Spectrum generator, preparation method thereof and preparation method of far-infrared radiant coating

A far-infrared radiation and generator technology, applied in the field of material engineering, can solve the problems of complex structure, complex production process and low radiation rate of spectrum generators, and achieve the effect of simple structure, simple production process and high radiation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

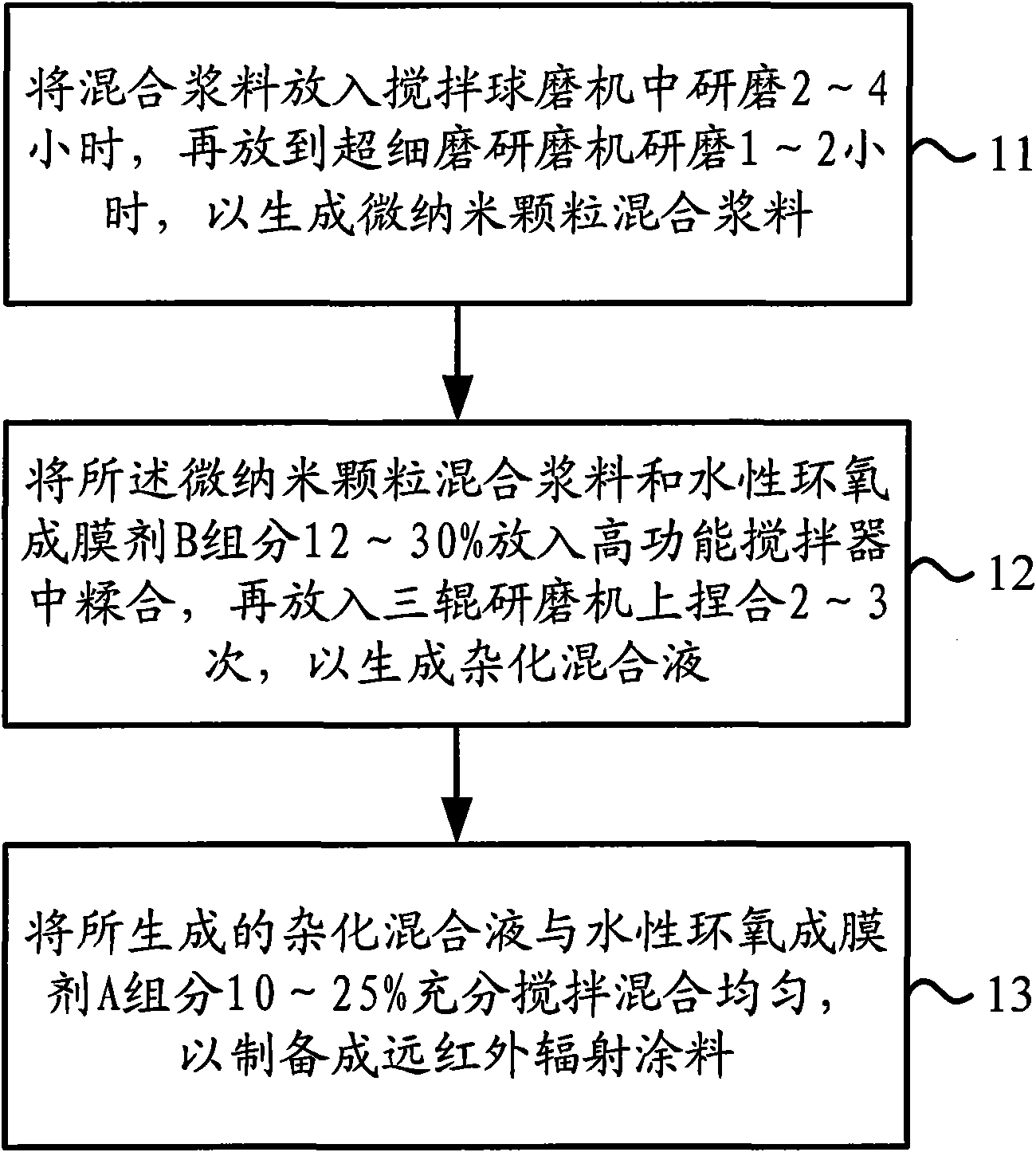

[0019] figure 1 It is a flow chart of the preparation method of the far-infrared radiation coating of the present invention. Such as figure 1 As shown, the preparation of the far-infrared radiation coating of the present embodiment needs mixed slurry and water-based epoxy film-forming agent, wherein the water-based epoxy film-forming agent includes water-based epoxy film-forming agent A component and water-based epoxy film-forming agent B group Further, the preparation method steps of the far-infrared radiation coating of the present embodiment specifically include:

[0020] Step 11, put the mixed slurry into a stirring ball mill and grind it for 2-4 hours, then put it into an ultra-fine grinding mill and grind it for 1-2 hours to generate a mixed slurry of micro-nano particles. The mixed slurry in this embodiment in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com