GO/Mn modified corncob charcoal organic fertilizer, preparation method and application thereof

A biochar and corncob technology, applied in the field of fertilizers, can solve the problems of not meeting the needs of crop growth, affecting the increase of crop yield and quality, low utilization rate of trace elements, etc., to improve the rhizosphere environment, high added value of products, improved Effects of structure and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

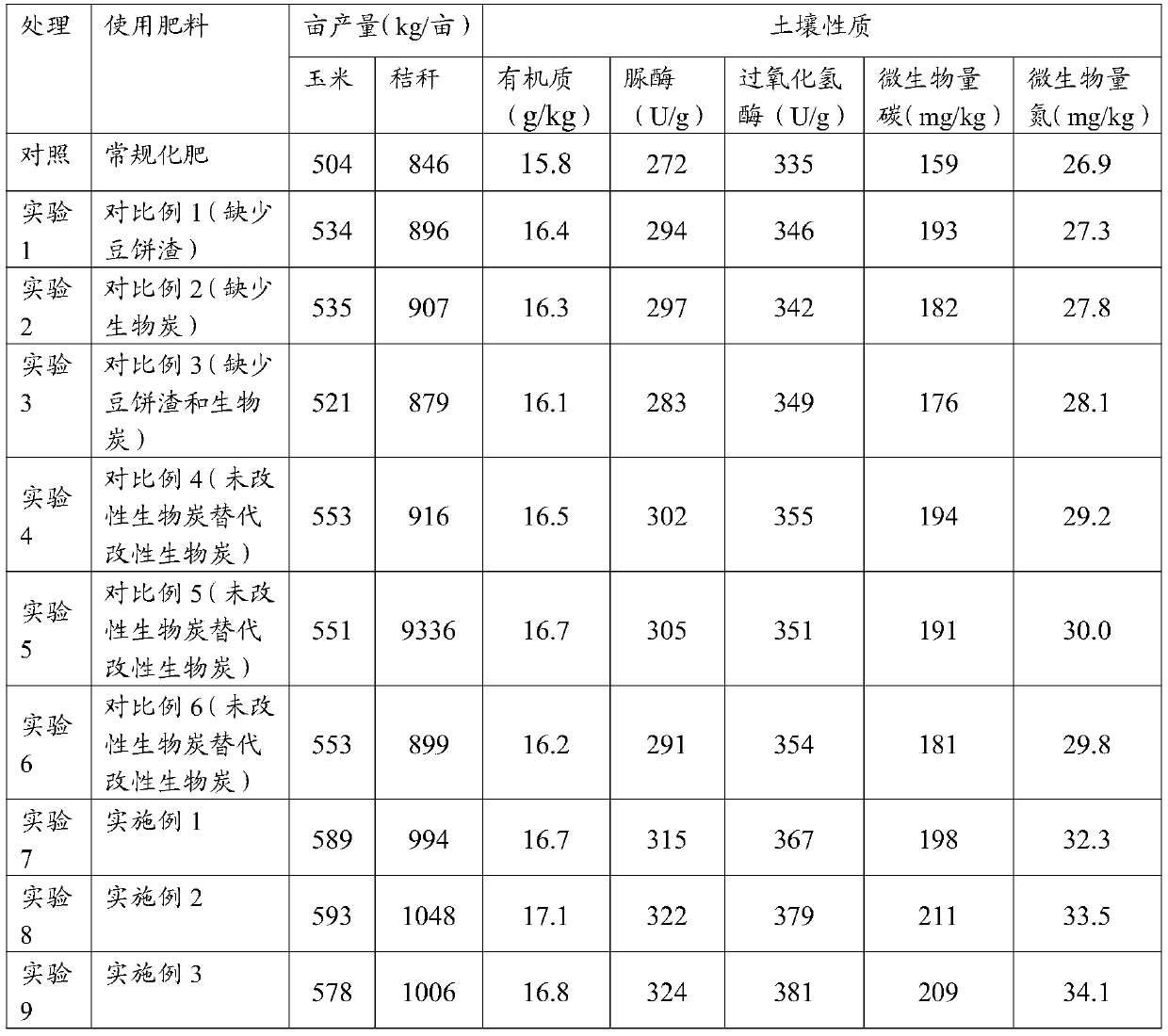

Examples

preparation example Construction

[0036] The raw material of the organic fertilizer provided by the invention includes GO / Mn modified corncob biochar. In parts by weight, the GO / Mn modified corncob biochar is preferably 22-28 parts, more preferably 25 parts. The preparation method of described GO / MnGO / Mn modified corn cob biochar comprises the following steps:

[0037] 1) mixing corncob powder and graphene oxide to obtain a mixture;

[0038] 2) carbonizing the mixture at 90-110° C. for 55-65 minutes to obtain biochar raw materials;

[0039] 3) mixing the biochar raw material and manganese chloride solution, and carbonizing at 500-600° C. for 3-5 hours to obtain the primary modified biochar;

[0040] 4) Remove ash from the modified biochar primary product to obtain GO / Mn modified corncob biochar.

[0041] In the present invention, the corncob powder is preferably obtained by removing surface attachments from corncobs, crushing and sieving. The method for removing surface attachments is preferably to wash th...

Embodiment 1

[0067] A preparation method of GO / Mn modified corn cob biochar-based organic fertilizer, comprising the following steps:

[0068] Weigh the following raw materials: 20kg of GO / Mn modified corncob biochar, 40kg of decomposed bean cake dregs, 18kg of fish bone meal, 10kg of enzyme residue, 7kg of biological humic acid, 5kg of molasses, 3kg of Bacillus subtilis compost starter and fiber Sulfase 0.35kg.

[0069] 1) Soybean cake dregs decomposing: inoculate Rhodotorula gum OP11 into bean cake dregs for aerobic fermentation and decomposing. Adjust the water content of bean cake dregs to 60%, and the concentration of bacteria solution is about 2×10 8 The spore suspension of Rhodotorula japonicus OP11 per spore / mL was added to bean cake dregs according to the inoculum amount of 1.5%, fully mixed and stirred, and naturally fermented for 12 days. The bean cake dregs are naturally air-dried to normal temperature, dried, pulverized in a pulverizer, and passed through a 20-mesh sieve to ...

Embodiment 2

[0079] A preparation method of GO / Mn modified corn cob biochar-based organic fertilizer, comprising the following steps:

[0080] Weigh the following raw materials by weight: 25kg of GO / Mn / biomass charcoal, 25kg of decomposed bean cake dregs, 15kg of fish bone meal, 15kg of enzyme residue, 5kg of biological humic acid, 3kg of molasses, 3kg of Bacillus subtilis compost starter and cellulose Enzyme 0.15kg.

[0081] 1) Decomposition of bean cake dregs: Inoculate Rhodotorula japonicus OP11 into bean cake dregs for aerobic fermentation and decomposition. Adjust the water content of bean cake dregs to 70%, and the concentration of bacteria solution is about 1×10 7 spores / mL Rhodotorula gum OP11 spore suspension was added to bean cake dregs according to the inoculum amount of 1%, fully mixed and stirred, and naturally fermented for 15 days. The decomposed bean cake dregs are naturally air-dried to normal temperature, dried, pulverized in a pulverizer, and passed through a 20-mesh s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com