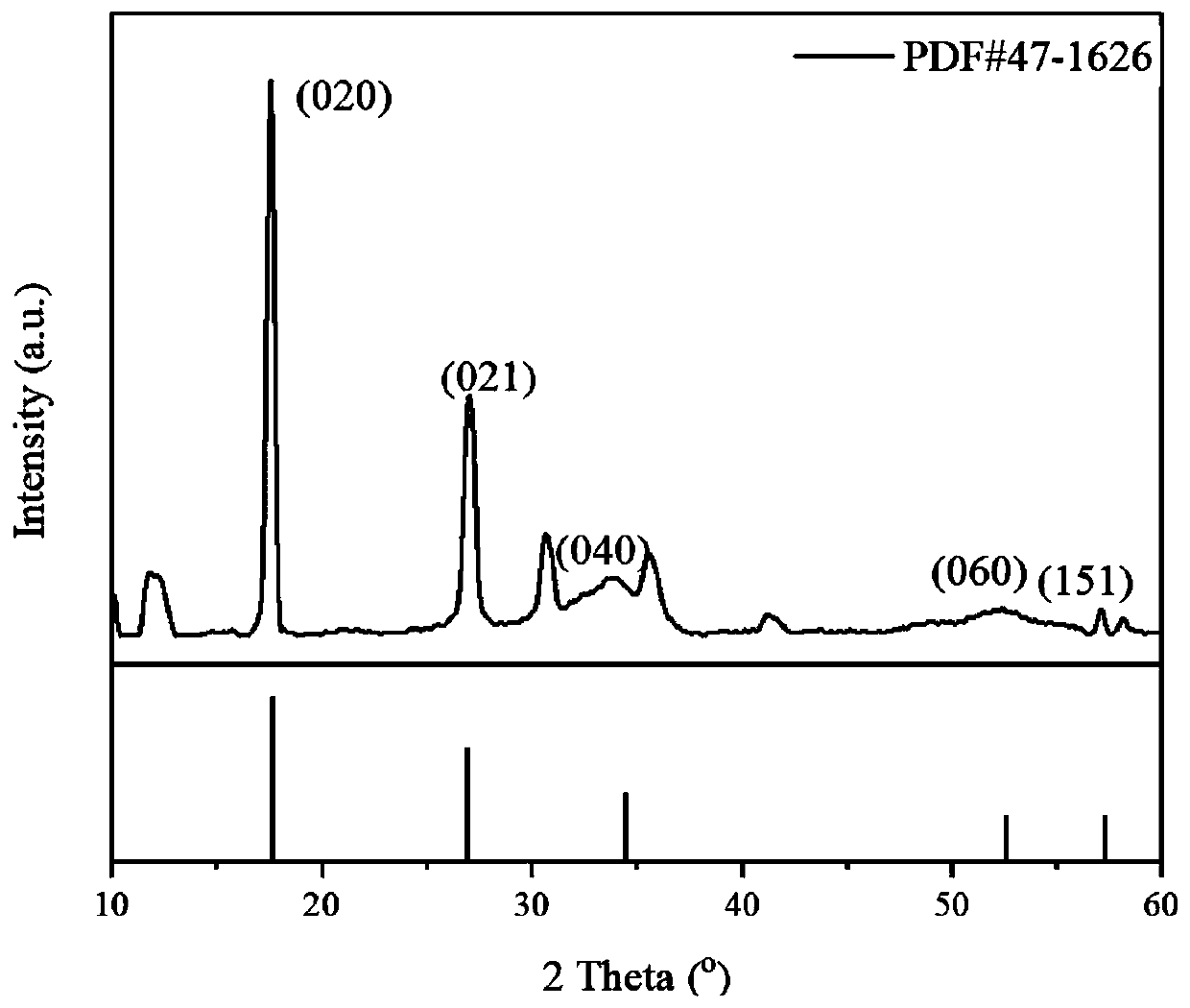

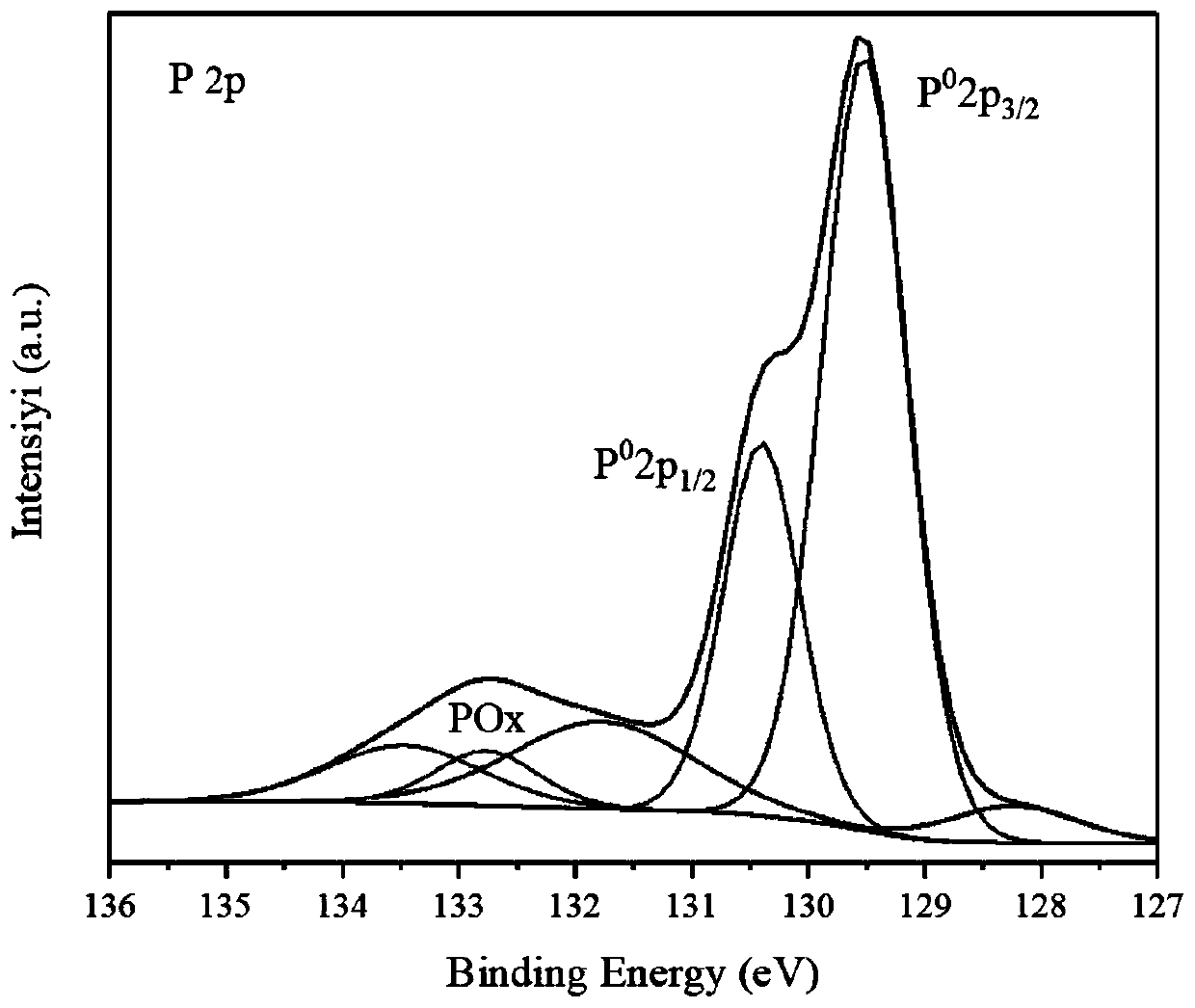

Low-cost high-crystallinity black phosphorus and preparation method thereof

A high-crystallinity, low-cost technology, applied in the preparation of phosphorus, etc., can solve the problems of uneven black phosphorus purity, long black phosphorus cycle, and many influencing factors, and achieve low raw material prices, low production costs, and production processes. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A low-cost high-crystallinity black phosphorus, its composition is shown in the following table:

[0035]

[0036] The steps that preparation method comprises are as follows:

[0037] (1) Mix the two-phase components according to the distribution ratio of the components and disperse evenly by magnetic stirring, the stirring speed is 600rpm, and the stirring time is 1h to obtain a red-black dispersion;

[0038] (2) According to the ratio of 30ml dispersion liquid: 50ml polytetrafluoroethylene lining, take the above dispersion liquid and add it to the polytetrafluoroethylene lining of the reactor;

[0039] (3) Tighten the polytetrafluoroethylene lining and place it in a high-temperature oven, and adjust the temperature to 180°C for 12 hours;

[0040] (4) After the reaction, the sample was washed with benzene, ethanol and water until neutral, and dried at 60° C. for 12 hours to obtain low-cost and high-crystallinity black phosphorus with a lamellar structure.

Embodiment 2

[0042] A low-cost high-crystallinity black phosphorus system, its components are shown in the following table:

[0043]

[0044] The preparation method of described low-cost high-crystallinity black phosphorus, the steps that it comprises are as follows:

