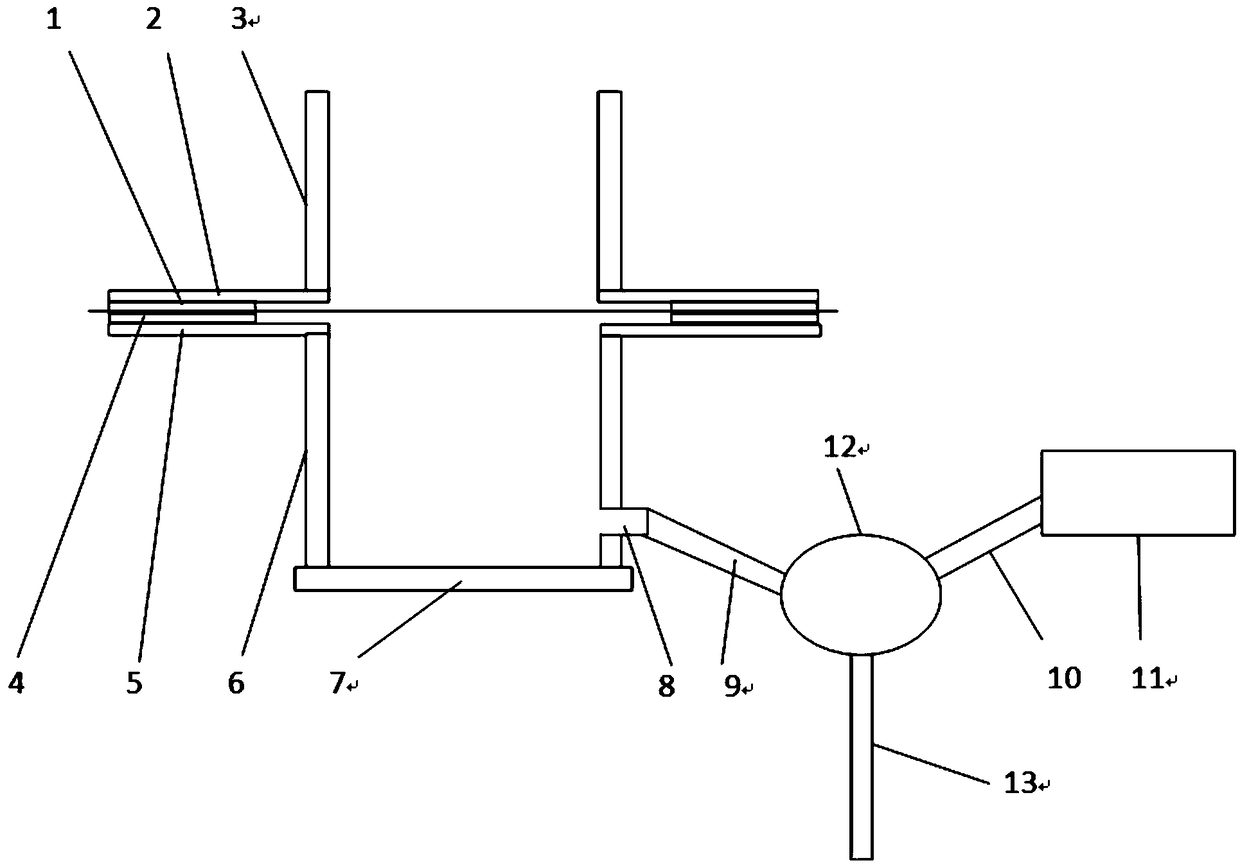

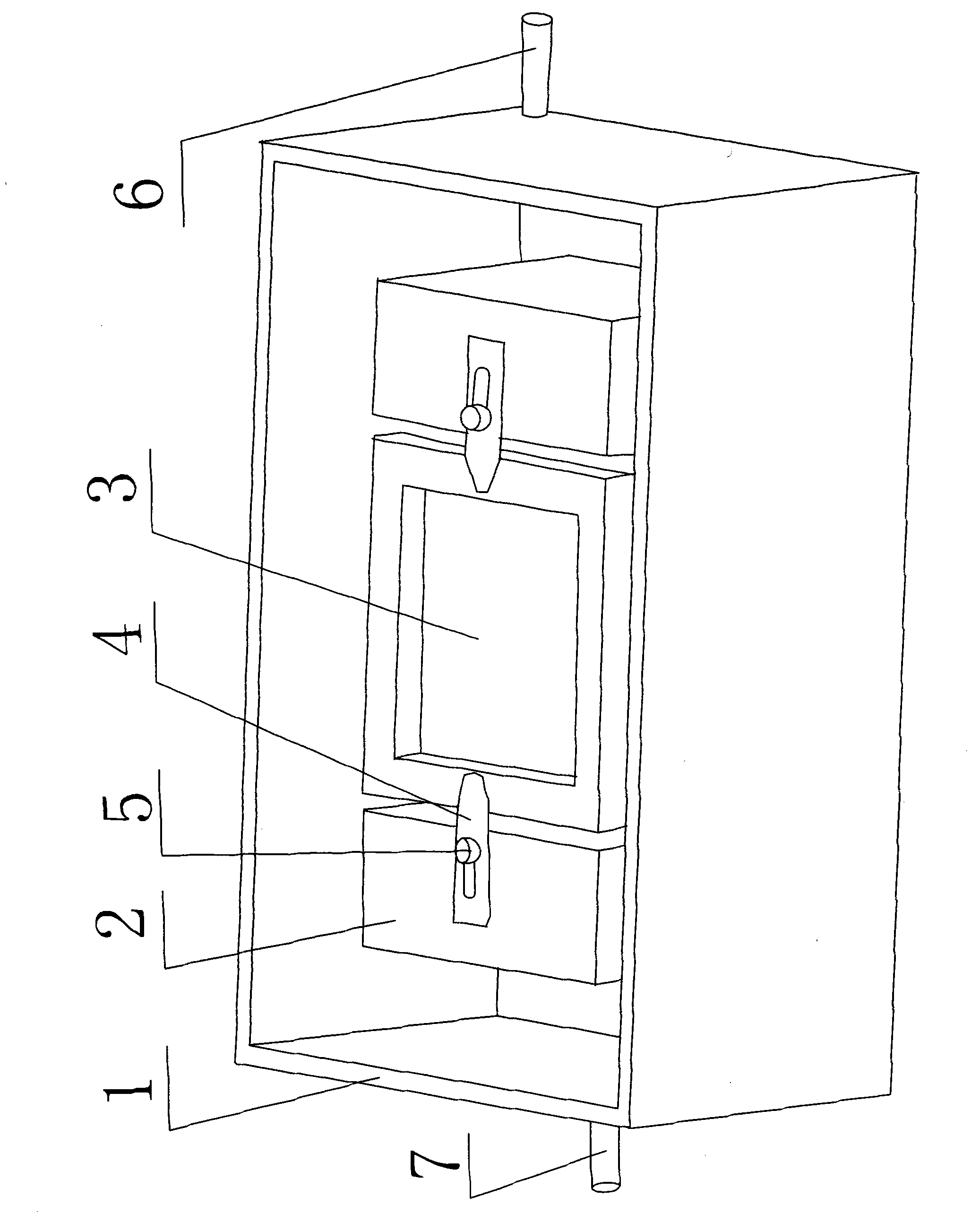

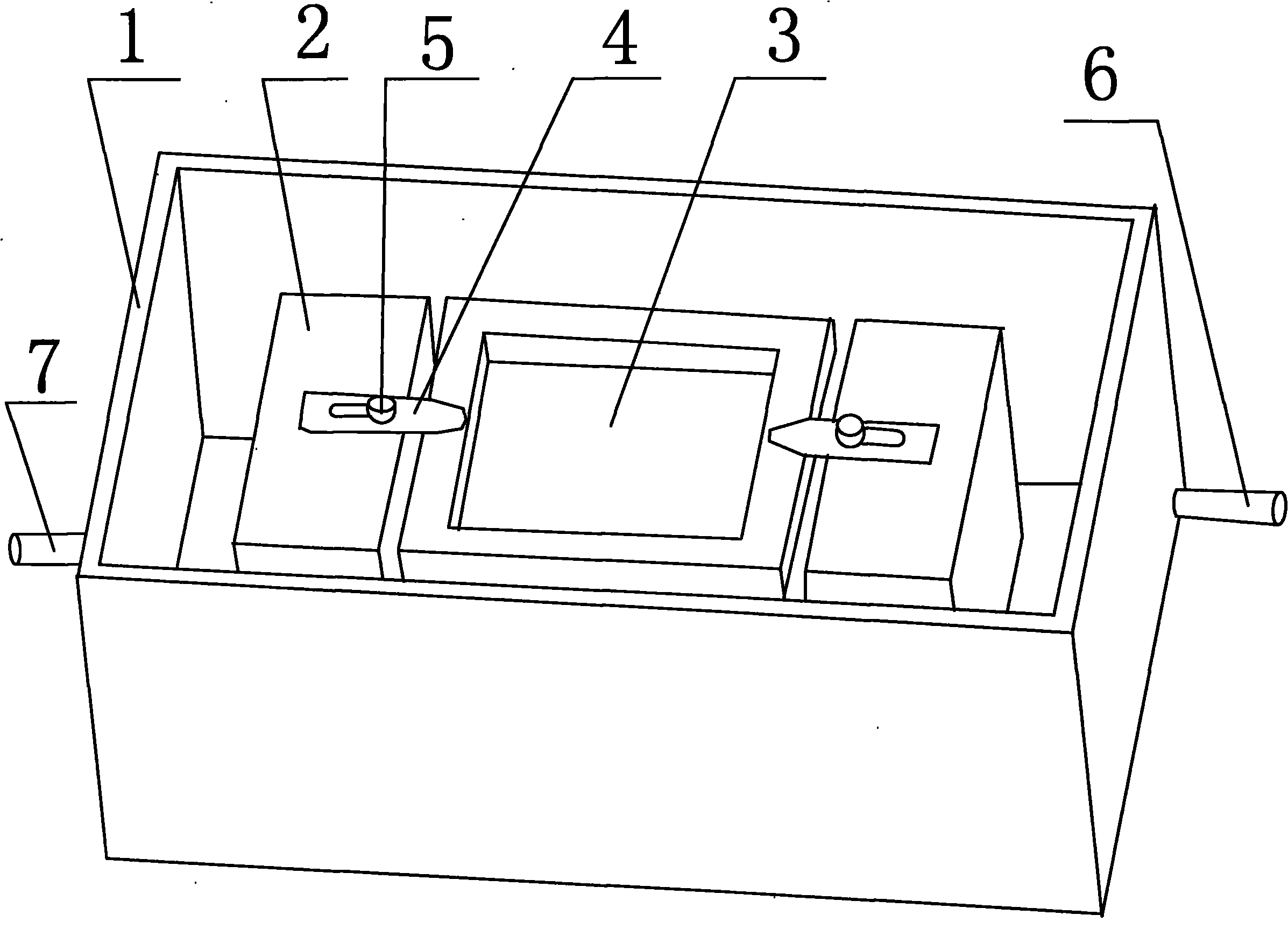

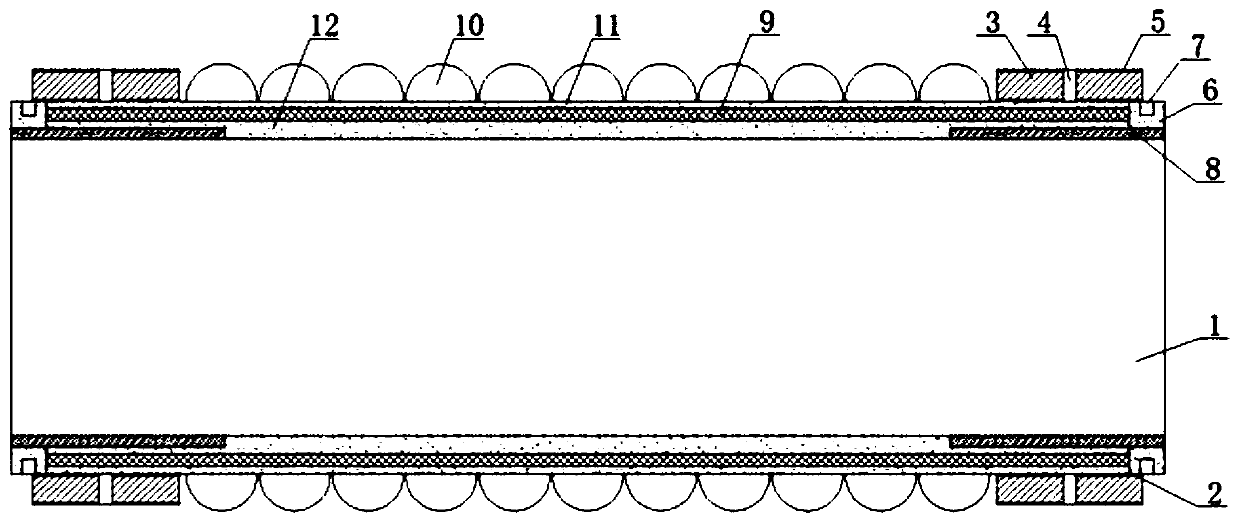

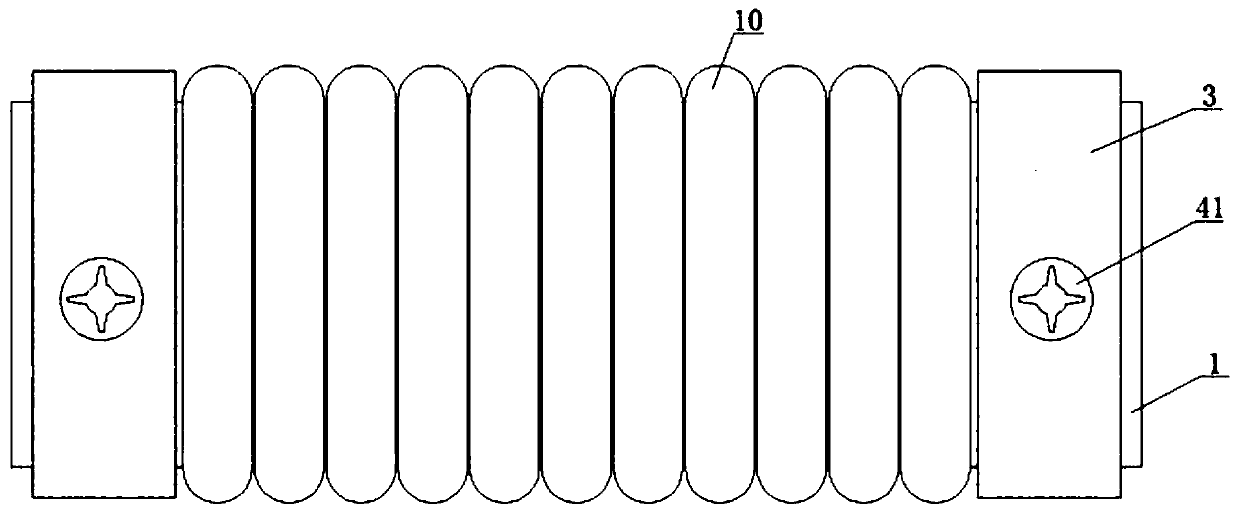

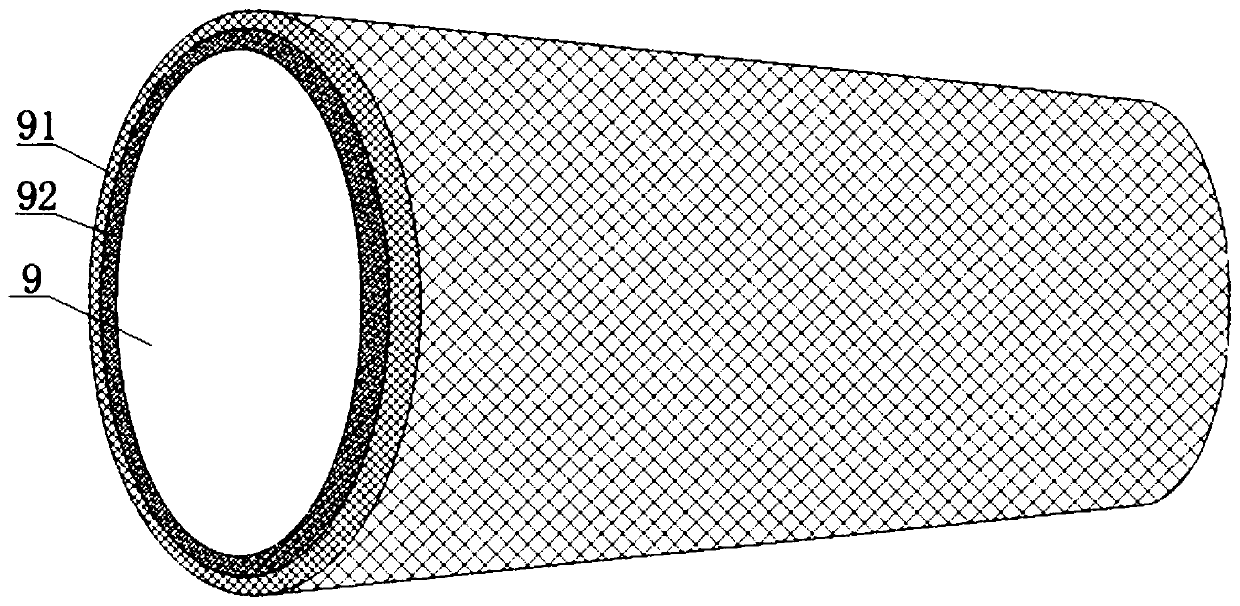

Mechanical processing device and method of ceramic-based complex curved surface parts with wave transmissivity

The invention relates to a mechanical processing device and a method of ceramic-based complex curved surface parts with wave transmissivity. Most of parts of an aircraft are products with complex curved surfaces, the design and production cycle is long, and the processing workload accounts for more than 65% of that of the whole system; and a wave-transmitting radome has the characteristics of small dimension, compact structure and the like as a key part of a fairing of the aircraft, thereby affecting the flight performance of the aircraft. The device comprises a water storage tank (1), wherein a padding block (2) is arranged in the water storage tank, a workpiece (3) is mounted in the middle of the padding block, a fire poker (4) with a long circular hole is arranged on the padding block (2), the fire poker is fixed on the padding block by using a bolt (5) when pressing the processed workpiece, a water outlet (6) is formed below one side outside the water storage tank, and a water inlet (7) is formed above one side outside the water storage tank. The device is used for SiO2 fiber- toughened SiO2 ceramic-based composite materials, in particular to mechanical processing of the ceramic-based complex curved surface parts with the wave transmissivity.

