Method of utilizing external force to crush, wash and purify slender carbon nanotube

A technology of carbon nanotubes and crushing liquid, which is applied in the field of new materials, can solve the problems of low purity, difficult separation, and difficult separation of carbon nanotubes and carbon fibers, and achieve the effect of high purification efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

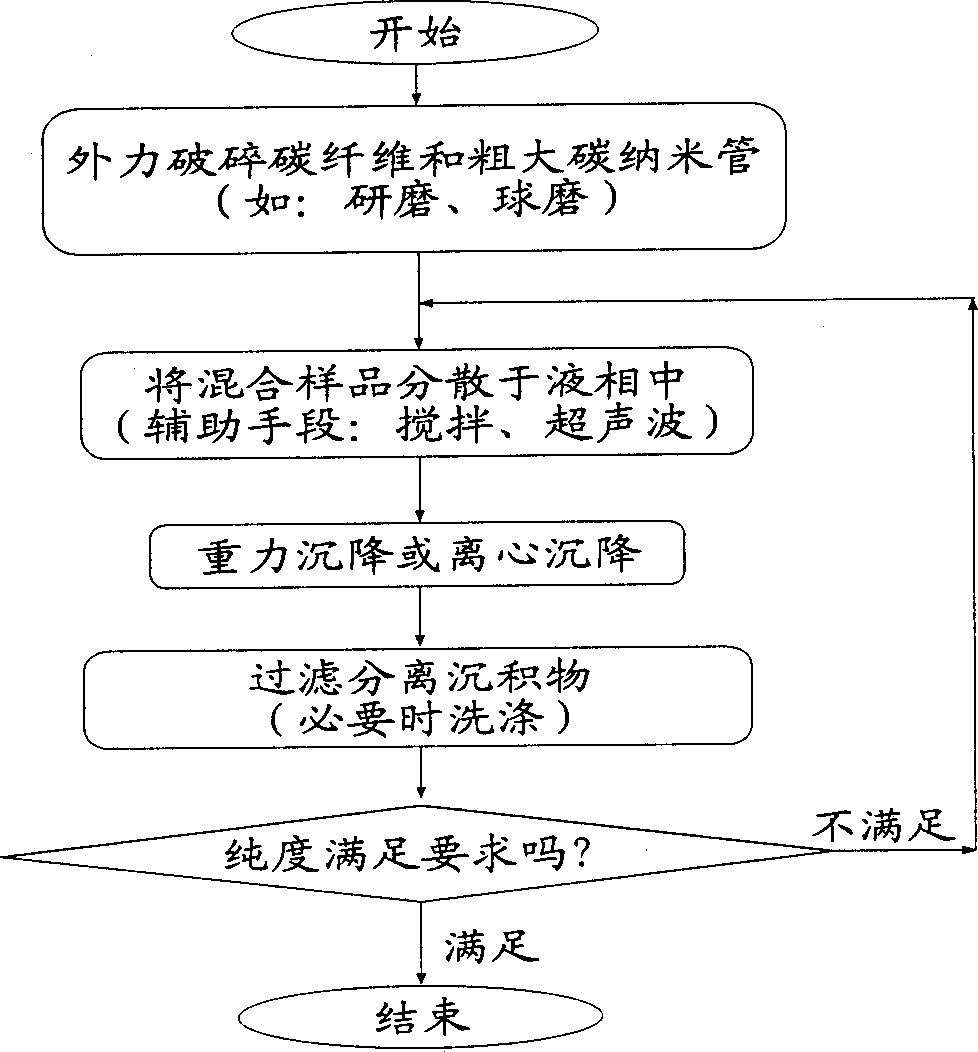

Method used

Image

Examples

Embodiment 1

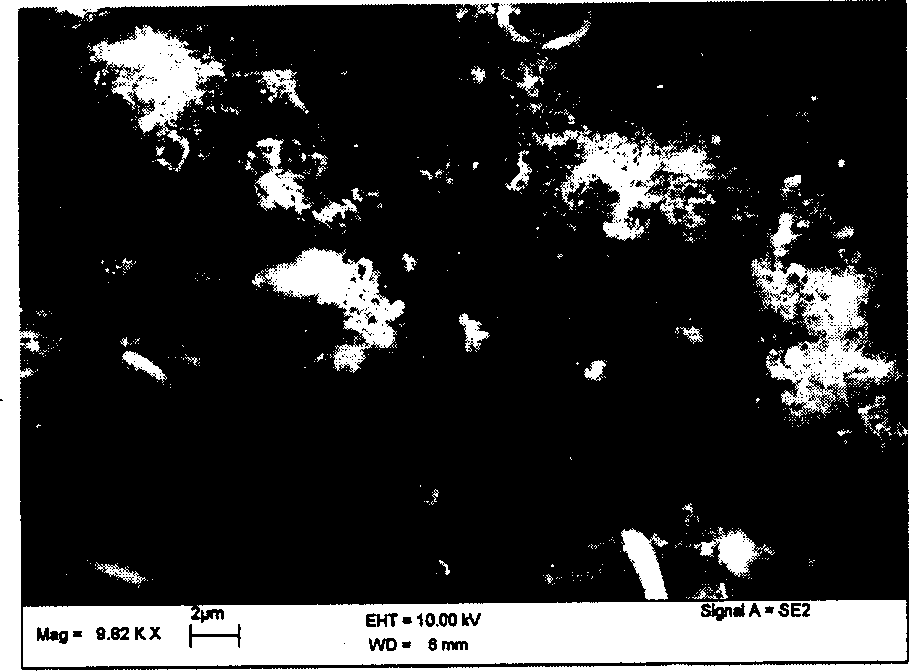

[0028] This example examines the effect of external force on the fragmentation of carbon fibers and thick carbon nanotubes and the suspension performance of their fragments in the liquid phase. The samples used are prepared by nano-agglomerated bed catalytic cracking method, and are mainly composed of carbon fibers and thick carbon nanotubes. Add 25 mg of sodium dodecylbenzenesulfonate to 100 mg of sample and grind for half an hour. The ground sample was placed in 25ml of deionized water, and the sample was dispersed using ultrasonic waves under stirring conditions. The stirring speed was 1500 rpm, the ultrasonic intensity was 5W / ml, and the ultrasonic time was 3 minutes. A suspension of the sample was obtained after ultrasonic dispersion.

[0029] Figure 2a It is a scanning electron micrograph of the original sample, in which a large number of coarse carbon fibers can be seen.

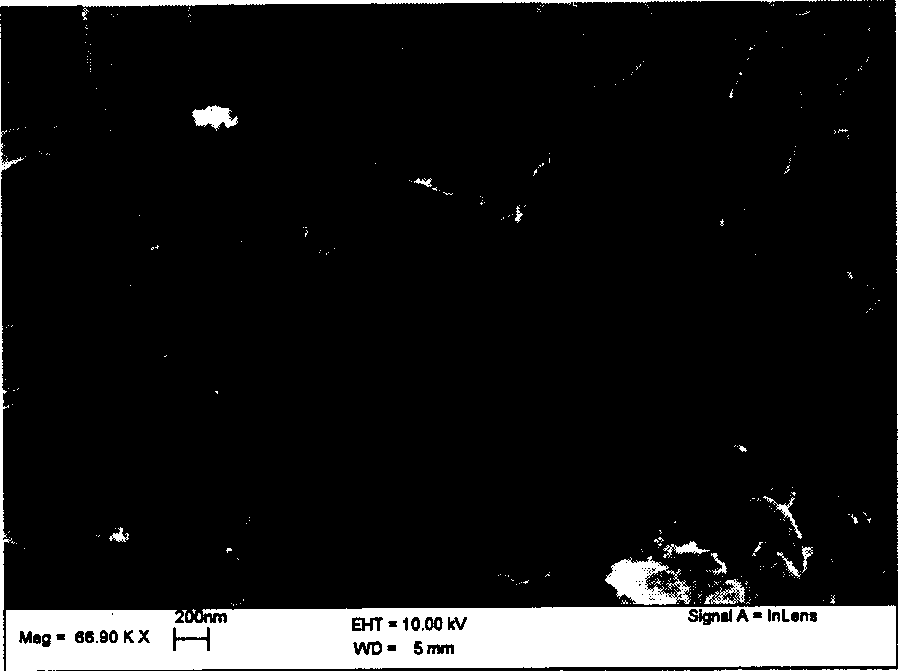

[0030] Figure 2b This is the scanning electron micrograph of the ground sample, from which m...

Embodiment 2

