Flexible pressure sensor using graphene as electrode material and preparation method thereof

A pressure sensor, electrode material technology, applied in the direction of measuring fluid pressure through electromagnetic components, measuring fluid pressure, instruments, etc., can solve the problem that the sensor cannot cope with complex stress and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

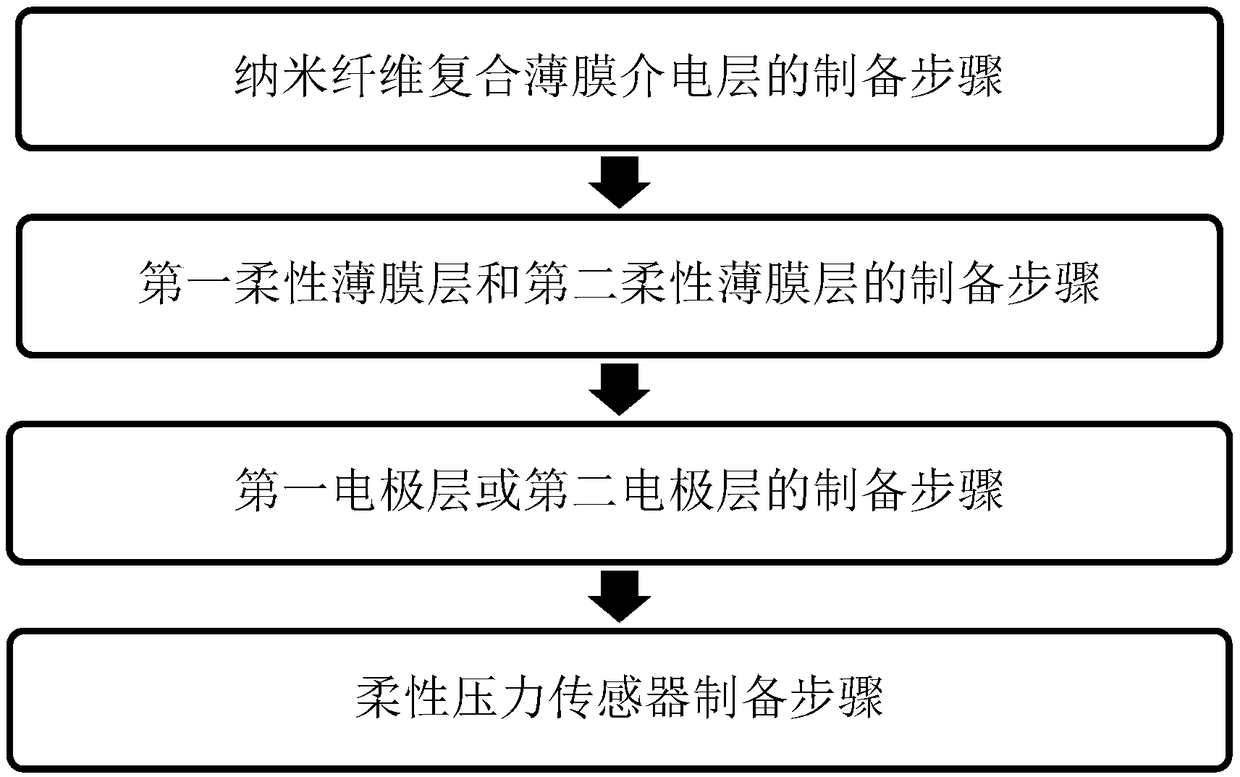

Method used

Image

Examples

Embodiment 1

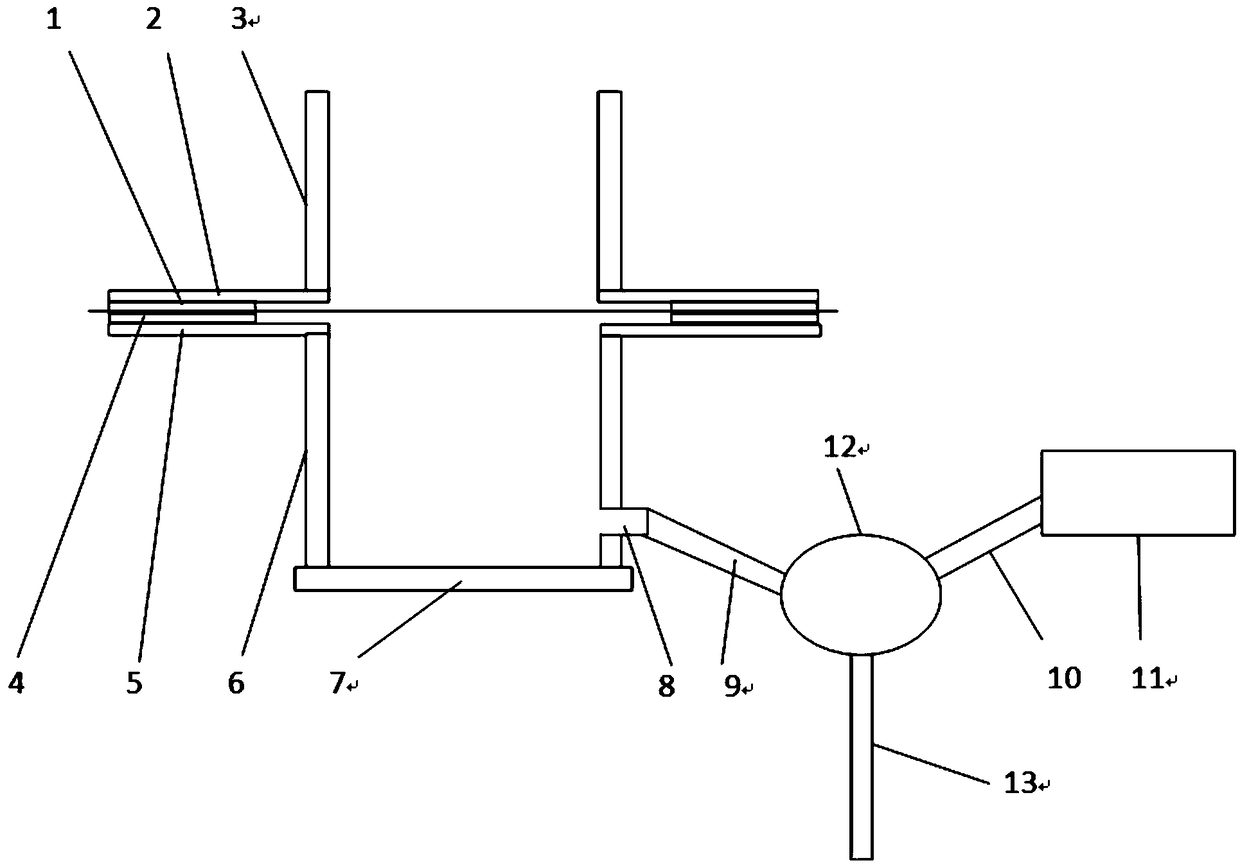

[0056] A preparation device for a composite material of graphene, nanofibers and nanoparticles, comprising: an upper cylinder 3, an upper pressure ring 2, an upper pressure ring rubber 1, a lower pressure ring rubber 4, a lower pressure ring 5, and a lower cylinder 6 , bottom plate 7, air outlet 8, air outlet pipe 9, buffer ball 12, lower liquid pipe 13, air extraction pipe 10, air extractor 11; Flange, the innermost side of the upper pressure ring has an upper groove that matches the upper flange, and the upper cylinder and the upper pressure ring are closely matched through the upper flange and the upper groove; the upper pressure ring rubber 1 is located under the upper pressure ring The surface is annular, and the lower pressure ring rubber 4 is located on the upper surface of the lower pressure ring and is annular. The upper pressure ring rubber 1 and the lower pressure ring rubber 4 have a thickness of 600um / 700um / 800um / 900um / A uniform thin layer of 1000um, and the uppe...

Embodiment 2

[0059] 1) Electrospinning membrane preparation steps: select an appropriate amount of PCL fiber and add it to 100ml of analytical pure chloroform, and disperse it ultrasonically for 20 minutes to obtain a PCL fiber chloroform dispersion with a mass percentage of 5%.