Owner:航天科工哈尔滨风华有限公司

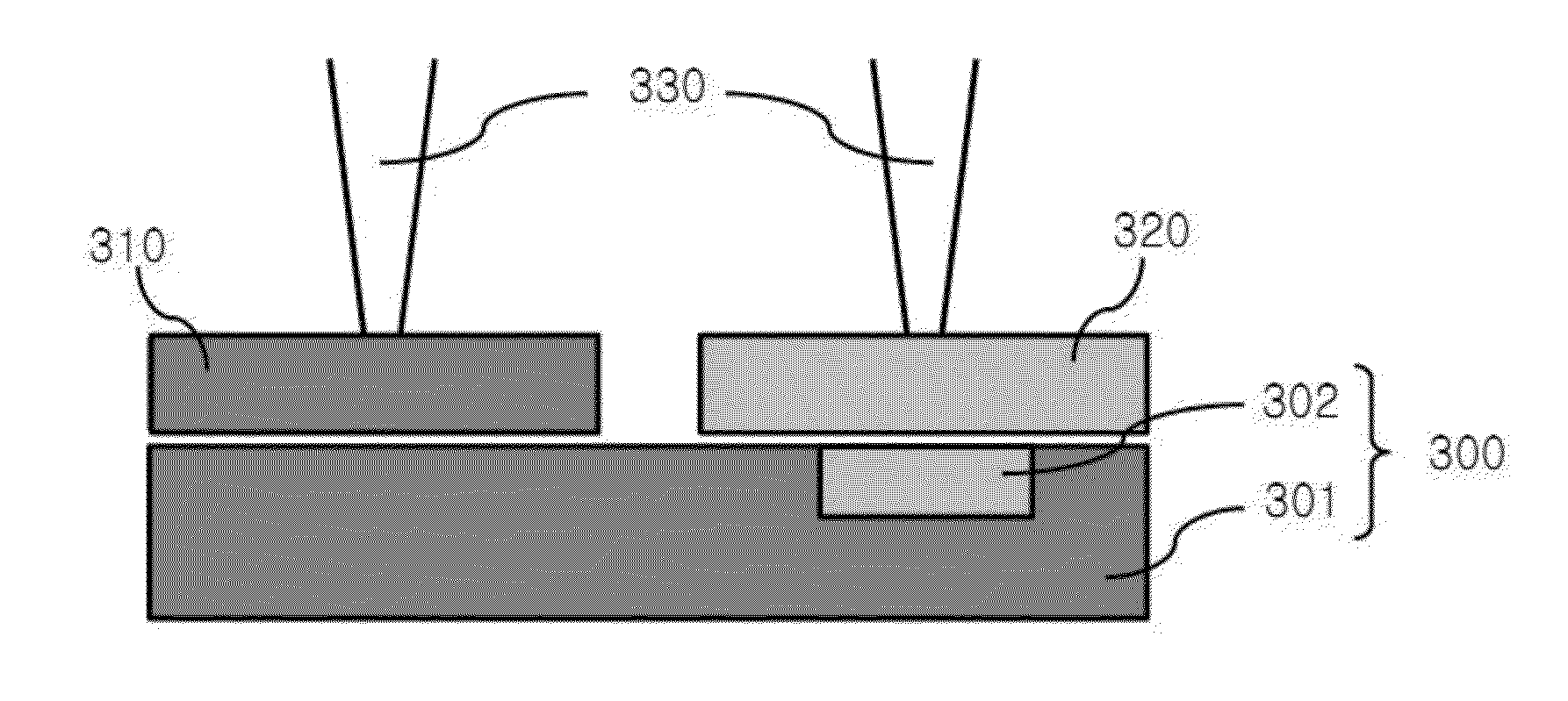

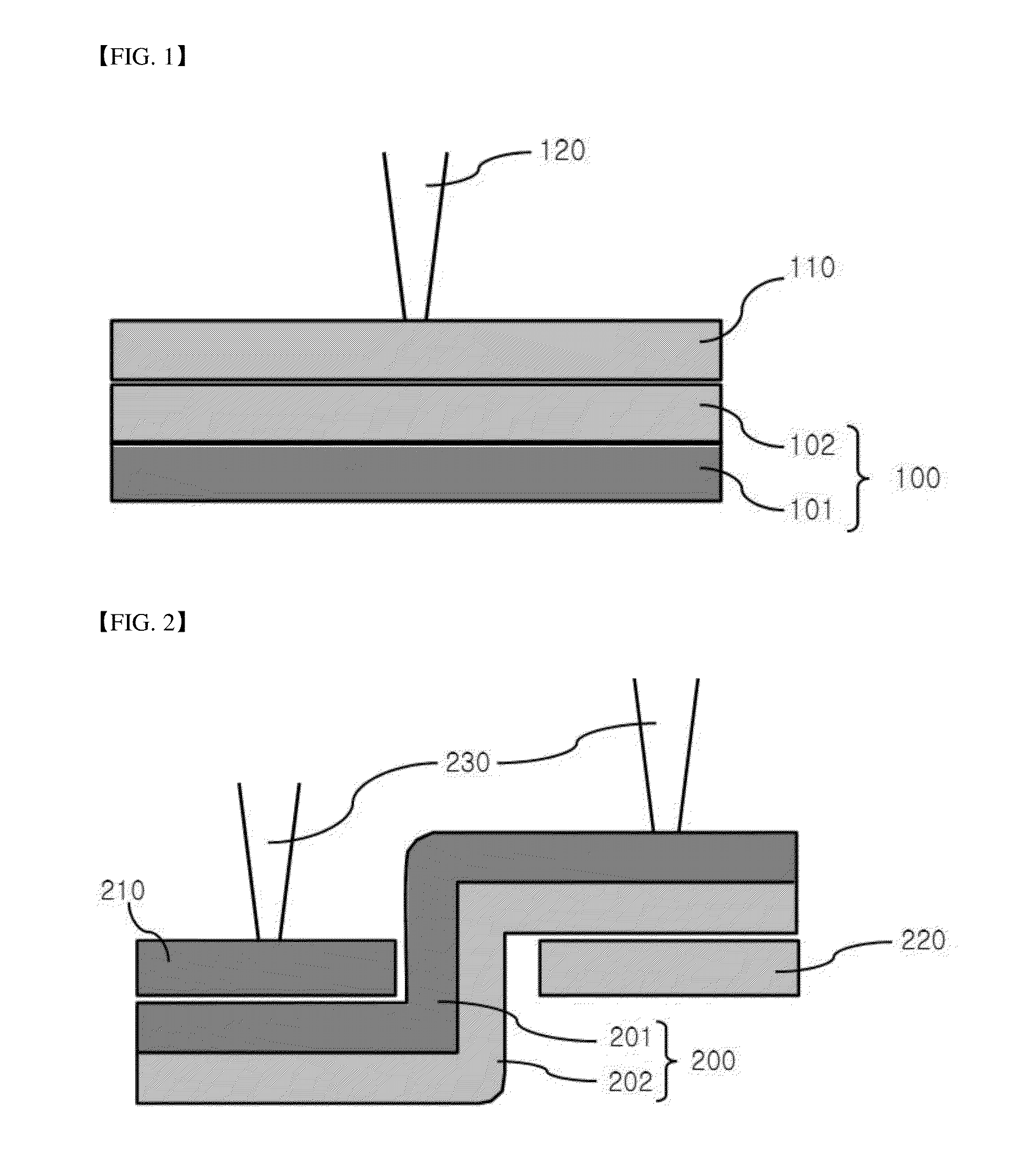

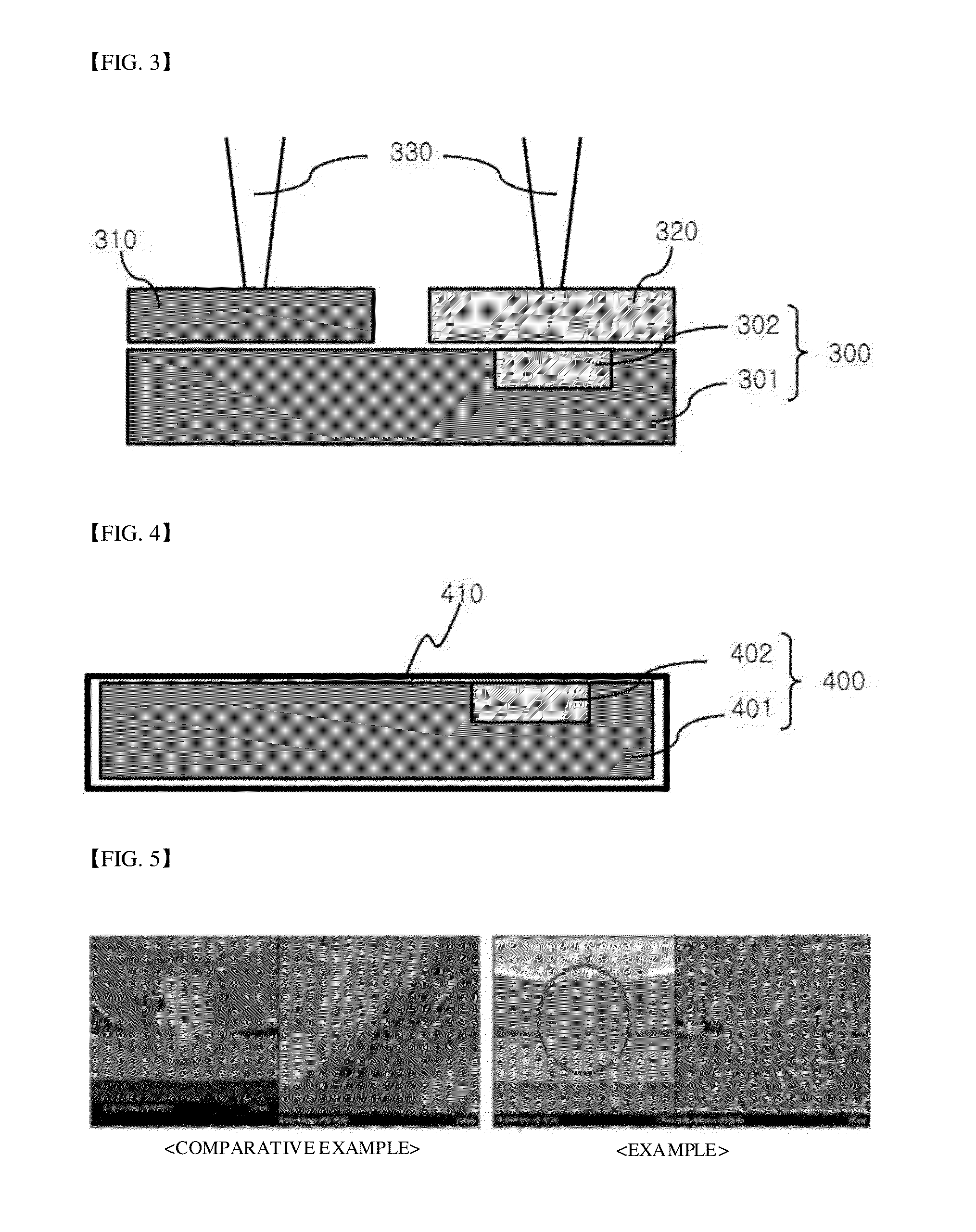

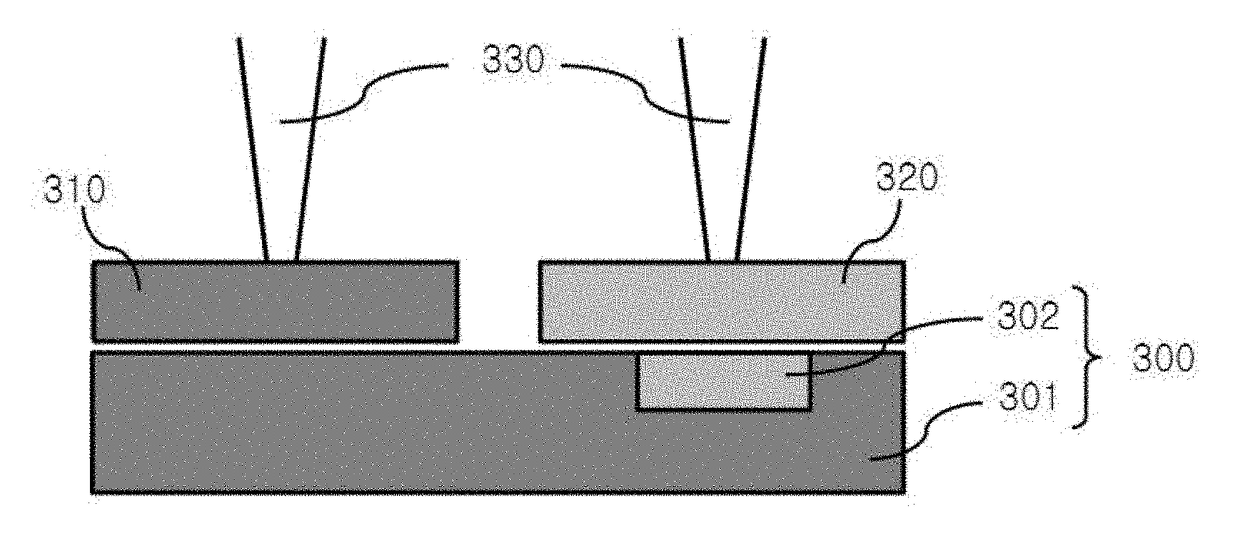

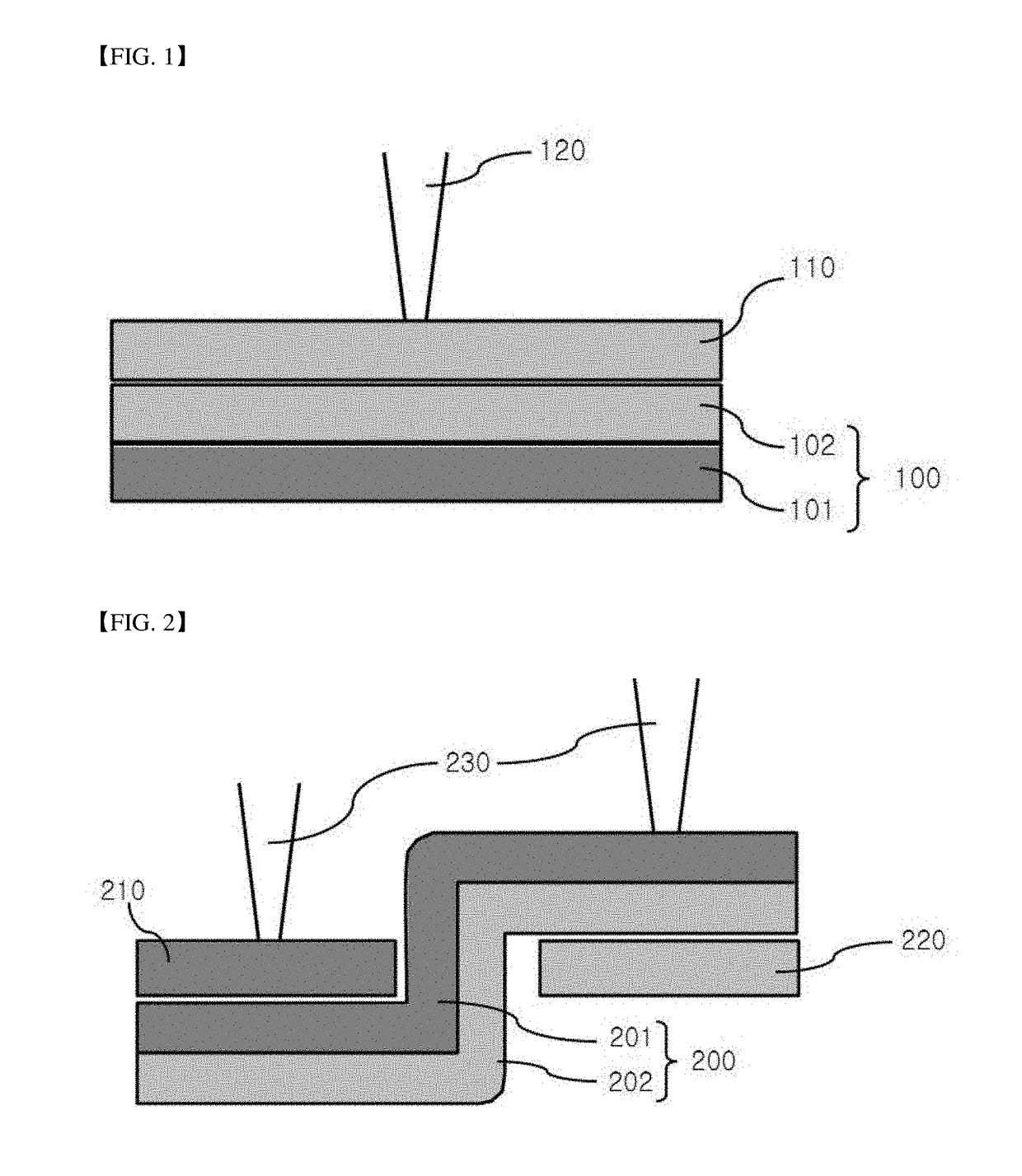

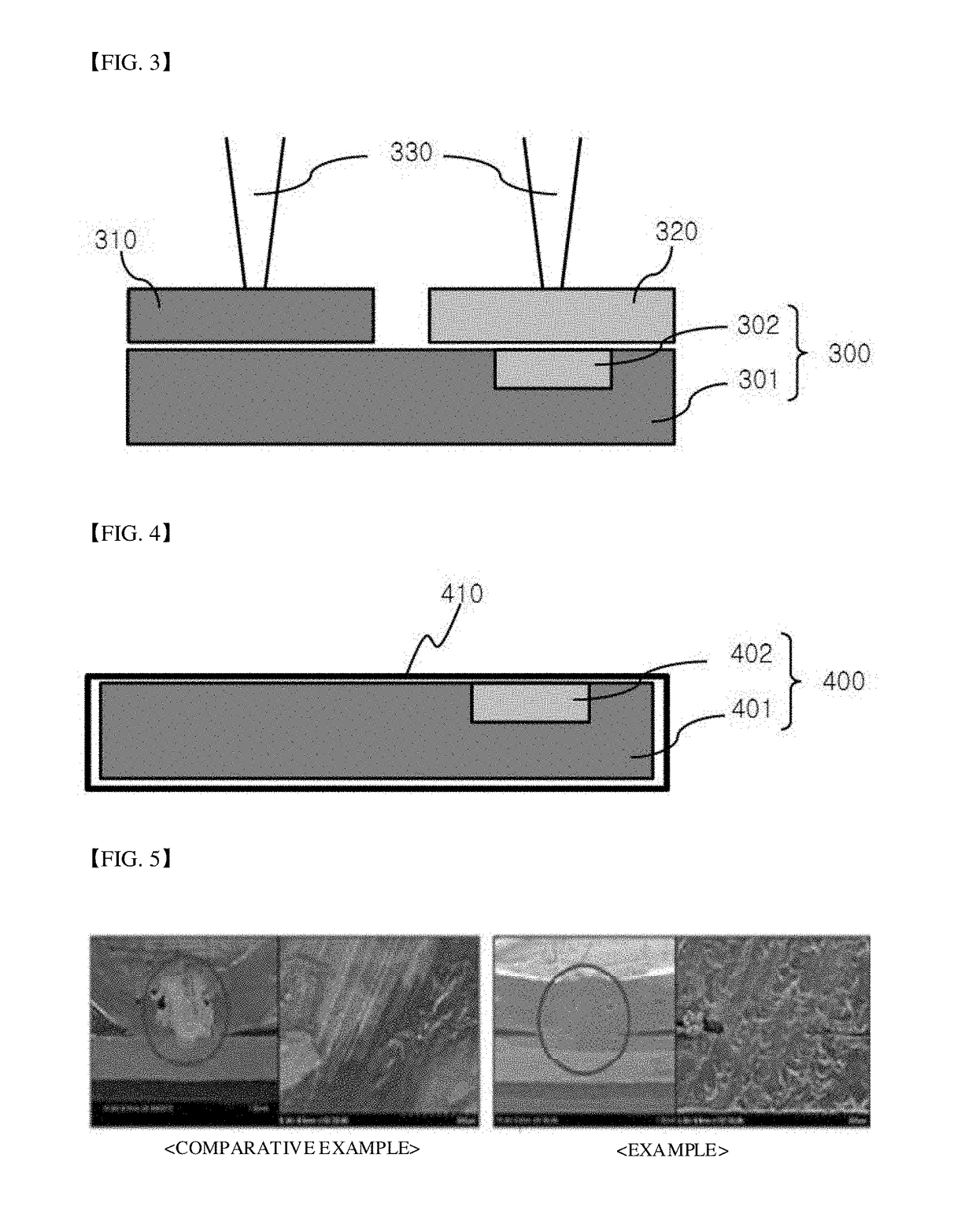

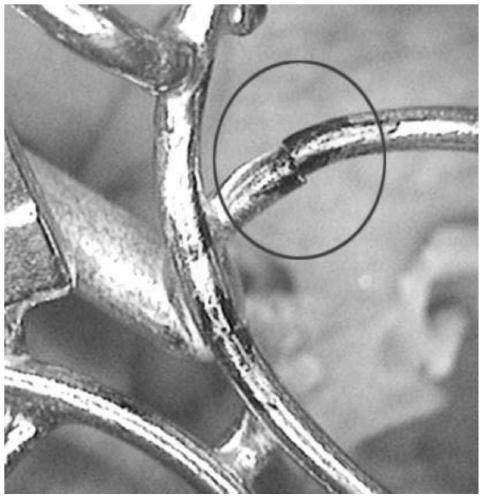

Battery module comprising connecting member composed of dissimilar metals

ActiveUS20160141583A1Easy to processNo brittle fracturePrimary cell to battery groupingSmall-sized cells cases/jacketsEngineeringBattery cell

Disclosed herein is a battery module including battery cells, electrode terminals of which are electrically connected to each other via a connecting member, wherein each of the battery cells is configured to have a structure in which an electrode assembly is mounted in a battery case made of a laminate sheet including a metal layer and a resin layer, and plate-shaped electrode terminals protrude from the battery case, the electrode terminals include a first electrode terminal and a second electrode terminal made of dissimilar metals, the connecting member includes a main connecting part, to which the first electrode terminal is welded, the main connecting part including the metal of the first electrode terminal, and a buried connecting part, to which the second electrode terminal is welded, the buried connecting part including the metal of the second electrode terminal, the buried connecting part is buried in the main connecting part in a state in which the buried connecting part is exposed at one surface of the main connecting part such that the buried connecting part has the same height as the main connecting part to form an even surface, and the first electrode terminal and the second electrode terminal are welded respectively to the main connecting part and the buried connecting part at one surface of the main connecting part at which the buried connecting part is exposed.

Owner:LG ENERGY SOLUTION LTD

Si3N4 foam ceramic reinforced aluminum-based composite material and preparation method and application thereof