[0033] Examples 2-4 are purification examples. The crude sample used was prepared by nano-agglomerated bed catalytic cracking method, which contained elongated carbon nanotubes, thick carbon nanotubes and carbon fibers. Add 10 mg sodium dodecylbenzenesulfonate to 50 mg crude sample and grind for half an hour. The ground sample was placed in 25ml of deionized water, and ultrasonic waves were added to disperse the samples under stirring conditions. The stirring speed was 1800 rpm, the ultrasonic intensity was 5W / ml, and the ultrasonic time was 3 minutes. A suspension of the sample was obtained after ultrasonic dispersion. The suspension was left to settle for 2 hours, and the sediment was separated by filtration and washed with 100 ml of deionized water.

[0034] Figure 2a It is a scanning electron microscope photo of the original sample, in which impurities such as elongated carbon nanotubes and thick carbon fibers coexist.

[0035] Figure 2b It is a transmission electro...

Embodiment 3

[0038] The crude sample used contained elongated carbon nanotubes, thick carbon nanotubes, and carbon fibers. To 440 mg crude sample was added 60 mg polyoxyethylene and triturated for two hours. Place the ground sample in 500ml of deionized water, and disperse the sample in an SK2200H ultrasonic pool for 30 minutes. A suspension of the sample was obtained after ultrasonic dispersion. The sediment and the suspension were separated by centrifugation at a speed of 1000 rpm and a centrifugation time of 20 minutes.

[0039] Electron microscope observations proved that the elongated carbon nanotubes were concentrated in the sediment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com