Design method of steel sleeve crack arrestor for high-grade steel gas pipeline

A technology of gas transmission pipeline and design method, which is applied in computer-aided design, design optimization/simulation, CAD circuit design and other directions, can solve the problems of complicated finite element calculation, etc., and achieve the effect of realizing crack arrest function and high-speed expansion and crack arrest function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

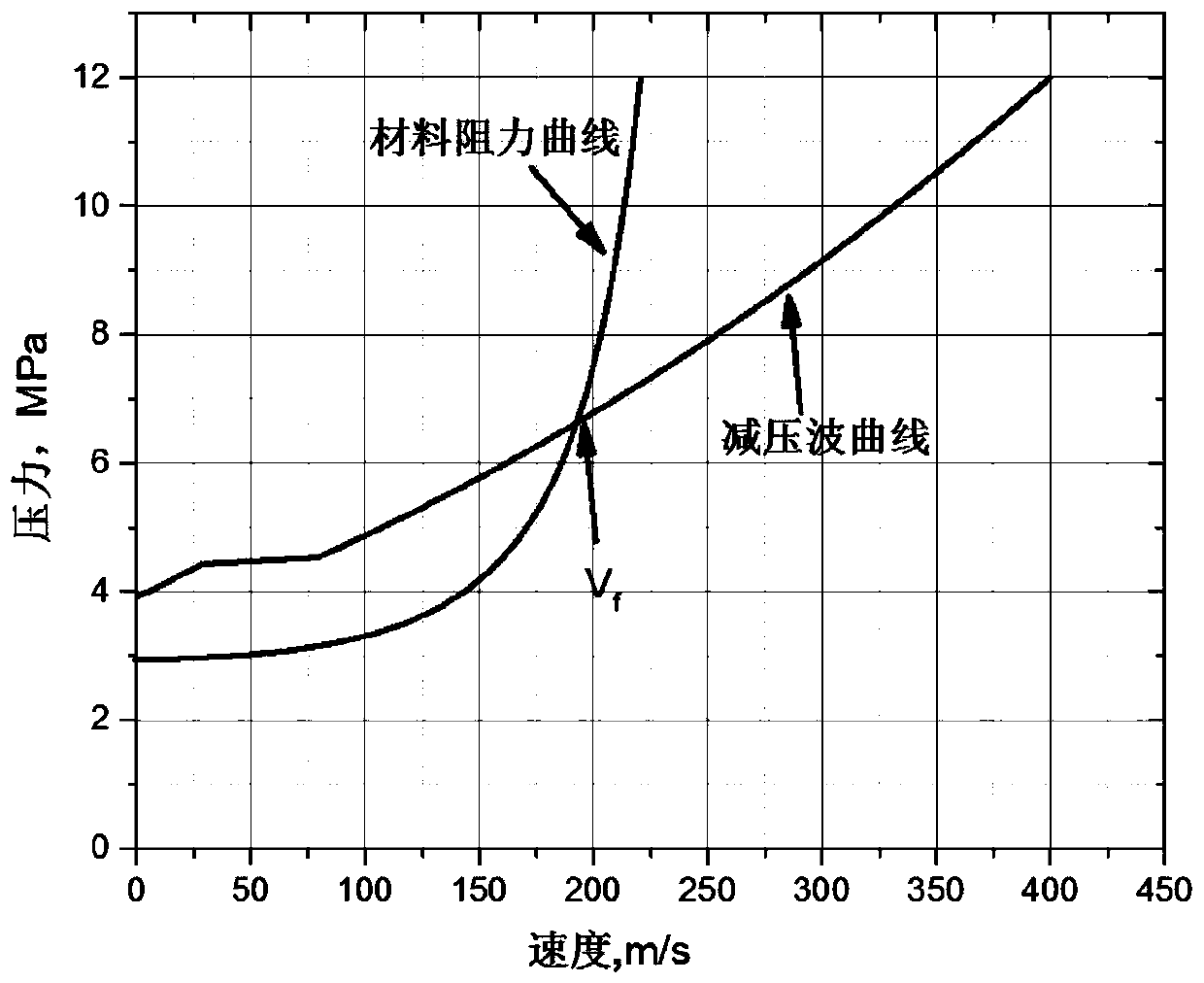

[0092] (1) First determine the pipeline parameters, and calculate the decompression wave curve through the BWRS state equation, and calculate the material resistance curve according to formulas 1 and 2.