The invention discloses a Si3N4 foam ceramic reinforced aluminum-based composite material and a preparation method and an application thereof. The composite material comprises an aluminum matrix and Si3N4 foam ceramic; and the Si3N4 foam ceramic comprises a Si3N4 foam ceramic skeleton and columnar beta Si3N4 crystal grains which grow on the hole wall of the Si3N4 foam ceramic skeleton in situ, thealuminum matrix uniformly fills pores of the Si3N4 foam ceramic skeleton, and the columnar beta Si3N4 crystal grains are coated with the aluminum matrix. The preparation method of the composite material comprises the following steps that liquid metal aluminum is pressed into the pores of the Si3N4 foam ceramic skeleton by adopting a vacuum air pressure infiltration process so as to obtain the Si3N4 foam ceramic reinforced aluminum-based composite material. The Si3N4 foam ceramic reinforced aluminum-based composite material has the advantages of being good in toughness and erosion resistance,good in mechanical processing performance and the like. The preparation method is simple in process and suitable for batch production.

Owner:NAT UNIV OF DEFENSE TECH

Thorium tungsten wire used for winding microwave oven magnetron and manufacturing method of thorium tungsten wire

ActiveCN103346054AIncrease in crystal defectsSuppress coarseningTransit-tube cathodesCold cathode manufactureMicrowave ovenThorium oxide

The invention belongs to the technical field of metal material manufacturing, and particularly relates to a thorium tungsten wire used for winding a microwave oven magnetron and a manufacturing method of the thorium tungsten wire. The thorium tungsten wire is characterized by comprising 0.5-1.5% of thorium oxide, 0.0020-0.0080% of potassium and 97-98% of tungsten. Compared with the prior art, the thorium tungsten wire and the manufacturing method have the advantages that (1) according to the thorium tungsten wire, though 0.0020-0.0080% of the potassium is added, thorium oxide particles are still fine and uniform; (2) the thorium tungsten wire contains microelement potassium in content, after coils of the microwave oven magnetron wound through the thorium tungsten wire are carbonized at a high temperature, crystal grains cannot grow larger easily, organization stability is maintained, and the situation that the microwave oven magnetron cannot break due to shaking in the packaging and delivery transportation processes after being produced is guaranteed.

