Preparation method for environment-friendly TPU

An environmentally friendly and prepolymer technology, which is applied in the field of preparation of environmentally friendly TPU, can solve the problems of unusable polyurethane and achieve the effects of improving environmental safety, good processing performance, and increasing the scope of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

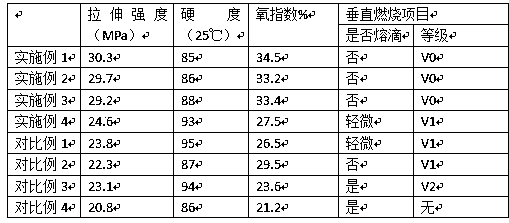

Embodiment 1

[0036] A kind of preparation method of environment-friendly TPU, is made of component A and component B,

[0037] Component A is polyurethane prepolymer, which is made of the following raw materials:

[0038] 55 parts of hexamethylene diisocyanate, 8 parts of polyether polyol, 50 parts of polyester polyol, 12 parts of composite additive, 0.09 part of catalyst;

[0039] Component B is a chain extender, and the chain extender is 1,4 butanediol;

[0040] The weight ratio of the component A to the component B is 3.4:1;

[0041] The composite additive is made of the following raw materials by weight: 26 parts of attapulgite, 4.5 parts of expanded graphite, 9 parts of magnesium hydroxide, and 11 parts of glass fiber.

[0042] The attapulgite in the composite additive is processed by the following methods:

[0043] (1) Add attapulgite to 3-5 times its weight in a nitric acid solution with a mass fraction of 5% and soak for 10-15 minutes, then wash it with deionized water for 3-4 t...

Embodiment 2

[0056] A kind of preparation method of environment-friendly TPU, is made of component A and component B,

[0057] Component A is polyurethane prepolymer, which is made of the following raw materials:

[0058] 60 parts of hexamethylene diisocyanate, 7 parts of polyether polyol, 53 parts of polyester polyol, 10 parts of composite additive, 0.1 part of catalyst;

[0059] Component B is a chain extender, and the chain extender is 1,2 propylene glycol;

[0060] The weight ratio of the component A to the component B is 3.31;

[0061] The composite additive is made of the following raw materials by weight: 27 parts of attapulgite, 4.2 parts of expanded graphite, 9 parts of magnesium hydroxide, and 11 parts of glass fiber.

[0062] The processing method of other raw materials is as embodiment 1.

Embodiment 3

[0064] A kind of preparation method of environment-friendly TPU, is made of component A and component B,

[0065] Component A is polyurethane prepolymer, which is made of the following raw materials:

[0066] 50 parts of hexamethylene diisocyanate, 10 parts of polyether polyol, 56 parts of polyester polyol, 11 parts of composite additives, 0.12 parts of catalyst;

[0067] Component B is a chain extender, and the chain extender is 1,4 butanediol;

[0068] The weight ratio of said component A to component B is 3.2:1;

[0069] The composite additive is made of the following raw materials by weight: 27 parts of attapulgite, 4.6 parts of expanded graphite, 9 parts of magnesium hydroxide, and 11 parts of glass fiber.

[0070] Other processing modes are as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com