Patents

Literature

109results about How to "The interface is tightly combined" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

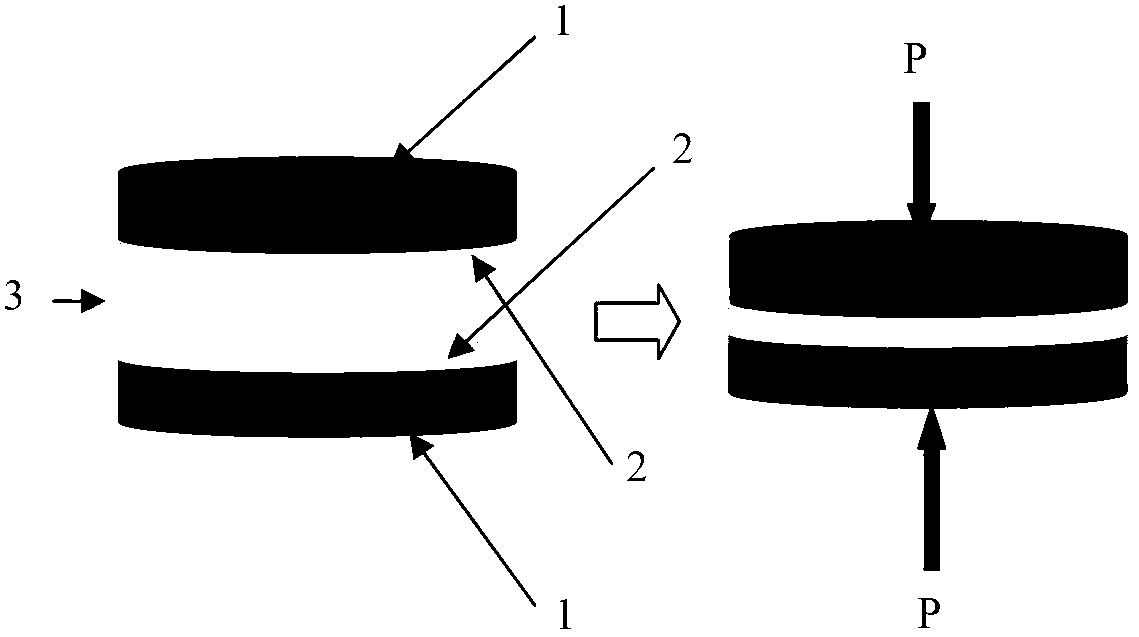

Preparation method for Ti3Al-TiAl laminated composite material

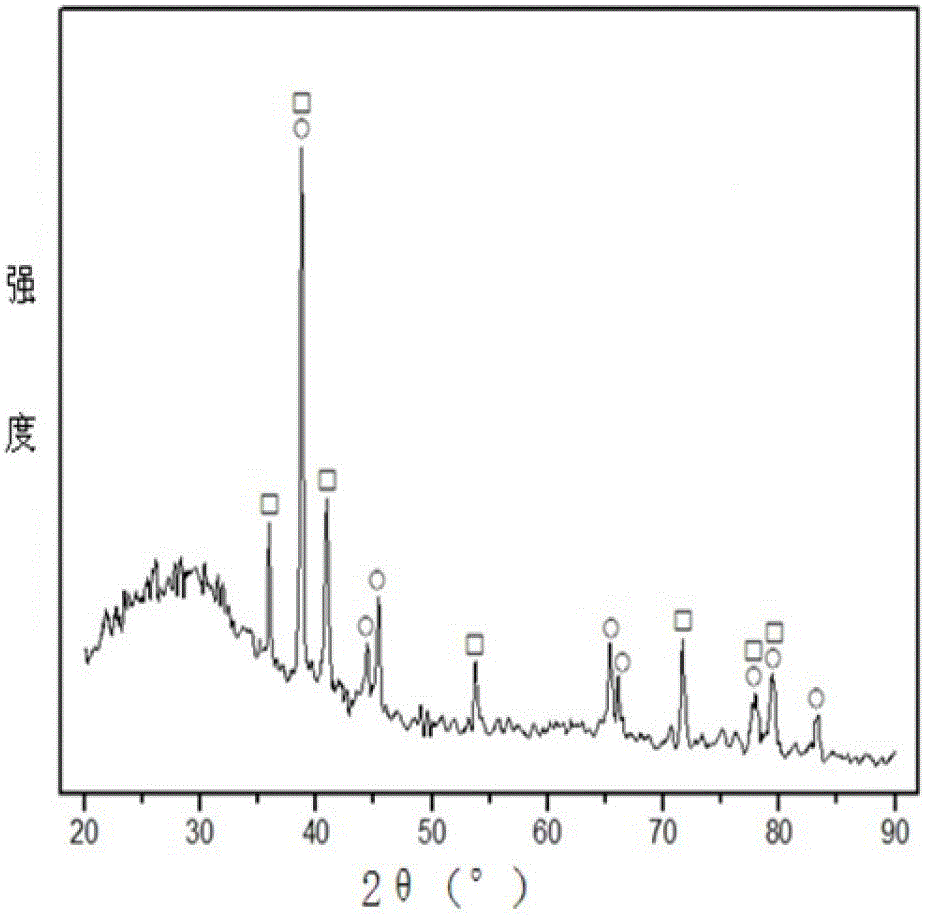

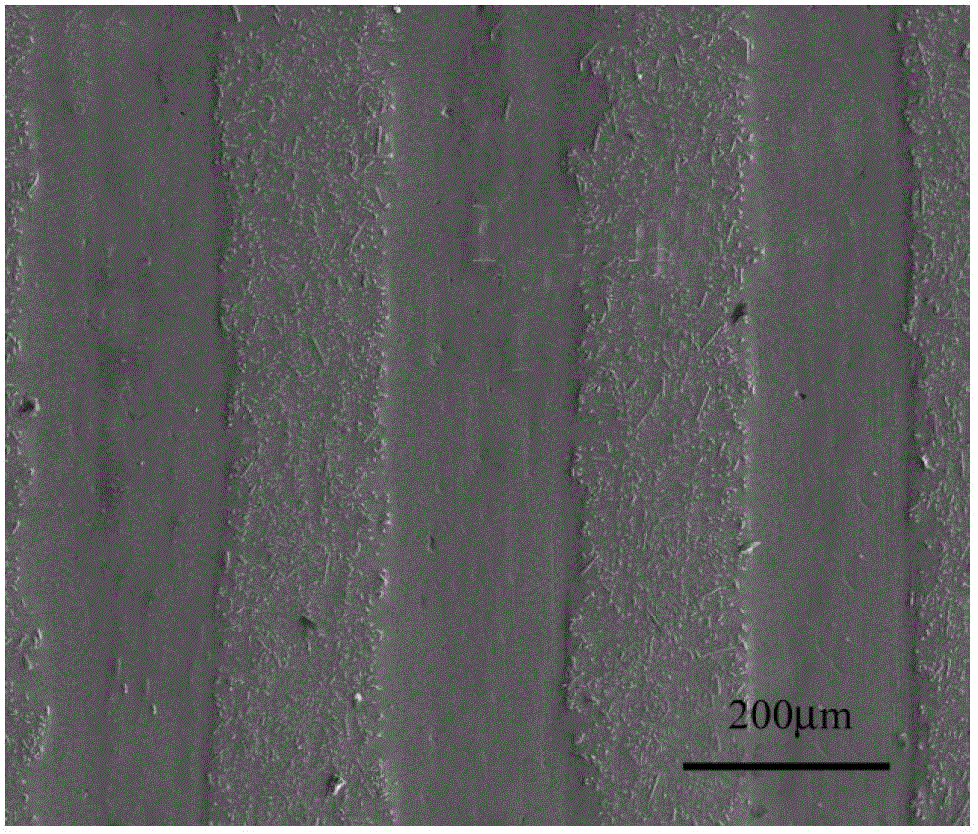

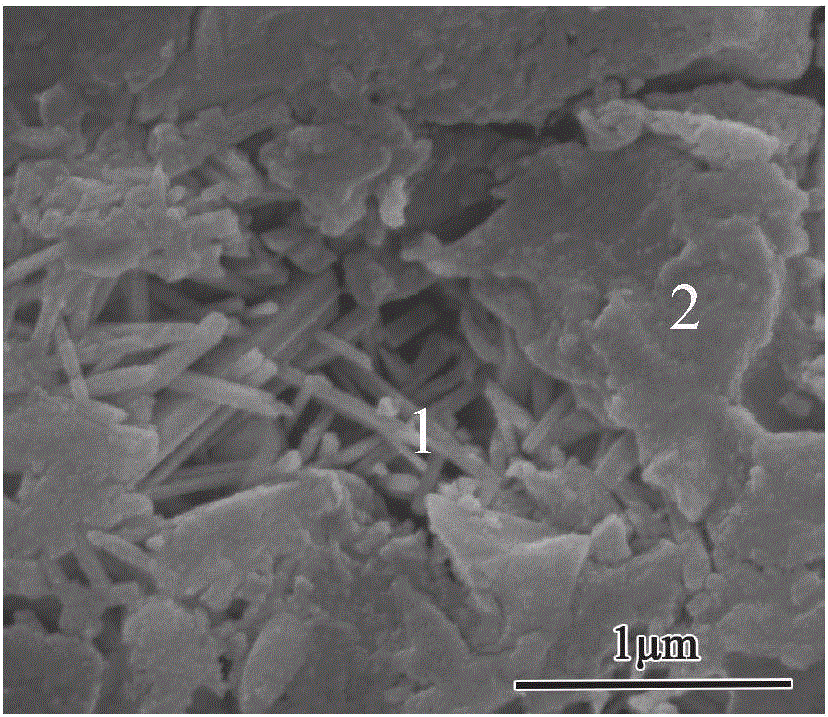

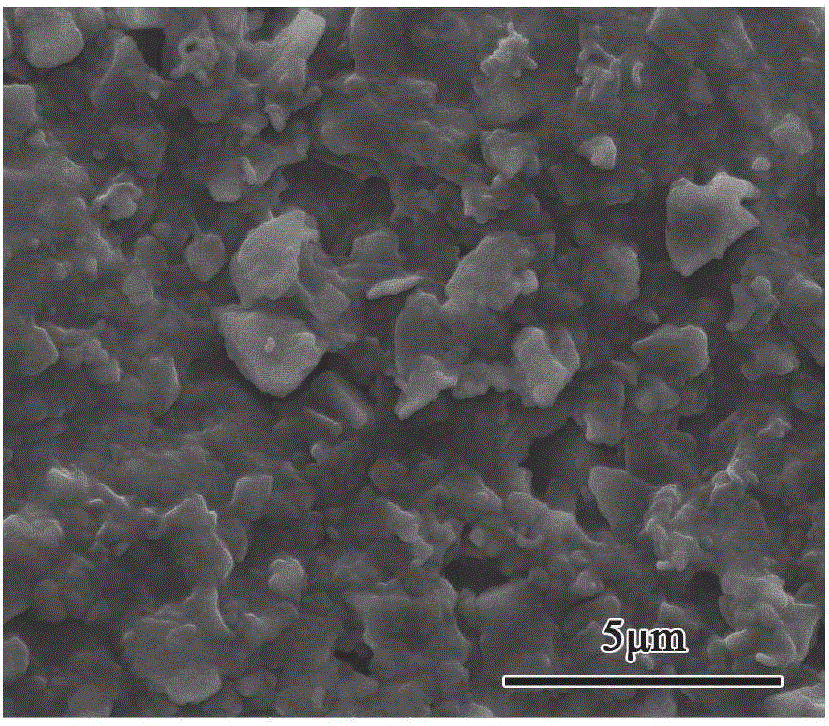

InactiveCN102744928ASimple production processLow costLaminationLamination apparatusTurbineLaminated composites

The invention discloses a preparation method for a Ti3Al-TiAl laminated composite material, relating to a preparation method for a metal laminated composite material and aiming at solving the problems of high requirement on equipment and complex process in a traditional preparation method. The preparation method for the laminated composite material comprises the following steps of: placing a Ti foil and an Al foil which are alternatively arranged in a stacking way into a vacuum hot press sintering furnace and heating to 300-500DEG C and simultaneously pressurizing; and secondly, unloading the pressure, heating the stacked foils to 600-800DEG C and maintaining the temperature, then heating the foils to 900-1300DEG C, simultaneously applying the pressure of 10-30MPa, maintaining the pressure and then cooling along with the furnace and withdrawing the die to obtain the Ti3Al-TiAl laminated composite material. According to the preparation method disclosed by the invention, the preparation of the laminated composite material can be finished at a time; a production process is simple and feasible; the requirement on the equipment is low; and the obtained laminated composite material is compact in interface bonding and is applied to aerospace turbine engine vanes, aerofoils and members of engines of high-grade cars.