Owner:威海多晶钨钼科技有限公司

Preparation method of environmental-friendly degradable high-density polyethylene pipe material

The invention discloses a preparation method of an environmental-friendly degradable high-density polyethylene pipe material. The polyethylene pipe material is prepared from the following ingredientsin parts by weight: 20 to 40 parts of high-density polyethylene, 10 to 20 parts of toughening master batch, 5 to 10 parts of calcium carbonate superfine powder, 4 to 12 parts of glass fiber, 2 to 6 parts of nanometer silicon micro powder, 2 to 6 parts of graphene, 3 to 9 parts of hollow microspheres, 2 to 8 parts of carbon nanometer tubes, 4 to 10 parts of silane coupling agents and 2 to 8 parts of fire retardants. The preparation method is simple; the prepared polyethylene pipe material has excellent fireproof, pressure-resistant and anti-tearing performance; meanwhile, the degradable performance is good; the environment pollution cannot be caused.

Owner:赵丽莎

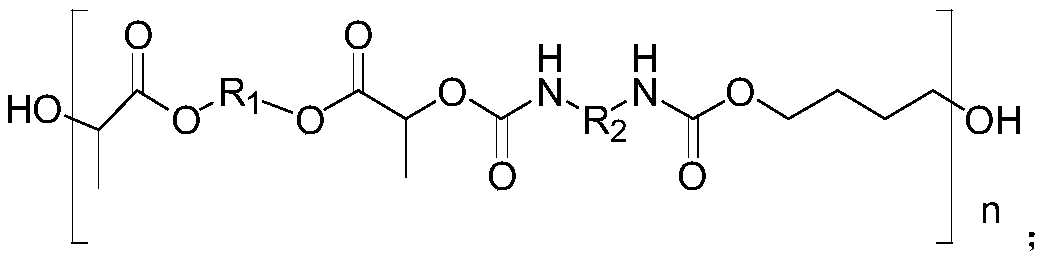

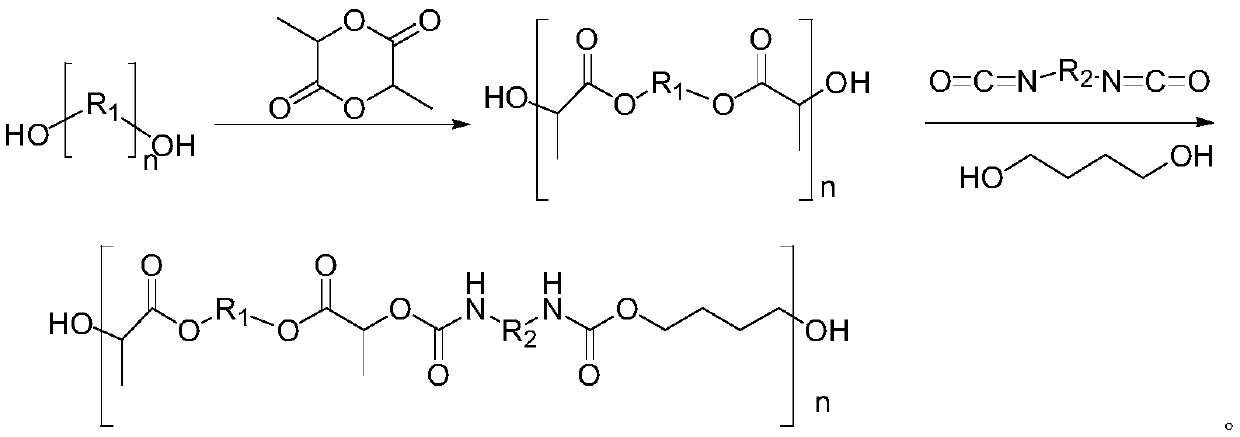

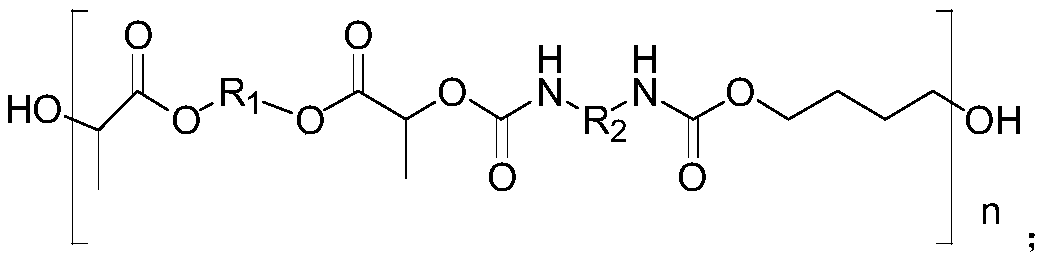

Polylactic acid-based thermoplastic polyurethane modified polylactic acid composite material and preparation method and application thereof in 3D printing consumables

ActiveCN111378262AImprove toughnessImprove roundnessAdditive manufacturing apparatusPolylactic acidThermoplastic polyurethane

The invention discloses a polylactic acid-based thermoplastic polyurethane modified polylactic acid composite material and a preparation method and application thereof in 3D printing consumables, which belong to the technical field of 3D printing. The material comprises the following raw material components in parts by mass: 60-90 parts of polylactic acid, 3 to 20 parts of polylactic acid-based thermoplastic polyurethane, 1-5 parts of an inorganic filler, 1-5 parts of a cross-linking agent, and 0.2 to 1 part of a stabilizing agent. The structural general formula of the polylactic acid-based thermoplastic polyurethane is shown in the specification, and a group R1 in the structural general formula is selected from polyalkyl ether, the group R2 is selected from one of straight-chain hexyl ormethane diphenyl, and the mesh number of the inorganic filler is 3000 to 5000 meshes. The composite material is good in 3D printing performance and high in printing precision.

Owner:XIAOGAN ESUN NEW MATERIAL +1

Grinding agent for dental ceramic material

ActiveCN101463229AGood dispersionUniform particle size distributionOther chemical processesPolishing compositions with abrasivesIonMachining process

The invention relates to a grinding agent for dental ceramic materials, comprising, based on weight percent, the following ingredients: 10%-40% of grinding materials; 0.1%-0.8% of a surfactant; 1%-10% of a brightening agent and deionized water as the balance. The invention has the following technical effects that: 1) the grinding agent has great dispersity and uniform particle size distribution, and can efficiently reduce scratches on the surface of the grinded dental ceramic materials while enhancing the brightness; 2) adding the surfactant can effectively control the uniformity of grinding and polishing during the course of working and lessen the defects on the surface; in addition, the polishing rate can be improved dramatically and the polishing process is free from the brittle fracture of the dental ceramic materials; 3) adding the brightening agent in the process of processing the dental ceramic materials can advance the brightness on the surface of the polished dental ceramic materials and naturalize the color thereof, thus meeting exquisite beauty appreciating demands of people; 4) the grinding solution of the invention is neutral and has good chemical stability and ideal usage safety.

