Patents

Literature

90results about How to "The generation process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

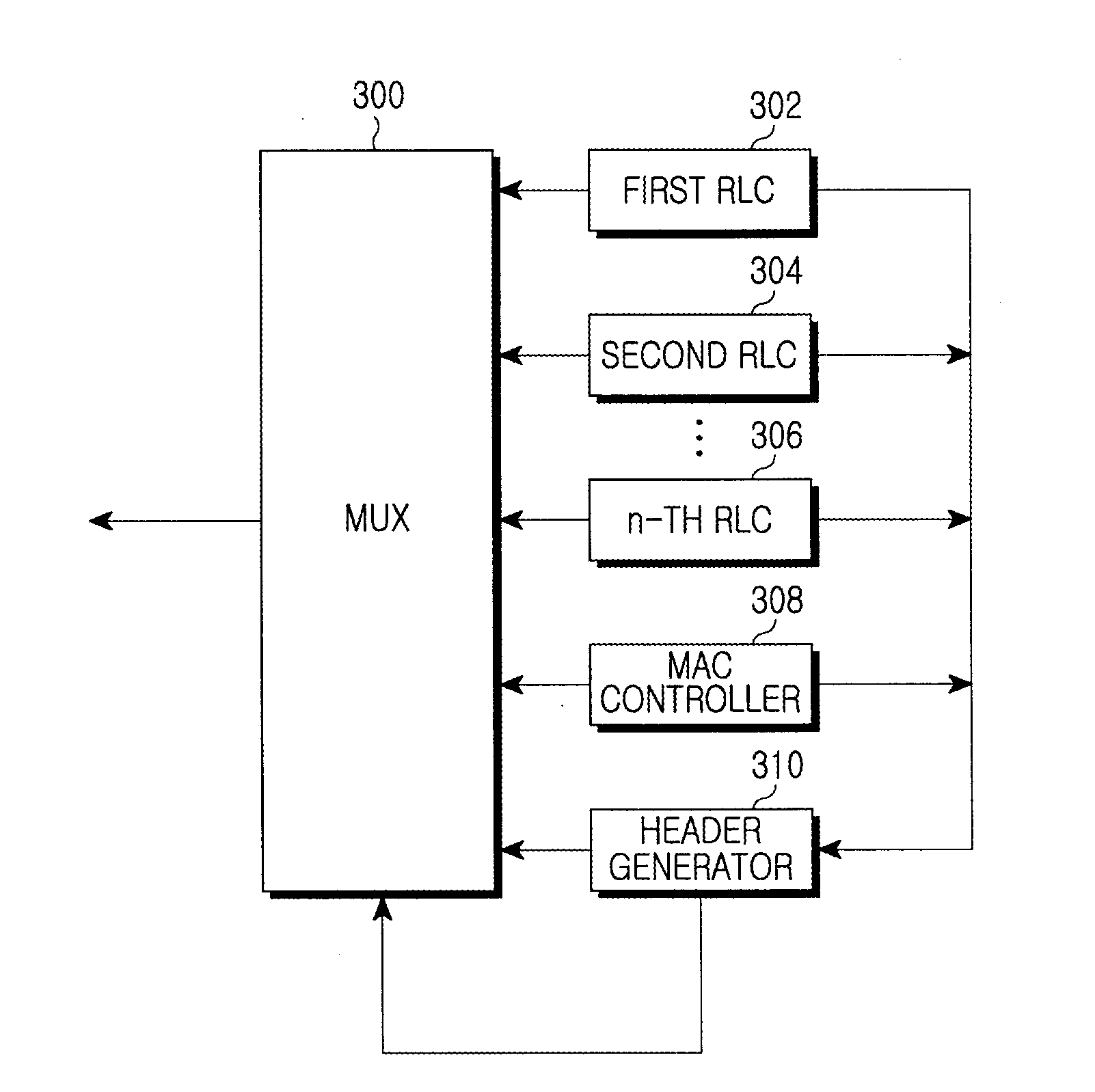

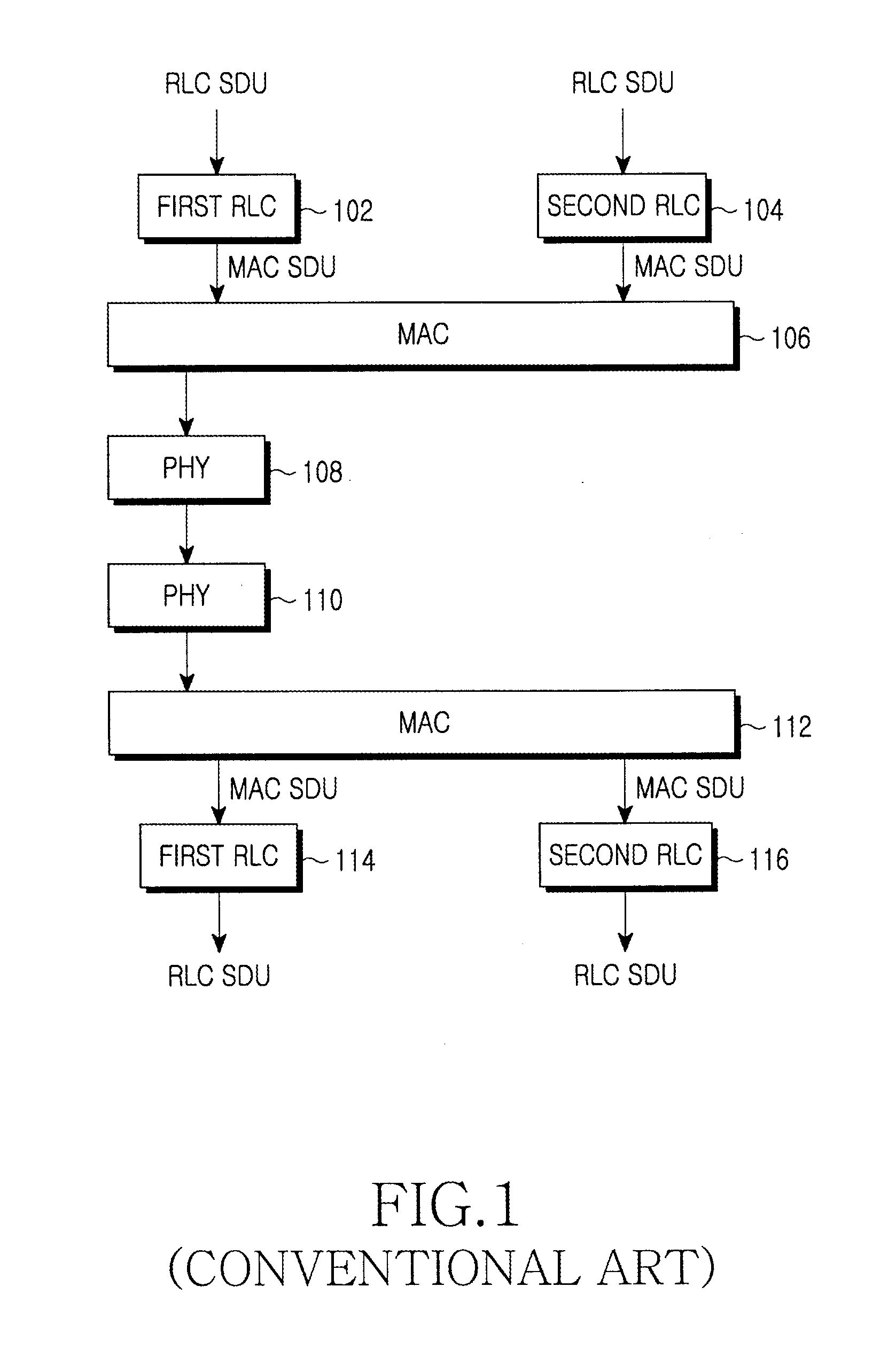

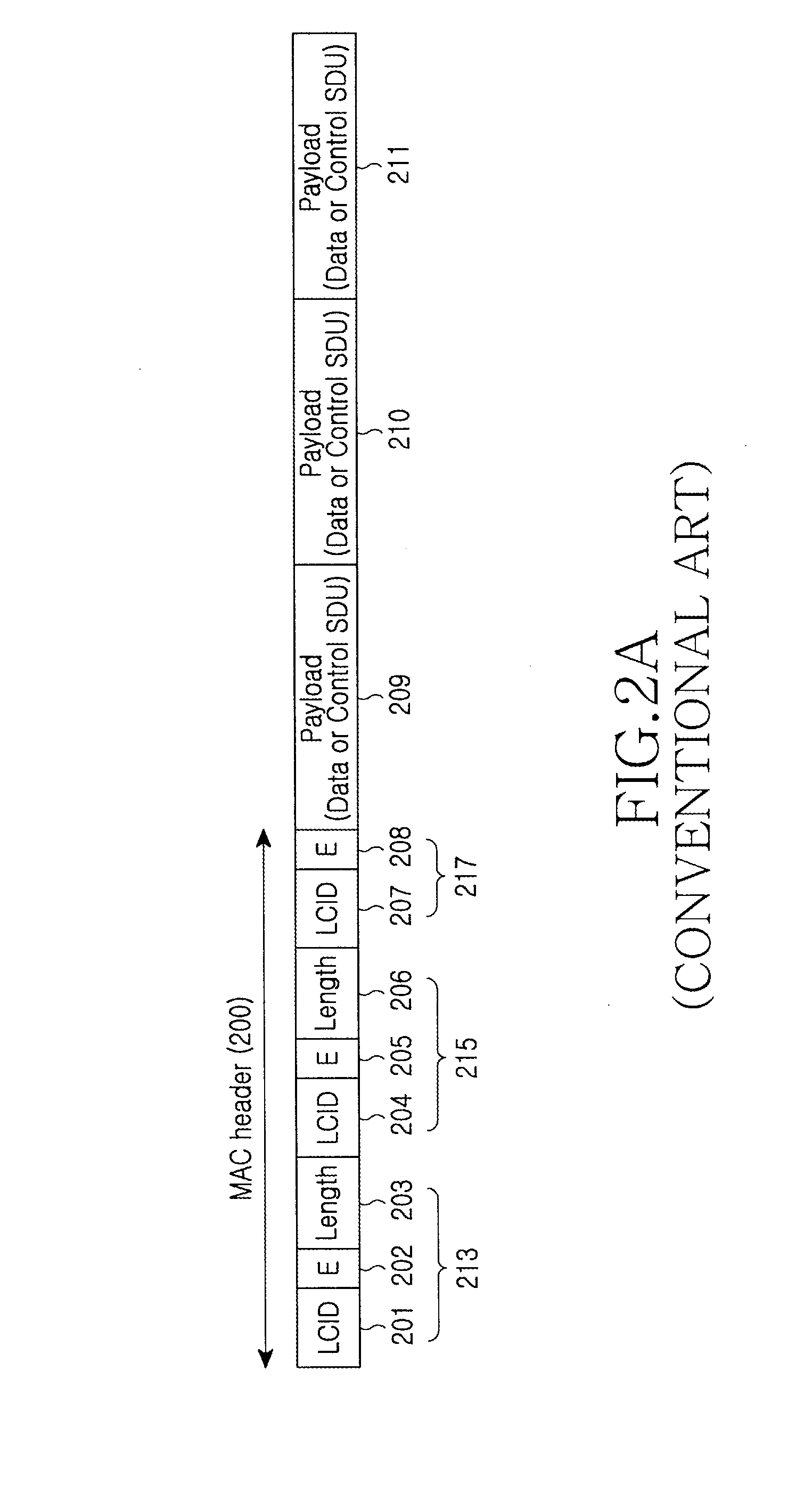

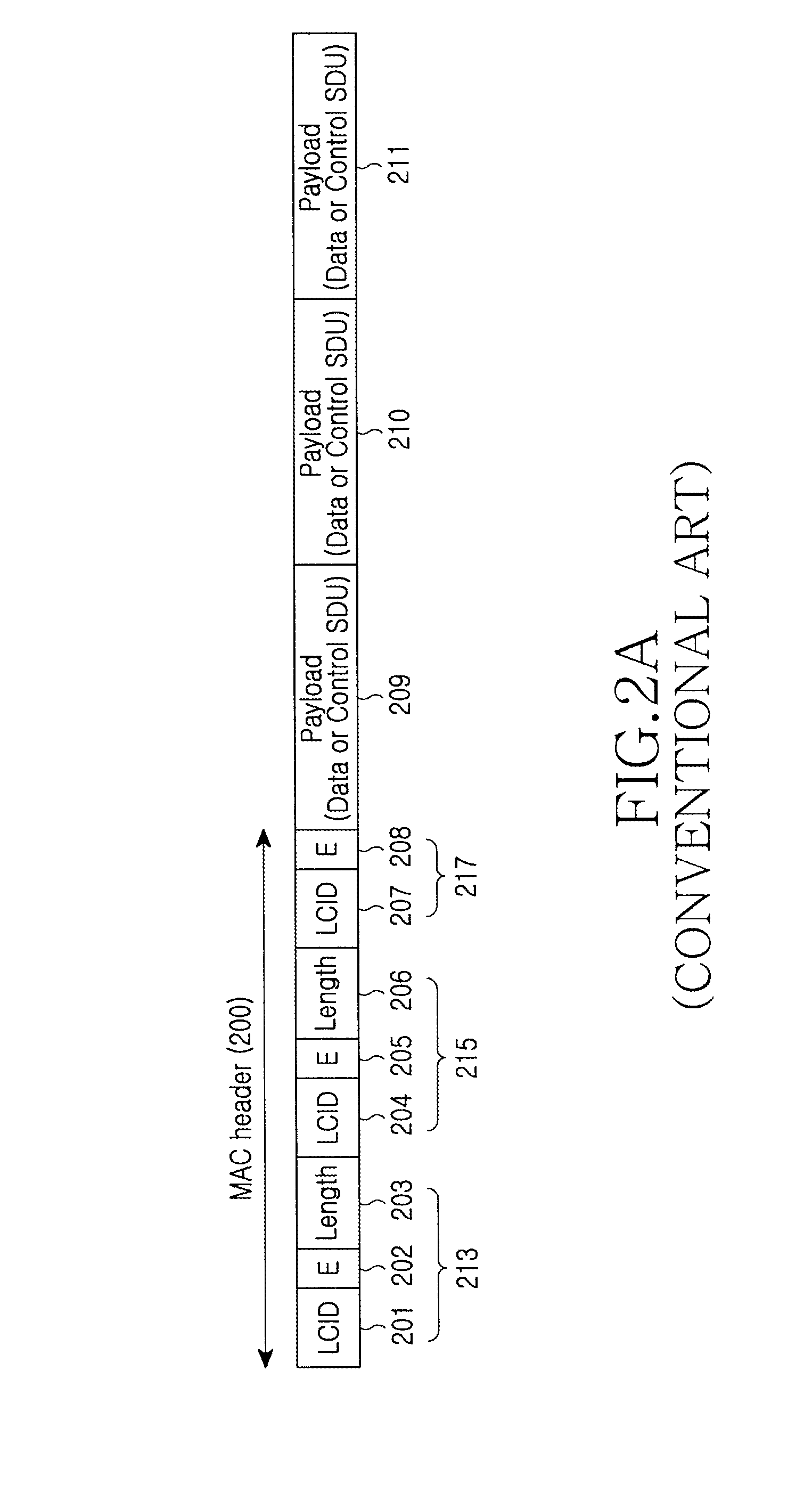

Apparatus and method for generating and parsing mac pdu in a mobile communication system

InactiveUS20090092138A1The generation process is simpleImprove processing speedNetwork traffic/resource managementTime-division multiplexReal-time computingPayload

