Si3N4 foam ceramic reinforced aluminum-based composite material and preparation method and application thereof

A technology of foam ceramics and reinforced aluminum base, which is applied in the field of composite materials, can solve the problems of high brittleness of ceramic materials, wear of composite materials, and affecting normal use, etc., and achieve the effect of improving bonding force, improving toughness, integrity and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

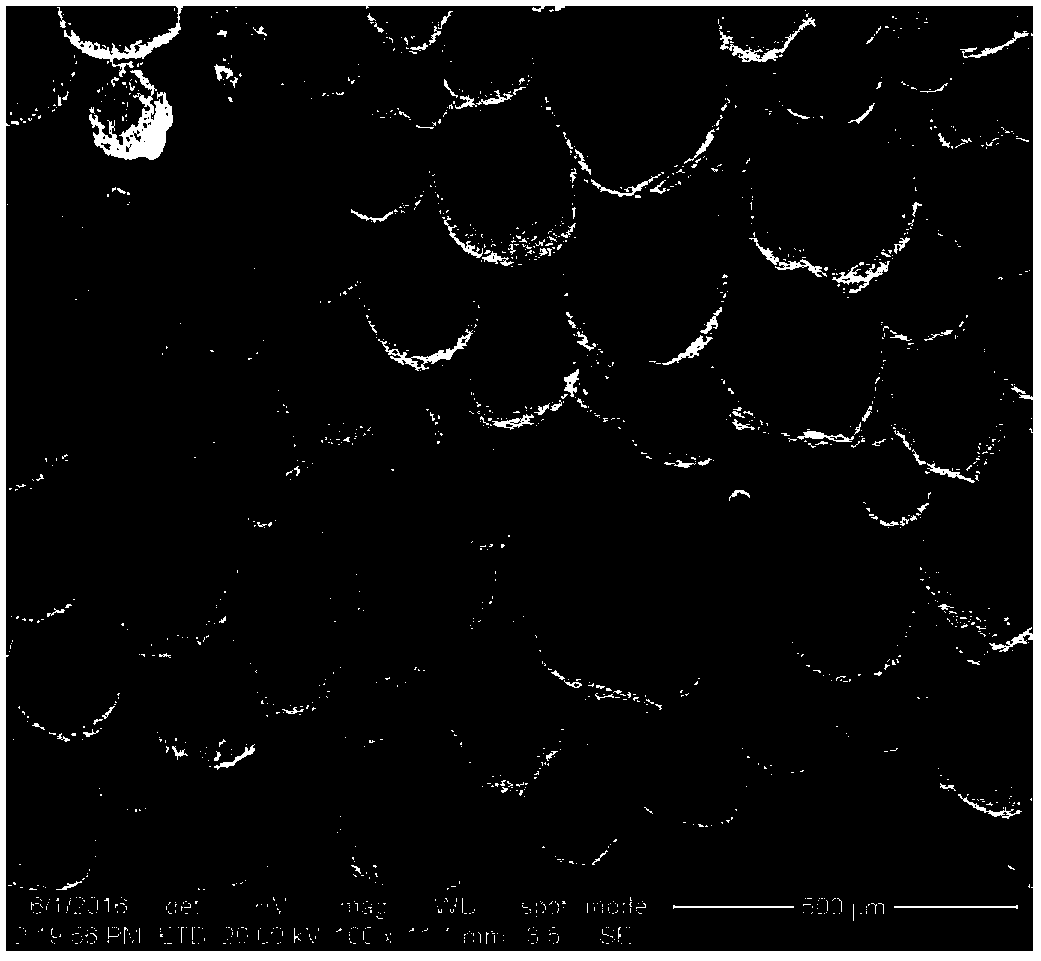

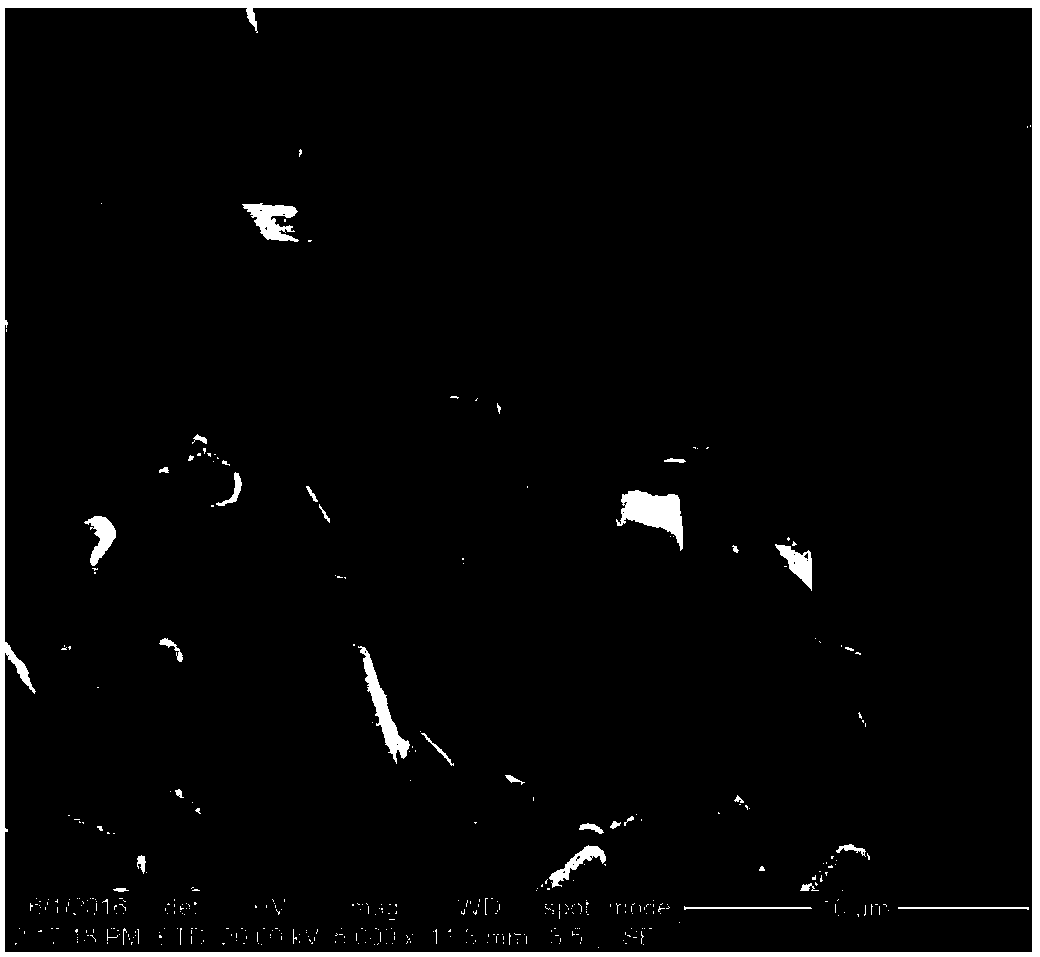

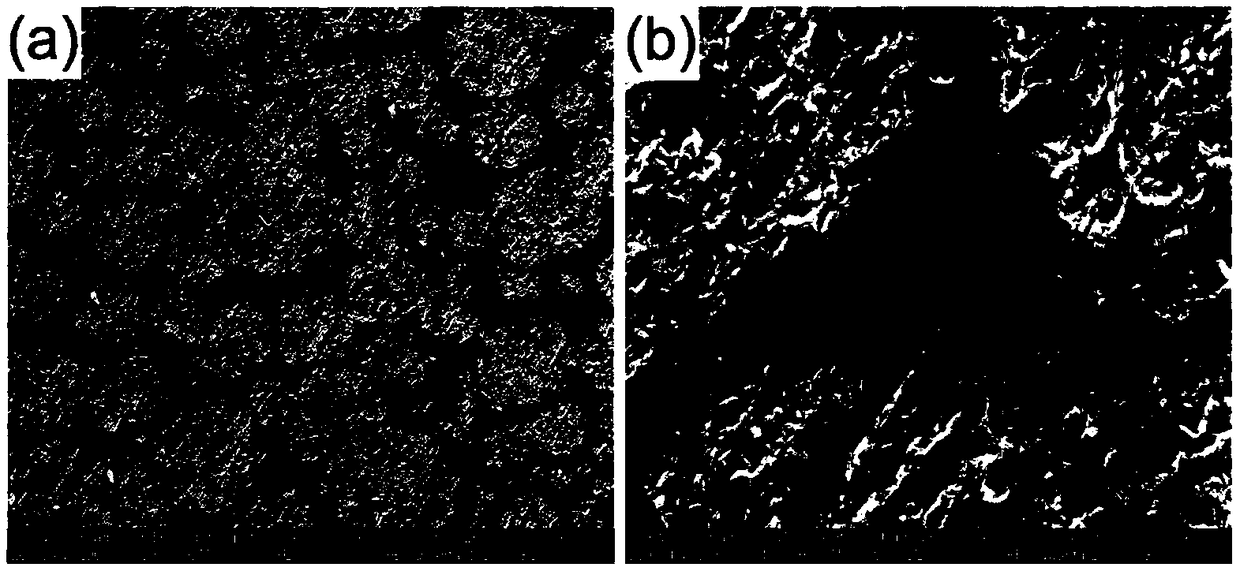

[0041] A kind of Si of the present invention 3 N 4 Ceramic foam reinforced aluminum matrix composites, including aluminum matrix and Si 3 N 4 ceramic foam, the Si 3 N 4 Foamed ceramics include Si 3 N 4 Foam ceramic framework and in situ growth on Si 3 N 4 Columnar β-Si on the framework pore wall of ceramic foam 3 N 4 Grain, aluminum matrix uniformly filled in Si 3 N 4 In the pores of the ceramic foam framework, columnar β-Si 3 N 4 The grains are surrounded by an aluminum matrix.

[0042] In this example, the aluminum matrix is in the Si 3 N 4 The volume percentage in the ceramic foam reinforced aluminum matrix composite material is 73.0%.