Owner:JIANGSU HAIXUN IND GROUP SHARE

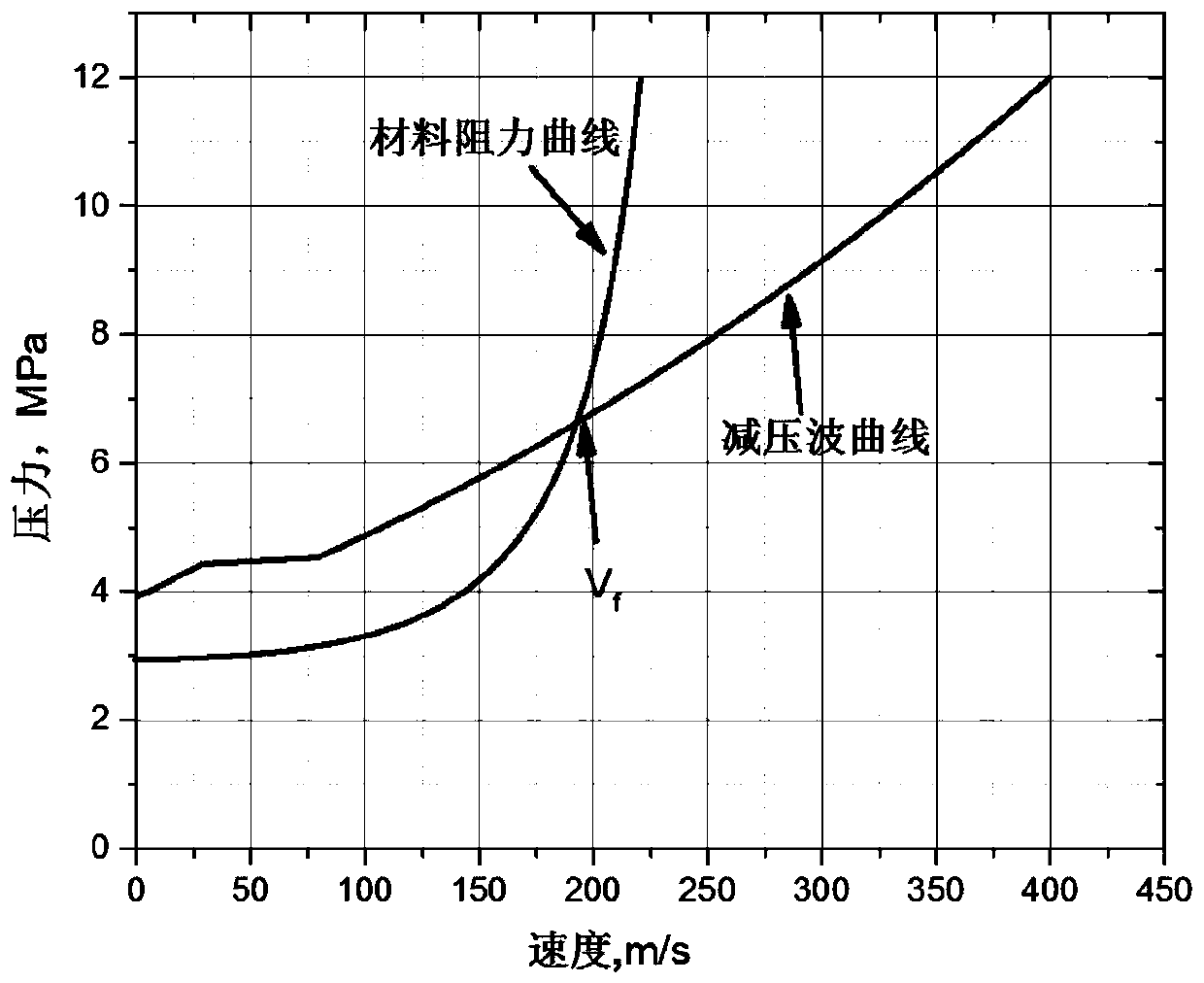

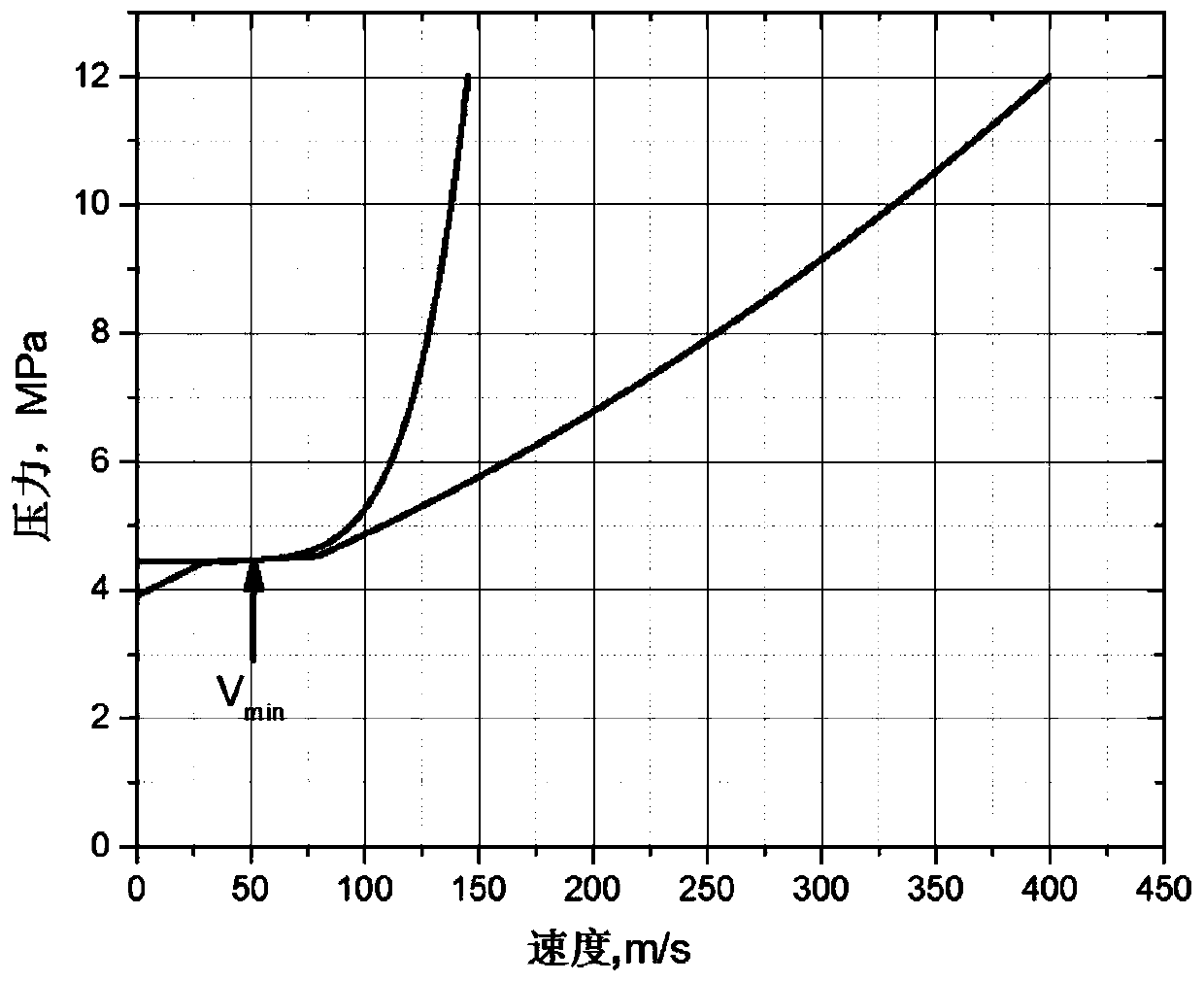

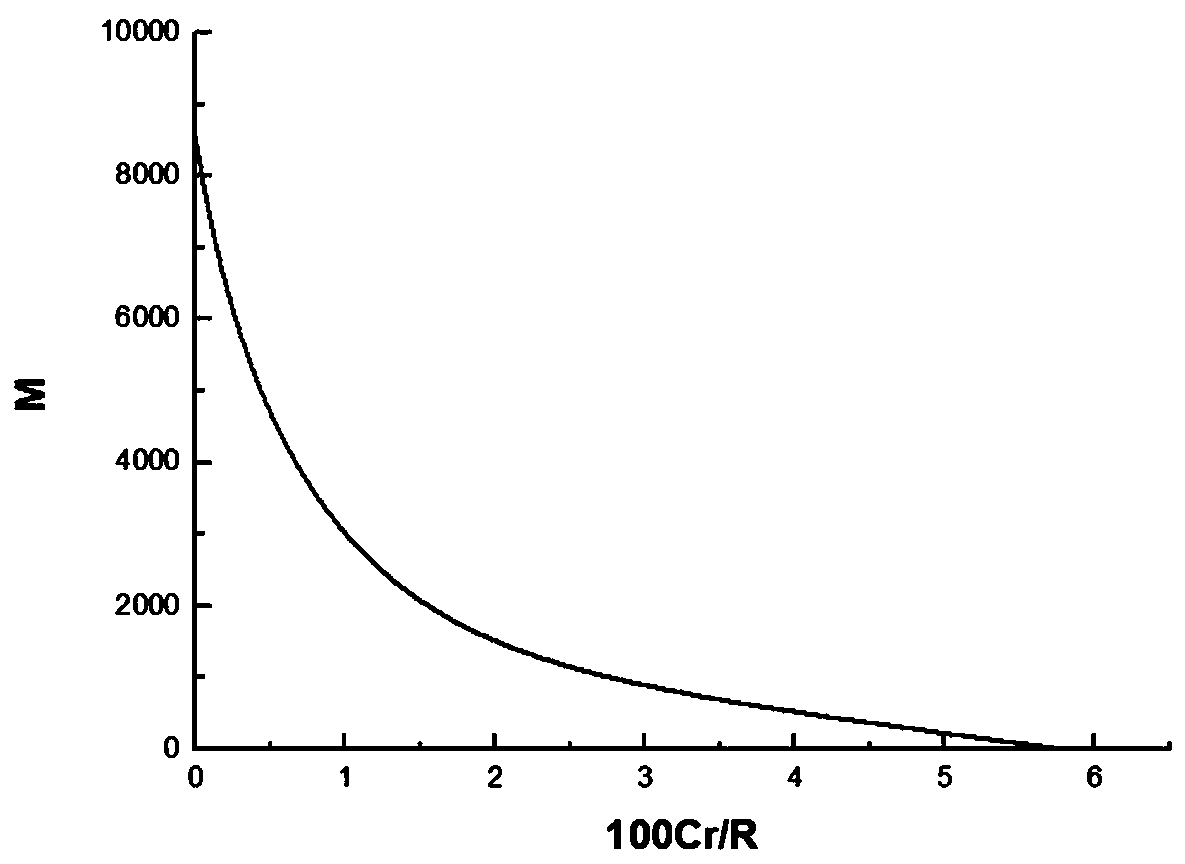

Design method of steel sleeve crack arrestor for high-grade steel gas pipeline

PendingCN110110386ARealize the crack arrest functionHigh-speed expansion and arrest functionDesign optimisation/simulationCAD circuit designGas explosionGas pipeline

The invention discloses a design method of a steel sleeve crack arrestor for a high-grade steel gas pipeline, which comprises the following steps: calculating a pressure reduction wave curve and a material resistance curve under the service condition of the pipeline according to pipeline technical indexes, and calculating the fracture speed Vf of the pipeline under the working condition through the pressure reduction wave curve and the material resistance curve; changing the fracture resistance f in the material resistance curve, and obtaining the minimum fracture speed Vmin of the pipeline inthe crack arresting process through calculation according to the tangent point of the pressure reduction wave curve and the material resistance curve; judging whether the current steel sleeve crack arrestor design method is applicable or not; selecting crack arrest equipment, DWTT shearing area requirement and clearance degree; calculating the thickness of the steel sleeve crack arrestor; and calculating crack arrestor length. The invention provides the design method of the steel sleeve crack arrestor for the X80 / X90 gas pipeline, and the steel sleeve crack arrestor designed by the method canrealize the crack arrestor function of high-speed crack expansion through verification of a full-size gas explosion test.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Preparation method of fresh-keeping rice noodles

The invention discloses a preparation method of fresh-keeping rice noodles. The method includes process steps of soaking rice; grinding the rice into pulp; steaming the rice noodles; pressing the ricenoodles; re-steaming the rice noodles; cooling the rice noodles; drying the rice noodles; and packaging the rice noodles. The preparation method is characterized in that: (1) in the process step of grinding the rice into pulp, an edible water-retaining agent and an edible strengthening agent are added, and water and rice starch in rice the pulp are formulated according to a proportion of 1:2.5; (2) in the cooling step, a preservative is added to a used cooling liquid, the ratio of the preservative to the cooling liquid is 90-110:1, and the cooling temperature is maintained at 20-50 DEG C; and(3) after a product is packaged, a sterilization process step is added, and sterilization treatment is performed by utilizing a pasteurization method. The fresh-keeping rice noodles prepared by the preparation method of the invention are convenient to eat, are easy to carry, can be stored at a room temperature for a long time, have no strip in appearance and no brittleness, is good in elasticity,is consistent in taste with fresh rice noodles, is low in processing and packaging cost, and reach the standard of microbiological indicators. The preparation method is low in investment, is low in cost, is obvious in effect, is reliable in quality and fresh-keeping function, and is harmless to a human body.

Owner:韦献艺

Tantalum tungsten alloy high-temperature oxidation resistant coating material, preparation method and tantalum tungsten alloy swivel nut

PendingCN109750289AHigh bonding strengthImprove toughnessNutsMetallic material coating processesOxidation resistantToughness

The invention relates to a tantalum tungsten alloy high-temperature oxidation resistant coating material, a preparation method and a tantalum tungsten alloy swivel nut. The coating material is characterized by consisting of, in percentage by mass, 7.0-9.0 wt% of MoSi2, 5.5-7.5 wt% of Mo, 4.0-6.0 wt% of W, 3.5-5.5 wt% of ZrO2, 2.5-4.5 wt% of HfO2, 2.5-3.5 wt% of Y2O3, 1.0-2.0 wt% of TiB2, and the balance Si. According to the tantalum tungsten alloy high-temperature oxidation resistant coating material and the preparation method, the coating material can be used in cooperation with a tantalum tungsten alloy in a high-temperature environment, and has good toughness, the combination force with a base material is high, the structure is compact, and the performance is excellent, and the problemof preparation of high-temperature antioxidation protecting coatings of tantalum tungsten alloy (Ta10W) swivel nuts in development of a novel supersonic speed engine is solved.