[0093] The design parameters of the X90 gas pipeline are shown in Table 1:

[0094] Table 1 X90 gas pipeline parameters

[0095]

[0096] The transport gas composition is shown in Table 2, and the natural gas temperature is 10°C.

[0097] natural gas components methane ethane Mole percent 85% 15%

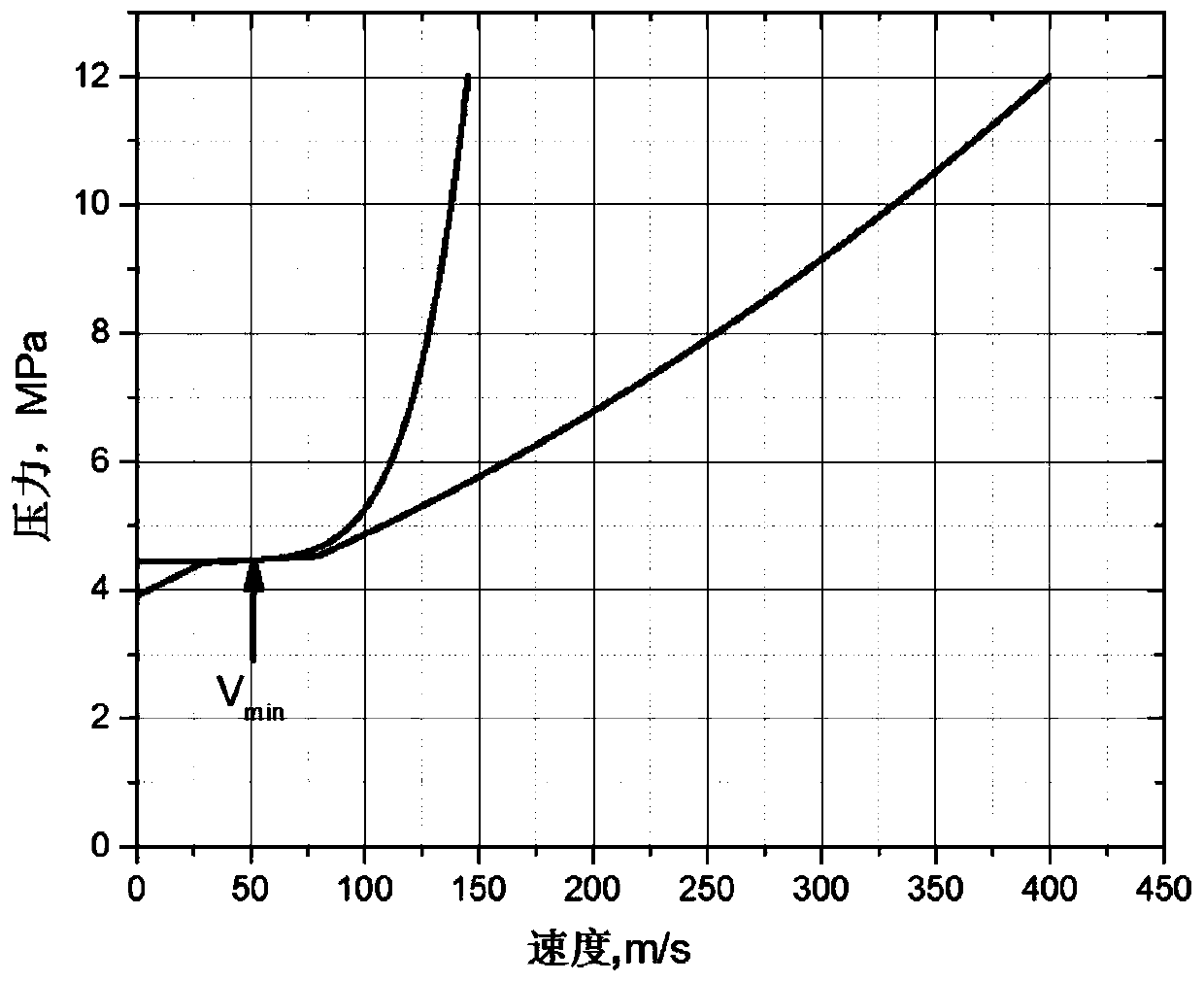

[0098] (2) Calculate the fracture velocity V of the pipeline under working conditions by using the decompression wave curve and the material resistance curve f and the minimum breaking velocity V min .