Owner:HARBIN INST OF TECH

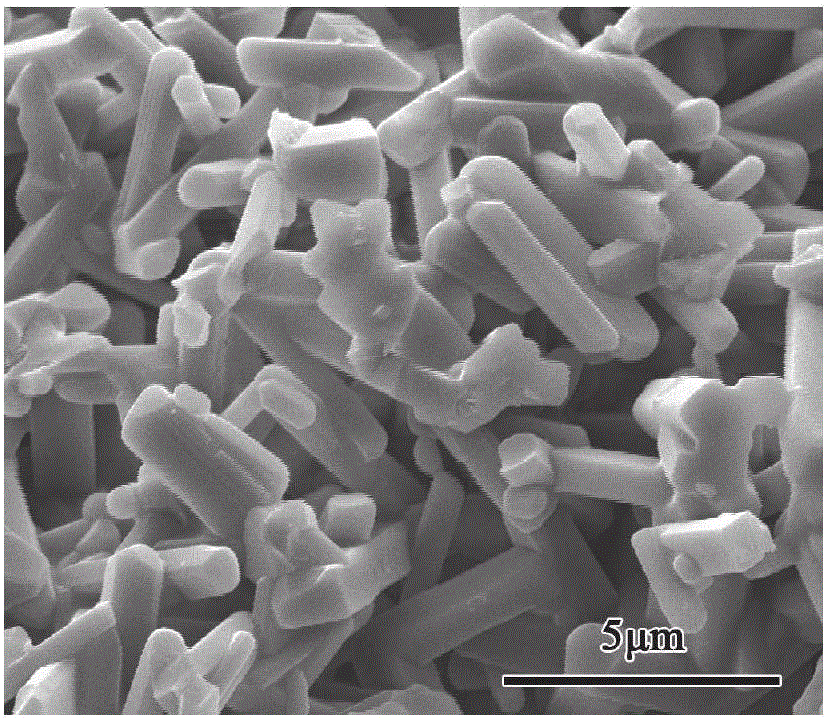

Method for in-situ synthesizing mullite whisker self-toughened mullite ceramics

The invention discloses a method for in-situ synthesizing mullite whisker self-toughened mullite ceramics. The method comprises the following steps: mixing 55-70 parts by weight of aluminum oxide, 20-30 parts by weight of silicon dioxide, 5-18 parts by weight of mullite whisker seed crystal, and 2-5 parts by weight of aluminum fluoride in a manner of wet grinding; pouring and curing to obtain a green body; sintering the green body at the temperature of 500 to 600 DEG C for the first time; sintering at the temperature of 900 to 1000 DEG C for the second time; sintering at the temperature of 1350-1550 DEG C for the third time so as to obtain the mullite ceramics. In addition, the invention also discloses the mullite ceramics prepared by the abovementioned method. According to the method, the raw materials, namely, aluminum oxide and silicon dioxide based on the ratio, conduct reaction under the synergistic effect of mullite whisker seed crystal and aluminum fluoride in parts by weight through the sectional sintering technology under the abovementioned temperature to obtain the high-toughness in-situ self-growth mullite whisker mullite ceramics; the high-activity seed crystal is added, so that the in-site uniform and dispersed distribution of the mullite whiskers in a substance can be realized, and thus the toughness of the ceramics can be effectively improved.

Owner:CENT SOUTH UNIV

Preparation method for silver-plating copper powder

InactiveCN105965010AImprove contact electrical performanceImprove antioxidant capacityTransportation and packagingMetal-working apparatusSilver plateDistilled water

The invention relates to a novel preparation method for silver-plating copper powder, belonging to the technical field of surface treatment. The novel preparation method comprises three technological steps of pretreatment, surface silver plating and posttreatment. Firstly, copper powder is washed with dilute sulphuric acid so as to remove an oxide layer on the surface of copper, and then the copper powder is washed to be neutral with distilled water; then the copper powder is subjected to sensitization and activating treatment with stannous chloride and a silver-ammonia solution, and then the copper powder is washed to be neutral with distilled water; a silver nitrate solution is added into ammonium hydroxide to prepare a silver-ammonia solution; then the silver-ammonia solution and a reducing agent are added into the copper powder, and then magnetic stirring is performed so that reaction is performed uniformly; after the reaction is finished, the copper powder is washed with water, filtered and dried; and then a ball milling method is adopted, so that combination of copper and silver interfaces is closer, and the plating layer is more smooth. Through the novel formula and technological improvement, the surface of the copper powder is coated with a uniform and compact silver layer; the inoxidizability and electrical conductivity of the copper powder are improved; and the application range of the copper powder is expanded. The method provided by the invention is simple in technology and easy for operation; and the silver-plating copper powder which is uniform in plating layer, high in inoxidizability and controllable in plating layer thickness can be obtained.

Owner:UNIV OF JINAN

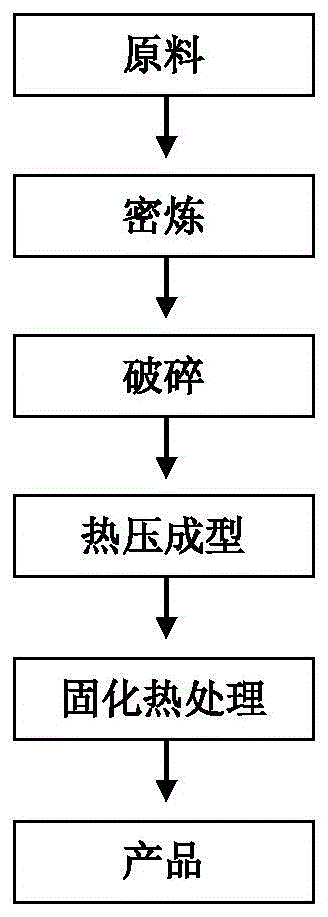

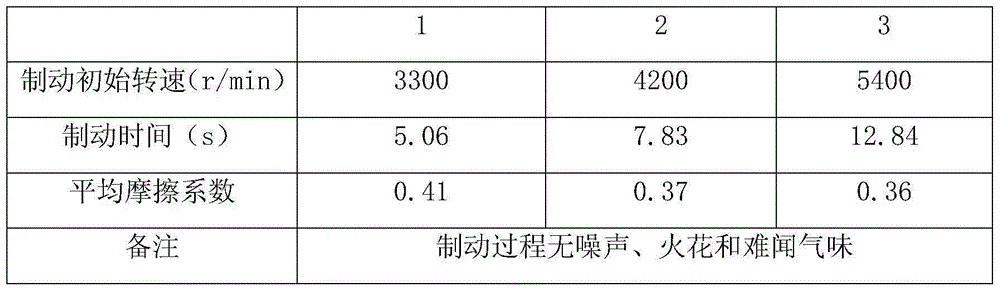

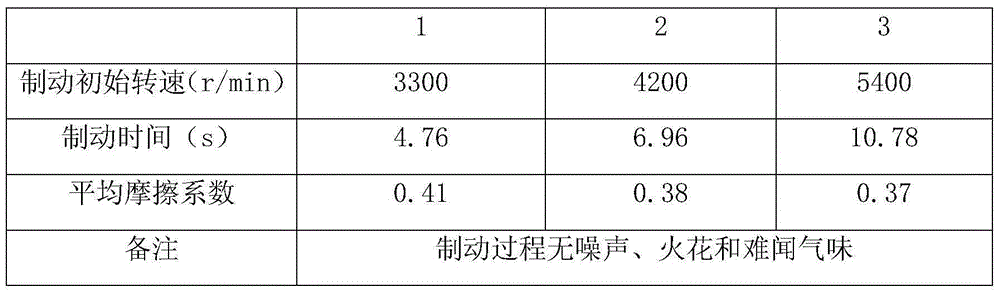

Calcium carbonate whisker reinforced rubber base friction material and preparation method therefor

InactiveCN105111532AImprove brittlenessImprove heat resistanceOther chemical processesFriction liningButadiene-styrene rubberPetroleum coke

The present invention discloses a calcium carbonate whisker reinforced rubber base friction material, and a preparation method therefor. The material comprises: 8-15 parts of nitrile rubber, 10-15 parts of styrene-butadiene rubber, 5-10 parts of phenolic resin, 5-25 parts of calcium carbonate whisker, 10-20 parts of steel fiber, 2-8 parts of sepiolite fiber, 0-8 parts of mineral fiber, 0-3 parts of aramid fiber, 5-8 parts of barium sulfate, 5-10 parts of magnesium oxide, 2-3 parts of aluminum oxide, 5-10 parts of flake graphite, 1-5 parts of carbon black, 5-10 parts of petroleum coke, 3-6 parts of Cardolite cashew nut shell oil friction powder, 0.5-1 parts of sulfur, and 0.5-1 parts of accelerator. The preparation method comprises process steps of such as material collocation, mixing, pressing molding and the like. Brake pads synthesized by the method provided by the invention have the advantages including excellent friction and wear performance, stable braking performance, high heat-resistant property, safe, environmentally-friendly, and low in cost; and is suitable for braking devices for automobiles and motive power machines, thereby achieving a very wide application prospect and applying to industrial production.

Owner:GUANGXI UNIV +2

Method for pretreating copper insert of copper-insert terminal of lead-acid storage battery before casting

ActiveCN101593823AExtended service lifeThe interface is tightly combinedSmall-sized cells cases/jacketsTinningPretreatment method

The invention provides a method for pretreating a copper insert before casting the copper insert of a copper-insert terminal of a lead-acid storage battery in a bus bar lead alloy bush seat, which comprises the following steps: (1) cleaning the surface of the copper insert; (2) tinning the copper insert; (3) preheating the copper insert; and (4) immersing the copper insert in molten lead alloy for a moment, taking the copper insert out, swinging the copper insert to remove lead alloy not firmly adhered to the surface of the lead alloy, immediately placing the copper insert into a cavity of a lead alloy bush seat of a bus bar casting mold, and casting lead alloy. In the pretreatment method, the copper insert casting process can make the joint of the interfaces of the copper insert and the bus bar lead alloy bush seat tight enough to greatly reduce slight leakage around the copper insert during use and prolong the service life of the battery to a maximum degree. The pretreatment method is simple in step and easy in operation, well solves critical problems in battery manufacturing and using industries, and has a great realistic significance.

Owner:GUANGDONG DYNAVOLT NEW ENERGY TECH CO LTD

Al4C3 modified Al-based composite and preparation method thereof

The invention discloses an Al4C3 modified Al-based composite and a preparation method thereof. The Al4C3 modified Al-based composite is prepared through the following method. The method comprises the steps that (1) oxidized graphene is prepared; (2) then pure aluminum powder is frozen at a low temperature to be kept for a period of time; (3) after the aluminum powder and a certain amount of graphene are mixed, a high-energy ball grinder is utilized for carrying out ball grinding on the above mixed frozen aluminum powder; (4) ball grinding is carried out after the aluminum powder and a certain amount of graphene are mixed, meanwhile, a small amount of Al4C3 powder is added gradually, and graphene coated aluminum powder interface bonding is further enhanced; (5) prepared graphene coated aluminum mixed powder is formed at certain pressure, and pressure maintaining is carried out under the pressing pressure; and (6) a blank obtained after cold pressing forming is put into heating equipment with inert gas shielding to be sintered, and finally the graphene coated aluminum-based composite excellent in comprehensive performance is prepared. The Al4C3 modified Al-based composite can be conveniently applied and popularized to the electronic industry.

Owner:ZHONGBEI UNIV

Graphene modified silicone rubber cable sheath material

InactiveCN106280475AAvoid attackReduce attackInsulated cablesInsulated conductorsPolymer scienceFumed silica

The invention discloses a graphene modified silicone rubber cable sheath material. The material is prepared from raw materials as follows: phenyl siloxane rubber, methyl vinyl silicone rubber, fluororubber, polybutadiene rubber, polyurethane, ethylene-acrylate rubber, zinc oxide, stearic acid, 2,4-dichlorobenzoyl peroxide, an assistant crosslinker TAIC, 2,5-dimethyl-2,5-di(tert-butylperoxy)hexane, cerium oxide, fumed silica, carbon black, nano calcium carbonate, stearic acid modified magnesium hydroxide, ammonium polyphosphate, modified graphene oxide, nano silicon carbide, magnesium stearate, triphenyl phosphate, tributyl citrate, an accelerator, an anti-aging agent and silane modified cellulose. The graphene modified silicone rubber cable sheath material is high in strength, excellent in heat resistance and flame retardation, good in aging resistance and long in service life.