Owner:NINGXIA ORIENT TANTALUM IND

Special casing nipple for oil well

ActiveCN111456649AImprove connection strengthAvoid breakingDrilling rodsDrilling casingsScrew threadMechanics

The invention relates to the technical field of casing nipples, and discloses a special casing nipple for an oil well. The special casing nipple for the oil well comprises a casing nipple, wherein thetwo ends of the casing nipple are separately provided with outer threads; the outer sides of the outer threads are in threaded connection to connecting casings; threaded holes are formed in the middle parts of the outer threads; anti-slide layers are arranged outside the connecting casings; the two ends of the casing nipple are separately provided with end rings; the two sides of each end ring are separately provided with jacks; and the inner sides of the two ends of the casing nipple are separately provided with inner threads. According to the special casing nipple disclosed by the invention, the connecting casings, the jacks and bolts are used for connecting the casing nipple to an oil extraction tube, and the connecting casings are rotated in a direction towards the joint of the two while the casing nipple is connected to the oil extraction tube, so that the threaded holes in the connecting casings correspond to the jacks; the bolts are inserted for fixing, connecting strength between the casing nipple and the oil extraction tube is remarkably improved, and a tube body is pressed to have a breaking phenomenon, and therefore, stability and reliability of the device are improved.

Owner:大安市鸿聚石油钻采有限公司

A flexible pressure sensor using graphene as an electrode material and its preparation method

ActiveCN109341902BStrong bending resistanceNo brittle fractureFluid pressure measurement by electric/magnetic elementsForce measurementNanofiberThin membrane

Provided is a flexible pressure sensor using graphene as the electrode material. Two outer flexible film layers are doped PCL electrospun films with graphene micro-sheets of which the average radial size is higher than 5-10 microns. Two electrode layers are conductive ink containing graphene micro-sheets with large radial size and nano-silver particles with minimal agglomeration. A dielectric layer is electrospun from nano-fibers. A preparation method for preparing the flexible pressure sensor and a special preparation device are further provided.

Owner:国宏中晶集团有限公司

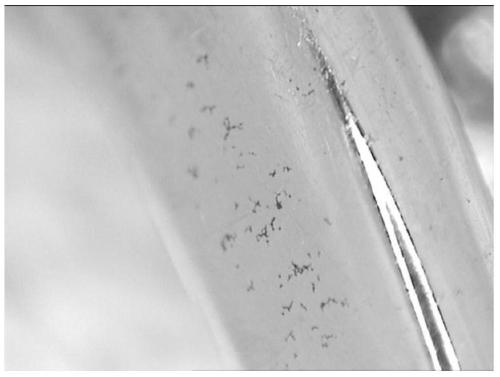

GH4033 high-accuracy hexagonal steel sectional material composite forming method

The invention discloses a GH4033 high-accuracy hexagonal steel sectional material composite forming method. A cold-rolling and cold-drawing composite forming process is mainly adopted to replace cold-draw forming in a traditional process. The process method mainly includes the steps of pretreatment, cold rolling, cold draw, solid solution treatment and the like, operation is simple, and the cost is low. According to a GH4033 hexagonal steel sectional material prepared through the method, the surface of the material is free of cracks, scratches and brittle failure, the surface smoothness is good, the dimensional accuracy reaches the 12th grade, the surface roughness reaches the degree of Ra<=0.8 [mu]m, the surface of the steel material is free of defects, and the using requirements of an aircraft can be met.

Owner:宝武特冶航研科技有限公司

Battery module comprising connecting member composed of dissimilar metals

ActiveUS10069129B2Easy to processNo brittle fractureSmall-sized cells cases/jacketsJackets/cases materialsEngineeringBattery cell