[0099] V determined from material resistance curve and decompression wave curve min =50m / s, V f =190m / s.

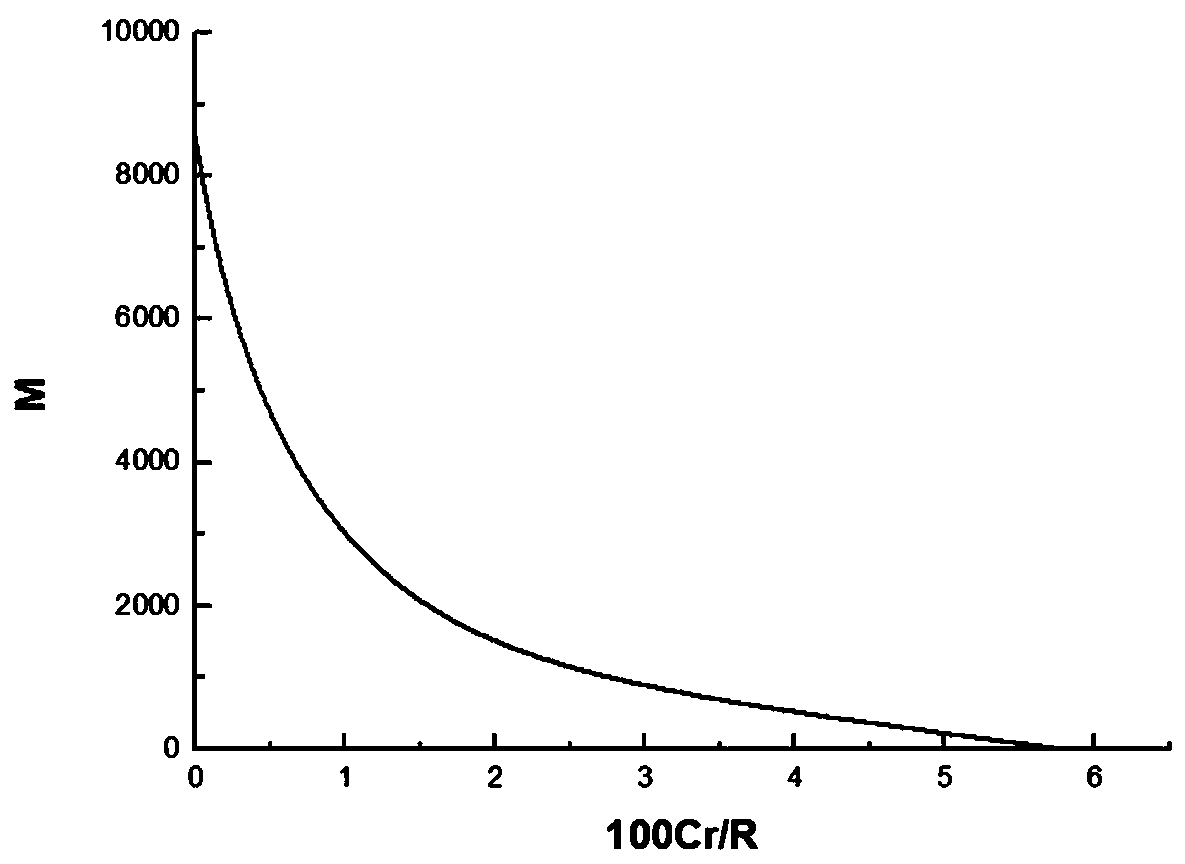

[0100] Suppose the gap C between the crack arrester and the gas pipeline r is 0mm, then V f maxCrack arrest can be carried out by a stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com