Owner:ANHUI LAND GRP

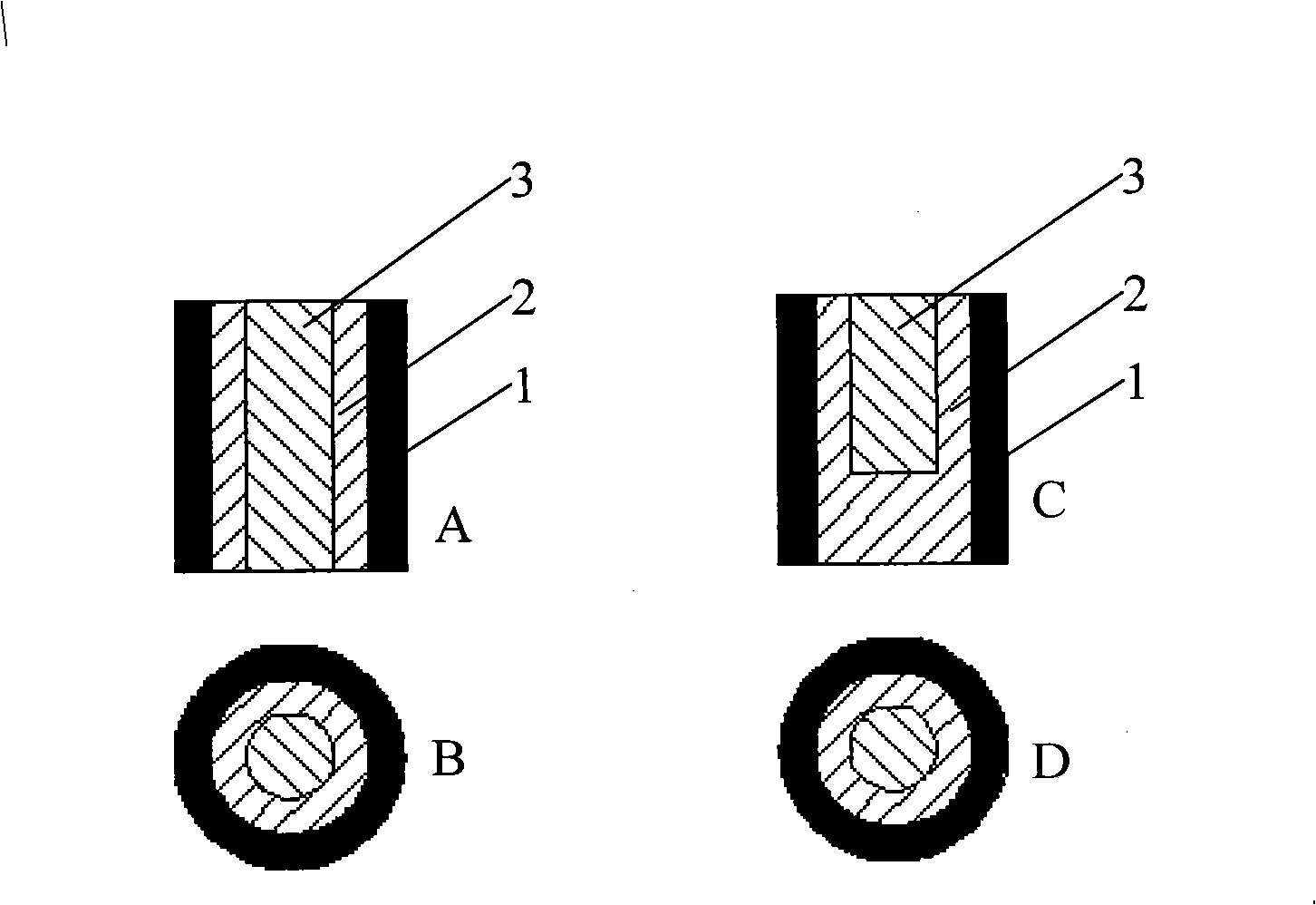

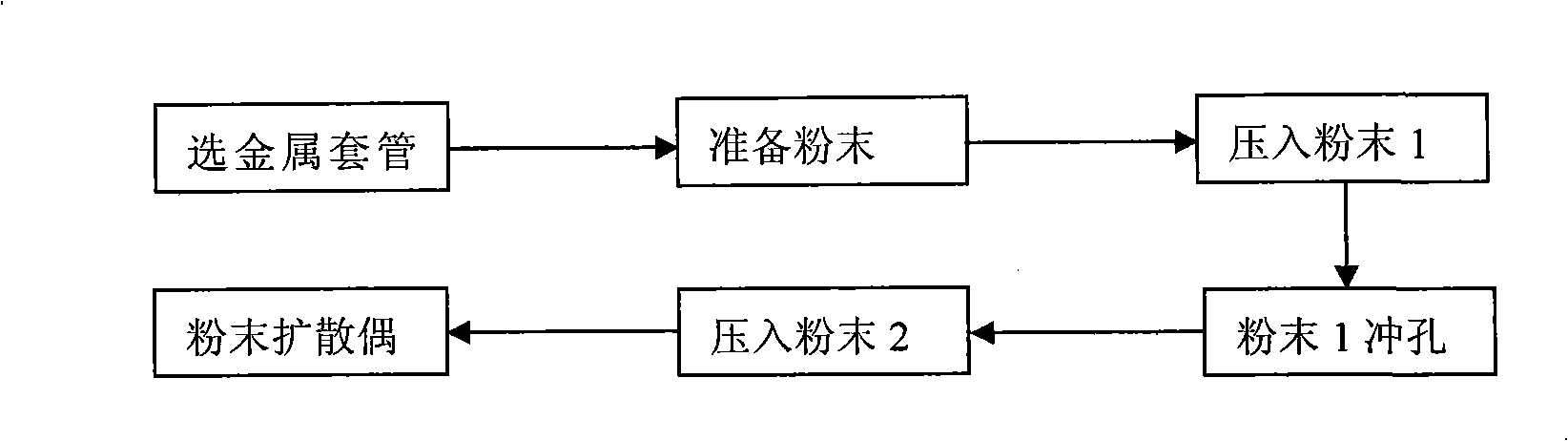

Method for preparing diffusion couple by using powder

InactiveCN101255060ALow cost manufacturingTightly boundCeramic shaping apparatusDiffusionChemical reaction

The invention relates to a method for producing diffusion couple with powders including the following steps: (1) powder material A is filled in a metal casing which do not diffuse or react with the contacted powder and then is pressed to form a compact; (2) the compact is punched by a die with a diameter which is 4-6 mm smaller than the inner diameter of the metal casing; (3) another powder material B is filled in the holes and then treated by compaction, sintering at a certain temperature, air-cooling to get a diffusion couple. The ring canning diffusion couple produced by compacting powder in the invention utilizes the high shrinkage of the outer powder in the sintering process to provide a interfacial binding force to the powder material of each layer in the jacket, thereby guaranteeing a full integration of the powder in each layer and providing a possibility to the preparation and the interface study of the layered composite powder materials.

Owner:CHONGQING UNIV

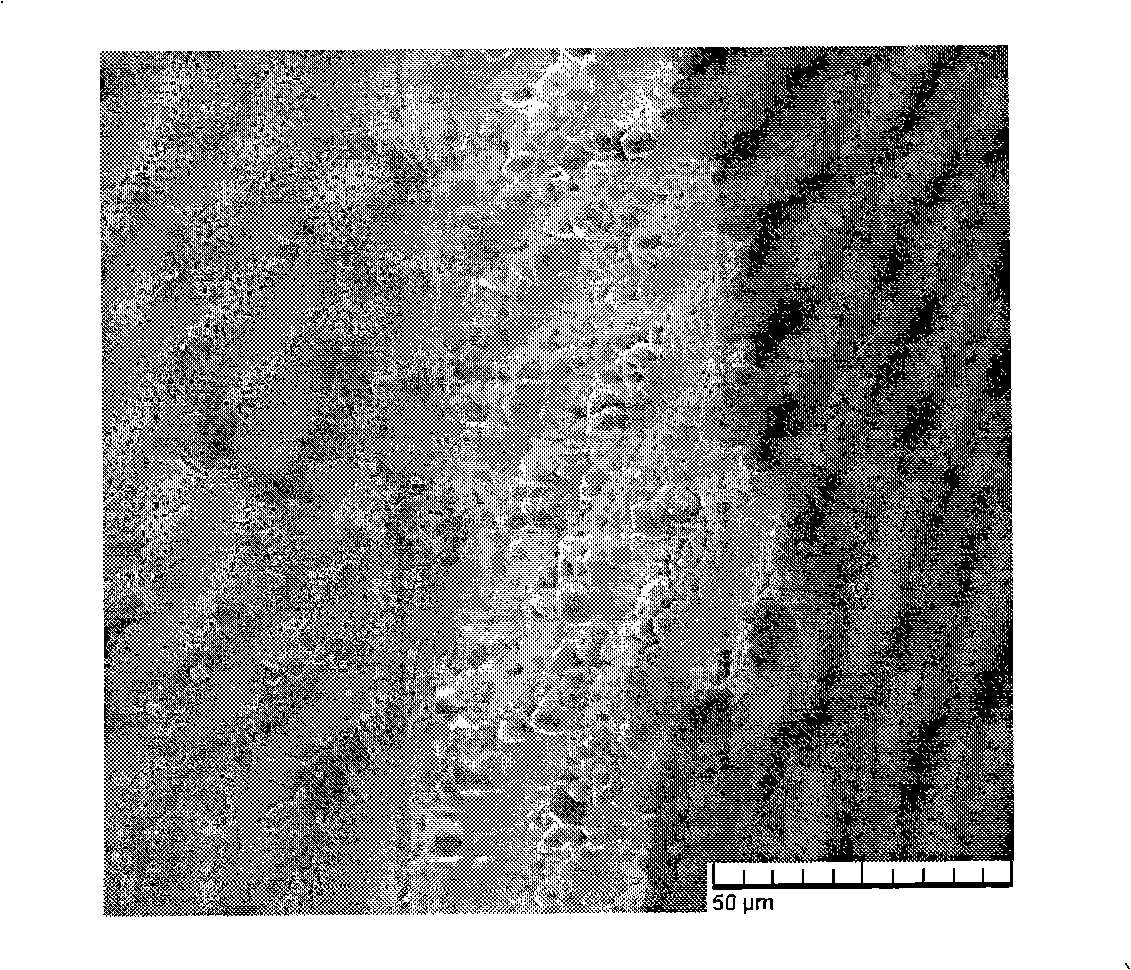

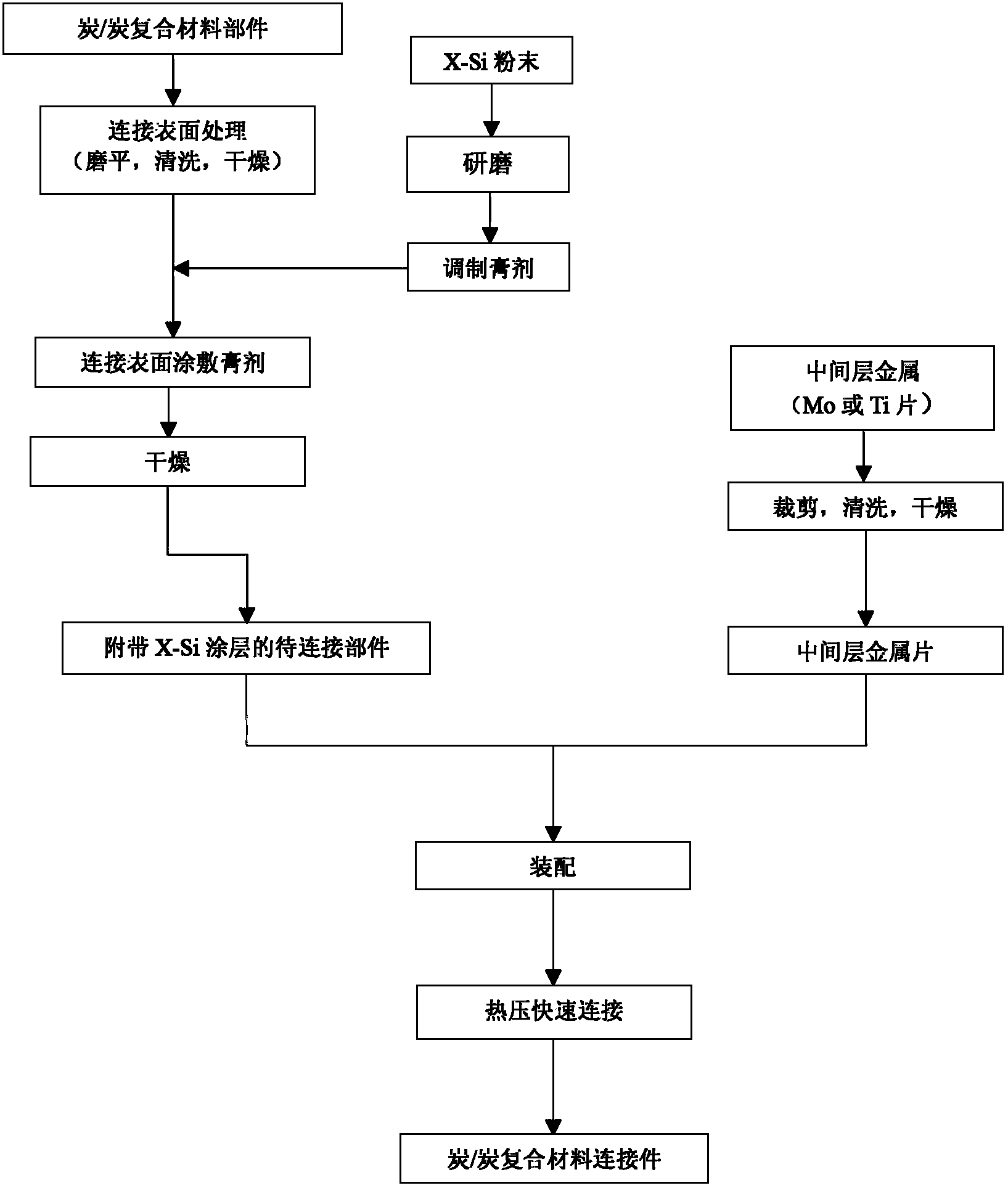

Fast connection method of carbon/carbon composite material

InactiveCN103232257AThe interface is tightly combinedEnables high temperature applicationsCarbon compositesMetal sheet

The invention discloses a fast connection method of a carbon / carbon composite material. The method includes the steps of: (1) preparation of an X-Si (X=Ni, Co, Ti or Cr) alloy paste; (2) pretreatment of the carbon / carbon composite material; (3) pretreatment of a middle layer metal sheet (including Mo or Ti sheet); (4) coating of a composite material connection surface with the X-Si alloy paste; and (5) assembling and quick connection: arranging two X-Si alloy coatings and one middle layer metal sheet in the middle of the connection surface of two carbon / carbon composite components so as to form an X-Si / middle layer metal sheet / X-Si sandwich structure, with the Si atomic percentage content of the X-Si alloy being 40-80%, under the conditions of 10-40MPa pressure assembling, vacuum protection and a heating rate of 100-300DEG C / min, conducting heating to 1200-1600DEG C, and performing heat preservation for 1-10min. The method disclosed in the invention can realize liquid phase connection of carbon / carbon composite materials. The process is simple, and the prepared connecting piece has a reliable structure and can be used in load bearing and high temperature application occasions.

