3D printing wire prepared from polylactic acid recycling material and preparation method

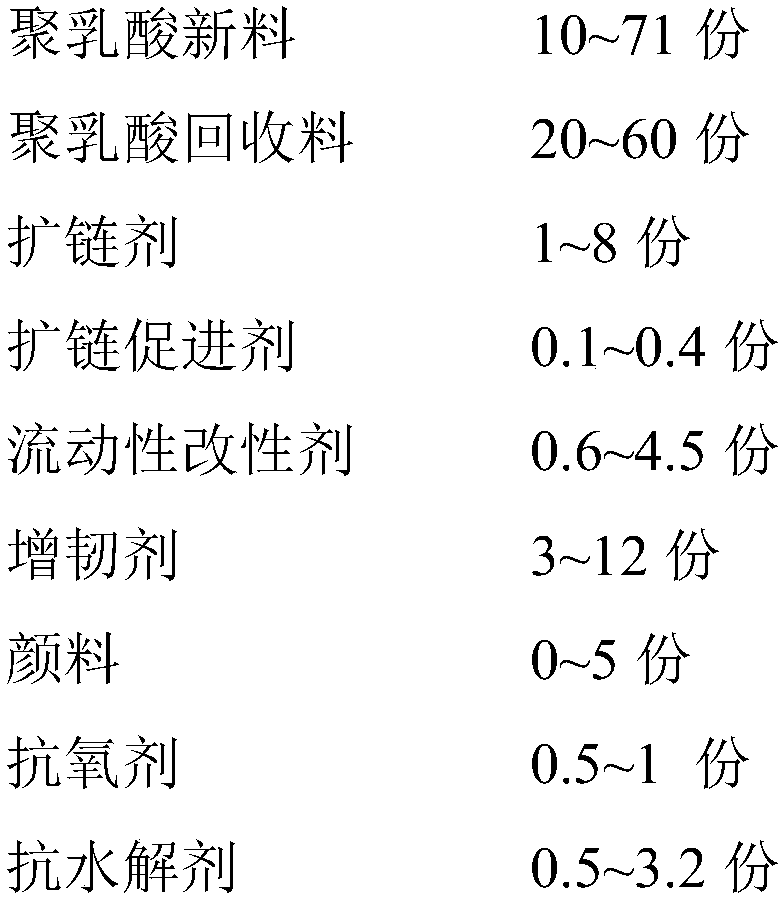

A technology of 3D printing and recycled materials, applied in the direction of additive processing, etc., can solve problems such as short shelf life, dent defects, 3D printing stop, etc., to meet the requirements of 3D printing, good 3D printing requirements, and simple preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