Owner:LG ENERGY SOLUTION LTD

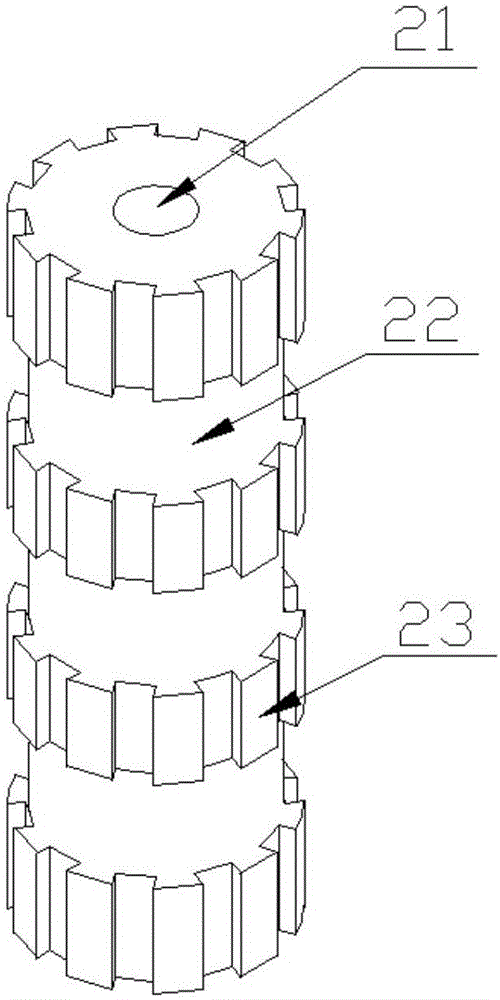

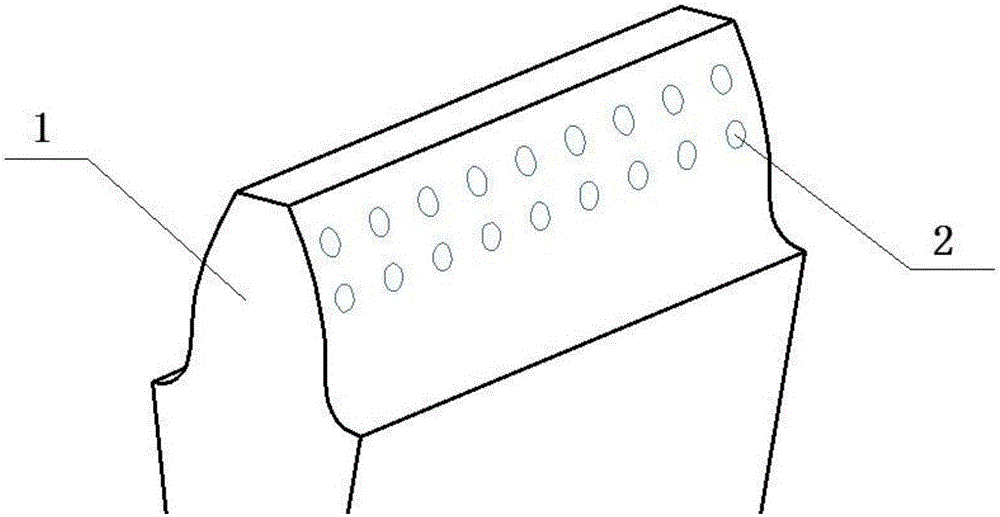

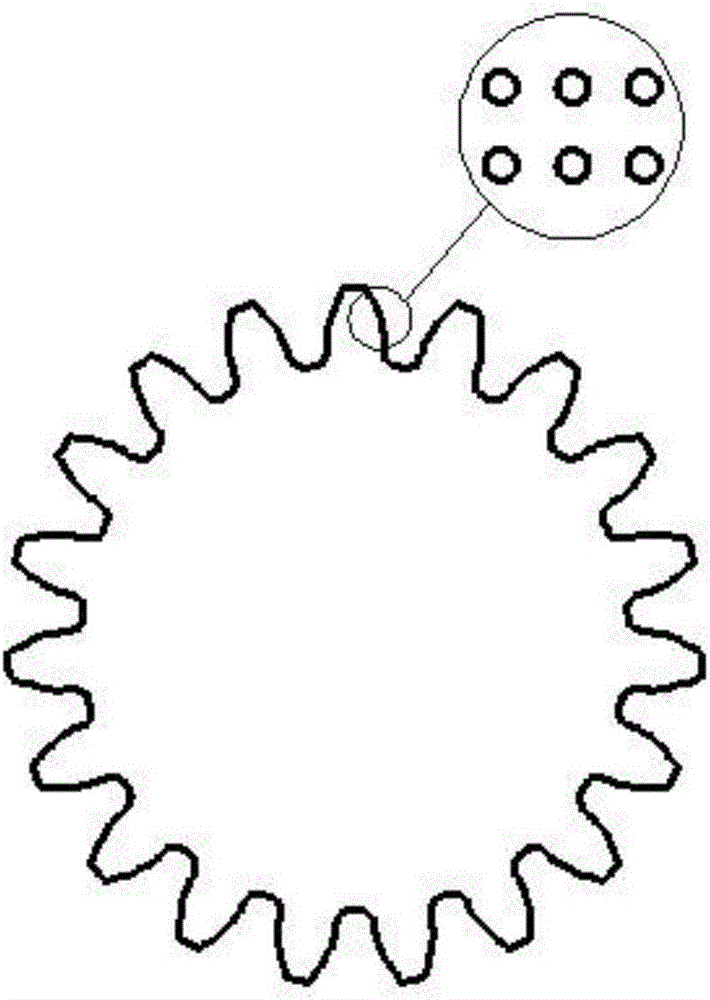

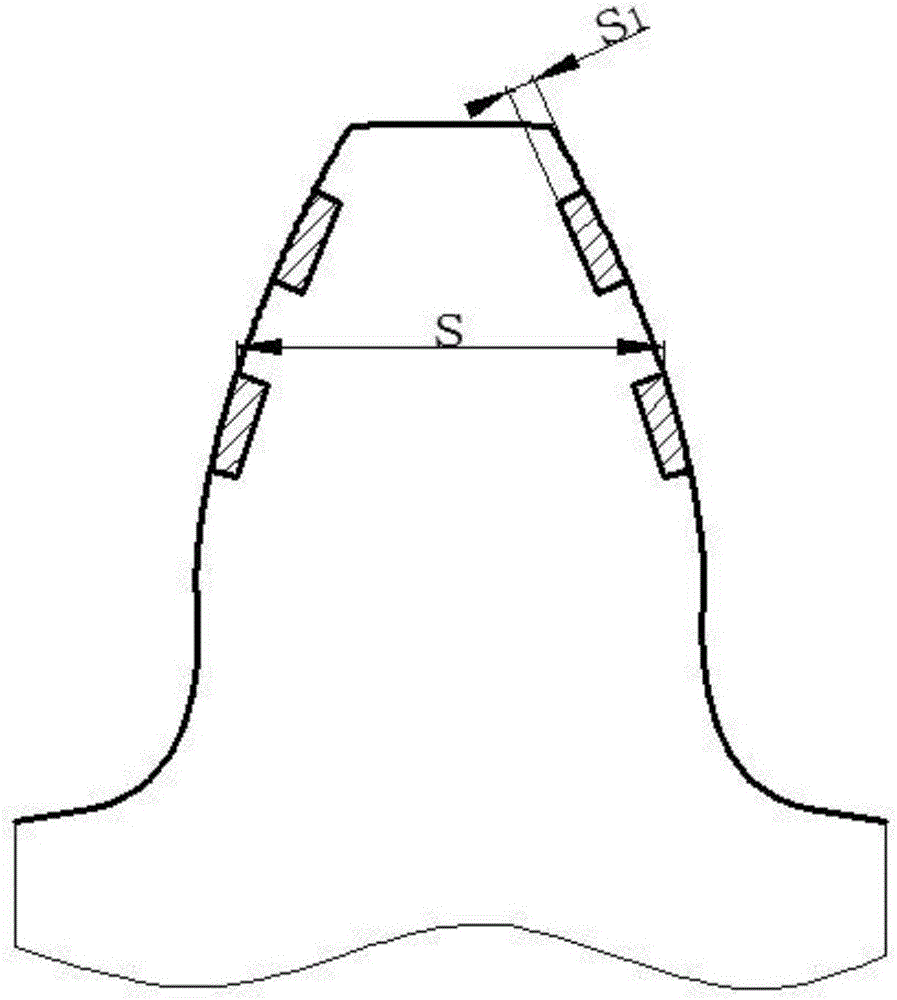

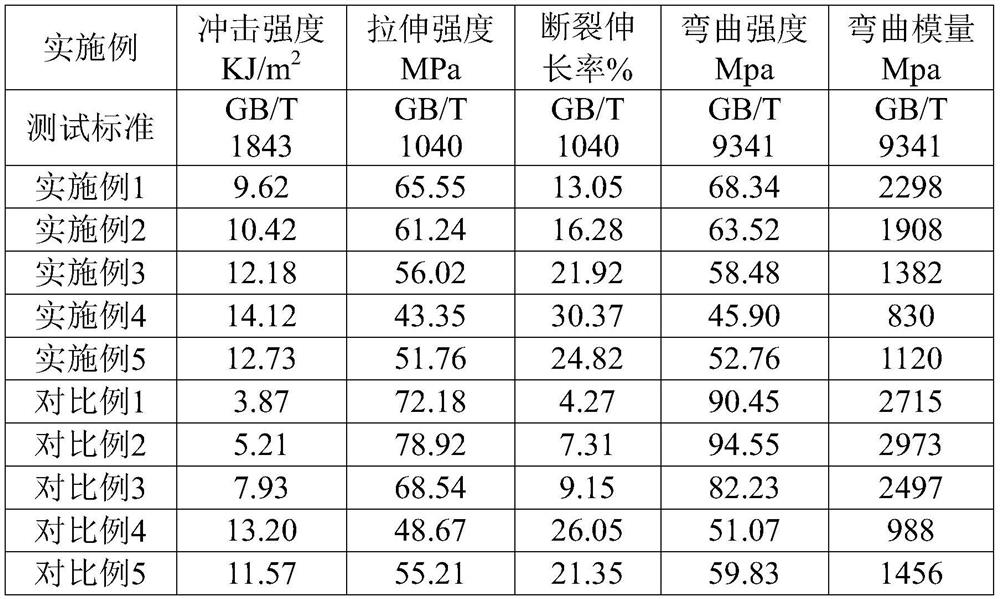

Wear-resisting gear with multi-material combined tooth face

InactiveCN105697720AImprove wear resistanceNo brittle fracturePortable liftingGearing elementsMulti materialState of art

The invention relates to a wear-resisting gear with a multi-material combined tooth face. About 15 to 20 round ceramic element bodies are embedded on the tooth face and are uniformly distributed; a projection area of the round element bodies on the tooth face accounts for 30% to 40% of the total area of the tooth face; a thickness of each round element body is approximately one tenth of a tooth thickness. According to the invention, performance characteristics of various materials are comprehensively applied; a ceramic material is embedded on a gear matrix made of a metal material; compared with the prior art, the wear-resisting gear has the advantages that wear resistance of the wear-resisting gear can be effectively improved, and the service life of the wear-resisting gear is greatly prolonged.

Owner:HEFEI UNIV OF TECH

Polyethylene pipe composite material

InactiveCN104629143AImproves Strength and ToughnessGood flame retardant and aging resistanceSilane couplingCoal

The invention relates to a polyethylene pipe composite material. The polyethylene pipe composite material is characterized by comprising the following main components in percentage by weight: 30.3-92% of inorganic filler, 0.3-2% of a modifying agent and 8-69.7% of a resin matrix, wherein the sum of the contents of all the components is 100%; the inorganic filler comprises hollow microspheres, glass fiber, mica, superfine calcium carbonate, glass fiber / mica, glass fiber / superfine calcium carbonate, mica / superfine calcium carbonate or glass fiber / mica / superfine calcium carbonate, wherein the hollow microspheres are refined from coal ash, and particle size of the hollow microspheres is 3-10mu m; the modifying agent is titanate ester, aluminic acid ester, titanate ester / aluminic acid ester or a silane coupling agent; and the resin matrix is high-density polyethylene. The polyethylene pipe composite material has the advantages that loop stiffness can be improved and cost can be reduced; therefore, the polyethylene pipe composite material has a great prospect.

Owner:许春光

Copolymerization toughening modified material for 3D printing PLA (polylactic acid) and preparation method of copolymerization toughening modified material

PendingCN114539750AFix compatibility issuesGood compatibilityAdditive manufacturing apparatusBio-packagingPolymer science3d printed

The invention discloses a copolymerization toughening modified material for 3D printing PLA (polylactic acid) and a preparation method of the copolymerization toughening modified material. The material is prepared from the following components in parts by weight: 60 to 90 parts of polylactic acid, 10 to 40 parts of thermoplastic polyurethane elastomer, 0.5 to 5 parts of epoxy polymer, 0.1 to 0.5 part of diglycidyl ether derivative, 0.2 to 1 part of lubricant, 0.2 to 1 part of heat stabilizer and 1 to 10 parts of inorganic filler, the preparation method comprises the following steps: drying the components, uniformly mixing, and carrying out melt co-extrusion by using a double-screw extruder. According to the method, the problems of thermodynamic incompatibility and phase separation in the blending extrusion process of PLA and TPU are solved, the toughening effect has long-acting stability, and when the method is applied to 3D printing, wire output is smooth, and the wire drawing effect is good.

Owner:SHENZHEN ESUN IND +1

Thoriated tungsten rhenium wire and preparation method thereof

ActiveCN103305740AGrains are not easy to growOrganizational stabilityMicrowave ovenMetallic materials

The invention relates to the technical field of preparation of a metal material, and particularly relates to a thoriated tungsten rhenium wire, which is especially suitable for winding a microwave oven magnetron, and a preparation method thereof. The thoriated tungsten rhenium wire is characterized by comprising the following components of 0.5-1.5% of thorium oxide, 0.3-0.5% of rhenium, 0.0020-0.0080% of potassium, and 97-98% of tungsten. Compared with the prior art, the thoriated tungsten rhenium wire has the following advantages that (1) according to the thoriated tungsten rhenium wire prepared by the method disclosed by the invention, thorium oxide particles are in fine and even distribution even if 0.0020-0.0080% of potassium is doped; and (2) the thoriated tungsten rhenium wire disclosed by the invention contains a microelement potassium in ingredient; a little of rhenium is added; the grain does not easily grow after the magnetron coil for the micro-wave oven wound by the thoriated tungsten rhenium wire is carbonized at a high temperature; stable tissue can be kept; and brittle failure caused by vibration in the transportation processes such as package, shipment and the like after production is finished can be ensured.