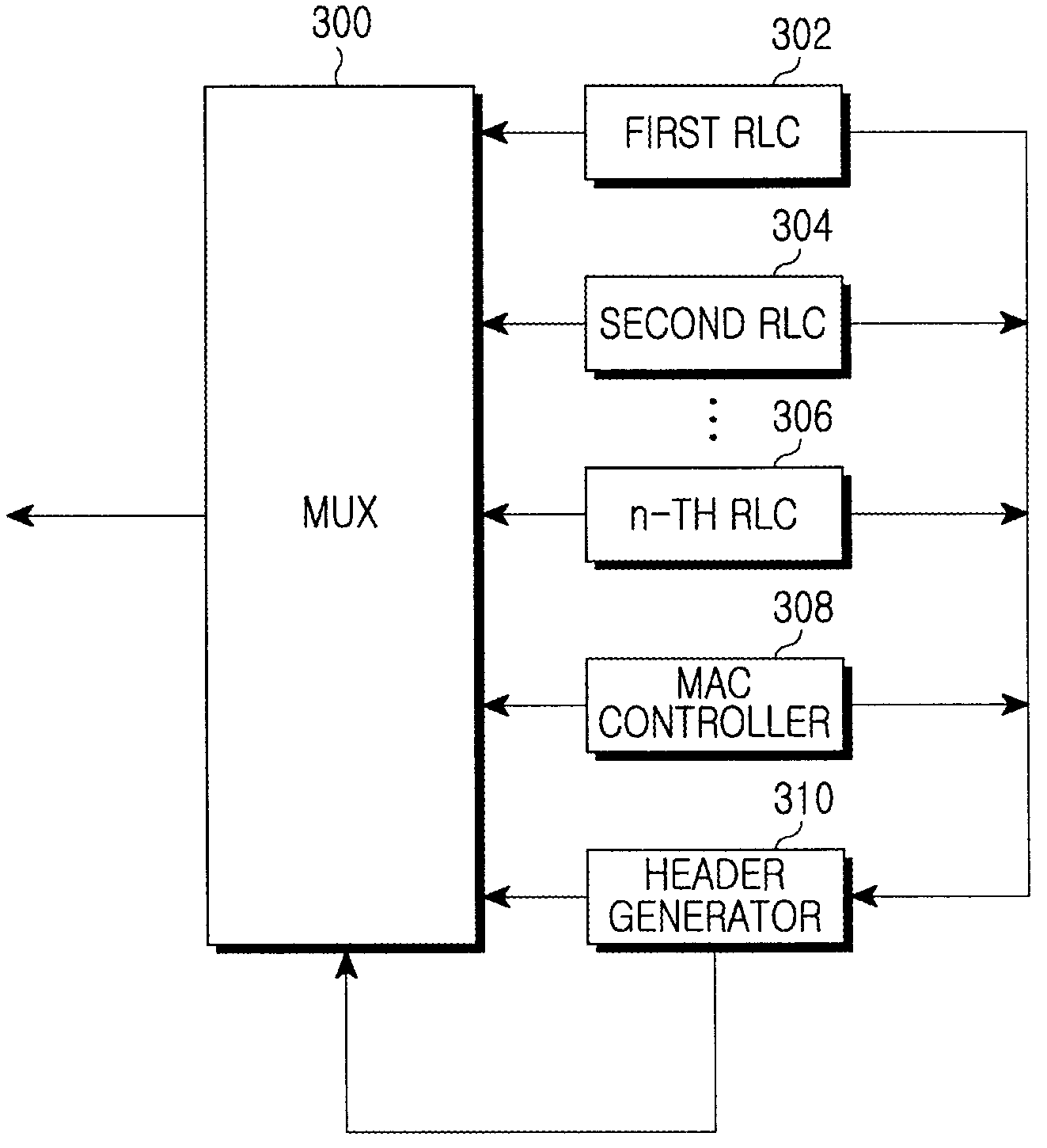

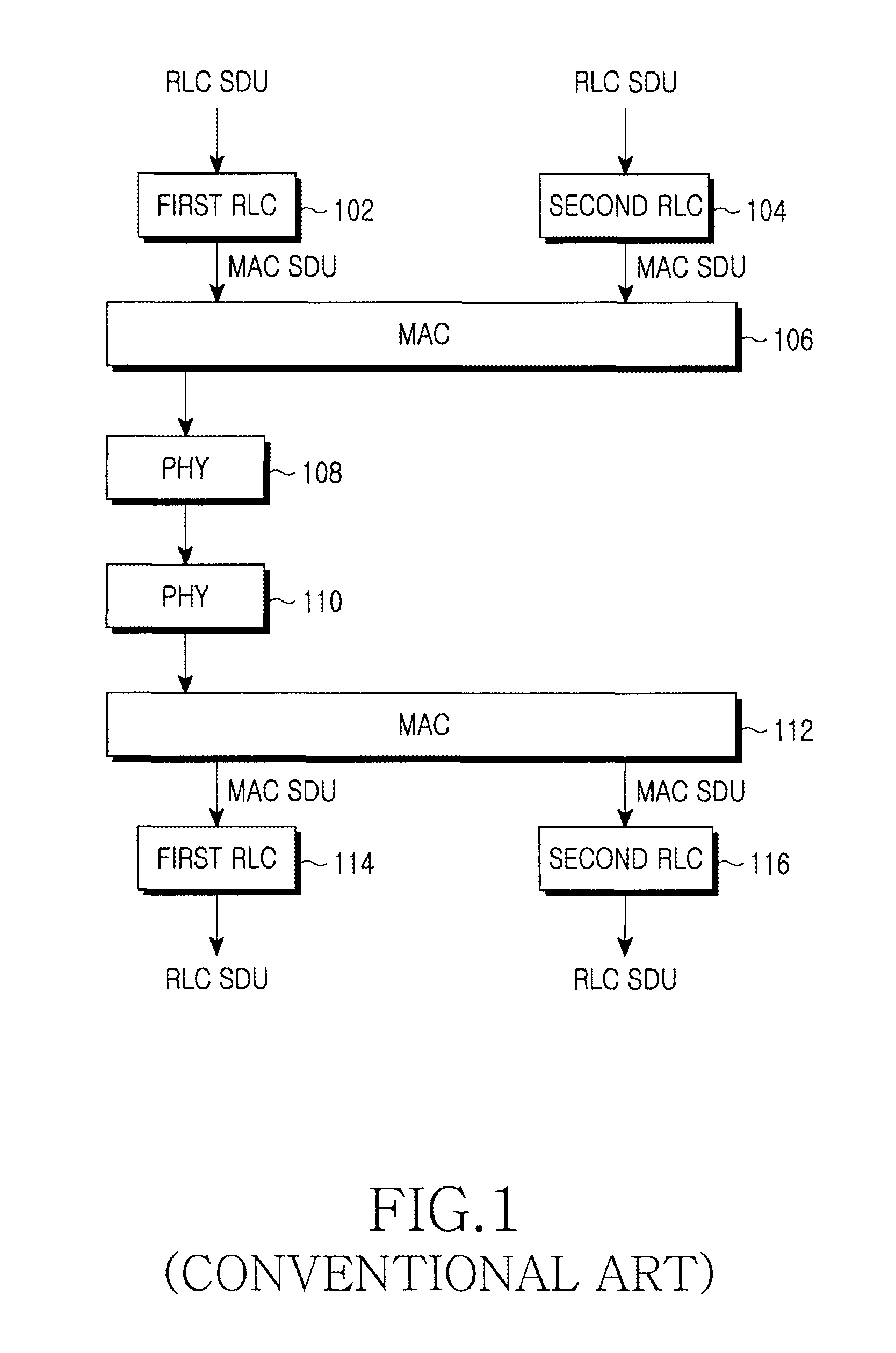

An apparatus and method for generating and parsing a MAC PDU in a mobile communication system are provided in which LCIDs of MAC SDUs to be multiplexed are checked, the length of an LF is determined for each of the MAC SDUs, referring to LF lengths predetermined for the LCIDs, a MAC header including the LCIDs and LFs of the determined lengths for the MAC SDUs is generated, and a MAC PDU is generated by attaching the MAC header to payload including the MAC SDUs. During the MAC header generation, if a padding size required for the MAC PDU generation calculated taking into account the absence of a last LF in the MAC header is larger than the length of the last LF, the last LF is included in the MAC header, the required padding size is recalculated, taking into account the inclusion of the last LF, and a padding is added according to the re-calculated padding size.

Owner:SAMSUNG ELECTRONICS CO LTD

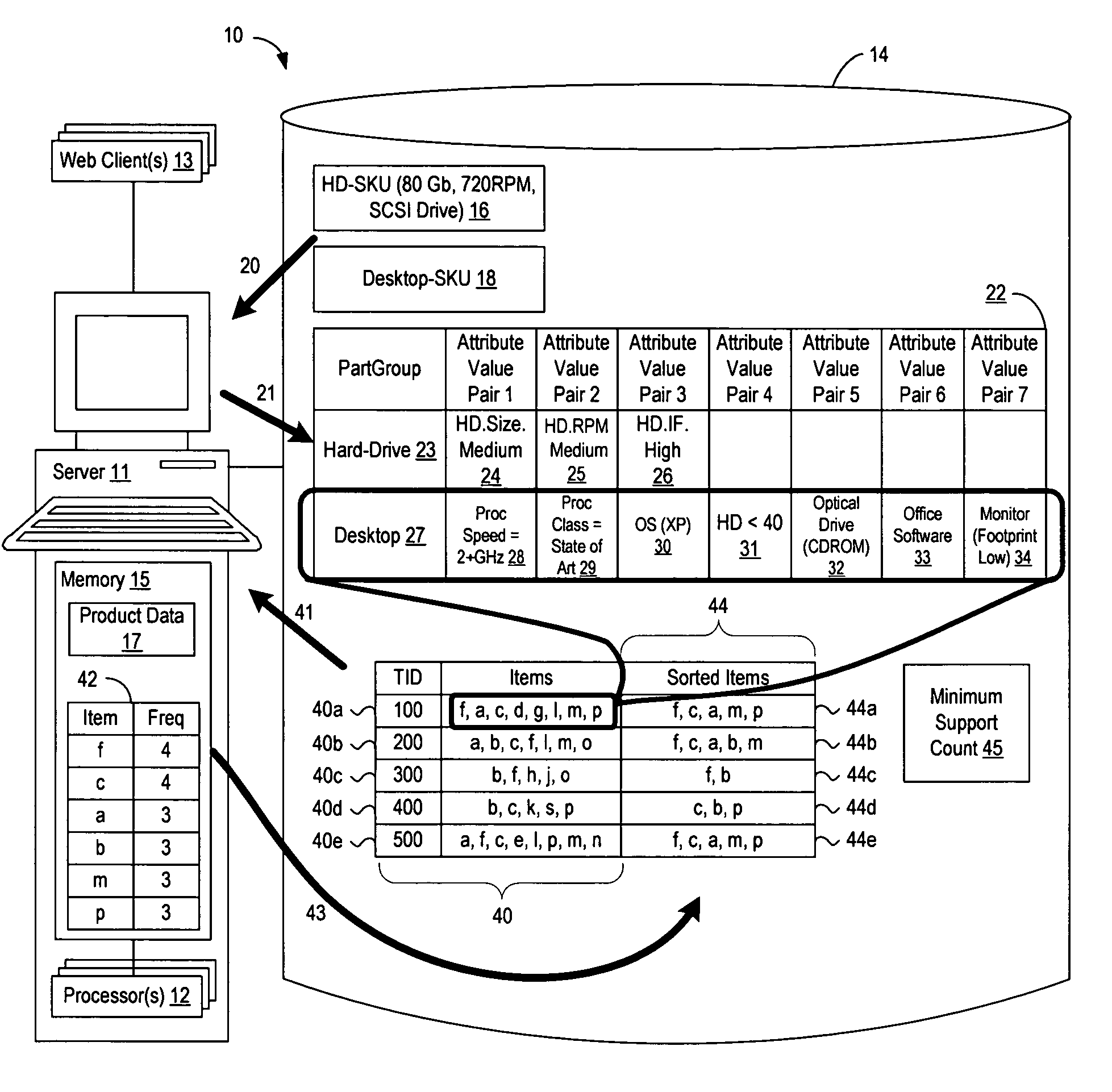

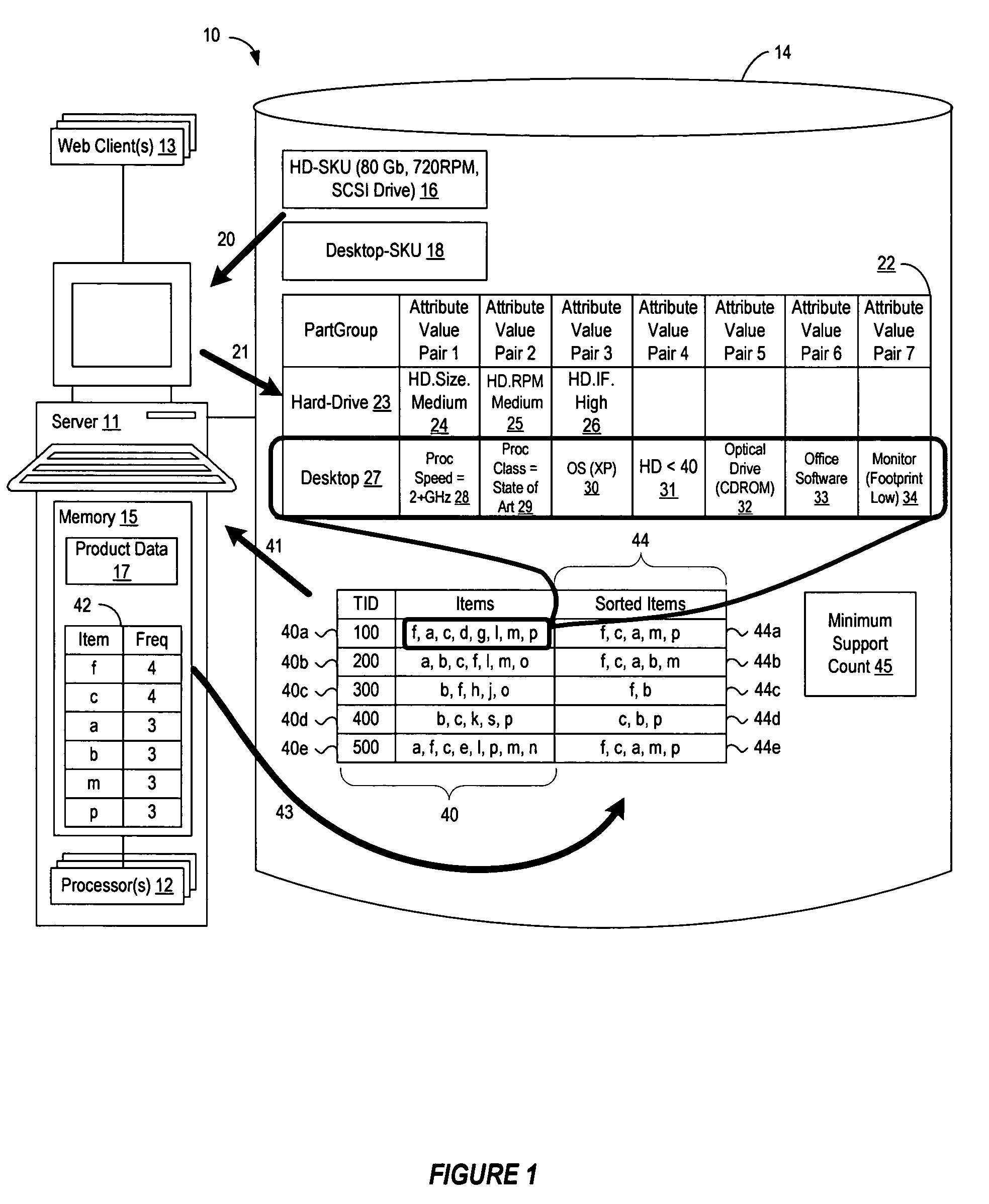

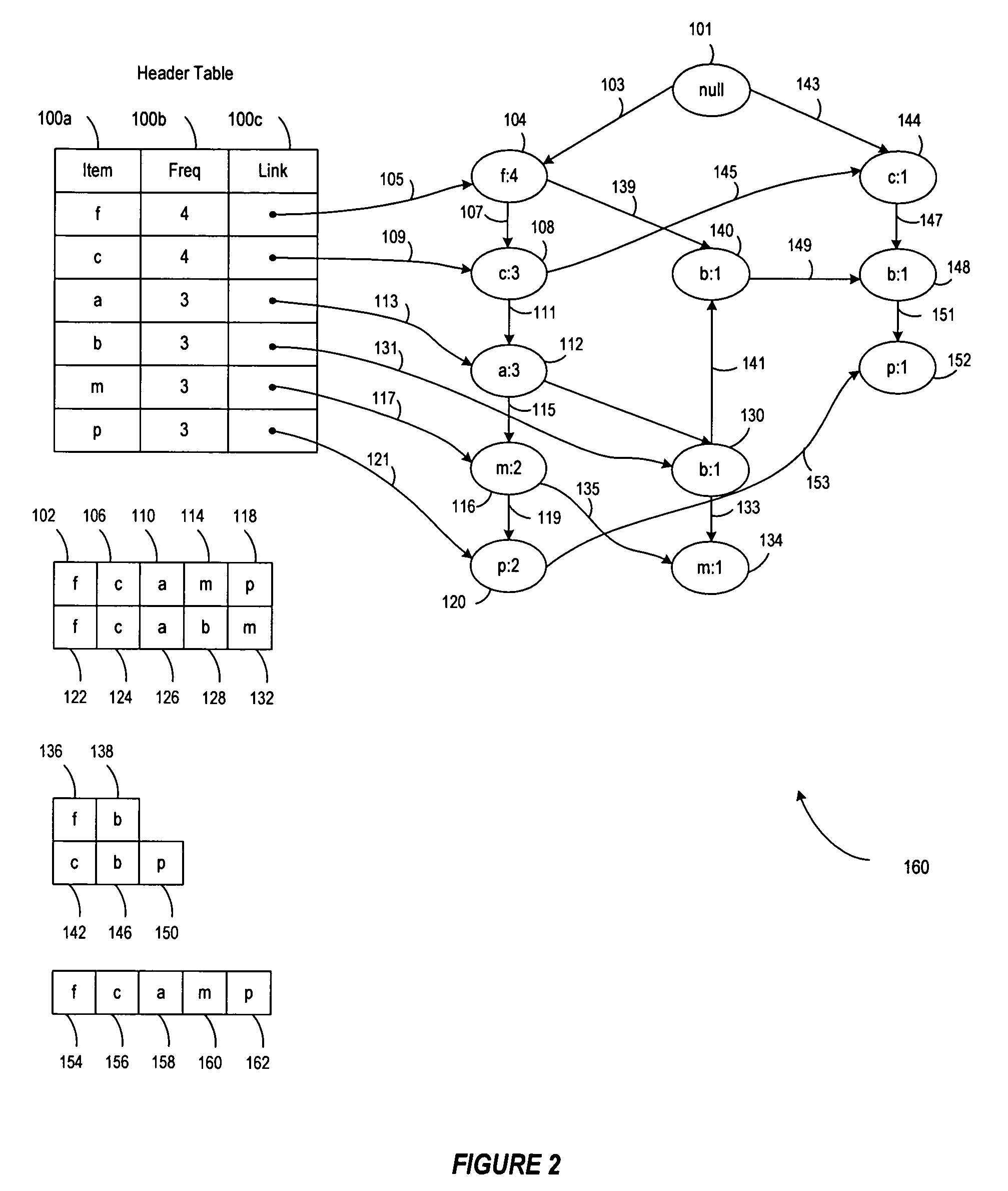

Attribute based association rule mining

ActiveUS7433879B1Improve patterningReduce in sizeData processing applicationsData miningRule miningInformation mapping

A data processing system processes data sets (such as low-resolution transaction data) into high-resolution data sets by mapping generic information into attribute-based specific information that is stored in a database. The extracting frequent pattern information from the database using frequent pattern growth techniques, a compact frequent pattern tree data structure efficiently holds frequent pattern information for multiple transactions having one or more items in each transaction. Frequent pattern data is transformed for ease of use with rule generation algorithms by removing redundant information (such as part group items) or by consolidating items corresponding to a part group and replacing those items with a proxy item for purposes of power set generation.