Owner:XI AN JIAOTONG UNIV

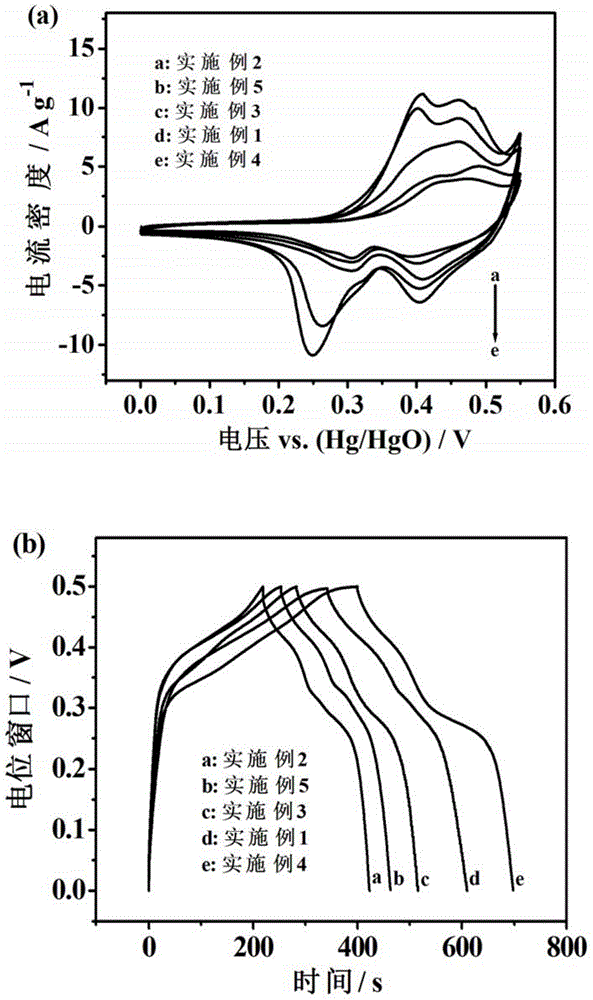

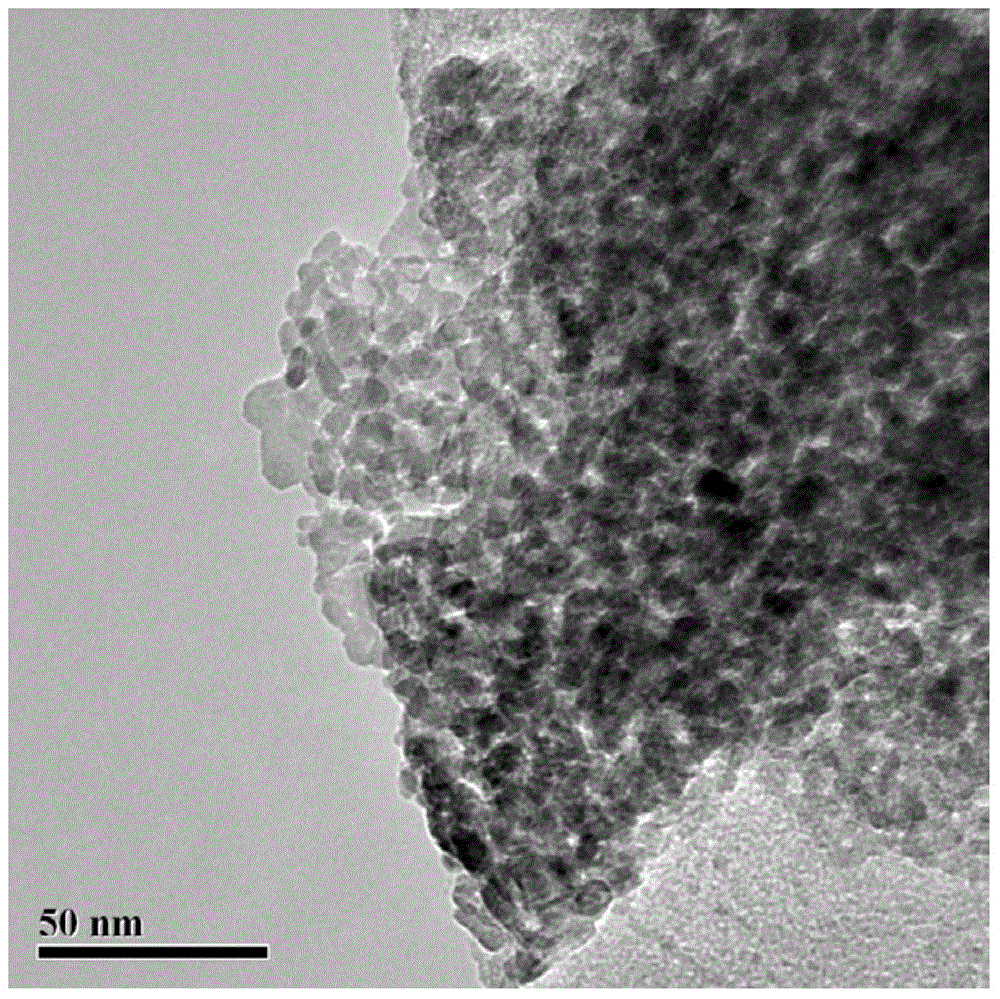

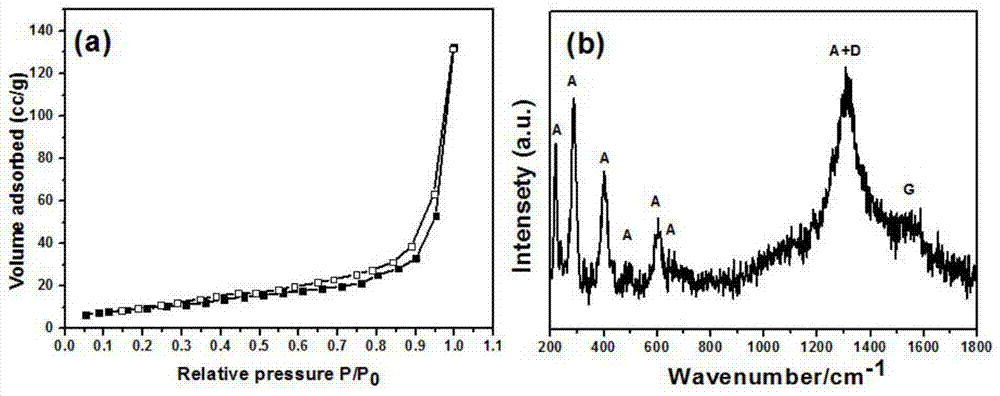

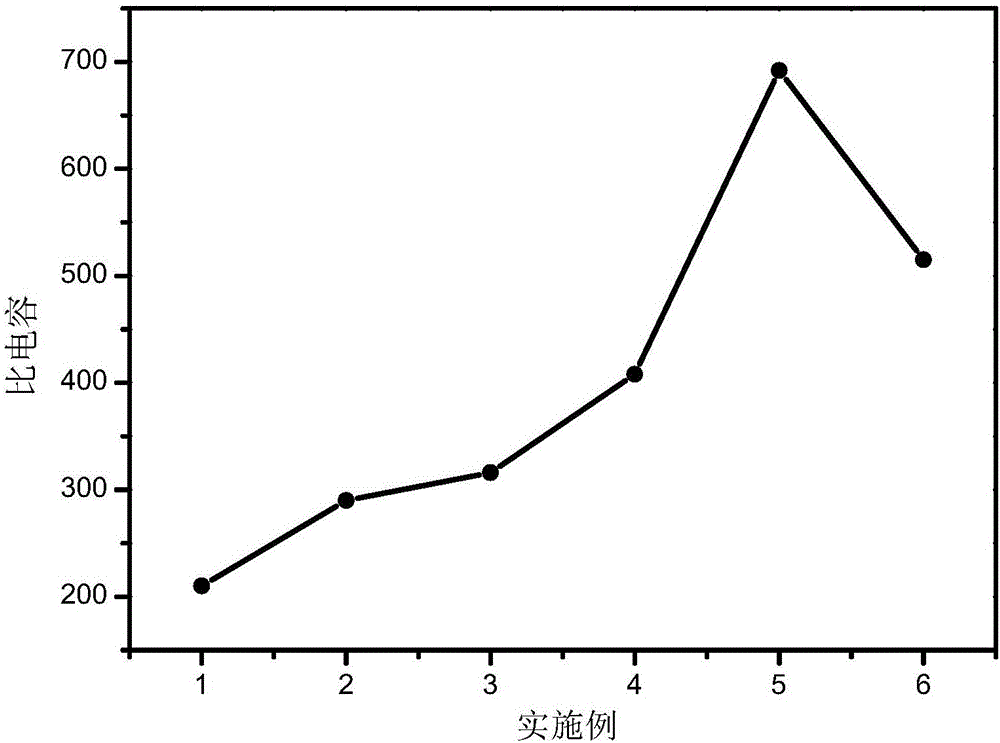

Method for preparing cobaltous oxide/graphene nanometer composite material

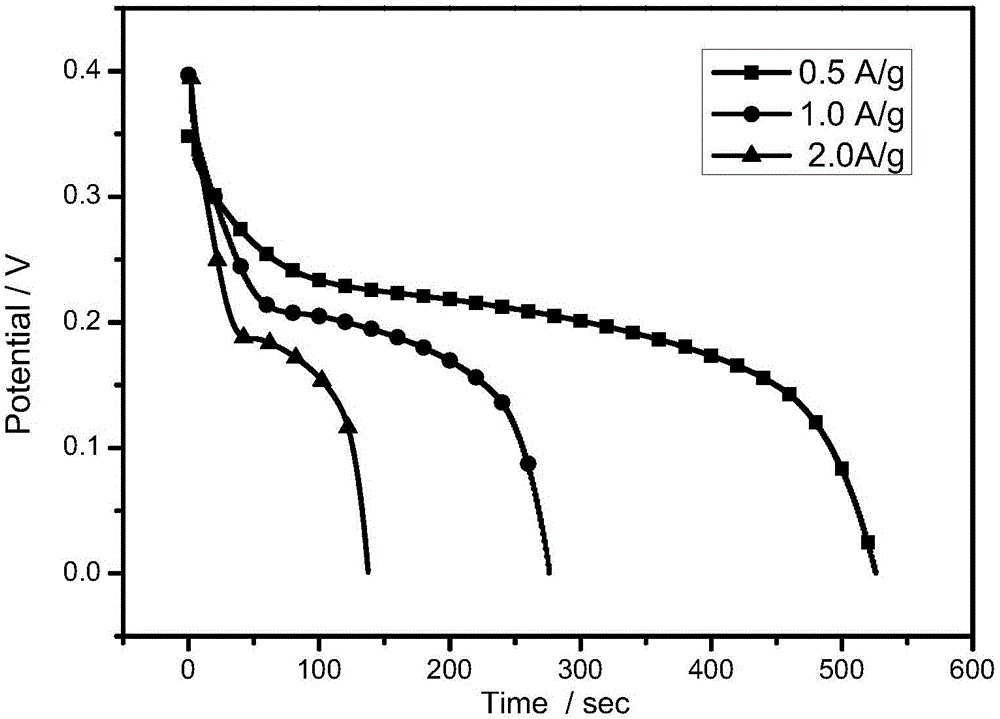

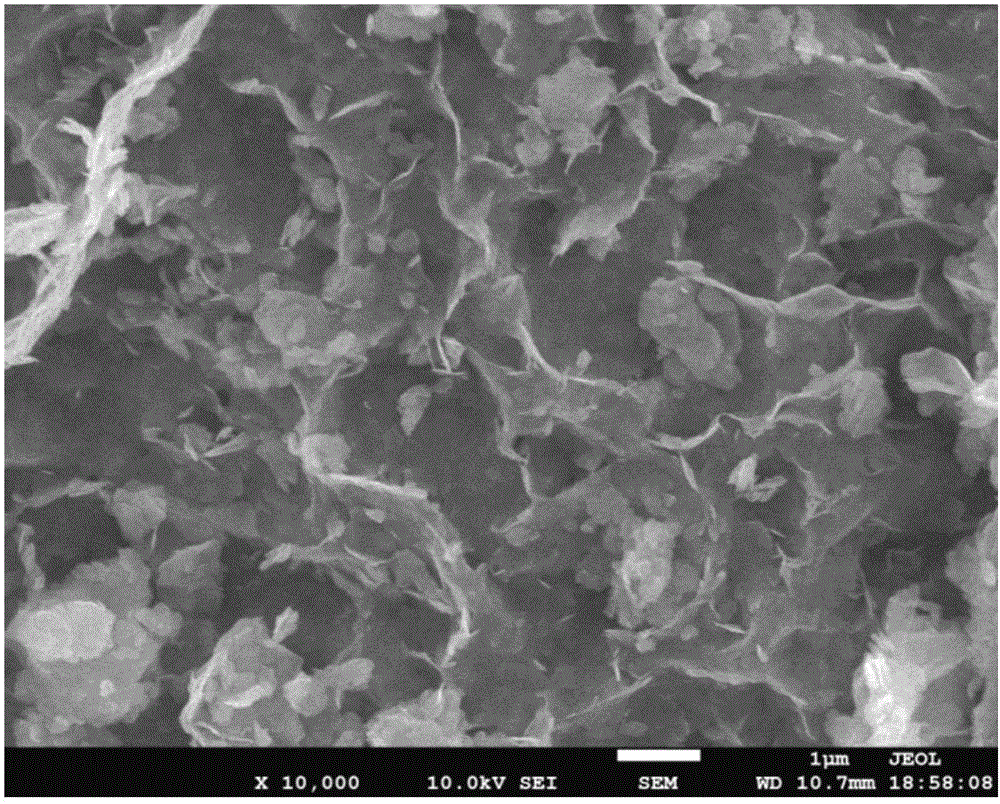

ActiveCN104835653AHigh specific capacityImprove cycle stabilityHybrid capacitor electrodesHybrid/EDL manufactureNano compositesGraphene nanocomposites

The invention provides a method for preparing a cobaltous oxide / graphene nanometer composite material, which comprises the steps of performing ultrasonic processing on graphite oxide in deionized water for obtaining graphene oxide solution, dissolving Co(NO3)2.6H2O into the deionized water for obtaining cobaltous nitrate solution, then dripping NH3.H2O, dispersing a generated solid product in the deionized water for preparing cobalt hydroxide colloidal solution; mixing the cobaltous nitrate solution with the cobalt hydroxide colloidal solution, performing washing and drying; and processing at the temperature of 150-500 DEG C for obtaining the cobaltous oxide / graphene nanometer composite material. The method for preparing the cobaltous oxide / graphene nanometer composite material has advantages of simple operation, high speed, large-scale production, and environment-friendly effect.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

