Tantalum tungsten alloy high-temperature oxidation resistant coating material, preparation method and tantalum tungsten alloy swivel nut

A high-temperature anti-oxidation, tantalum-tungsten alloy technology, which is applied in the coating process of metal materials, coatings, nuts, etc., can solve the problems of low bonding strength, poor strength and mechanical properties, coating peeling, etc., and achieve high bonding strength, Excellent performance and strong binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

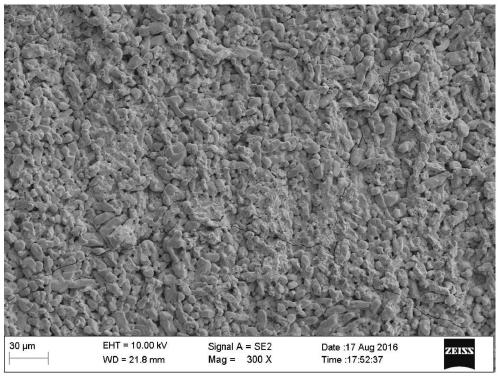

[0023] Coating raw material powder according to MoSi 2 7.5Wt%, Mo 6.5Wt%, W 4.5Wt%, ZrO 2 4.5Wt%, HfO 2 3.0Wt%, Y 2 o 3 3.5wt%, TiB 2 It is 1.5wt%, and the balance is mixed with Si. For mixing and milling, it is required that the particle size of the added powder is not greater than 350 mesh.

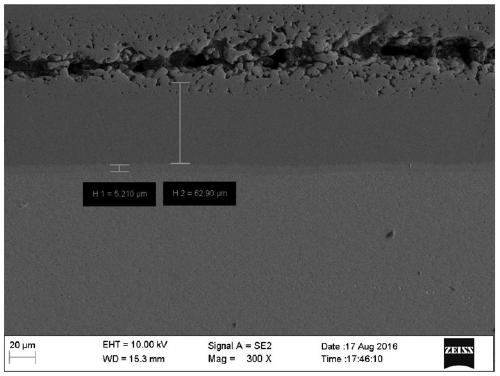

[0024] Add the polyethylene glycol of 3Wt% of the aforementioned material powder, add the absolute ethanol of 1.5 times the volume of the aforementioned material powder, and use liquid nitrogen low-temperature ball milling for 15 hours to prepare the coating slurry, and spray the coating slurry on the tantalum On the tungsten alloy substrate, put the coated tantalum-tungsten alloy coating at 1550 ° C, and the vacuum is not lower than 1.0×10 -2 Sintering under Pa conditions for 40 minutes to make a high-temperature anti-oxidation coating. The coating thickness is 65 μm.

Embodiment 2

[0026] Coating raw material powder according to MoSi 2 9.0Wt%, Mo 5.5Wt%, W 6.0Wt%, ZrO 2 3.5Wt%, HfO 2 4.5wt%, Y 2 o 3 2.5Wt%; TiB 2 It is 1.0Wt%, and the balance is Si ratio mixing, adds the polyethylene glycol of 5Wt%, after adding the dehydrated alcohol of 1.0 times of aforementioned material volume again, makes coating slurry with liquid nitrogen low-temperature ball milling for 20 hours, will The coating slurry is sprayed on the tantalum-tungsten alloy substrate, and the coated tantalum-tungsten alloy coating is placed at 1600°C and the vacuum is not lower than 1.0×10 -2 Sintering under Pa conditions for 30 minutes to make a high-temperature anti-oxidation coating. The coating thickness is 75 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com