Owner:VERSATA DEV GROUP

Geopolymer-based inorganic artificial stone

The invention relates to geopolymer-based inorganic artificial stone. The traditional artificial stone has the shortcomings of easy yellowing, deformation and aging, high cost, highly-possible fire or melting after receiving heat radiation and the like. The geopolymer-based inorganic artificial stone provided by the invention is prepared from the following raw materials in percentage by mass: 5-15% of water glass, 5-20% of superfine slag powder, 60-80% of stone particles, 0.1-0.3% of pigment, 0.1-0.5% of redispersible latex powder, 1-3% of fiber and 3-5% of water. The geopolymer-based inorganic artificial stone provided by the invention has the characteristics of stable structure, high strength, good wear resistance, environment-friendly raw materials, simple production process, low cost and high smooth finish, and is non-toxic and environment-friendly. Apart from low cost, high product hardness and good surface smoothness, the geopolymer-based inorganic artificial stone also has the advantages that the production process is simple and convenient, the raw materials are widely available, the production process is environment-friendly, and the raw materials are environment-friendly.

Owner:广西启利新材料科技股份有限公司

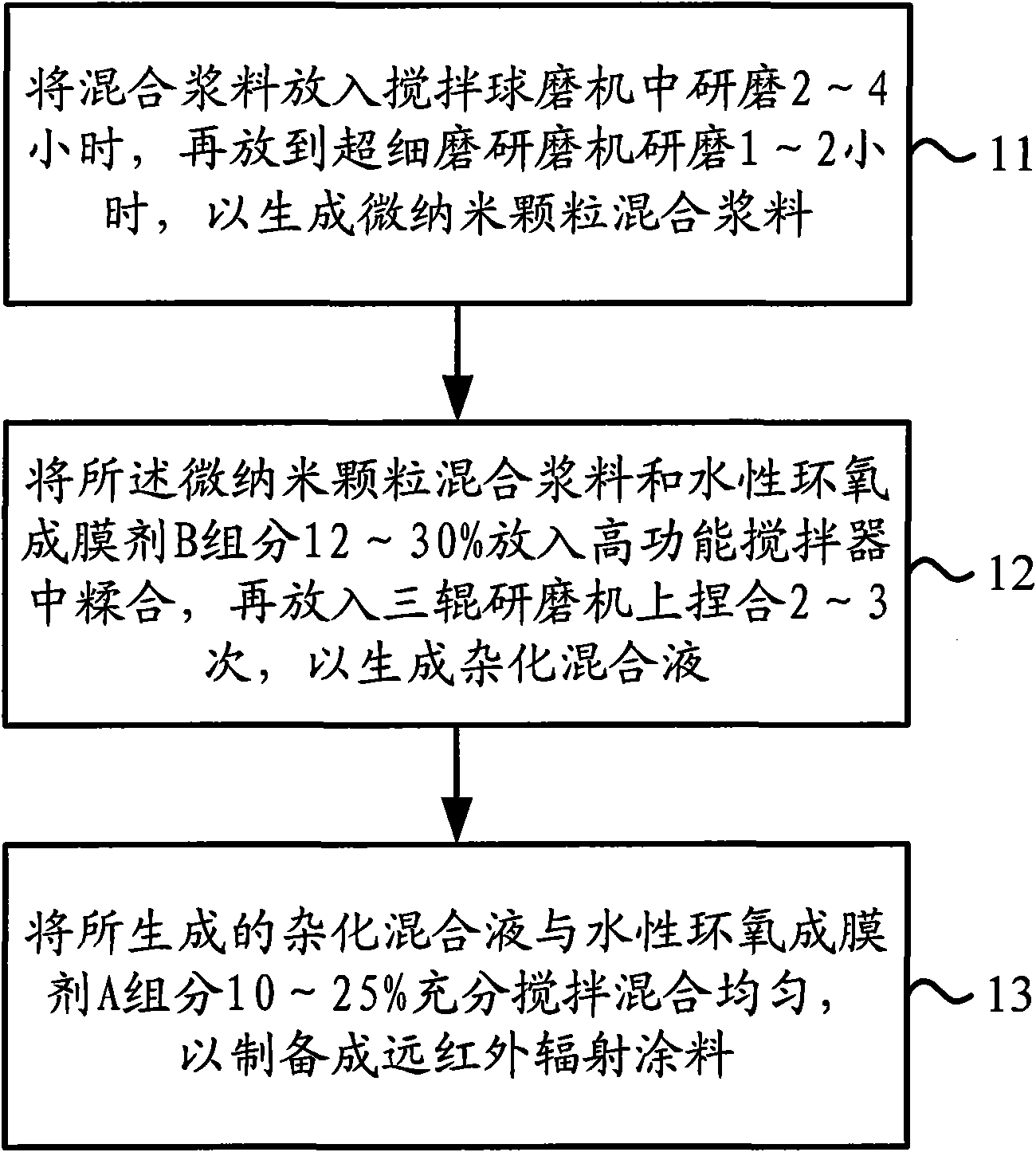

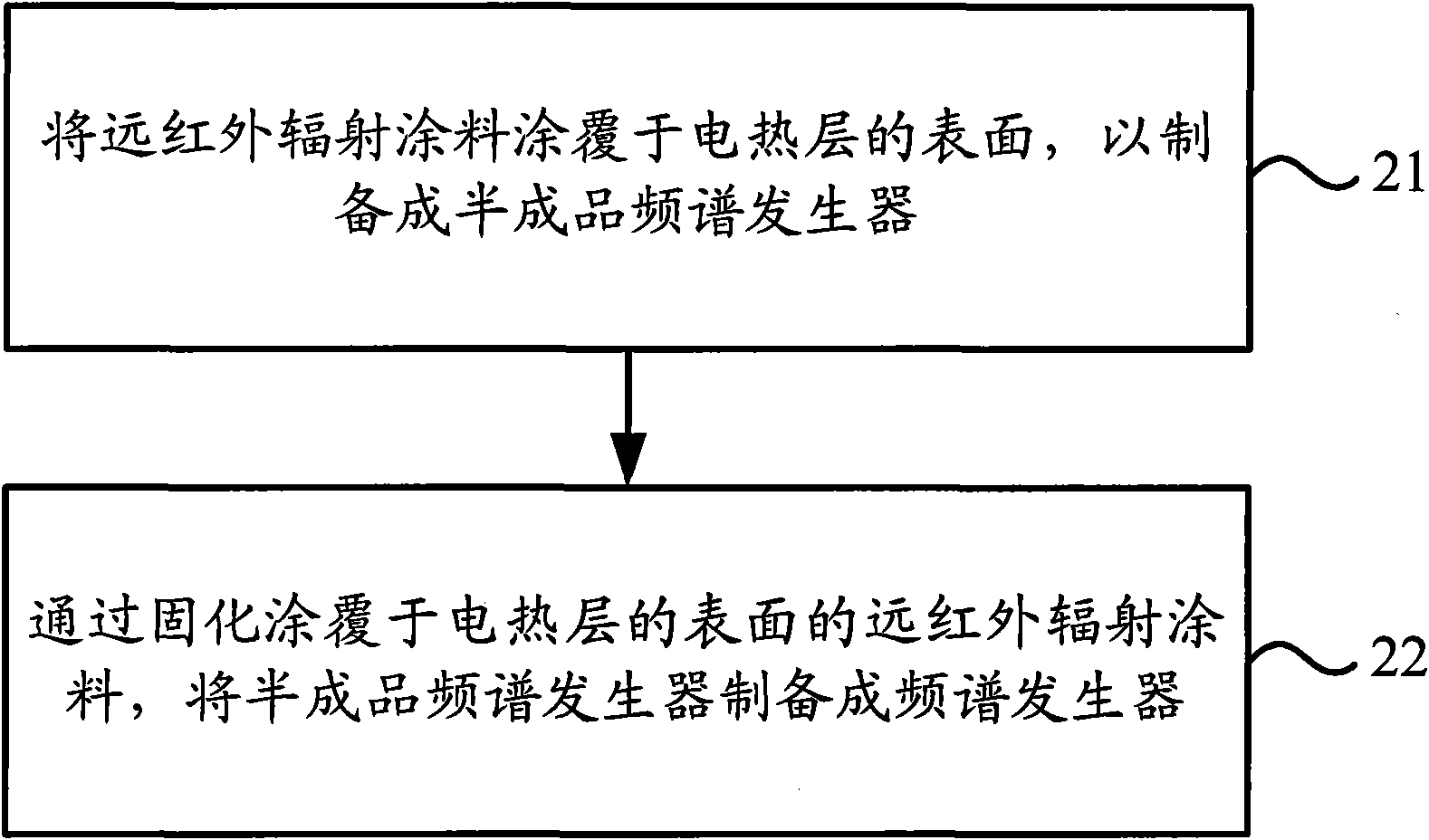

Spectrum generator, preparation method thereof and preparation method of far-infrared radiant coating

ActiveCN102031051ASimple structureThe generation process is simpleOhmic-resistance heatingLight therapyEpoxyMicro nano

The invention discloses a spectrum generator, a preparation method thereof and a preparation method of a far-infrared radiant coating. The preparation method of the far-infrared radiant coating comprises the following steps: putting a mixed slurry into a ball-stirring mill, grinding for 2-4 hours, then putting the slurry into an ultra-fine grinding machine, and grinding for 1-2 hours, so as to generate a mixed slurry of micro-nano particles; putting the mixed slurry of micro-nano particles and 12-30% of a component B of a water borne epoxy film-forming agent into a high-function stirrer for mixing, and putting the mixture into a three-roll grinder for kneading 2-3 times, so as to generate a hybrid mixed solution, wherein the component B of the water borne epoxy film-forming agent is a water borne epoxy curing agent; stirring and mixing the generated hybrid mixed solution and 10-25% of a component A of the water borne epoxy film-forming agent thoroughly and uniformly, so as to prepare the far-infrared radiant coating, wherein the component A of the water borne epoxy film-forming agent is epoxy resin or a epoxy resin mixture. By utilizing the method provided by the invention, the aims that the far-infrared radiant coating is prepared with a simple process and the radiant wavelength of the coating matches well with the best absorption wavelength of human body are realized.

Owner:GUANGDONG JUNFENG BFS TECH

Ca/Zn compound heat stabilizer

InactiveCN101857682AProlong the discoloration timeImprove heat resistancePolyvinyl chlorideLead salt

Owner:CHONGQING UNIV

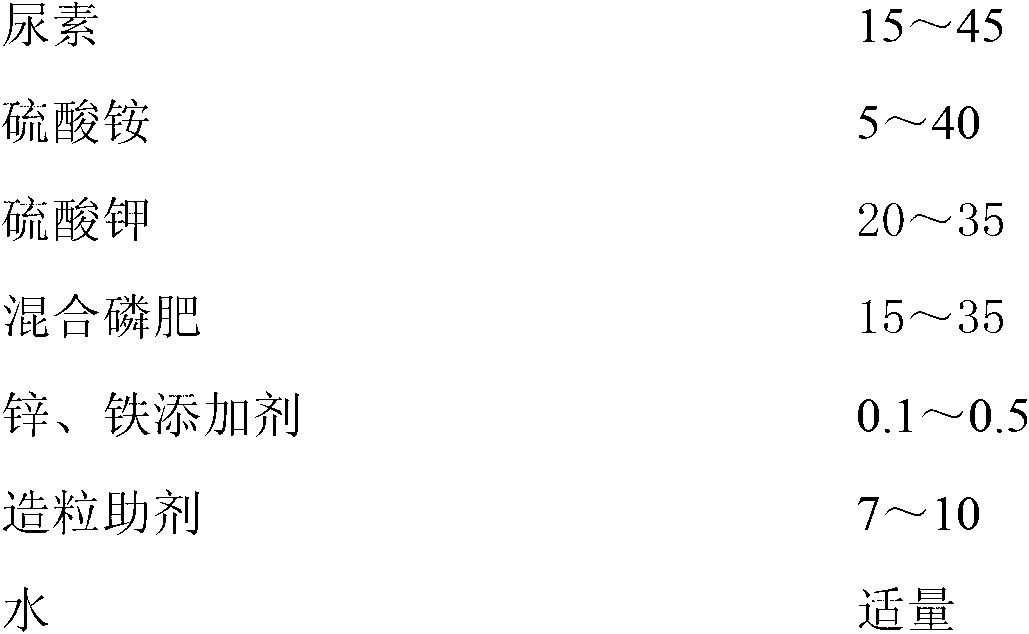

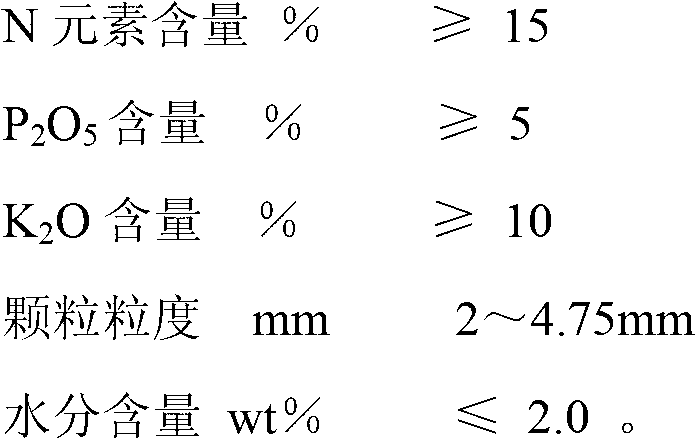

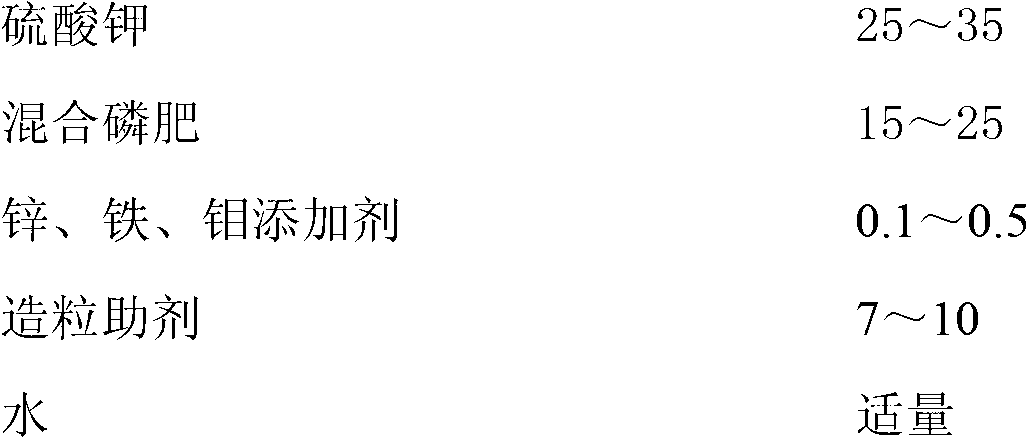

Preparation method for special slow-release long-acting compound fertilizer for corn

ActiveCN103058751AMeet nutrient needsIncrease productionFertilizer mixturesDusting powdersStearic acid