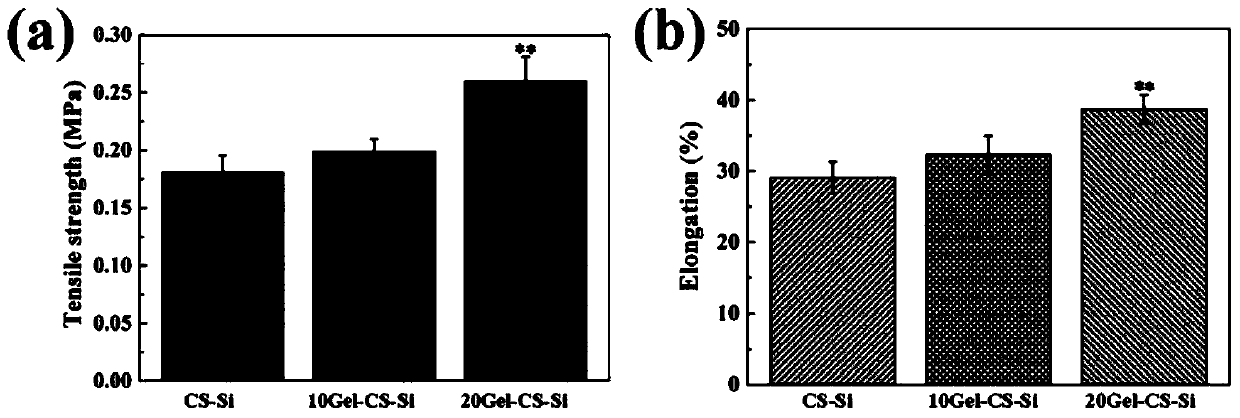

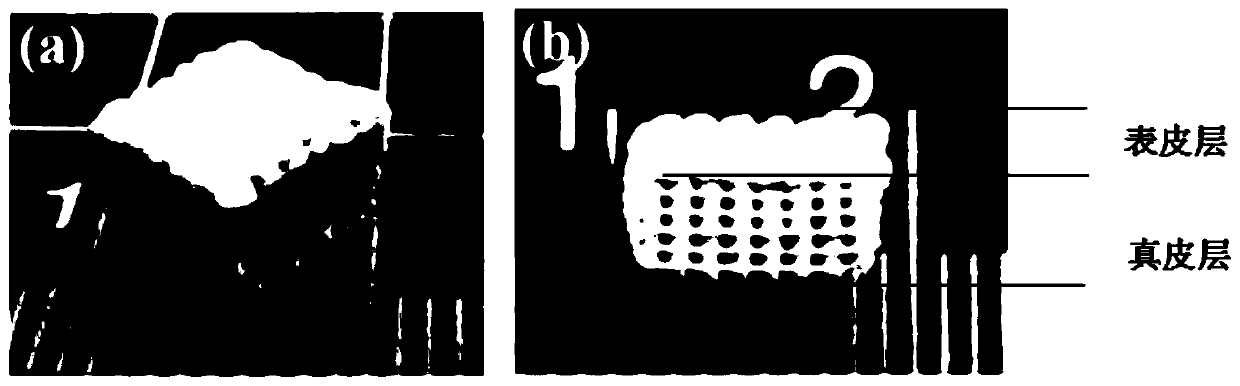

Method for preparing full-thickness skin tissue engineering scaffold with gradient pore structure

ActiveCN110302432AThe preparation process is precise and easy to controlImprove product qualityAdditive manufacturing apparatusProsthesisDefect repairBiocompatibility Testing

The invention relates to the technical field of tissue engineering skin, and concretely relates to a method for preparing a full-thickness skin tissue engineering scaffold with a gradient pore structure. The organic-inorganic hybrid materials are prepared by a sol-gel technique. According to the structure and composition characteristics of skin tissue, a CS-Si-Gel component is selected as a dermislayer and a CS-Si component is used as an epidermal layer, and the full-thickness skin tissue engineering scaffold with the gradient pore structure is successfully constructed by using a multi-nozzleprinting system. The material selected by the invention has excellent biocompatibility, antibacterial property, and the like, and the prepared scaffold has the advantage of structural bionics. In addition, a 3D scanning modeling technology is used for layered printing, stacking layer by layer is carried out, which can be customized, so that the success rate of full-thickness skin defect repair can be increased. The skin tissue engineering scaffold can also be used for in vitro skin model research and plays an important role in drug and cosmetic testing as well as on cancer research.

Owner:SOUTH CHINA UNIV OF TECH

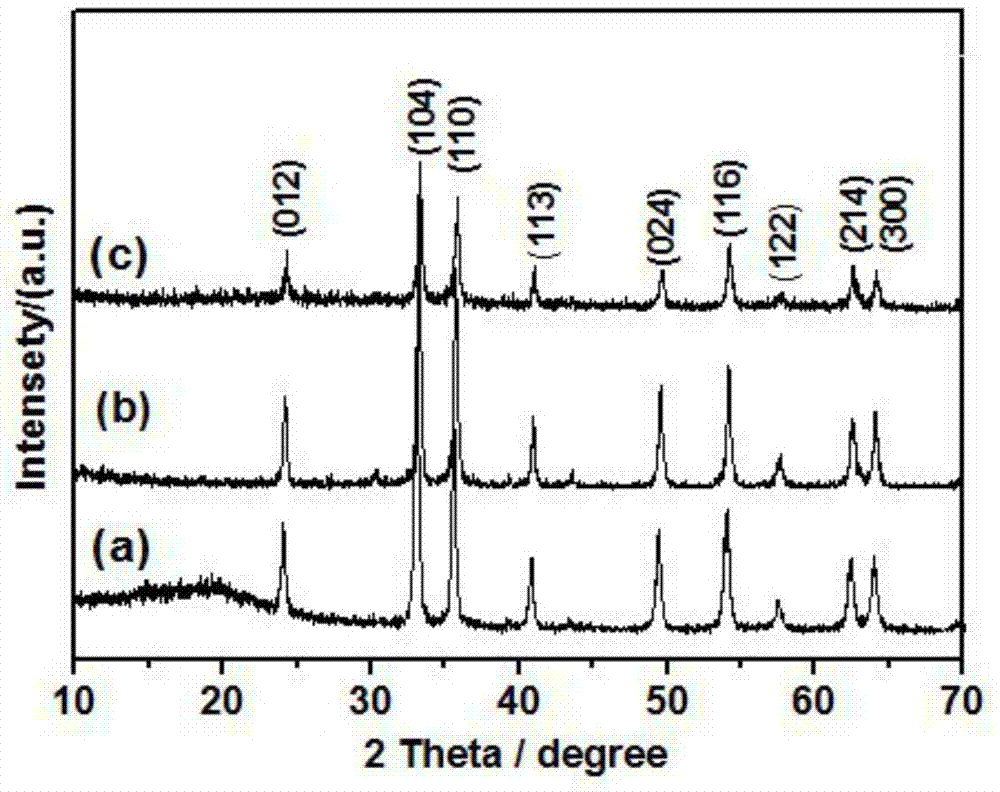

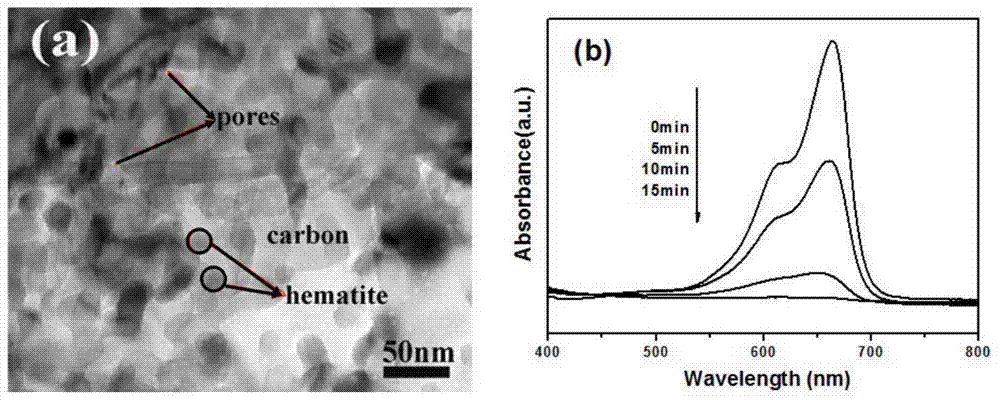

Preparation method of carbon-ferric oxide nanocomposite material

ActiveCN104492437AWell mixedImprove photocatalytic performanceMetal/metal-oxides/metal-hydroxide catalystsPhotocatalytic degradationMaterials science

The invention discloses a preparation method of a carbon-ferric oxide (alpha-Fe2O3) nanocomposite material, belonging to the field of synthesizing an inorganic material. The carbon-ferric oxide nanocomposite material is obtained through one-step reaction by adopting an ferrous source, a carbon source and an auxiliary as raw materials, without the need of subsequent treatment, and the prepared carbon-ferric oxide nanocatalyst and ferric oxide realize nanoscale composition, the specific surface area is large, the carbon-ferric oxide nanocomposite material has a mesoporous structure, the solar utilization rate is high, the catalysis performance is good, and the carbon-ferric oxide nanocomposite material can be used in the field of a functional material, especially the field of photocatalytic degradation of organic pollutants. According to the preparation method, the raw materials are easily available, a template, a surfactant, a precipitator and the like are not needed during the preparation process, the technology is simple, the production cost is low, and large-scale production is easy to realize.

Owner:UNIV OF SCI & TECH BEIJING

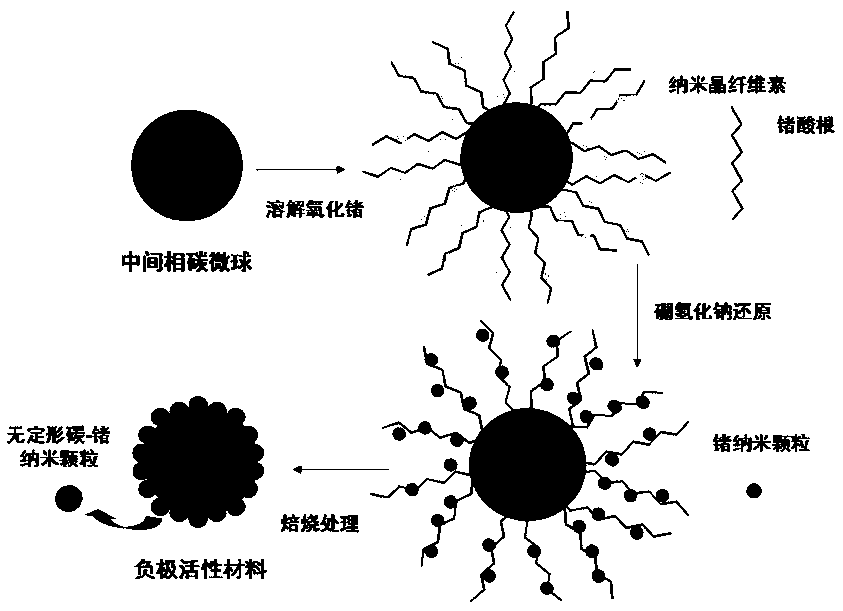

Lithium-ion battery germanium/carbon composite negative electrode material and preparation method and application thereof

ActiveCN110085847AImprove cycle stabilityAvoid reunionNegative electrodesSecondary cellsCelluloseCarbon composites

The invention discloses a lithium-ion battery germanium / carbon composite negative electrode material and a preparation method and an application thereof. The composite negative electrode material includes germanium nanoparticles, mesocarbon microbeads and amorphous carbon. The preparation method comprises the steps of (1) dissolving GeO2 in an alkaline solution, adding nanocrystalline cellulose, adjusting the pH-value of the obtained first suspension, adding the mesocarbon microbeads and stirring to form a second suspension, and transferring the second suspension to a water bath; (2) preparingan NaBH4 solution, adding the heated second suspension, stirring for reaction in the water bath, washing wafer vacuum filtration, then carrying out vacuum drying, roasting the dried solid in an inertgas or reducing atmosphere to obtain the product. The composite negative electrode material disclosed by the invention has high mass capacity and volume specific capacity, can effectively alleviate the volume change and pulverization of germanium, is high in cycle stability and good in compatibility with a propylene carbonate containing electrolyte, has the advantages of good low-temperature electrochemical performance and the like and can be applied to lithium-ion batteries.

Owner:NAT UNIV OF DEFENSE TECH

High-temperature-resistant high-fire-retardant silicone tube

The invention discloses a high-temperature-resistant high-fire-retardant silicone tube which is extruded from a silicone rubber composite material. The silicone rubber composite material comprises the following raw materials: methyl vinyl silicone rubber, methyl vinyl phenyl polysiloxane rubber, ethylene-propylene-diene rubber, cis-polybutadiene rubber, polyurethane, an ethylene-octene copolymer, zinc oxide, stearic acid, 2,5-dimethyl-2,5-di(t-butyl peroxy)hexane, methyltris(methylethylketoxime)silane, triallyl cyanurate, composite pigments and fillers, a catalyst, one or more antioxidants, tricresyl phosphate and melamine resin, wherein the composite pigments and fillers are obtained by mixing cerium oxide, aluminum hydroxide, magnesium hydroxide, micro-capsulated red phosphorus, nanometer calcium carbonate, iron oxide, diatomite, silicon carbide, trichlorovinylsilane, hexamethylcyclotrisilazane, divinyl tetramethyl disiloxane and an imidazolium ionic liquid. The silicone tube provided by the invention is high in strength, high-temperature resistance and aging resistance, excellent in fire-retardant property, and long in service life.

