Method for fabricating composite geomaterial in wide size

A technology of composite geotechnical and manufacturing methods, which is applied in the field of civil engineering, can solve problems such as inability to achieve anti-seepage effect and troublesome manufacturing, and achieve the effects of low requirements for production equipment, simple construction, and good environmental performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

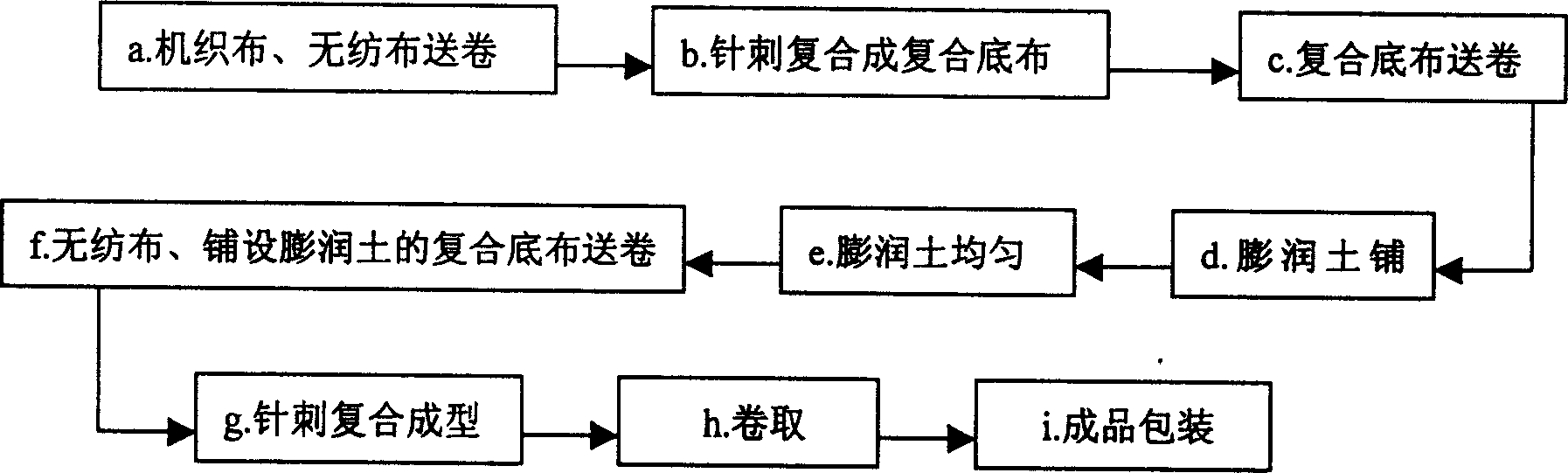

Method used

Image

Examples

Embodiment 1

[0013] Example 1: The woven fabric and the non-woven fabric are respectively fed into rolls at a speed of 2 m / min, and sent into the needling machine through the guide roller, the needling speed is 2 meters / min, and the needling frequency is 300 times / min , so that it is connected into a composite base fabric whose strength and elongation meet the design requirements. When the composite base fabric is sent into the powder spreading device at 2 m / min, the powder spreading roller starts to sprinkle powder at a speed of 400 g / min. Adjust the horizontal feeding screw roller to send the powdery or granular ore and nutritious soil to the entire width of the composite base cloth. The powdery or granular form and the nutrient soil are evenly spread, and the non-woven fabric and the composite base fabric laid with bentonite are sent to the roll at a speed of 2 m / min, and sent to the acupuncture machine through the cloth guide roller, and the acupuncture speed is 2 meters per minute, ac...

Embodiment 2

[0014] Example 2: The woven fabric and the non-woven fabric are respectively fed into rolls at a speed of 3 m / min, and sent into the needling machine through the guide roller, the needling speed is 3 meters / min, and the needling frequency is 700 times / min , so that it is connected into a composite base fabric whose strength and elongation meet the design requirements. When the composite base fabric is sent into the powder spreading device at 3 m / min, the powder spreading roller starts to sprinkle powder at a speed of 800 g / min. Adjust the horizontal feeding screw roller to send the powdery or granular ore and nutritious soil to the entire width of the composite base cloth. The powdery or granular form and the nutrient soil are evenly spread out, and the non-woven fabric and the composite base fabric laid with bentonite are respectively sent to roll at a speed of 3 m / min, and sent to the acupuncture machine through the cloth guide roller, and the needle punching speed is 3 m / min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com