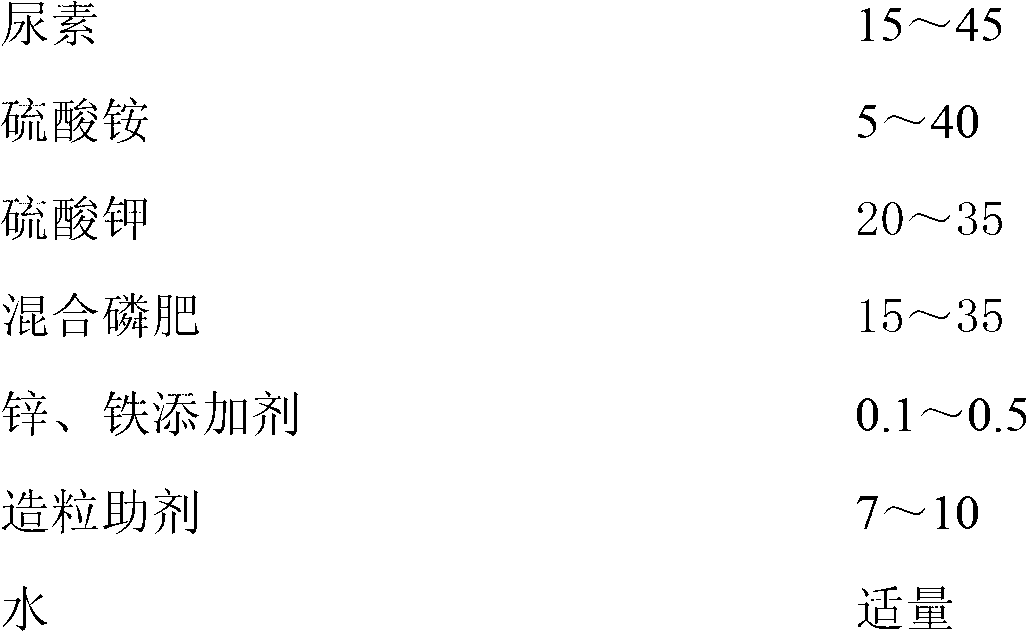

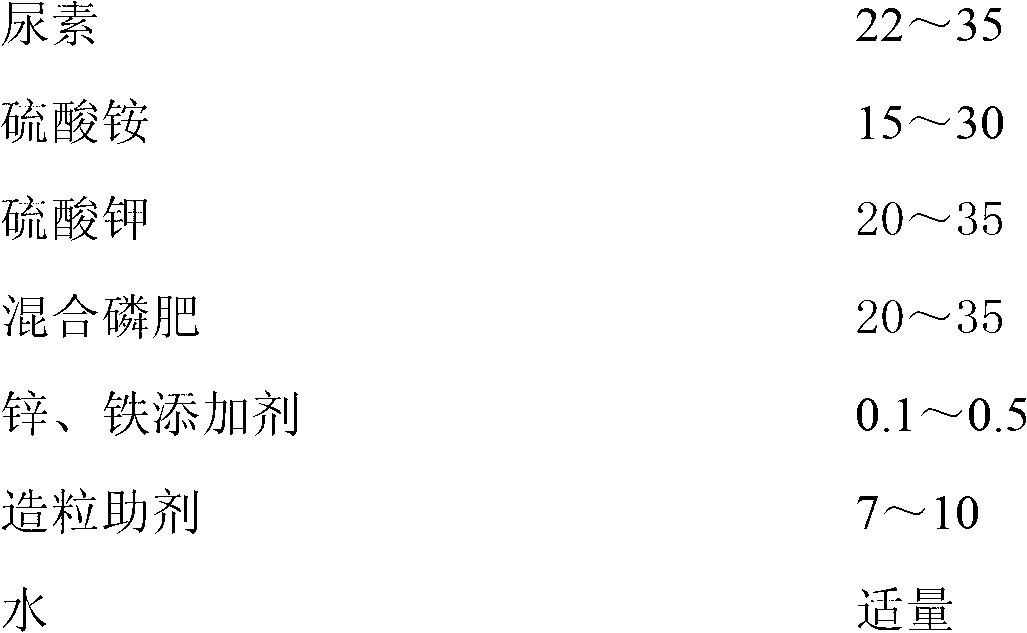

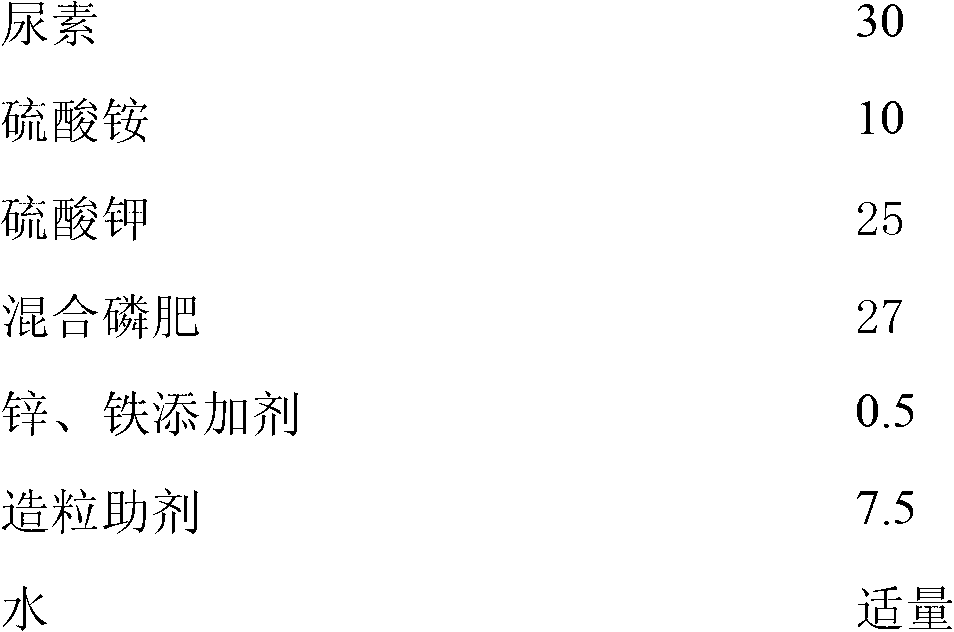

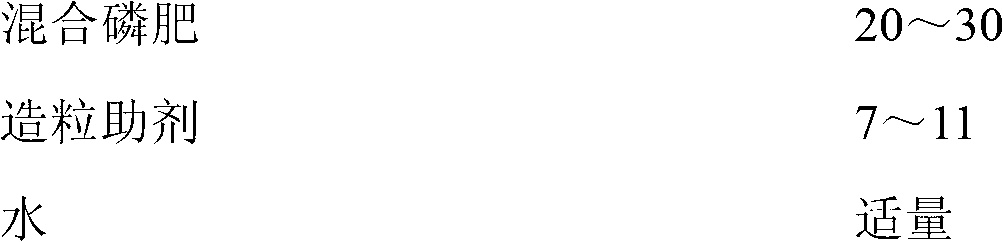

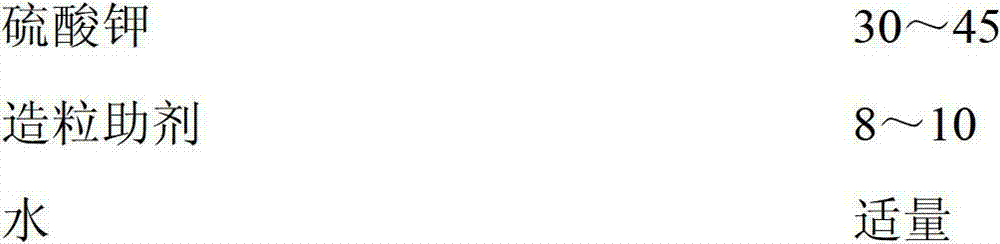

The invention provides a preparation method for a corn-special slow-release long-acting compound fertilizer, and belongs to the preparation of a mixture of a plurality of fertilizers and components without special fertilizer efficiency. The corn-special slow-release long-acting compound fertilizer is prepared by taking compound fertilizer particles as fertilizer cores, then performing coating and dusting powder treatments. The compound fertilizer particles are prepared by the following raw materials by mass: 15 to 45 parts of urea, 5 to 40 parts of ammonium sulfate, 20 to 35 parts of potassium sulfate, 15 to 35 parts of a mixed phosphate fertilizer, 0.1 to 0.5 part of a zinc and iron additive, 7 to 10 parts of a granulating auxiliary agent and a proper amount of water. The preparation method for the compound fertilizer comprises the following steps: (1) preparation of a compound of a potash fertilizer and a nitrogen fertilizer; (2) preparation of the mixed phosphate fertilizer; (3) preparation of mixed particles of the components of the compound fertilizer; (4) coating with stearic acid; (5) powder spreading of a modified zeolite powder material; and (6) screening, metering, quality inspection and packaging of qualified fertilizer. The invention provides the preparation method for the corn-special slow-release long-acting compound fertilizer which has overall nutrients and excellent slow releasing performance, improves both output and quality of corn, and saves resources and protects the environment.