Owner:安徽都邦电器有限公司

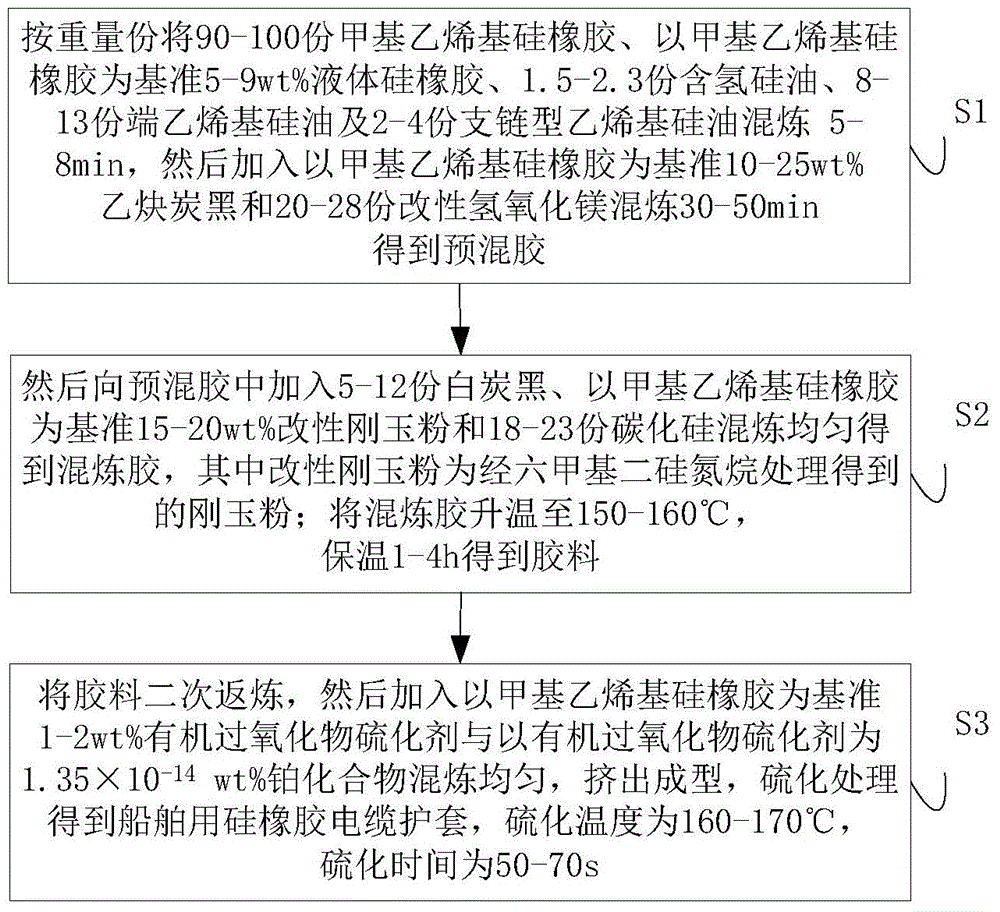

Preparation process for silicone rubber cable sheath used for ship

InactiveCN104788964AImprove conductivityHigh hardnessPlastic/resin/waxes insulatorsInsulated cablesVulcanizationPolymer science

The invention discloses a preparation process for a silicone rubber cable sheath used for a ship. The preparation process comprises the following steps: mixing methyl vinyl silicone rubber, liquid silicone rubber, hydrogen-containing silicone oil, vinyl-terminated silicone oil and branched-chain vinyl silicone oil for 5 to 8 mi, then adding acetylene carbon black and modified magnesium hydroxide and carrying out mixing for 30 to 50 min so as to obtain premixed rubber; adding white carbon black, modified corundum powder and silicon carbide into the premixed rubber, carrying out uniform mixing so as to obtain mixed stock, heating the mixed stock to a temperature of 150 to 160 DEG C and maintaining the temperature for 1 to 4 h so as to obtain a rubber compound; and subjecting the rubber compound to secondary remilling, then adding an organic peroxide vulcanizing agent and a platinum compound and successively carrying out uniform mixing, extrusion molding and vulcanization so as to obtain the silicone rubber cable sheath used for the ship. The silicone rubber cable sheath prepared in the invention has the advantages of stable fire resistance, good insulating properties and good mechanical properties; and the preparation process is simple and poses little environmental pollution.

Owner:ANHUI TIANCAI CABLE GRP

Novel gel coat resin for die and preparation method for novel gel coat resin

ActiveCN104845511AThe interface is tightly combinedImprove mechanical propertiesPigment treatment with organosilicon compoundsPolyester coatingsFumed silicaSilicon dioxide

The invention provides novel gel coat resin for a die. The novel gel coat resin comprises the following components in parts by weight: 80 to 93 parts of unsaturated polyester resin, 0.2 to 2 parts of fumed silica, 0.1 to 0.5 part of a dispersant, 0.1 to 0.5 part of an antifoaming agent, 0.1 to 0.3 part of a polymerization inhibitor, 0.1 to 0.3 part of an initiator, 5 to 15 parts of nanometer silicon carbide and 0.5 to 2 parts of a coupling agent. The invention further discloses a preparation method for the gel coat resin for the die. The gel coat resin for the die has higher mechanical performance and flexibility.

Owner:WUJIANG ZHENYU SEWING EQUIP

Method for preparing graphene-based nickel oxide nanocomposite

ActiveCN105140044AAchieve compositeImproved quasi-capacitive characteristicsMaterial nanotechnologyHybrid capacitor electrodesNitrateNickel oxide hydroxide

A method for preparing a graphene-based nickel oxide nanocomposite is disclosed. The method comprises steps of: performing ultrasonic processing on graphite oxide in deionized water to obtain a graphene oxide solution; dissolving nickel nitrate into the deionized water, dropwise adding NH3.H20 until the pH of the solution reaching 8-10, stirring, standing and suction filtrating to obtain nickel hydroxide sediment; adding the nickel hydroxide sediment into the deionized water and performing ultrasonic processing to obtain a nickel hydroxide colloidal solution; mixing and stirring the graphene oxide solution and the nickel hydroxide colloidal solution, standing, suction filtrating, and then drying and grinding to obtain powdery graphene-based nickel oxide nanocomposite, calcining the powdery graphene-based nickel oxide nanocomposite in an inert atmosphere to obtain the graphene-based nickel oxide nanocomposite. The method has the advantages of simple preparation method, lower cost, environment friendliness and suitability for mass-scale production.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

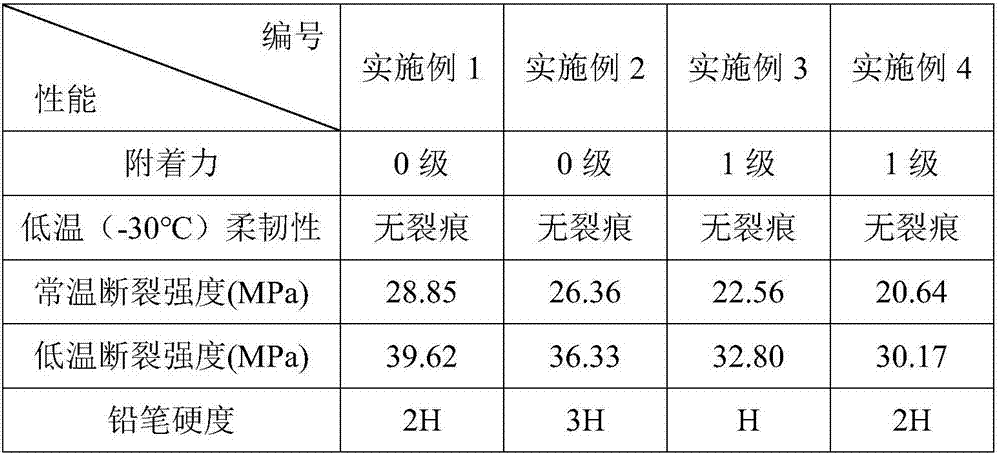

Low-temperature-resistant and abrasion-resistant polyurethane coating and preparation method thereof

ActiveCN106893466AAvoid reunionImprove low temperature performancePolyurea/polyurethane coatingsPolyesterPolyol

The invention relates to a low-temperature-resistant and abrasion-resistant polyurethane coating and a preparation method thereof. The low-temperature-resistant and abrasion-resistant polyurethane coating is prepared from, by weight, 45-60 parts of polyurethane matrix resin, 0.5-6 parts of low-temperature polyester polyols, 3-20 parts of surface modifier modified micron powder, 5-12 parts of curing agents, 30-50 parts of solvent and 0.5-3 parts of defoamer. The low-temperature-resistant performance of the obtained polyurethane coating can be excellent by adding the low-temperature-resistant polyurethane matrix resin on the basis that the strong adhesion, excellent room-temperature mechanical performance, good stability and other characteristics of original polyurethane coatings are retained, the hardness of the coating is improved by adding the micron powder, and accordingly the coating has excellent abrasion-resistant performance. The coating can be used for protection of aircraft, wind turbine blades and other facilities in a low-temperature environment.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

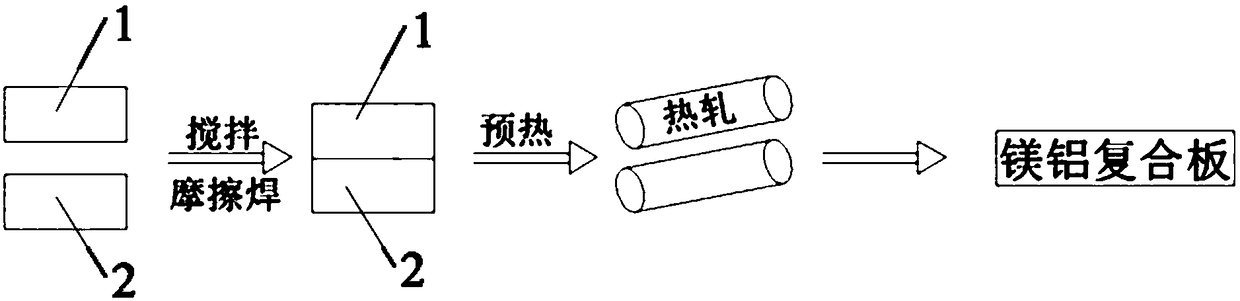

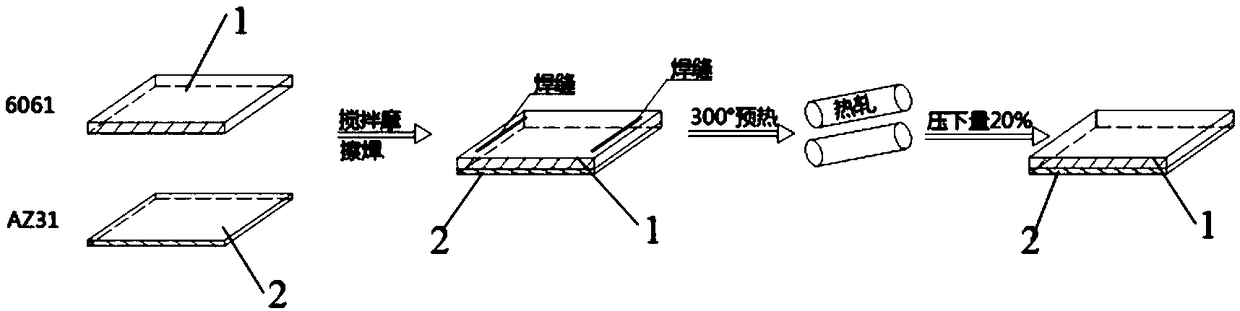

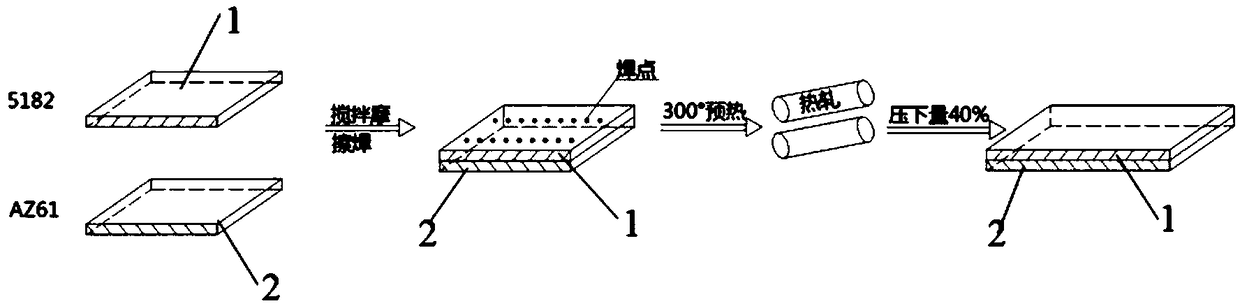

Aluminum magnesium alloy composite board and preparing method thereof

InactiveCN108687159ALow densityEasy to processLamination ancillary operationsLaminationFriction weldingComposite plate

The invention discloses an aluminum magnesium alloy composite board. The aluminum magnesium alloy composite board comprises an aluminum alloy board and a magnesium alloy board; the aluminum alloy board and the magnesium alloy board are stacked, and through friction stir welding, connection is achieved; the aluminum alloy board and the magnesium alloy board which are welded and stacked together aresubject to hot rolling to form the aluminum magnesium alloy composite board; a preparing method of the aluminum magnesium alloy composite board comprises the steps that the steps that the aluminum alloy board and the magnesium alloy board are machined to the predetermined dimension for standby application; secondly, the aluminum alloy board and the magnesium alloy board to be subject to standby application are subject to mechanical treatment and chemical cleaning, and surface oil stains and an oxide film can be removed; thirdly, the prepared aluminum alloy board and the prepared magnesium alloy board are horizontally stacked on a welding worktable, and are fixed through a clamp; fourthly, the stir friction welding manner is used for welding the aluminum alloy board and magnesium alloy board laminated slab; fifthly, the welded aluminum alloy board and magnesium alloy board composite board is put into a box type resistance furnace to be preheated; and sixthly, the preheated aluminum alloy board and magnesium alloy board composite board is fed into a rolling mill to be subject to hot rolling.