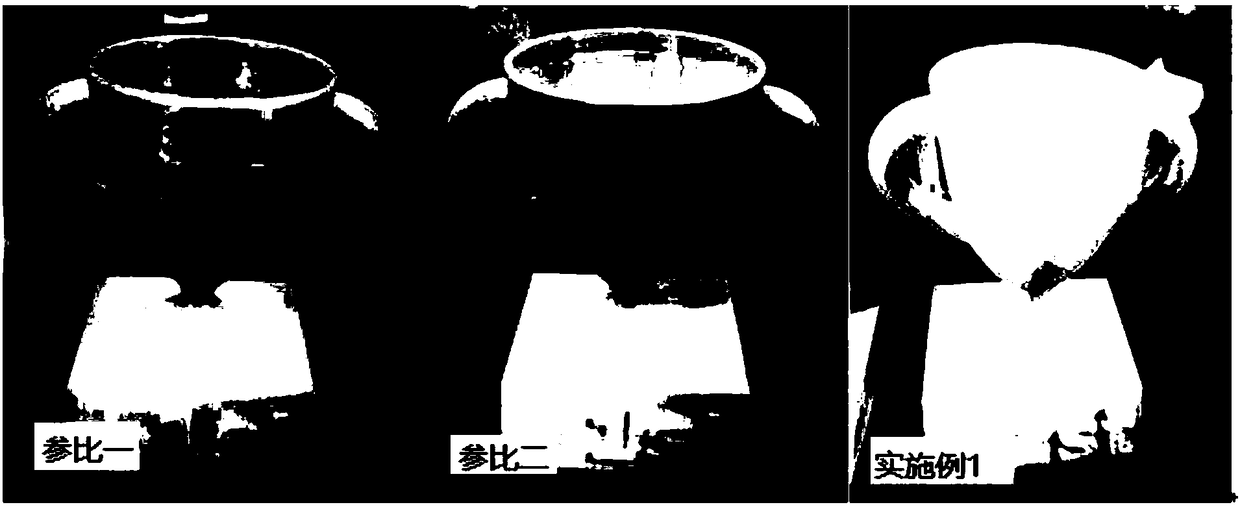

Embodiment 1

[0036] The white polylactic acid recycled material (the primary material manufacturer is Zhejiang Hisun Biomaterials Co., Ltd., the brand is PLA REVODE195, and the recycled material is extruded with a single screw with the temperature set at 185, 190, 190, 190, 180, 170 °C The prepared 3D printing wire, which is stored in dry conditions and exceeds the shelf life of 10 months, the gloss of the material has decreased and the melt index has increased by more than 30%)) pellets, the length of the pellets is 0.2 to 0.3 cm; the pellets The reclaimed polylactic acid was dried in an oven at a temperature of 50°C for 8 hours; it was added to a high-speed dispersion mixer with a speed of 300r / min and stirred for 3 minutes; within 5 minutes, it was pumped into neopentyl glycol diglycidol For the mixed liquid composed of ether and dimethylimidazole, continue stirring at a high speed of 1300r / min for 10-20 minutes; stop stirring; bake all the mixed materials in a vacuum oven at 70°C for 4 ...

Embodiment 2

[0043] The white polylactic acid recycled material (the primary material manufacturer is Zhejiang Hisun Biomaterials Co., Ltd., the brand is PLA REVODE 190, and the recycled material is a single-screw extruder with the temperature set at 180, 195, 195, 190, 180, and 175 °C The produced 3D printing wire with a diameter not up to the standard, placed under dry conditions for 12 months, the gloss of the material decreased, and the melt index increased by more than 30%) was pelletized, and the length of the pellets was 0.2 to 0.3 cm; Dry the granulated polylactic acid reclaimed material in an oven at 40°C for 12 hours; add it to a high-speed dispersion mixer with a speed of 200r / m and stir it for 3 minutes; pump ethylene glycol dishrink in 5 minutes For the mixed liquid composed of glyceryl ether and salicylaldehyde, continue to stir at a high speed of 1200r / min for 10-20 minutes; stop stirring; bake all the mixed materials in a vacuum oven at 60°C for 2 hours; wait until the tempe...

Embodiment 3

[0049] White polylactic acid recycled material (the primary material manufacturer is Zhejiang Hisun Biomaterials Co., Ltd., the brand is PLA REVODE 195) (the recycled material is a single screw with the temperature set at 185, 190, 190, 190, 180, 170 °C Extruded 3D printing wires with a diameter less than the standard, and placed under dry conditions for 24 months, the gloss of the material has decreased and the melt index has increased by more than 30%) pellets, the length of the pellets is 0.2 to 0.3 cm ; Place the granulated polylactic acid recycled material in an oven at a temperature of 50°C and dry it for 8 hours; and add it to a high-speed dispersion mixer with a speed of 500r / min and stir it for 3 minutes; For the mixed liquid composed of glycerol ether and dimethylbenzylamine, continue to stir at a high speed of 1300r / min for 10-20 minutes; stop stirring; bake all the mixed materials in a vacuum oven at 70°C for 2 hours; wait for the temperature to drop After reaching...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com