Owner:SHIKEFENG CHEM IND

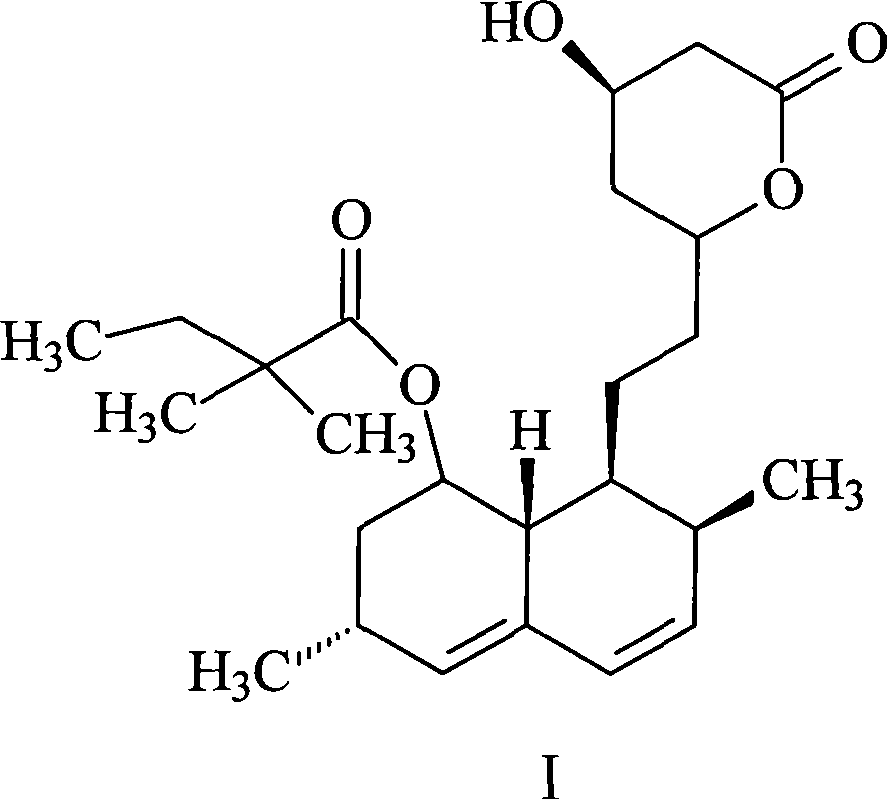

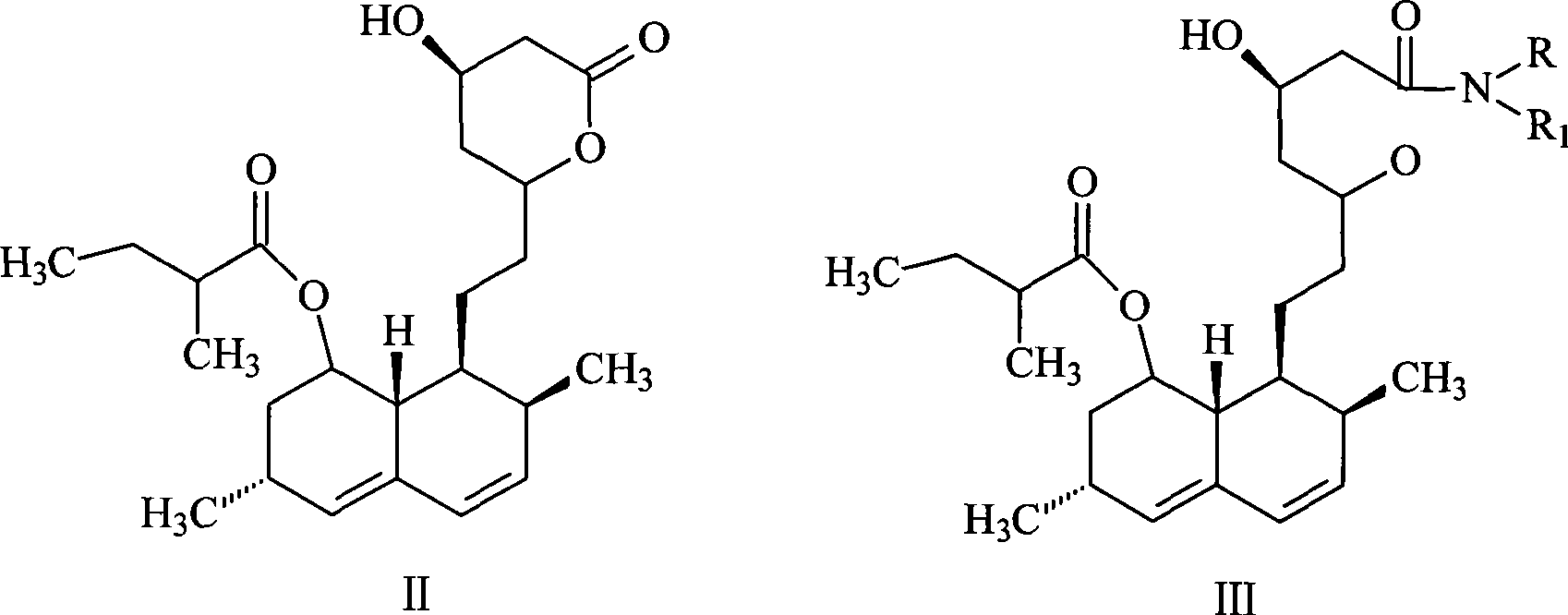

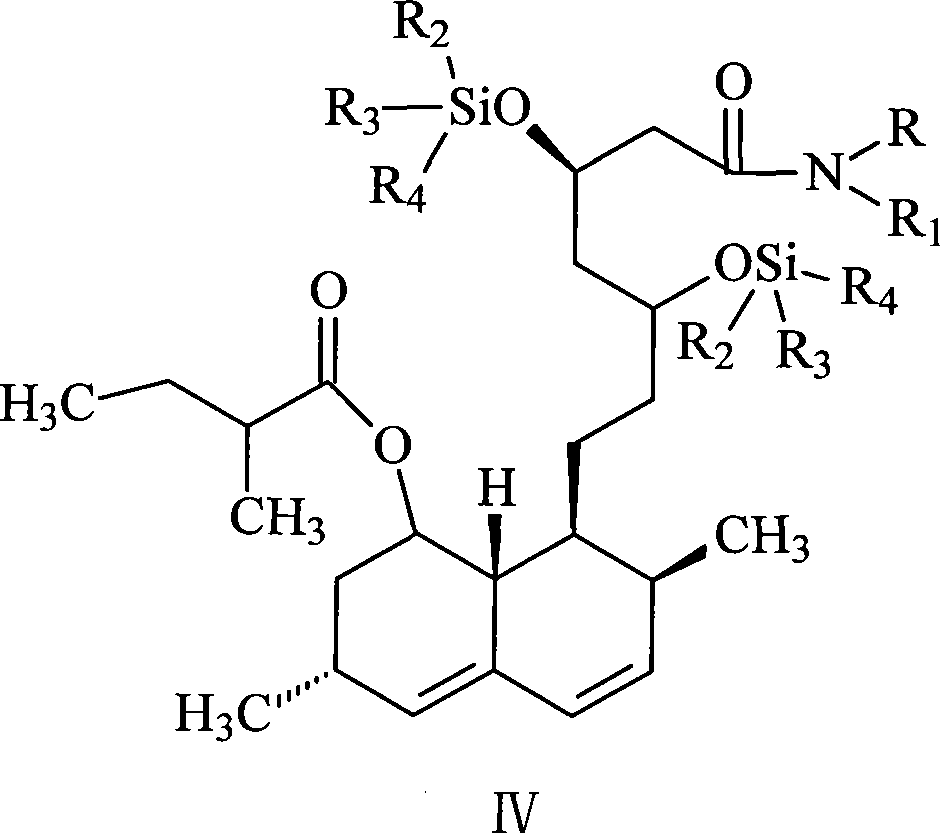

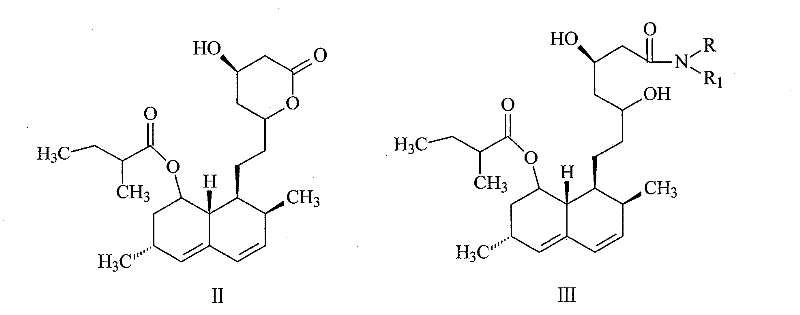

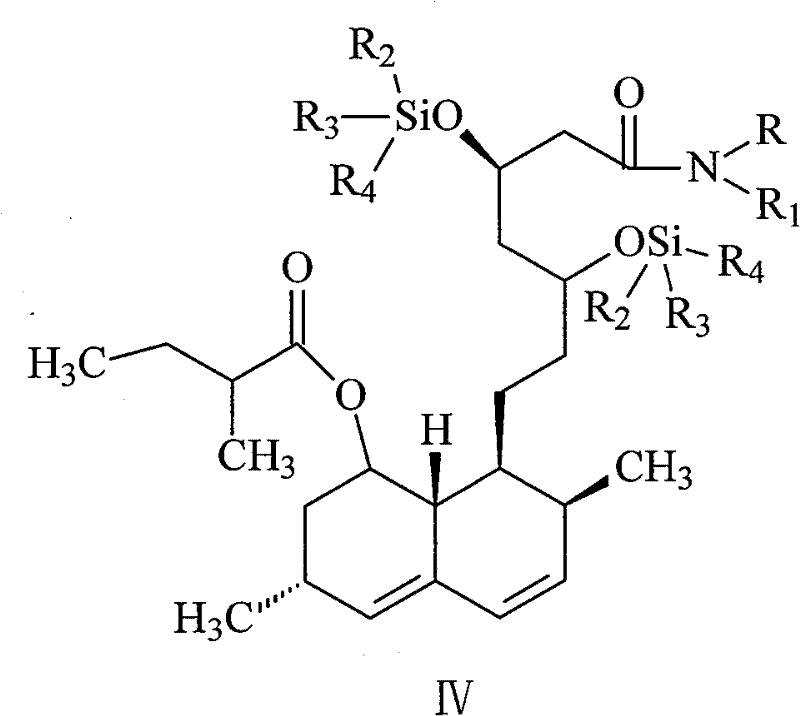

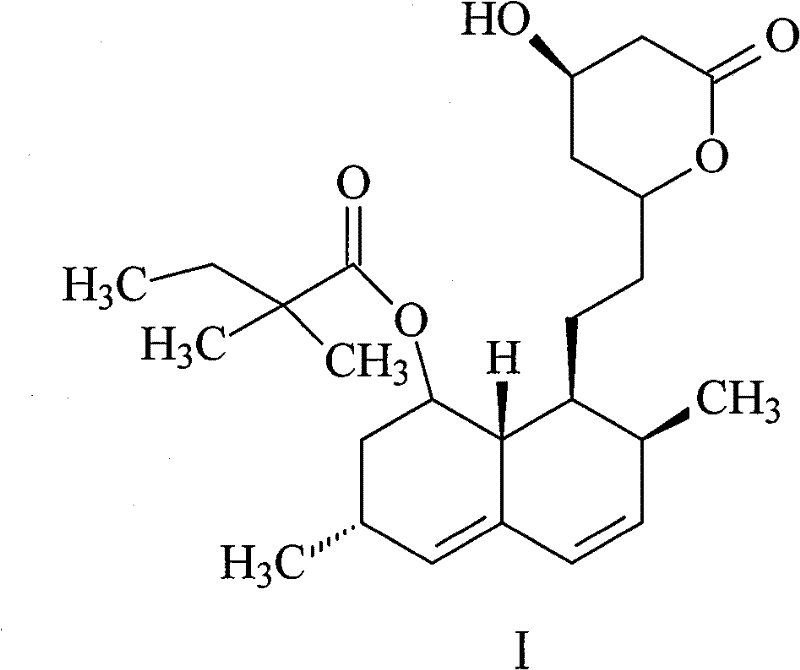

Preparation method of simvastatin

ActiveCN101381356AReduce manufacturing costSimple production processOrganic chemistryMetabolism disorderLovastatinHydrolysis

The invention discloses a method for preparing simvastatin. The method is as follows: a. lovastatin and alkylamine are prepared into lovastatin amide; b. hydroxyl groups in lovastatin amide molecules are protected, and lovastatin amide di-(trimethyl) silyl ether is generated; c. the lovastatin amide dimethyl (trimethyl) silyl ether is subjected to methylation, so as to obtain simvastatin amide di-silyl ether; d. the simvastatin amide di-silyl ether is protected, and simvastatin amide is generated; e. the simvastatin amide is subjected to hydrolysis and is added with ammonia gas, and simvastatin ammonium salt is obtained; and f. the simvastatin ammonium salt is subjected to ring closure to generate the simvastatin. The method takes a composite solvent of tetrahydrofuran and cyclonexane as a solvent for the protective reaction; the lovastatin amide di-(trimethyl) silyl ether can directly perform methylation reaction without alkaline washing and water scrubbing; after water scrubbing of methylate, protective groups are automatically fallen off, thereby the reaction for removing the protective groups is saved and the products can directly perform ammonium salt reaction. The method simplifies the synthesis technique of the simvastatin.

Owner:HEBEI GUOLONG PHARMA CO LTD

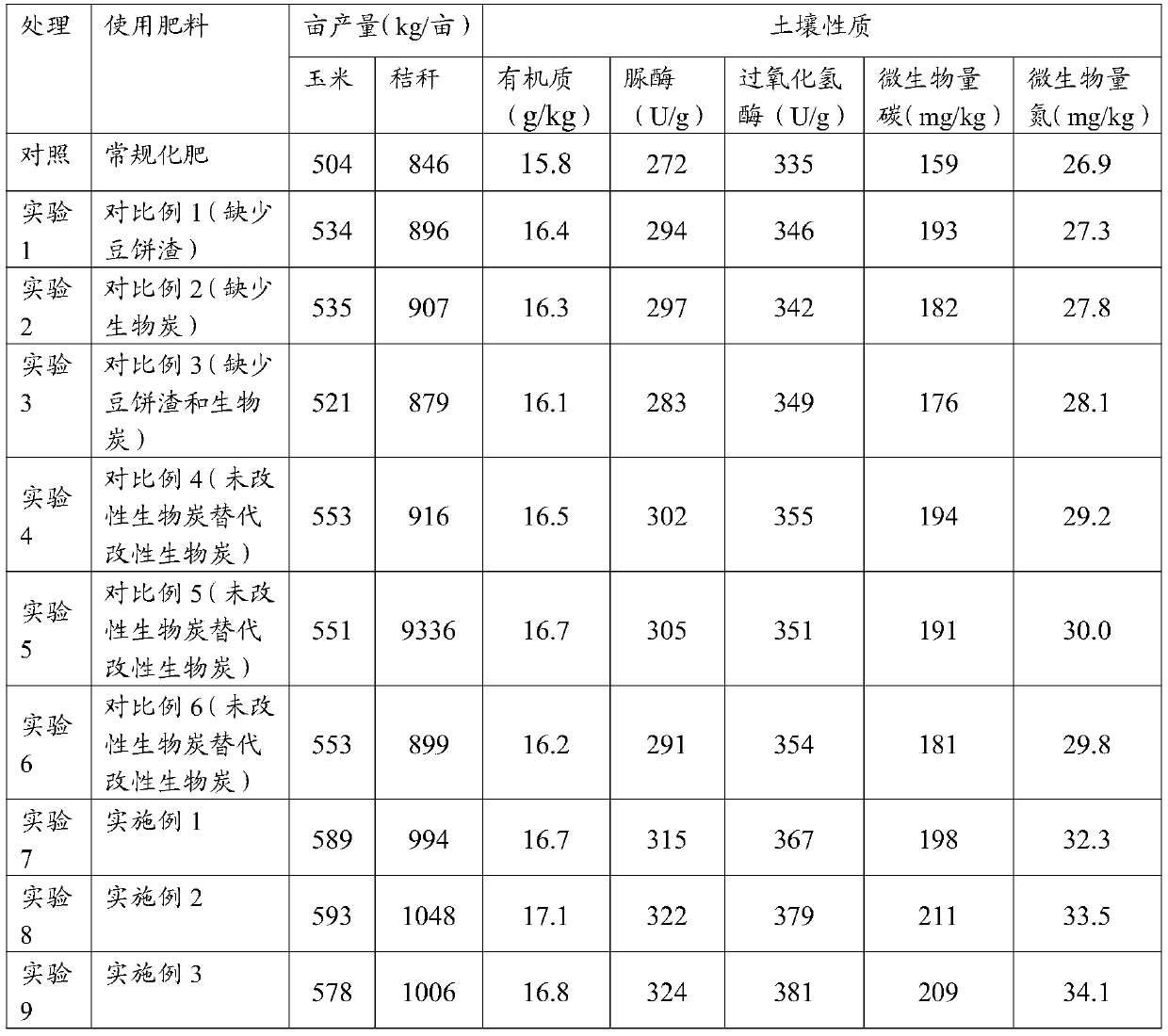

Biological organic fertilizer special for grain and preparation method of biological organic fertilizer

InactiveCN107935657AReduce pollutionThe generation process is simpleExcrement fertilisersBioloigcal waste fertilisersPoultry manureFermentation

The invention discloses biological organic fertilizer special for grain and a preparation method of the biological organic fertilizer. Fresh livestock and poultry manure, natural turf soil and agricultural waste are mixed evenly for fermentation, and the fermented mixture is compounded with biochar, humic acid, clay and the like to prepare the organic fertilizer, wherein the weight ratios of the basic components are as follows: 10-15 parts of the turf soil, 60-70 parts of the livestock and poultry manure, 5-10 parts of the humic acid, 15-20 parts of the agricultural waste, 5-10 parts of the clay, 5-10 parts of the biochar and 0.1-0.5 part of biological agents; the preparation method comprises the steps of fermentation, mixing, granulation, drying, cooling, screening and packaging. The biological organic fertilizer special for the grain has the advantages of rich raw materials, a simple process and low cost, has the effects of promoting grain growth, improving the grain quality and edible quality of millet, and improving the soil fertility, and solves the problems of loss of nutrients in the livestock and poultry manure and agricultural waste and pollution of the livestock and poultry manure and agricultural waste to the surrounding environment, thereby turning waste into treasure.

Owner:吉林省松岭有机肥业科技有限公司

Method for compounding WC-based nano composite powder by precursor method

PendingCN108543952AReduce manufacturing costReduce energy costsNanotechnologyArgon atmosphereTungstate

A method for compounding WC-based nano composite powder by a precursor method is characterized by comprising the following steps that firstly, water-soluble tungstate with a mass percent of 32.0%-45.0%, water-soluble cobalt salt with a mass percent of 10.0%-15.0%, water-soluble vanadium / chrome salt mixtures with a mass percent of 0.3%-0.5% and water-soluble organic carbon with a mass percent of40.0%-56.0% are dissolved in deionized water; secondly, solutions in the first step are evenly stirred with a glass rod and then heated and dried to obtain precursor composite powder containing a tungsten source, a cobalt source, a chrome source, a vanadium source and a carbon source; and thirdly, the precursor composite powder obtained in the second step is put in a high temperature reacting furnace, sintering is carried out under the condition of vacuum or argon atmosphere protection, and finally the WC-based composite powder with a nanometer size is prepared. According to the method, the preparation cost can be greatly reduced, the preparation cycle is shortened, and the method has the characteristics of being simple in process, even in product and the like and is suitable for industrial production.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Slow-release compound fertilizer applicable to plantation of corn

ActiveCN103058754AMeet nutrient needsIncrease productionDi-calcium phosphate fertilisersFertilising methodsDusting powdersStearic acid

The invention provides a corn-special slow-release long-acting compound fertilizer and belongs to the preparation of a mixture of a plurality of fertilizers and components with no special fertilizer efficiency. The invention is characterized in that the compound fertilizer is prepared by taking compound fertilizer particles as fertilizer cores, then performing coating and dusting powder treatment; the compound fertilizer particles are prepared by the following raw materials by the mass: 15 to 45 parts of urea, 5 to 40 parts of ammonium sulfate, 20 to 35 parts of potassium sulfate, 15 to 35 parts of a mixed phosphate fertilizer, 0.1 to 0.5 part of a zinc and iron additive, 7 to 10 parts of a granulating auxiliary agent and a proper amount of water. A preparation method for the compound fertilizer comprises the following steps: (1) preparation of a compound of a potash fertilizer and a nitrogen fertilizer; (2) preparation of the mixed phosphate fertilizer; (3) preparation of mixed particles of the components of the compound fertilizer; (4) coating with stearic acid; (5) powder spreading of a modified zeolite powder material; and (6) screening, metering, quality inspection and packaging of qualified fertilizer. The scorn-pecial slow-release long-acting compound fertilizer applicable to plantation of corn provided by the invention has overall nutrients and excellent slow releasing performance, improves both output and quality of corn, and saves resources and protects the environment.

Owner:甘肃施可丰生态科技有限公司

Preparation method for special slow-release long-acting compound fertilizer for paddy rice

ActiveCN103058752AReduce manufacturing costImprove protectionDi-calcium phosphate fertilisersAmmonium salt fertilisersStearic acidNutrient

The invention provides a preparation method for a special slow-release long-acting compound fertilizer for paddy rice. The compound fertilizer is a mixture of a plurality of fertilizers and components with no special fertilizer efficiency. The compound fertilizer granules are as fertilizer core and processed by coating and dusting powder; the compound fertilizer granules are characterized by being prepared from the following raw materials by mass: 25 to 45 parts of urea, 8 to 25 parts of ammonium chloride, 20 to 35 parts of potassium chloride, 20 to 35 parts of a mixed phosphate fertilizer, 7 to 11 parts of a granulating auxiliary agent and a proper amount of water. The preparation method for the compound fertilizer comprises the following steps: (1) preparation of a compound of a potash fertilizer and a nitrogen fertilizer; (2) preparation of the mixed phosphate fertilizer; (3) preparation of mixed particles of the components of the compound fertilizer; (4) coating with stearic acid; (5) powder spreading of a modified zeolite powder material; and (6) screening, metering, quality inspection and packaging of qualified fertilizer. The invention provides the preparation method for the special slow-release long-acting compound fertilizer which has overall nutrients and excellent slow releasing performance, enables fertilizer effectiveness to be maximumly performed, improves both output and quality of paddy rice and has low manufacturing cost.

Owner:SHIKEFENG CHEM IND

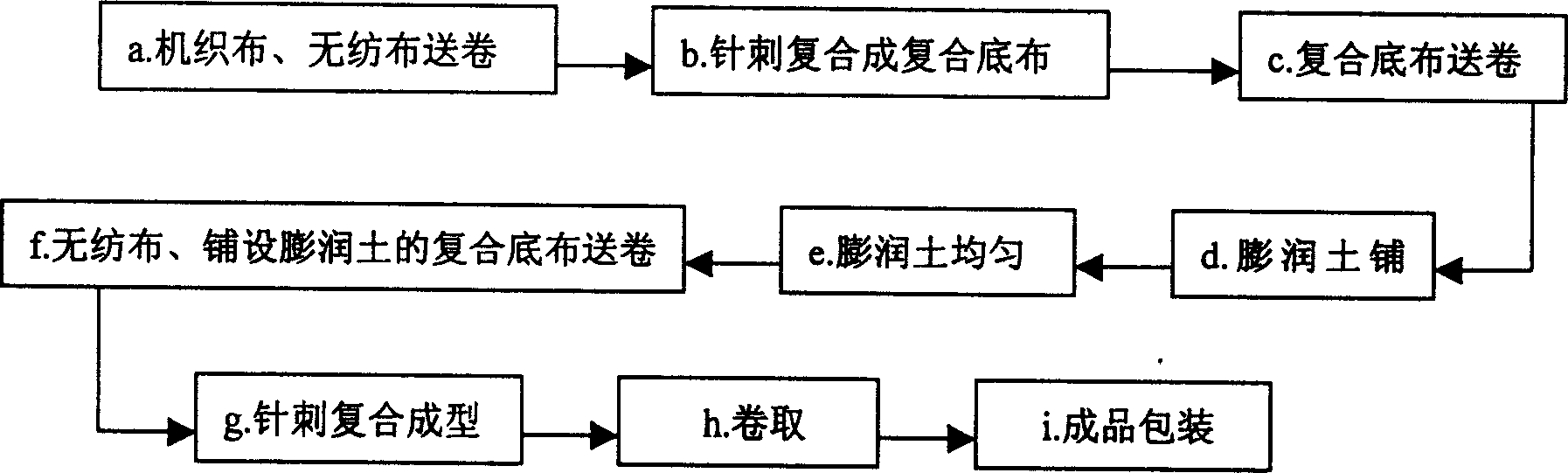

Method for fabricating composite geomaterial in wide size

Owner:SHANGHAI NEW TECHTEXTILES

A preparation method for a long-acting slow-release chlorine-based nitrogen and potassium-containing compound fertilizer

ActiveCN103058763AImprove protectionAvoid the disadvantages of high investment costsAgriculture gas emission reductionAmmonium salt fertilisersPotassiumStearic acid

The invention provides a preparation method for a long-acting slow-release chlorine-based nitrogen and potassium-containing compound fertilizer. The compound fertilizer belongs to mixed fertilizers containing substances affecting nitrification of ammonium-containing compounds or urea in soil, and is characterized by being prepared by: first preparing chlorine-based nitrogen and potassium-containing compound fertilizer granules, and then performing primary coating and a secondary surface powder putting by using a modified zeolite powder to the chlorine-based nitrogen and potassium-containing compound fertilizer granules by using stearic acid; wherein: the chlorine-based nitrogen and potassium-containing compound fertilizer is prepared from the following raw materials, by weight: 30-60 parts of urea, 10-20 parts of ammonium chloride, 22-53 parts of potassium chloride, 7-11 parts of granulating aids, and an appropriate amount of water. Provided is a preparation method by using which a long-acting slow-release chlorine-based nitrogen and potassium-containing compound fertilizer having good slow-release effect and high fertilizer utilization rate can be produced, wherein the elemental chlorine in the compound fertilizer can play a full role in the growth of crops, the process is simple, the production cost is low, and coating materials are easy to be degraded in the soil by microbes, which is beneficial to soil, air and water environmental protection. The long-acting slow-release chlorine-based nitrogen and potassium-containing compound fertilizer has a good sustained-release effect, and high fertilizer utilization rate, suitable for applying to various crops.