[0043] In this example, columnar β-Si 3 N 4 The column length of crystal grains is 1-3 μm, and the column diameter is 100-300 nm.

[0044] In this example, Si 3 N 4 The open porosity of the foamed ceramic skeleton is 73.0%, and the pore diameter is 100-300nm.

[0045] A kind of Si of above-mentioned present embodimen...

Embodiment 2

[0066] A kind of Si of the present invention 3 N 4 Ceramic foam reinforced aluminum matrix composites, including aluminum matrix and Si 3 N 4 ceramic foam, the Si 3 N 4 Foamed ceramics include Si 3 N 4 Foam ceramic framework and in situ growth on Si 3 N 4 Columnar β-Si on the framework pore wall of ceramic foam 3 N 4 Grain, aluminum matrix uniformly filled in Si 3 N 4 In the pores of the ceramic foam framework, columnar β-Si 3 N 4 The grains are surrounded by an aluminum matrix.

[0067] In this example, the aluminum matrix is in the Si 3 N 4 The volume percentage in the foam ceramic reinforced aluminum matrix composite material is 62.0%.

[0068] In this example, columnar β-Si 3 N 4 The column length of crystal grains is 1-5 μm, and the column diameter is 100-300 nm.

[0069] In this example, Si 3 N 4 The open porosity of the foamed ceramic skeleton is 62.0%, and the pore diameter is 100-250 μm.

[0070] A kind of Si of above-mentioned present embodime...

Embodiment 3

[0090] A kind of Si of the present invention 3 N 4 Ceramic foam reinforced aluminum matrix composites, including aluminum matrix and Si 3 N 4 ceramic foam, the Si 3 N 4 Foamed ceramics include Si 3 N 4 Foam ceramic framework and in situ growth on Si 3 N 4 Columnar β-Si on the framework pore wall of ceramic foam 3 N 4 Grain, aluminum matrix uniformly filled in Si 3 N 4 In the pores of the ceramic foam framework, columnar β-Si 3 N 4 The grains are surrounded by an aluminum matrix.

[0091] In this example, the aluminum matrix is in the Si 3 N 4 The volume percentage in the foamed ceramic reinforced aluminum matrix composite is 49.7%.

[0092] In this example, columnar β-Si 3 N 4 The column length of the crystal grains is 1-3 μm, and the column diameter is 50-400 nm.

[0093] In this example, Si 3 N 4 The open porosity of the foamed ceramic skeleton is 49.7%, and the pore diameter is 50-250 μm.

[0094] A kind of Si of above-mentioned present embodiment 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com