Owner:ZOTYE INT AUTOMOBILE TRADING CO LTD

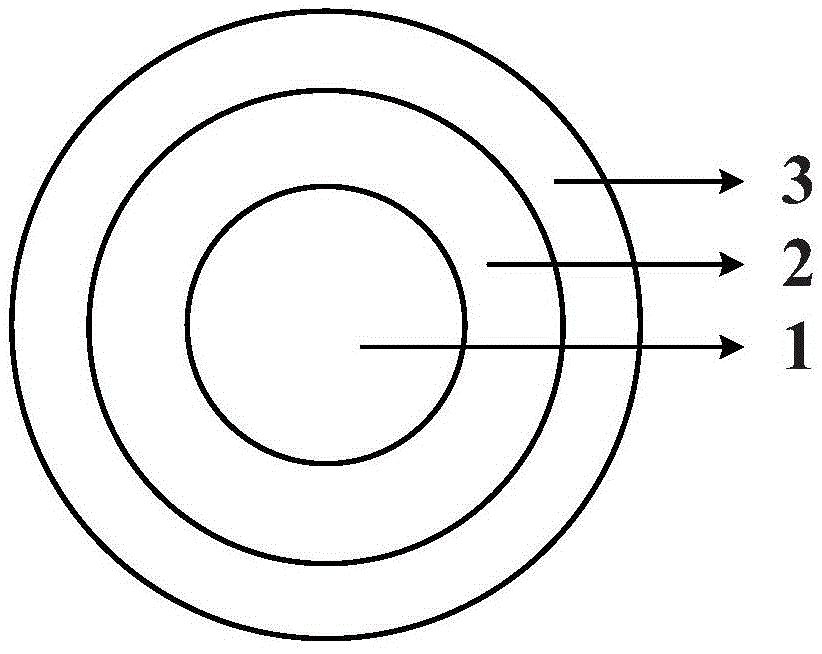

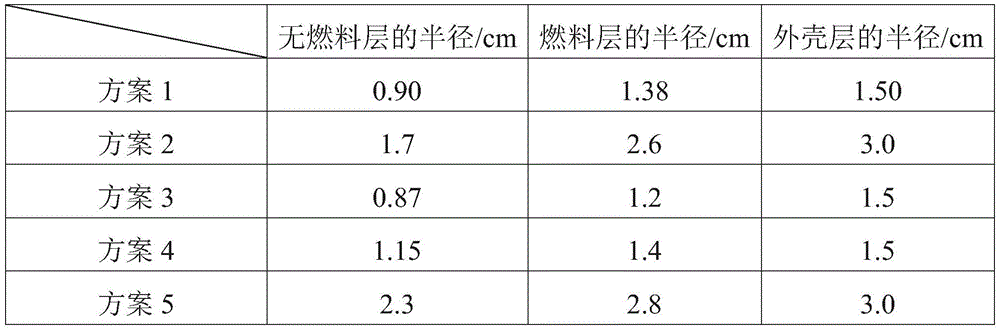

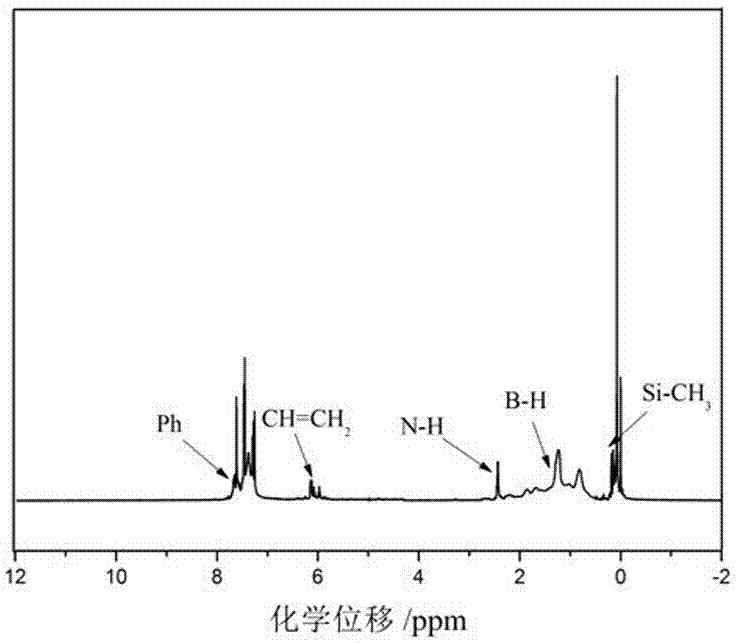

Fuel element and preparation method and application thereof

ActiveCN106158053ADensity adjustableAdjustable densityFuel elementsNuclear energy generationInterfacial bindingHeavy metals

The invention discloses a fuel element and a preparation method and application thereof. The fuel element is a ball and sequentially comprises a fuel-free layer, a fuel layer and a shell layer from inside to outside, and the fuel-free layer, the fuel layer and the shell layer are concentric. The fuel-free layer is spherical phenolic-resin-based foam carbon with the volume density being 0.5-1.2 g / cm<3> and the compressive strength being 40-90 MPa. Grooves are formed in the surface of the phenolic-resin-based foam carbon. The fuel element is adjustable in volume density, the volume density is lower when design parameters are the same, the heavy metal loading capacity is higher when volume densities are the same, interfaces between the fuel-free layer and the fuel layer are closely combined, the fuel element has the advantages that the shell layer is compact in structure and molten salt infiltration can be prevented, the fuel element can be used in a reactor, and the preparation method is simple and low in cost.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

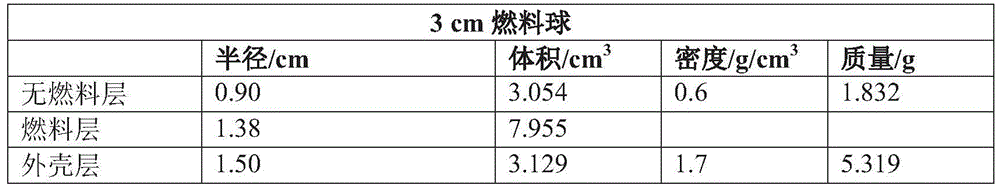

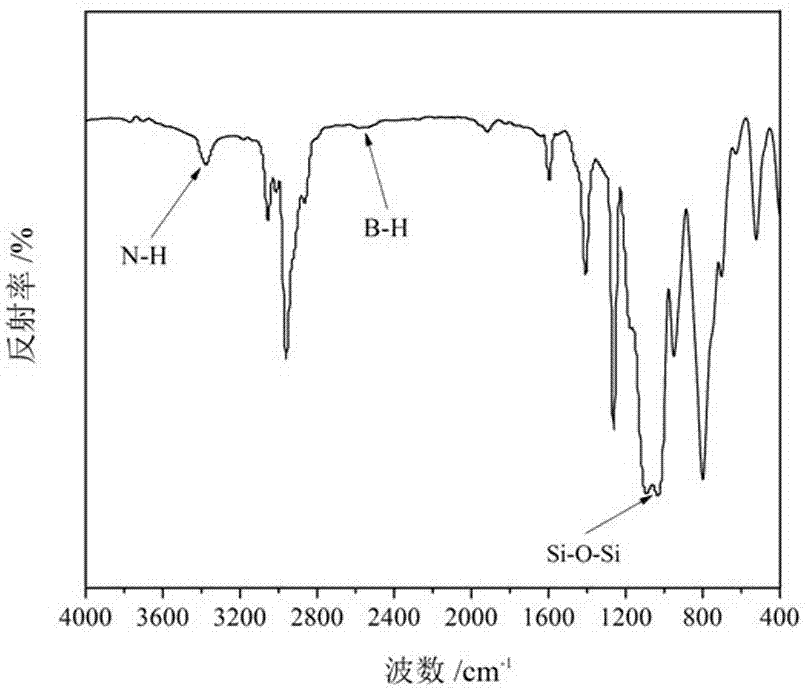

Carborane ceramic precursor system and preparation method and application thereof

The invention discloses a carborane ceramic precursor system and a preparation method and application thereof. Particularly, 1, 1'-silicon alkyl methylene-2, 2'-bis(silicon dimethyl) biscarborane is used as a reaction raw material, and 1, 1'-silicon alkyl methylene-2, 2'-bis(hydroxyl silicon dimethyl) biscarborane is prepared; triethylene trimethyl ring trisilazane is used as an initial raw material and reacted with dimethyl chlorosilane to obtain 1, 3, 5-trimethyl-1, 3, 5-tri[(i)beta( / i)-( dimethyl chlorine silicon) ethyl] cyclotrisiloxane is obtained; then the novel carborane ceramic precursor is prepared. The precursor takes cyclo-silazane as a framework support, and is provided with a cross-linked network structure; thus the precursor has very good ceramic yield in further crosslinking process; therefore, a compact ceramic coating can be formed on the surface of the carbon fiber. The preparation method has the advantages of simple preparation technique, mild reaction condition, and easily-obtained raw materials; the carborane ceramic precursor system is applicable to the industrial amplifying production. The heat resistance and the oxidization resistance of the carbon fiber after coating treatment are very excellent.

Owner:SUZHOU UNIV

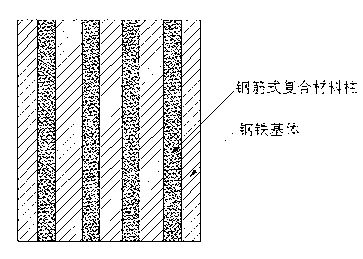

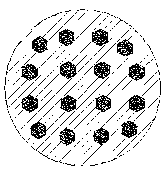

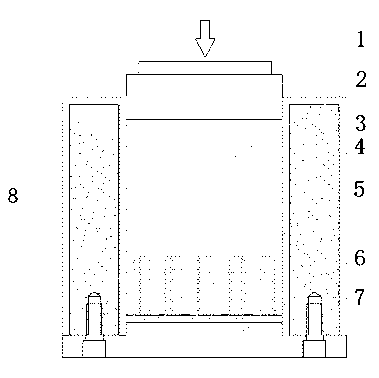

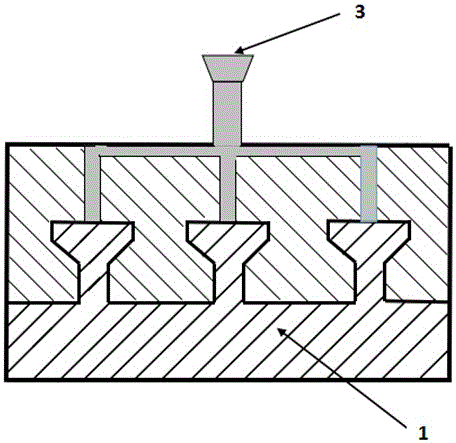

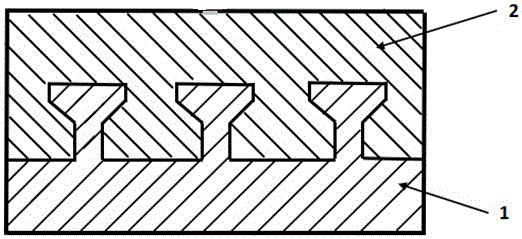

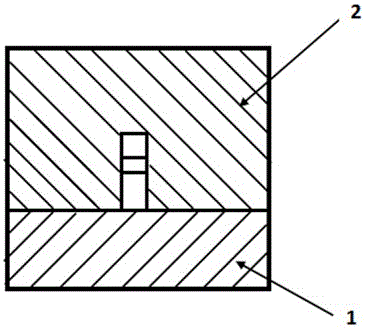

Steel-based composite and preparation method and preparation device thereof

The invention relates to a steel-based composite and a preparation method and a preparation device thereof, and belongs to the technical field of steel-based composites. The steel-based composite comprises a steel base and reinforced composite columns parallelly arranged in the steel base, and is prepared by processes of pressing, sintering, pouring, condensing and the like. The preparation device of the steel-based composite comprises a mould base, a composite mould casing and a pressing head, wherein the composite mould casing is in the shape of a hollow cylinder with the lower end connected with the mould base and consists of a low-heat-conduction ceramic layer and hot-work die steel, the low-heat-conduction ceramic layer is packaged by the hot-work die steel on the periphery, the pressing head is disposed inside the composite mould casing and capable of moving freely along the inner wall, and the size of the pressing head is matched with the inner diameter of the composite mould casing. The steel-based composite has excellent bearing capacity and wear resistance. The preparation method is easy in processing, short in production cycle and facilitates mechanical batch production. The preparation device is reusable, and accordingly production cost is reduced.

Owner:KUNMING UNIV OF SCI & TECH

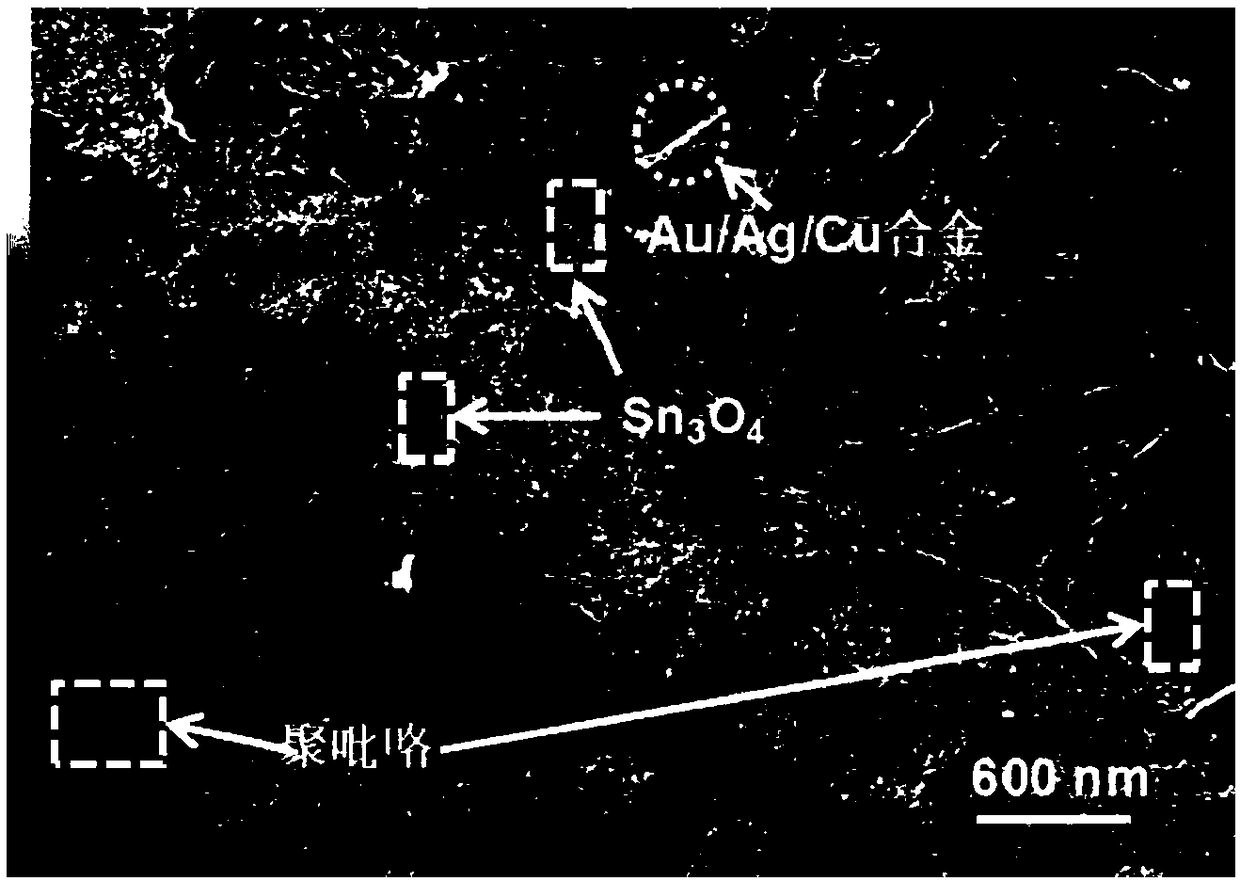

Preparation method of polypyrrole/metal-modified Sn3O4 nano composite photocatalytic material

InactiveCN109107614AEnhanced Broad Spectrum Light AbsorptionImprove photocatalytic performanceGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsHeterojunctionPhotocatalytic reaction

The invention discloses a preparation method of a polypyrrole / metal-modified Sn3O4 nano composite photocatalytic material. The nano composite material is a composite photocatalyst material obtained byloading and dispersing metal-modified Sn3O4 semiconductor heterojunction on polypyrrole in a chemical bond complexing form; and the metal-modified Sn3O4 is obtained by separately loading metal nano particles of a single-component metal or multi-component alloy of Pt, Au, Ag, Cu and the like having a plasma resonant effect onto Sn3O4. The photo-induced electron-hole separation rate in the photocatalytic reaction can be sufficiently improved by utilizing the visible light photocatalytic oxidation and reduction characteristics of Sn3O4, the plasma resonant effect of metal nano particles, photo conduction and conductivity of polypyrrole as well as the chemical bond heterojunction structure among different components, so that the performance for degrading pollutants in a photocatalytic oxidation and reduction manner and generating hydrogen by photocatalytic and decomposition of water can be improved. The easy-to-mold characteristic of polypyrrole can effectively avoid the recycling difficulty of the powder material.