Owner:SHIKEFENG CHEM IND

Preparation method of simvastatin

ActiveCN101381356BReduce manufacturing costSimple production processOrganic chemistryMetabolism disorderLovastatinHydrolysis

Owner:HEBEI GUOLONG PHARMA CO LTD

Slow release compound fertilizer applicable to plantation of tobacco

The invention provides a slow release compound fertilizer applicable to plantation of tobacco. The slow release compound fertilizer is a mixture of a plurality of fertilizers containing substances which exert influence on nitrification of urea in soil and components with no special fertilizer efficiency and is prepared by taking compound fertilizer particles as the fertilizer core, then performing coating and dusting powder treatment. The compound fertilizer particles are prepared from the following raw materials by mass: 20 to 45 parts of urea, 10 to 20 parts of ammonium sulfate, 20 to 40 parts of potassium sulfate, 10 to 30 parts of a mixed phosphate fertilizer, 0.1 to 0.5 part of a zinc, copper, boron and molybdenum additive, 6 to 12 parts of a granulating auxiliary agent and a proper amount of water. A preparation method for the slow release compound fertilizer comprises the following steps: (1) preparation of a compound of a potash fertilizer and a nitrogen fertilizer; (2) preparation of the mixed phosphate fertilizer; (3) preparation of the compound fertilizer particles; (4) coating with stearic acid; (5) powder spreading of a modified zeolite powder material; and (6) screening. The invention provides the slow release compound fertilizer applicable to plantation of tobacco which has overall nutrients and excellent slow releasing performance, not only enables a high fertilizer utilization rate to be obtained, but also improves both output and quality of tobacco.

Owner:SHIKEFENG CHEM IND

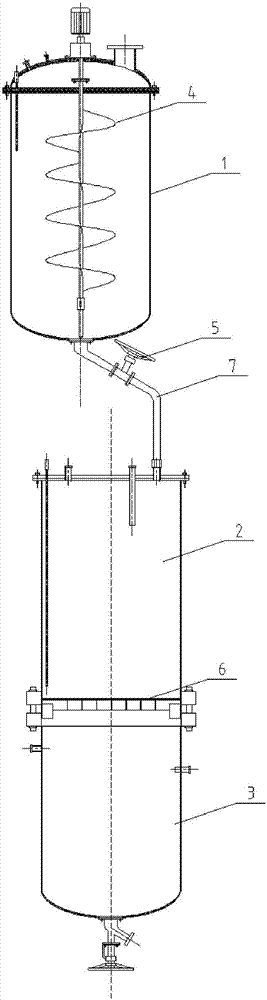

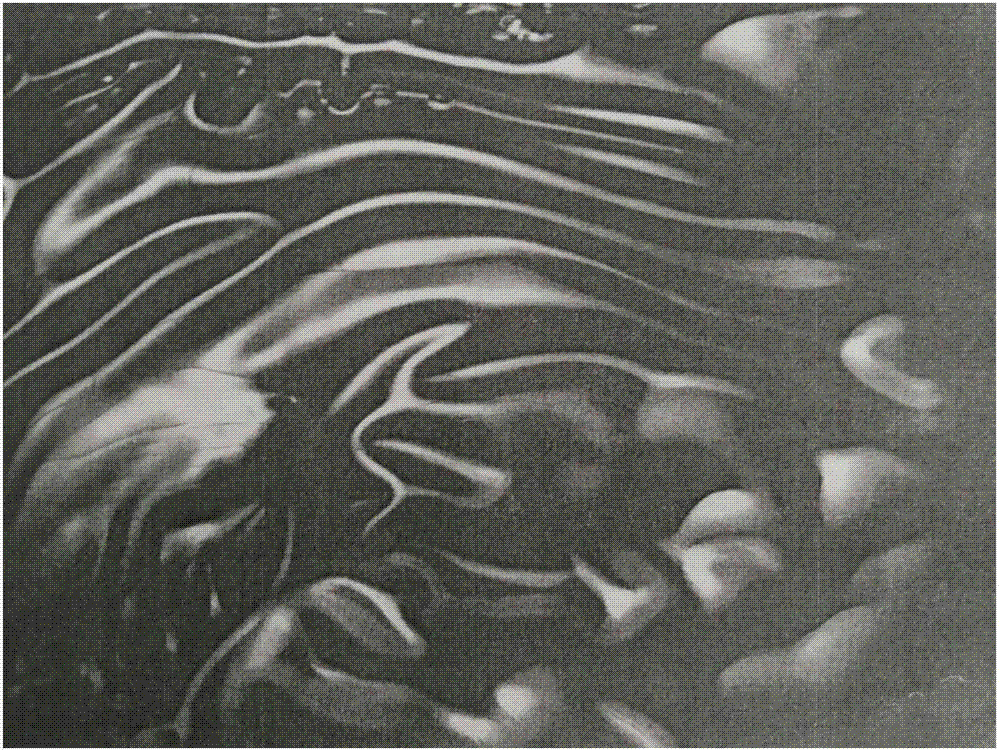

Method for preparing mesophase pitch by utilizing mesotherm coal pitch

ActiveCN107163969ALow ash contentSimple structureWorking-up pitch/asphalt/bitumen by chemical meansTar working-up by chemical refiningMetallurgyReaction temperature

The invention discloses a method for preparing mesophase pitch on the basis of mesotherm coal pitch used as a raw material. The method comprises the following steps: firstly, performing preheating polycondensation reaction, precise heat filtering and cutting light component treatment on the mesotherm coal pitch, thereby acquiring refined coal pitch with ultralow quinoline insoluble content, and then performing heating polycondensation reaction for 1-10h on the refined coal pitch under the reaction temperature of 400-460 DEG C, pressure of 3-5MPa and stirring speed of 50-500r / min, thereby acquiring the mesophase pitch. According to the invention, an integrated device is adopted for simultaneously completing the operations, such as, heating polycondensation and heat filtering and is assisted by simple light component cutting and drying technologies to prepare high-quality mesophase pitch; the production technology is simplified; the production cost is lowered; the yield of the acquired mesophase pitch is within 10-30%; the pitch is low in ash content and has an excellent optical tissue structure.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

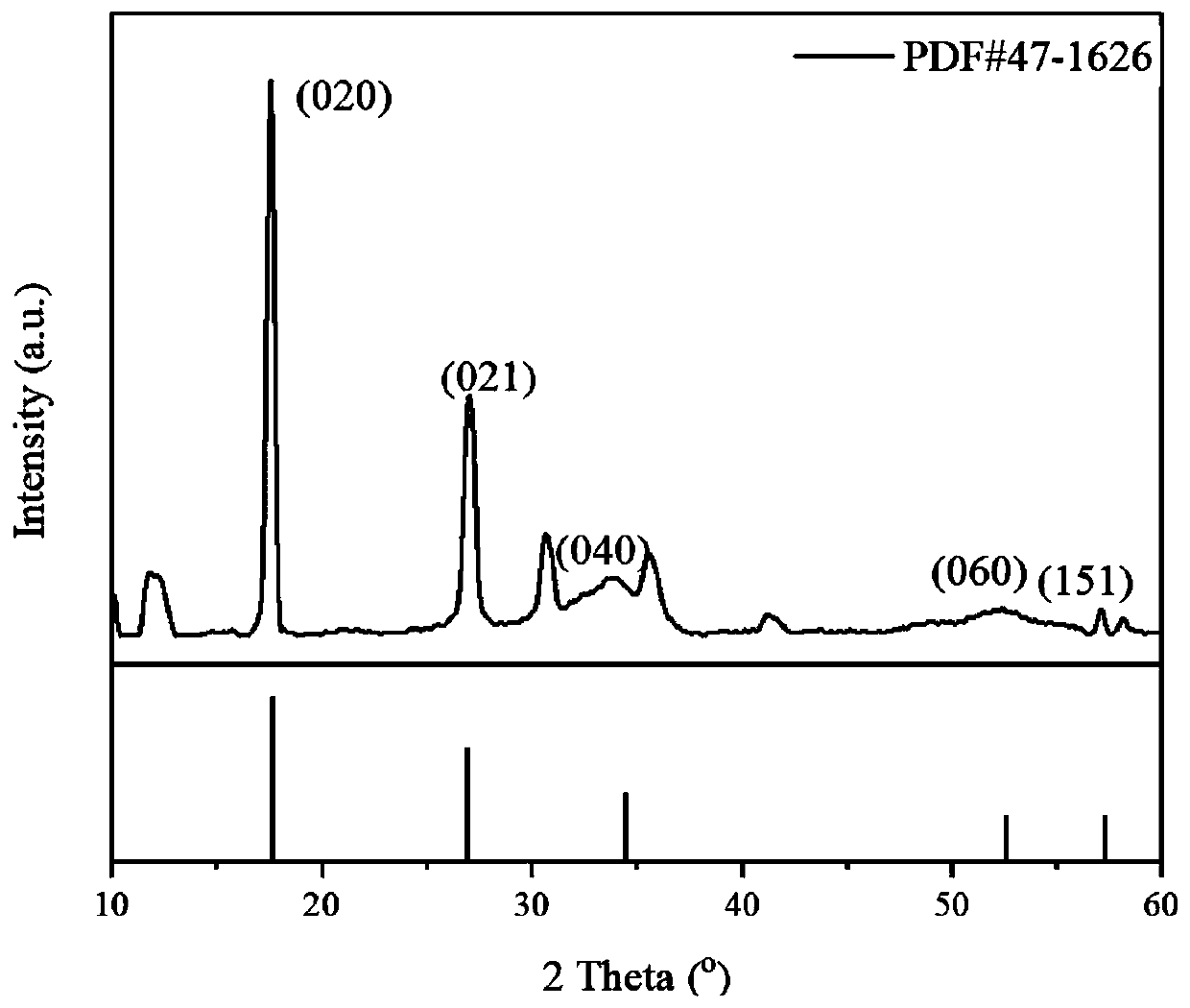

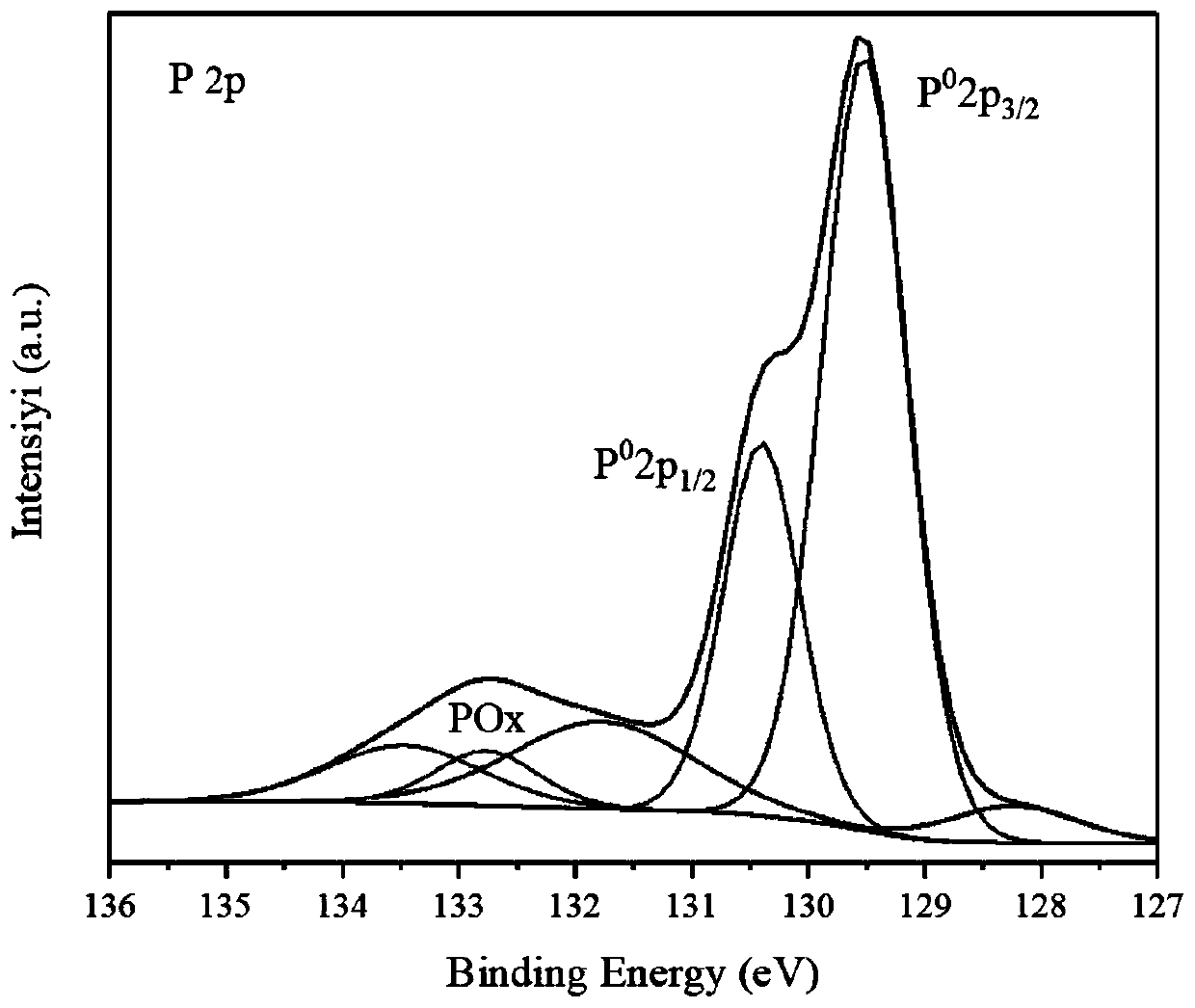

Low-cost high-crystallinity black phosphorus and preparation method thereof

PendingCN111483990AHigh purityStable in naturePhosphorus preparationAntioxidant capacityPhysical chemistry

The invention discloses low-cost high-crystallinity black phosphorus which is prepared from a phosphorus source and an amine solvent through a solvothermal method, and further discloses a preparationmethod of the low-cost high-crystallinity black phosphorus. The preparation method of the black phosphorus is mild in reaction, easy to control and simple in process, and the prepared black phosphorushas very high crystallinity and oxidation resistance, can replace black phosphorus prepared by a high-temperature mineralization method in some application aspects, and can meet the requirements of people on black phosphorus performance.