[0060]Select an electrospinning voltage of 10kV, an extrusion speed of 2.5ml / h, a receiving distance of 20cm, an electrospinning time of 2h, and an ambient temperature of 4°C to obtain a PCL electrospun membrane. Here, the voltage is as low as possible, the speed is as slow as possible, and the ambient temperature is high. It is expected to obtain an electrospun membrane with a gap as large as possible for subsequent preparations.

[0061] 2) Membrane clamping step: select the PCL electrospun membrane that is larger than the area of the upper pressure ring (2) or the lower pressure ring (5), and use a sufficient amount of tetrahydrofuran, absolute ethanol, double distilled water, and absolute ethanol in sequence...

Embodiment 3

[0065] 1) Electrospinning membrane preparation steps: select an appropriate amount of PCL fiber and add it to 100ml of analytically pure chloroform, and disperse it ultrasonically for 25 minutes to obtain a chloroform dispersion of PCL fiber with a mass percentage of 6%.

[0066] Select an electrospinning voltage of 12kV, an extrusion speed of 3.5ml / h, a receiving distance of 25cm, an electrospinning time of 2h, and an ambient temperature of 5°C to obtain a PCL electrospun membrane. Here, the voltage is as low as possible, the speed is as slow as possible, and the ambient temperature is high. It is expected to obtain an electrospun membrane with a gap as large as possible for subsequent preparations.

[0067] 2) Membrane clamping step: select the PCL electrospun membrane that is larger than the area of the upper pressure ring (2) or the lower pressure ring (5), and use a sufficient amount of tetrahydrofuran, absolute ethanol, double distilled water, and absolute ethanol in se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radial size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com