[0045] (1) Mix the two phases of red phosphorus and pentamethylenediamine according to the distribution ratio of the components and disperse them uniformly by ultrasonic, the ultrasonic power is 500w, and the ultrasonic time is 1h, to obtain a red-black dispersion;

[0046] (2) According to the ratio of 30ml dispersion liquid: 50ml polytetrafluoroethylene lining, take the above dispersion liquid and add it to the polytetrafluoroethylene lining of the reactor;

[0047] (3) Tighten the polytetrafluoroethylene lining and place it in a high-temperature oven to raise the temperature to 240°C for 12 hours;

[0048] (4) After the reaction, the sample was washed with benzene, ethanol, and water until neutral, and dried at 60° C....

Embodiment 3

[0050] A low-cost high-crystallinity black phosphorus, its composition is shown in the following table:

[0051]

[0052] The preparation method of described low-cost high-crystallinity black phosphorus, the steps that it comprises are as follows:

[0053] (1) Mix the two phases of yellow phosphorus, phosphorus pentoxide and ethylenediamine according to the component distribution ratio and mechanically stir to disperse evenly, the stirring speed is 350rpm, and the stirring time is 2h to obtain a red-black dispersion;

[0054] (2) According to the ratio of 32ml dispersion liquid: 51ml polytetrafluoroethylene lining, take the above dispersion liquid into the polytetrafluoroethylene lining;

[0055] (3) Tighten the polytetrafluoroethylene lining and place it in a high-temperature oven to raise the temperature to 220°C for 12 hours;

[0056] (4) After the reaction, the sample was washed with benzene, ethanol, and water until neutral, and dried at 55°C for 13 hours to obtain la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com