Owner:KUNMING UNIV OF SCI & TECH

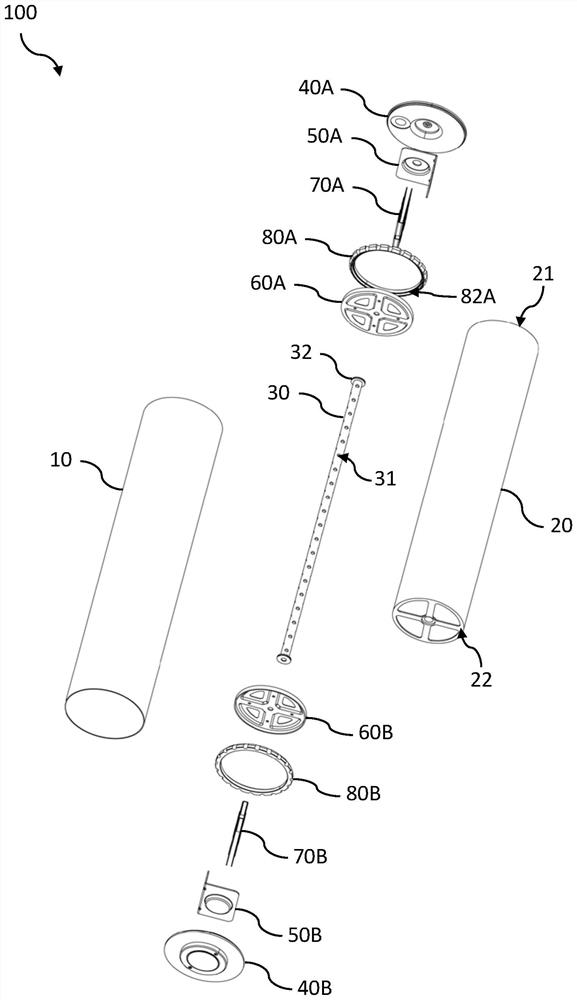

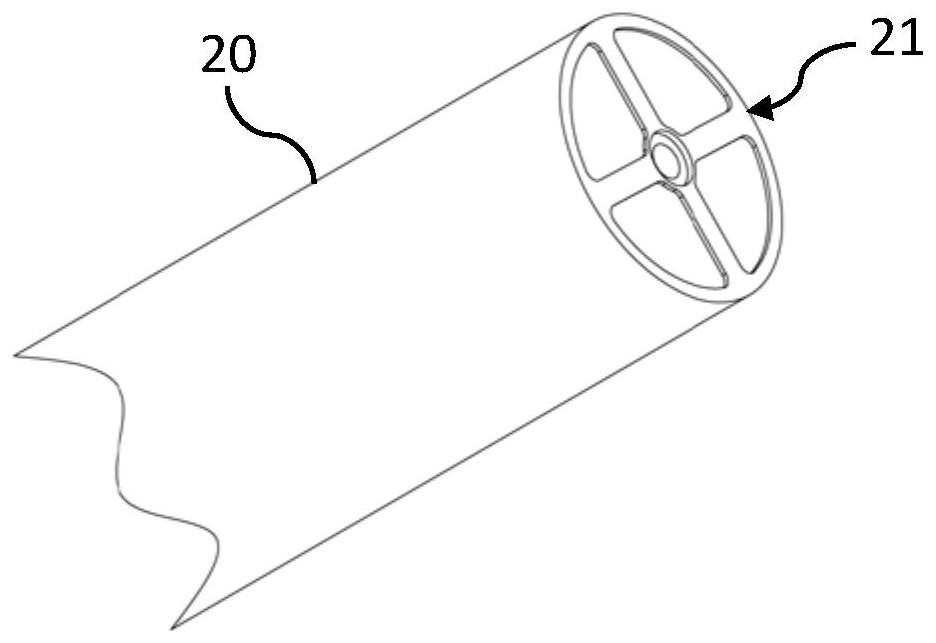

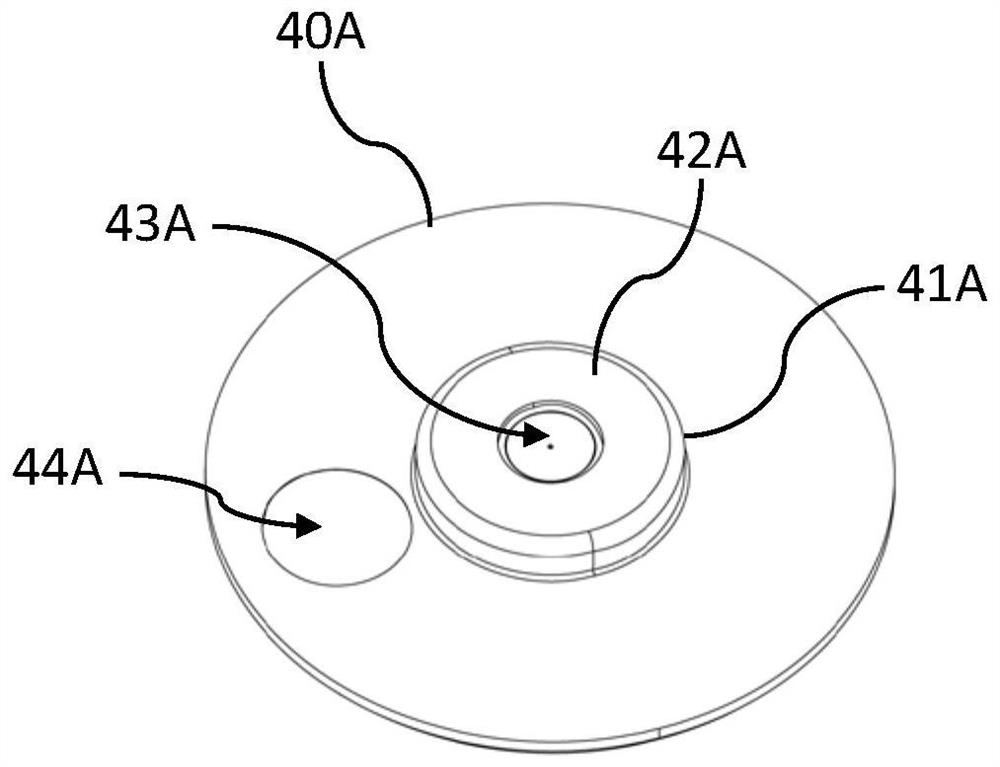

Cylindrical lithium battery and manufacturing method thereof

PendingCN114221073ASolve the diversion bottleneckImprove diversion capacityFinal product manufactureLi-accumulatorsElectrical connectionEngineering

The invention provides a cylindrical lithium battery and a manufacturing method thereof. The cylindrical lithium battery of the present invention comprises: a housing; the full-tab roll core is provided with a kneaded positive end surface and a kneaded negative end surface; a central tube; and two cover plates, two flow deflectors, two current collecting discs, two current collecting sheets and two insulating supports. Wherein the cover plate is welded with one end of the shell in a closed manner, a cover plate boss is punched at the central position of the cover plate, and an electrode column is mounted in the cover plate boss. A flow deflector boss matched with the cover plate boss is punched at one end of the flow deflector, and the flow deflector boss is electrically connected with the electrode column and connected to the cover plate in advance. The current collecting disc is welded with the end face of the rubbing electrode, a central pipe positioning hole is formed in the central position of the current collecting disc, and the current collecting sheet is connected to the central position of the current collecting disc in advance and is connected with the flow deflector after being bent at a preset bending position. And one side end of the insulating bracket is clamped and fixed on the collector plate, the other side end of the insulating bracket is propped against the cover plate, and the outer edge of the insulating bracket is propped against the inner wall of the shell.

Owner:苏州比耐新能源科技有限公司

Environment-friendly slow-release sulfur-based nitrogen potassium compound fertilizer

ActiveCN103159550AAdapt to needsEasy to degradeDi-calcium phosphate fertilisersFertilising methodsAmmonium compoundsSoil science

The invention discloses environment-friendly slow-release sulfur-based nitrogen potassium compound fertilizer and belongs to the compound fertilizer which contains material influencing digestion of ammonium compounds or urea in soil. The environment-friendly slow-release sulfur-based nitrogen potassium compound fertilizer is characterized by comprising the following steps of preparing sulfur-based nitrogen potassium compound fertilizer granules at first and then conducting once stearic acid and coating and secondary modified zeolite power application on the sulfur-based nitrogen potassium compound fertilizer granules to obtain the environment-friendly slow-release sulfur-based nitrogen potassium compound fertilizer, wherein the sulfur-based nitrogen potassium compound fertilizer granules comprise, by weight, 31-57 parts of urea, 10-20 parts of ammonium sulfate, 20-50 parts of potassium sulfate, 6-12 parts of granulation promoter, and appropriate water. The environment-friendly slow-release sulfur-based nitrogen potassium compound fertilizer prepared through the preparation method is good in slow-release effect, high in fertilizer utilization efficiency, simple in technology, low in production cost, beneficial to protection of the soil, the atmosphere and the water environment due to the fact that coating film material is prone to being degraded through microorganism in the soil, and wide in application range. The environment-friendly slow-release sulfur-based nitrogen potassium compound fertilizer is appropriate for grain crops, vegetables and fruits and used for seed fertilizer, base fertilizer and topdressing fertilizer. In addition, the environment-friendly slow-release sulfur-based nitrogen potassium compound fertilizer can be mixed with all kinds of market compound phosphoric fertilizer to be used.

Owner:SHIKEFENG CHEM IND

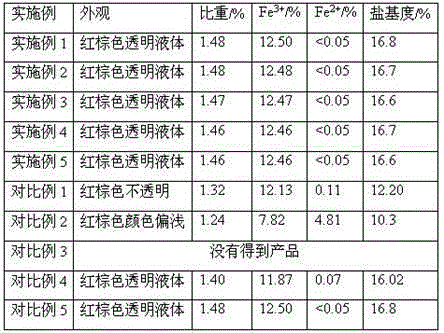

Rapid synthesis technology for poly-ferric sulfate aluminum

ActiveCN105036276AGood flocculation effectThe generation process is simpleIron sulfatesChemical recyclingChemistryLiquid oxygen

The invention relates to a rapid synthesis technology for poly-ferric sulfate aluminum and belongs to the technical field of water treatment flocculating agents. The rapid synthesis technology is characterized by comprising the specific preparation steps that materials of, by mass, 51.9%-56% of iron vitriol, 1%-5% of dissolvable aluminum hydroxide, 9.3%-9.6% of sulfuric acid and 33.5% of water are added in a reactor; a manganese dioxide catalyst is added in the reactor, and liquid oxygen is sprayed into the reactor at the same time; in the process, the reaction temperature is controlled to range from 45 DEG C to 55 DEG C; hydrolysis and polymerization reactions are automatically carried out while the oxidation reaction is carried out in the reactor, spray drying is carried out on the materials after the reactions are carried out for 30 min-40 min, the poly-ferric sulfate aluminum is obtained, and the manganese dioxide catalyst is recycled. The technology is simple in generation technology, the production period is greatly shortened, the production cost is reduced, harmful residues in the product are eliminated, and the product is nonpoisonous and harmless.

Owner:SHANDONG SANFENG GROUP

GO/Mn modified corncob charcoal organic fertilizer, preparation method and application thereof

InactiveCN109879708AReduce pollutionThe generation process is simpleCereal cultivationFertilizer mixturesOrganic contentFermentation starter

The invention provides a GO / Mn modified corncob charcoal organic fertilizer, a preparation method and an application thereof and belongs to the technical field of fertilizers. The organic fertilizer is prepared by fermenting the following raw materials: 20-30 parts of modified corncob charcoal, 25-45 parts of rotten bean cake residue, 10-15 parts of ferment residue, 10-15 parts of fishbone dust, 5-7 parts of biologic humic acid, 3-5 parts of molasses, 2-4 parts of bacillus subtilis compost leavening agent and 0.15-0.3 part of cellulase. The modified corncob charcoal is modified with graphene oxide and Mn. The rotten bean cake residue is prepared by naturally fermenting bean cake residue in rhodotorula mucilaginosa OP11 strain with preservation number of CGMCC No.13540. When the organic fertilizer is applied to corn planting, organic content of soil can be supplemented, water and nutrition can be effectively preserved and soil fertility can be promoted. The GO / Mn modified corncob charcoal organic fertilizer is an ideal organic fertilizer and is capable of achieving the effects of reducing fertilizer and preserving fertilizer.

Owner:QINGDAO AGRI UNIV

SPC solid wood composite floor

InactiveCN108019028ARaw materials are easy to obtainNot easy to crack and deformFlooringSolid woodWax

The invention provides an SPC solid wood composite floor comprising a PVC board and a solid wood board skin. The PVC board and the solid wood board skin are glued and fixed into a whole; the PVC boardcomprises, by weight, 80-130 parts of PVC resin, 260-350 parts of calcium carbonate powder, 1-1.5 parts of PE wax, 5.5-8 parts of a calcium and zinc stabilizer, 6-12 parts of ACR-401, and 3-4.5 partsof stearic acid. The SPC solid wood composite floor is attractive and generous, safe and environmentally friendly, and not only are the natural wood grain, texture, and foot feeling of solid wood floor obtained, but also the SPC solid wood composite floor has suitable elasticity and is not prone to being deformed and cracked, and has excellent performance in water and moisture resistance, impactresistance, corrosion resistance, and anti-skid and wear-resistance.

Owner:ANHUI TIANRUN PLASTIC IND

Biochar based organic fertilizer special for millet and preparation method thereof

InactiveCN108101714AReduce pollutionThe generation process is simpleExcrement fertilisersSolid/semi-solid fertilisersSlow Growth RateOrganic fertilizer

The invention relates to a biochar based organic fertilizer and a preparation method thereof, in particular to a biochar based organic fertilizer special for millet and a preparation method thereof. The invention aims to solve the technical problems that existing millet fertilization can cause slow growth rate of millet, excess fertilizer application can result in environmental pollution and decline of grain eating quality. The biochar based organic fertilizer provided by the invention is composed of sheep manure, turfy soil, straw, humic acid, biochar and a microbial fermentation agent. The preparation method of the biochar based organic fertilizer provided by the invention includes: 1. fermentation; 2. mixing; 3. granulation; 4. drying; 5. cooling; 6. screening; and 7. packaging. The biochar based organic fertilizer special for millet reaches the effects of drought resistance, land cultivation, production increase, and enhancement of nutrition and eating quality, and is an optimal fertilizer source for organic cultivation of millet. The organic materials needed by the organic fertilizer provided by the invention are organic waste and are easily available, also the cost is low, the process is advanced, and the method can achieve large-scale production.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

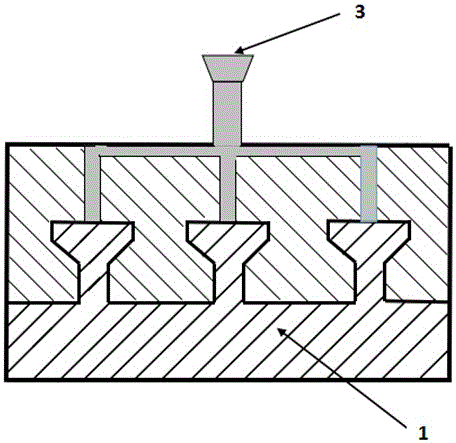

Bimetallic wear-resisting lining plate and preparation method thereof

InactiveCN106350738AIncrease composite areaThe interface is tightly combinedGrain treatmentsQuenching agentsManganeseAlloy

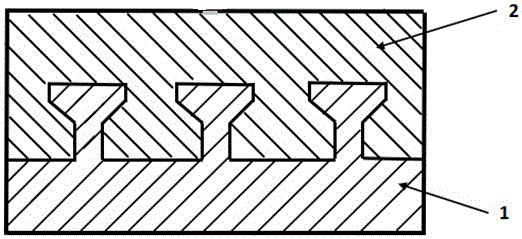

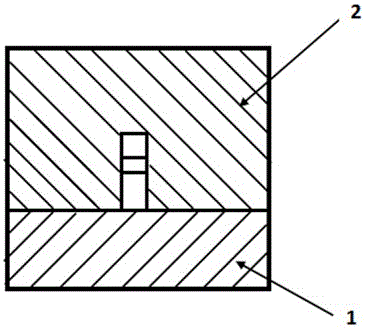

The invention discloses a bimetallic wear-resisting lining plate and a preparation method thereof and belongs to the technical field of metal material casting. The bimetallic wear-resisting lining plate comprises a matrix layer and a wear-resisting layer, wherein the wear-resisting layer is provided with more than two T-type projections inlaid into the matrix layer, the height ratio of every T-type projection to the wear-resisting layer is 1:1.2-1:2, the height ratio of the wear-resisting layer to the matrix layer is 1:1-1:3, the width ratio of every T-type projection to the lining plate is 1:8-1:15, the wear-resisting layer and the T-type projections are made of medium-carbon low-alloy silicon-manganese steel, the matrix layer is made of low-alloy carbon steel, and the bimetallic wear-resisting lining plate is prepared through compounding, smelting, casting, annealing and isothermal quenching. The bimetallic wear-resisting lining plate and the preparation method thereof have the advantages that through adoption of reasonable structural design and a layered casting technology, combination of a composite layer at an interface is closer, and the composite layer is less prone to separation; produced through the thermal treatment technology of simple isothermal quenching, the bimetallic wear-resisting lining plate is highly resistant to wear, high in tenacity, simple in preparation technology and convenient to produce, and production cost can be reduced effectively.

Owner:KUNMING UNIV OF SCI & TECH

Apparatus and method for generating and parsing MAC PDU in a mobile communication system

InactiveUS7796648B2The generation process is simpleImprove processing speedNetwork traffic/resource managementTime-division multiplexMobile communication systemsComputer science

Owner:SAMSUNG ELECTRONICS CO LTD

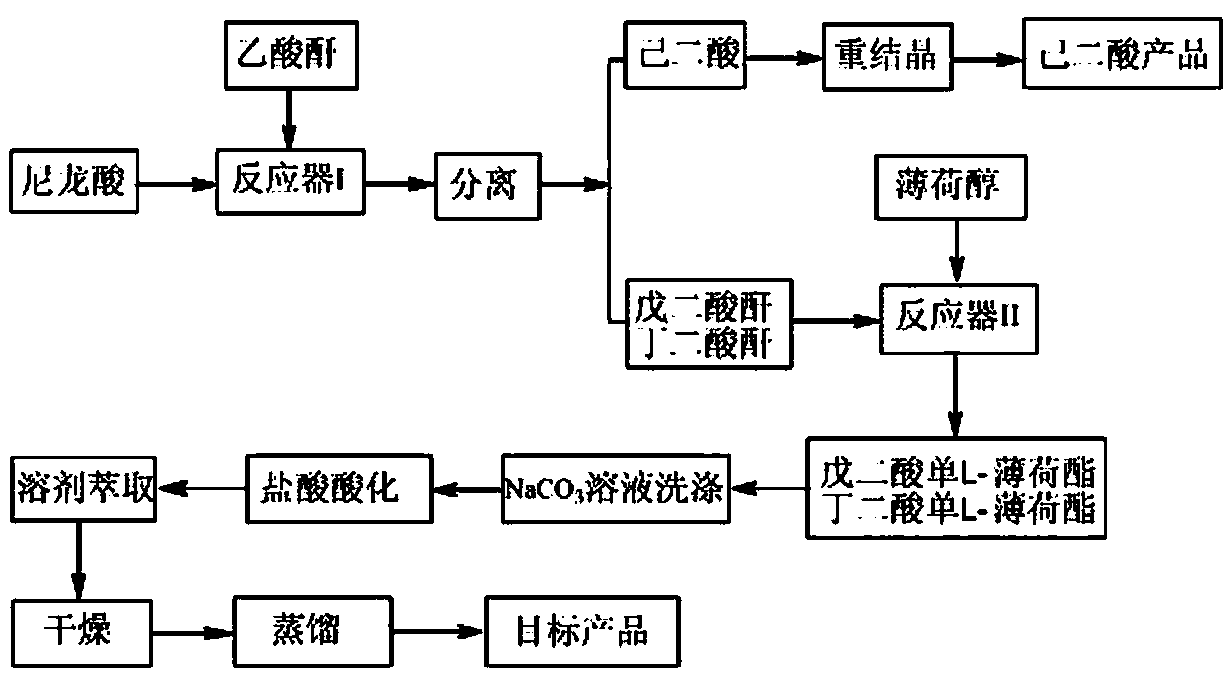

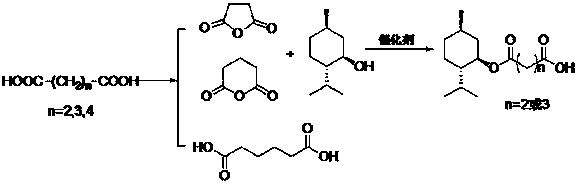

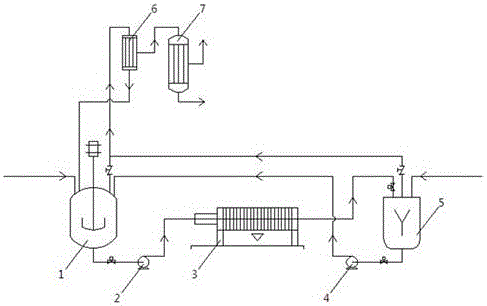

Method for preparing mixed dibasic acid mono-L-menthyl acetate by using nylon acid

ActiveCN103772199AEasy to reuseThe generation process is simpleOrganic compound preparationCarboxylic acid esters preparationGlutaric anhydrideChemical synthesis

The invention discloses a method for preparing mixed dibasic acid mono-L-menthyl acetate by using nylon acid and belongs to the field of organic chemical synthesis. The method comprises the following steps: by taking the nylon acid as an initial raw material, obtaining a binary anhydride (comprising glutaric anhydride and butanedioic anhydride) mixture through acetic anhydride dehydration; and further reacting with menthol, and obtaining mixed dibasic acid mono-L-menthyl acetate (comprising glutaric acid mono-L-menthyl acetate and butanedioic acid mono-L-menthyl acetate). The production process is simple, the raw materials are easily available, the yield is high, special reaction or separation and purification equipment is not needed, and the method is suitable for industrial production.