Owner:威海多晶钨钼科技有限公司

Preparation method of high-toughness polylactic acid membrane

The invention discloses a preparation method of a high-toughness polylactic acid membrane, and belongs to the technical field of polylactic acid membrane preparation. The method includes the steps of modifying montmorillonite by cetyl trimethyl ammonium bromide to prepare organic modified montmorillonite for use, taking nano crystalline cellulose, paraformaldehyde and the like to be stirred and mixed and then centrifuged to obtain precipitates, washing and drying the precipitates, making the precipitates, the organic modified montmorillonite for use and the like mixed, extruded and granulated to prepare a material master batch, and conducting extrusion-blow molding to prepare the high-toughness polylactic acid membrane. The method has the advantages that the preparation steps are simple, the obtained polylactic acid membrane is high in crystallinity, and the polylactic acid membrane has good toughness and is free of brittle fractures after being used.

Owner:CHANGZHOU YAHUAN ENVIRONMENTAL PROTECTION TECH

A red gold alloy for firing high-temperature transparent enamel and its preparation method

ActiveCN105087997BGood high temperature oxidation resistanceGood transparencyThermal expansionScandium

The invention discloses red gold alloy used for firing high-temperature transparent enamel and a preparing method of the red gold alloy. The red gold alloy used for firing the high-temperature transparent enamel comprises, by weight, 75.0-75.5% of gold, 22.5-23.2% of copper, 0.9-1.2% of silver, 0.5-0.8% of zinc, 0.2-0.4% of palladium, 0.01-0.03% of silicon, 0.008-0.02% of scandium, 0.0005%-0.001% of boron and other inevitable impurities. The preparing method of the red gold alloy for firing the high-temperature transparent enamel is characterized by comprising the steps that firstly, raw materials are melted under the protective atmosphere; and secondly, after all the materials are melted down, the temperature of molten metal is adjusted, and an ingot casting is obtained through casting. The red gold alloy has good high-temperature oxidation resisting performance, and high-temperature firing can be better borne; the thermal expansion coefficient is close to the thermal expansion coefficient of common gold high-temperature enamel; superior cold machining performance is achieved, and the phenomenon of brittle failures does not occur in the machining process; and grains are fine, the organization is compact, and a highly-polished surface can be obtained.

Owner:GUANGZHOU PANYU POLYTECHNIC +1

Low-temperature soluble aluminum alloy and application

ActiveCN114752827ARefine the grain sizeReduce segregationProcess efficiency improvementSolution treatmentIngot casting

The invention discloses a low-temperature soluble aluminum alloy and application thereof, and the aluminum alloy comprises the following elements in percentage by weight: 1.5 wt% of Mg, 1wt% of Ga, 0.7 wt% of In, 1wt% of Sn, and the balance of Al and inevitable impurity elements. The tensile strength of the steel plate is 390-460 MPa, and the ductility of the steel plate is 12-20%. The soluble aluminum alloy is obtained by carrying out homogenization treatment, hot extrusion treatment, solution treatment and aging treatment on the components after smelting and ingot casting. The soluble aluminum alloy material can be used as a material of a fracturing tool for shale oil and gas exploitation. The prepared low-temperature soluble aluminum alloy has a low-temperature phase, can be used in a low-temperature environment, and is soluble at low temperature and controllable in solubility.

Owner:SHAANXI UNIV OF SCI & TECH

Polyurethane rigid foam for covering austenitic stainless steel and preparation method thereof

The invention discloses a polyurethane rigid foam plastic for covering austenitic stainless steel, which is prepared from component A and component B. Component A consists of 100 parts by weight of polyol, 3.0-5.5 parts of amine catalyst, physical hair 7-20 parts of foam agent, 1.5-2.5 parts of water, 2.0-3.5 parts of foam stabilizer and 0.05-1.10 parts of chloride ion scavenger; component B is polyphenyl polymethylene polyisocyanate; the polyurethane rigid The leached chloride ion content of foamed plastics is ≤45mg / kg. The preparation method is as follows: uniformly mix the materials in component A to obtain component A; stir and mix component A and component B uniformly to obtain a mixed material, and pour the mixed material into a mold to solidify and form it. The foamed plastic in this application can basically avoid corrosion of stainless steel due to the influence of chloride ions in the insulation material, and reduce the harm caused by the factors of chloride ions in the insulation material.

Owner:南京红宝丽新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com