Owner:CHINA TOBACCO HENAN IND +1

Method for preparing gas-phase hydrogen chloride by utilizing chlorosilane residue

ActiveCN106629604AEfficient collectionThe generation process is simpleSilicaHydrogen productionPhysical chemistryProcess engineering

The invention discloses a method for preparing gas-phase hydrogen chloride by utilizing chlorosilane residue and belongs to the field of polycrystalline silicon residue treatment. The method comprises the following steps: performing hydrolysis reaction on the chlorosilane residue under a high-concentration sulfuric acid atmosphere, wherein hydrogen chloride gas is difficult to dissolve in liquid and can volatilize under the water absorption effect of the sulfuric acid; guiding the hydrogen chloride gas, the hydrogen generated from hydrolysis reaction and vaporized chlorosilane residue into a condenser and a high-pressure separator in turn; and treating and then separating, thereby acquiring a hydrogen chloride product. According to the invention, the production process is simple and reasonable, the resource utilization problem of the chlorosilane residue can be solved and the hydrogen chloride can be effectively recycled.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of water-soluble pectin of shaddock albedo

The present invention relates to a preparation method of water-soluble pectin of shaddock albedo. The method comprises the following steps: bake drying or naturally drying shaddock albedo and cutting the shaddock albedo into chunks, immersing the shaddock albedo chunks into 95% ethanol for more than 12 h and drying; adopting a hot water extraction method to prepare the water-soluble pectin with a ratio of the shaddock albedo to water being 1: 10-1: 50 at a temperature of 60-100 DEG C, carrying out extraction for 1 to 3 times each lasting 1 to 5 h, and stirring constantly; filtering extraction liquid to obtain a supernatant; concentrating the supernatant to 1 / 8 to 1 / 10 of the original volume, carrying out alcohol precipitation for 12 h, centrifugating for 5 to 10 min at a speed of 3000 r / min to 4800 r / min, collecting the precipitation, drying the precipitation at a temperature of 40-55 DEG C, and then obtaining the water-soluble pectin. According to the present invention, the waste of shaddock peel is reused, resource utilization is improved; the preparation method has high extraction efficiency and no toxic and hazardous organic reagent, and the product is safe; the process is simple, and the application prospects are extensive.

Owner:NANCHANG UNIV

Preparation method of polyglycerol lactate

InactiveCN103145552AThe generation process is simpleHigh yieldOrganic compound preparationCarboxylic acid esters preparationChemical synthesisEsterification reaction

The invention discloses a preparation method of polyglycerol lactate, and belongs to the field of organic chemical synthesis. The method comprises the following steps of: adding a catalyst, lactic acid and a water-carrying agent for esterification reaction under the protection of nitrogen by taking polyglycerol with the polymerization degree of 3-8 as a raw material to obtain a polyglycerol lactate crude product; and processing to obtain a polyglycerol lactate product with high ester content. The method disclosed by the invention has the advantages of simple production process, available raw material and high yield and is suitable for industrialized production.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD +1

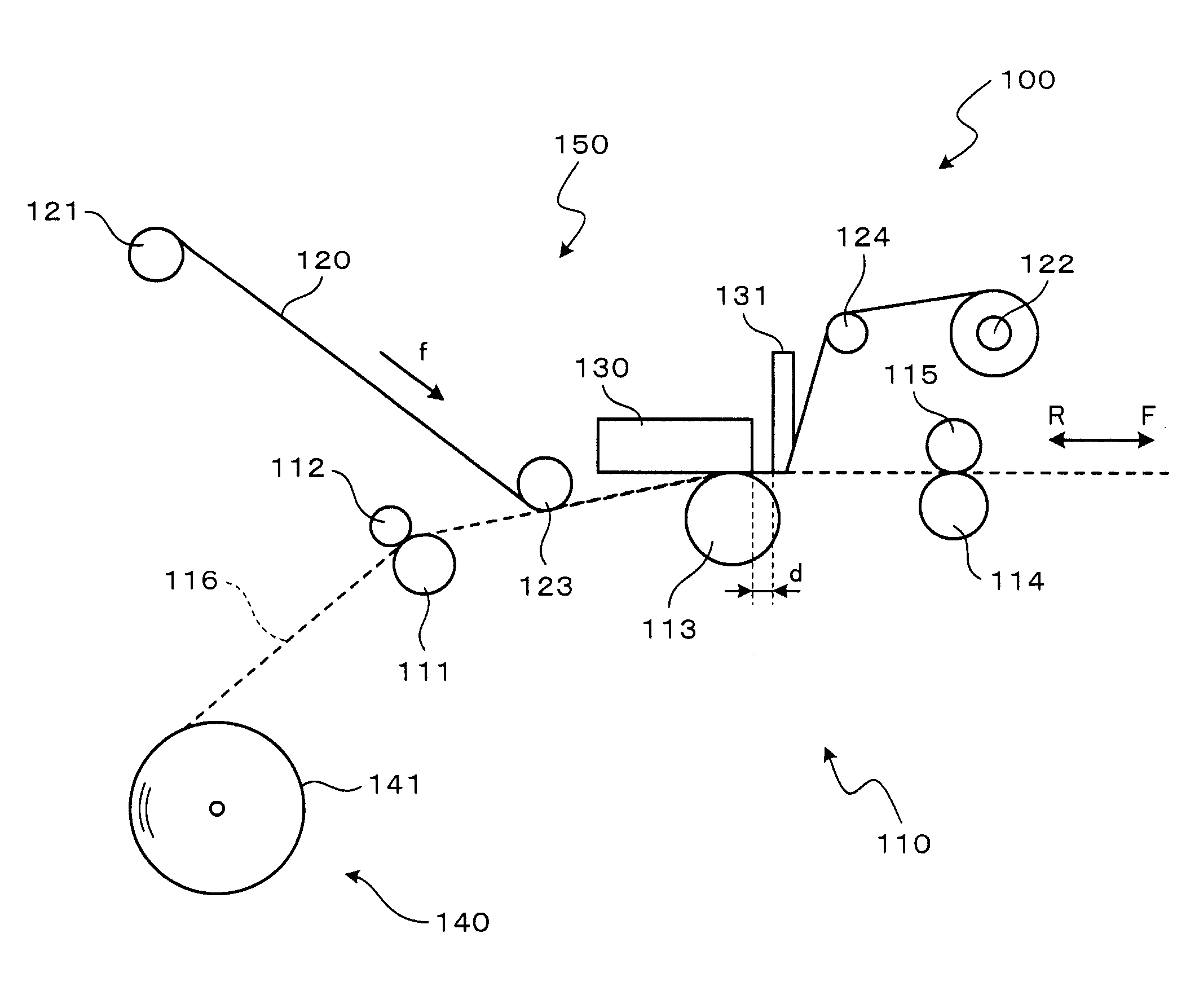

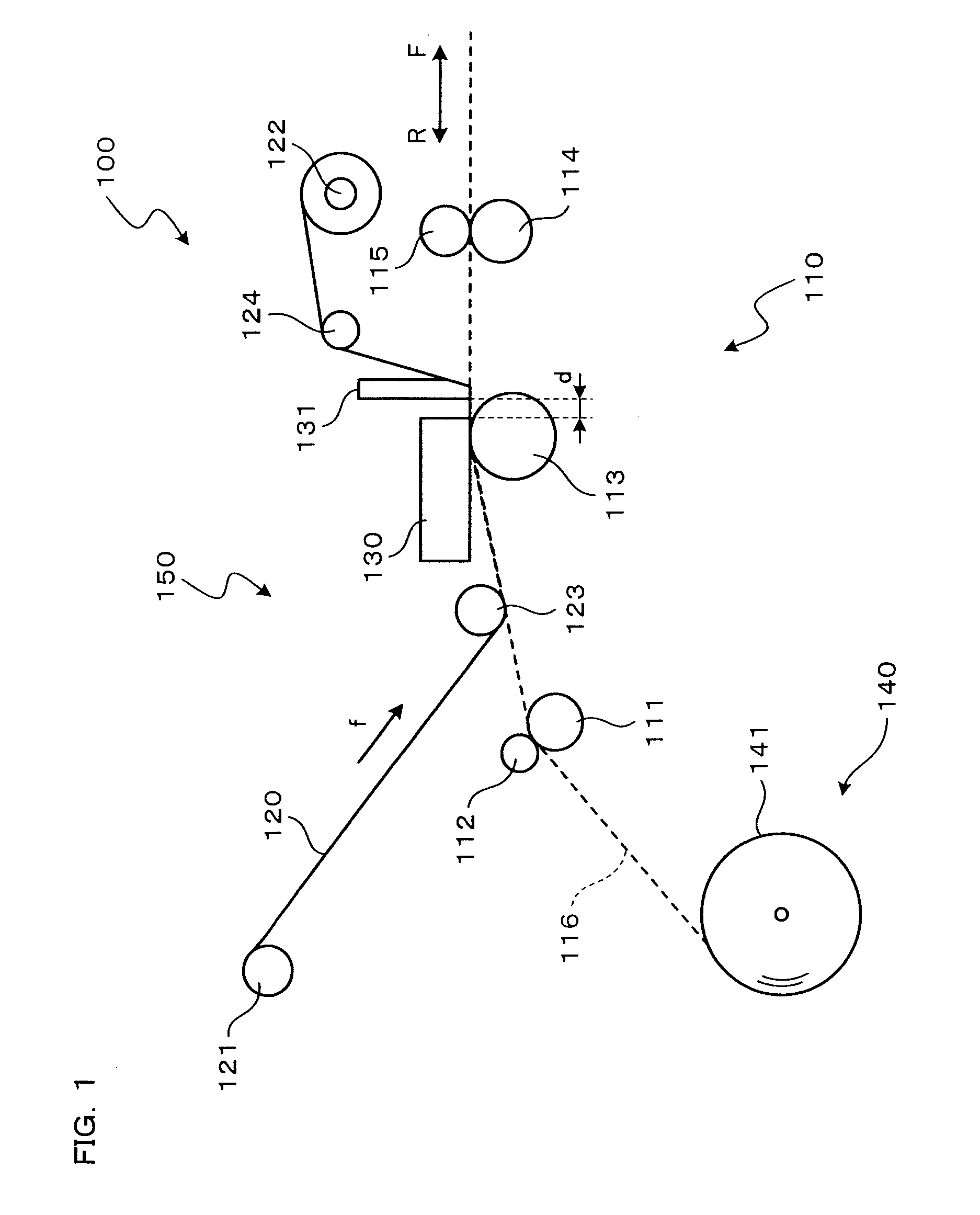

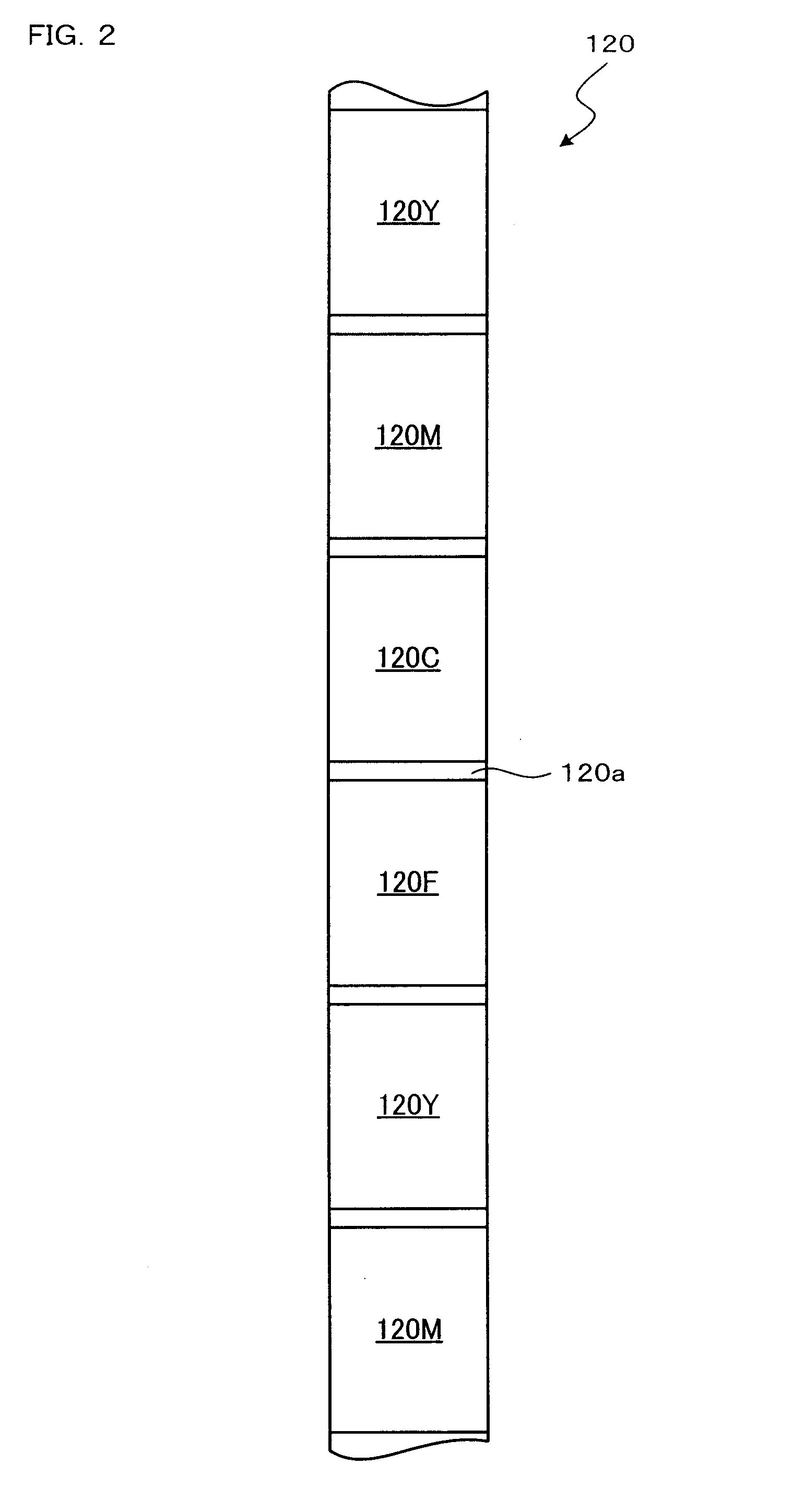

Image forming apparatus and method for forming image

InactiveUS20090040539A1Reduce memory capacityReduce capacityImage enhancementDigitally marking record carriersImage formationComputer science

Data concerning a transfer pattern of lamination transparent film is not externally sent and stored in a memory but generated by a random pattern generating module of a color controlling DSP 22. A random number generating section 23a generates a pseudorandom number for each dot of one line; a tone data obtaining section 23b obtains tone data corresponding to the pseudorandom number; and a transferring section 23c transfers the tone data to a head signal converting ASIC 24. Tone data for each dot of one line is alternately written in line buffers 1 and 2. Using the tone data written in the line buffers 1 and 2, a thermal head 130 transfers transparent film 120F.

Owner:SHINKO ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com