Owner:PINGDINGSHAN UNIVERSITY

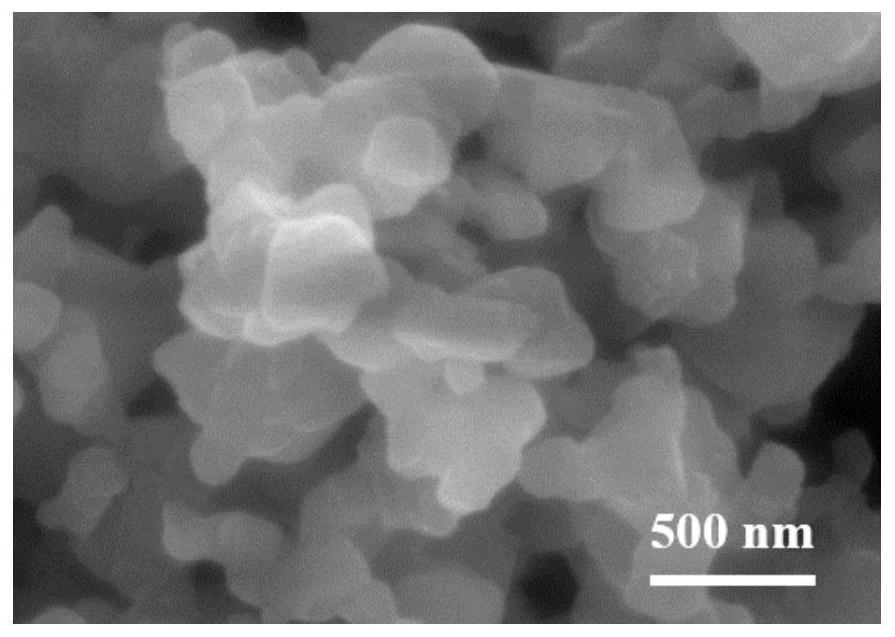

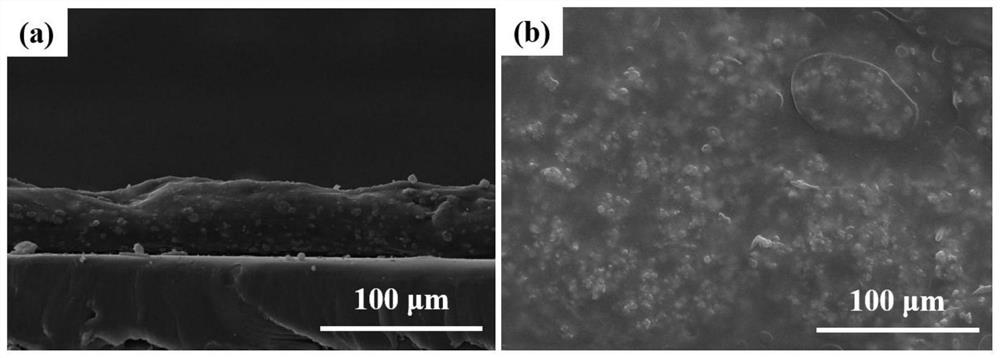

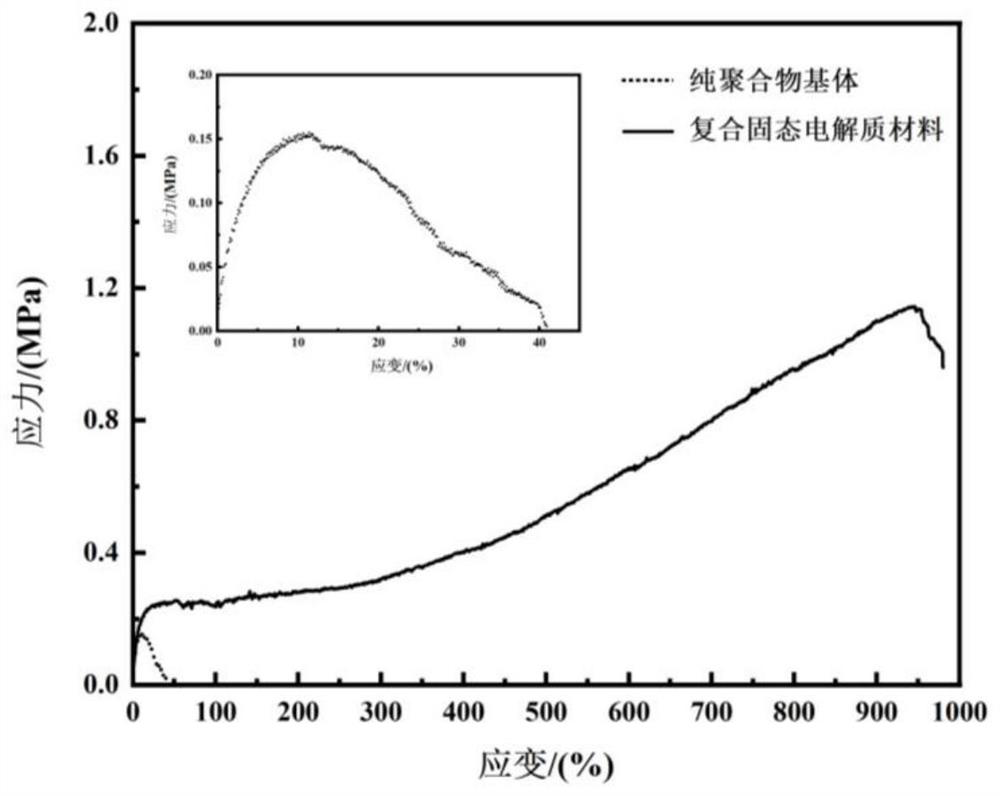

Ultrathin composite solid-state electrolyte membrane and preparation method thereof

PendingCN113161606AUniform compositionFlat surfaceSolid electrolytesSecondary cellsSolid state electrolyteAdhesive

The invention discloses an ultrathin composite solid-state electrolyte membrane and a preparation method thereof. The ultrathin composite solid-state electrolyte membrane is a membrane formed by compounding an inorganic solid-state electrolyte filler and a polymer matrix. According to the invention, an adhesive is introduced into a composite system, and the membrane material of the composite solid-state electrolyte is prepared on the substrate attached with the silicone oil on the surface by adopting the tape casting method, and has the advantages of easiness in demolding, extremely small thickness, uniform and compact components, flat and smooth surface and the like. The electrochemical performance is better, and particularly, the ionic conductivity of the membrane is obviously improved. Meanwhile, the inorganic filler and the polymer matrix are tightly combined by the adhesive, so that the mechanical property of the film is remarkably improved, the growth of dendritic crystals can be effectively inhibited, and the safety of a solid-state battery is ensured.

Owner:SOUTHEAST UNIV

Method for electrodepositing iron-nickel alloy plating on surface of carbon-based material

The invention relates to a method for electrodepositing iron-nickel alloy plating on the surface of a carbon-based material and belongs to the technical field of surface treatment. The carbon-based material is subjected to heat treatment and ultrasonically cleaned, and thus a pretreated carbon-based material is obtained; an iron-nickel alloy electrodepositing solution is prepared; with the pretreated carbon-based material as a cathode, an iron-nickel alloy plate as an anode and the iron-nickel alloy electrodepositing solution serves as an electroplating solution, electrodepositing is conductedat 30-50 DEG C for 5-60 min through a direct-current power source; and the cathode is taken out, cleaned and dried, and thus the iron-nickel alloy plating is obtained. The iron-nickel alloy plating can be electroplated on the surface of the carbon-based material, the thermal expansion coefficient of the plating is close to that of the carbon-based material, micron-scale interface bonding is achieved between the plating and the carbon-based material, and tight interface bonding can be still kept after a heat cycle from the indoor temperature to the temperature of 800 DEG C.

Owner:KUNMING UNIV OF SCI & TECH

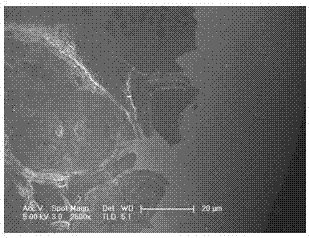

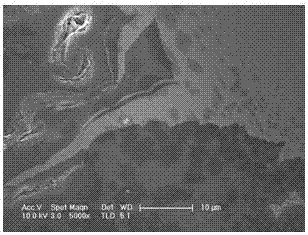

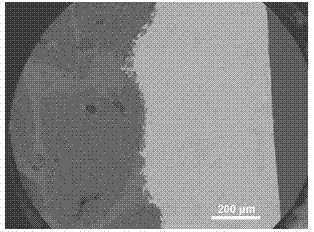

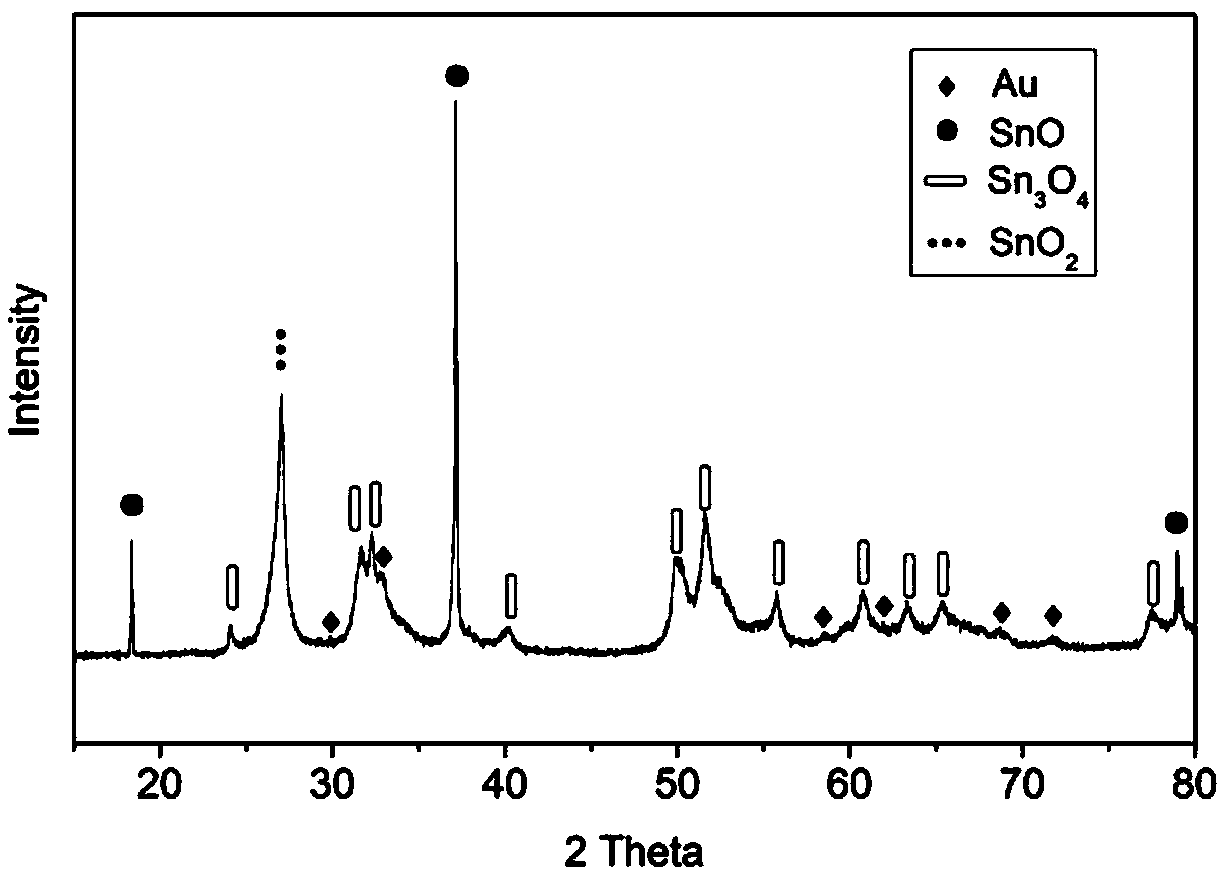

Preparation method of Au modified SnO/Sn3O4/SnO2 nano composite photocatalytic material

InactiveCN109092307AEnhanced light absorptionEasy to separateHydrogen productionHydrogen/synthetic gas productionHeterojunctionPhotocatalytic water splitting

The invention relates to a preparation method of an Au modified SnO / Sn3O4 / SnO2 nano composite photocatalytic material. The nano composite material is obtained by placing chloroauric acid and a tin source into a solvent, a surfactant and a reducing agent and forming chemical bond complexing among composite ingredients of the materials according to an ice salt bath and solvent combined hot wet chemical in-situ synthesis method. The composite material prepared by the invention utilizes a plasma resonance effect of Au metal nanoparticles, an excellent energy level matching heterojunction structureamong composite components of a tin oxide material and excellent electron conduction of Au metal nanoparticles, and implements rapid electron-hole separation in the process of cooperating photocatalytic oxidation and reduction degradation of pollutants with photocatalytic water splitting hydrogen production, thereby improving efficiency of photocatalytic water splitting and photocatalytic rhodamine B degradation of the Au modified SnO / Sn3O4 / SnO2 nano composite photocatalytic material.

Owner:PINGDINGSHAN UNIVERSITY

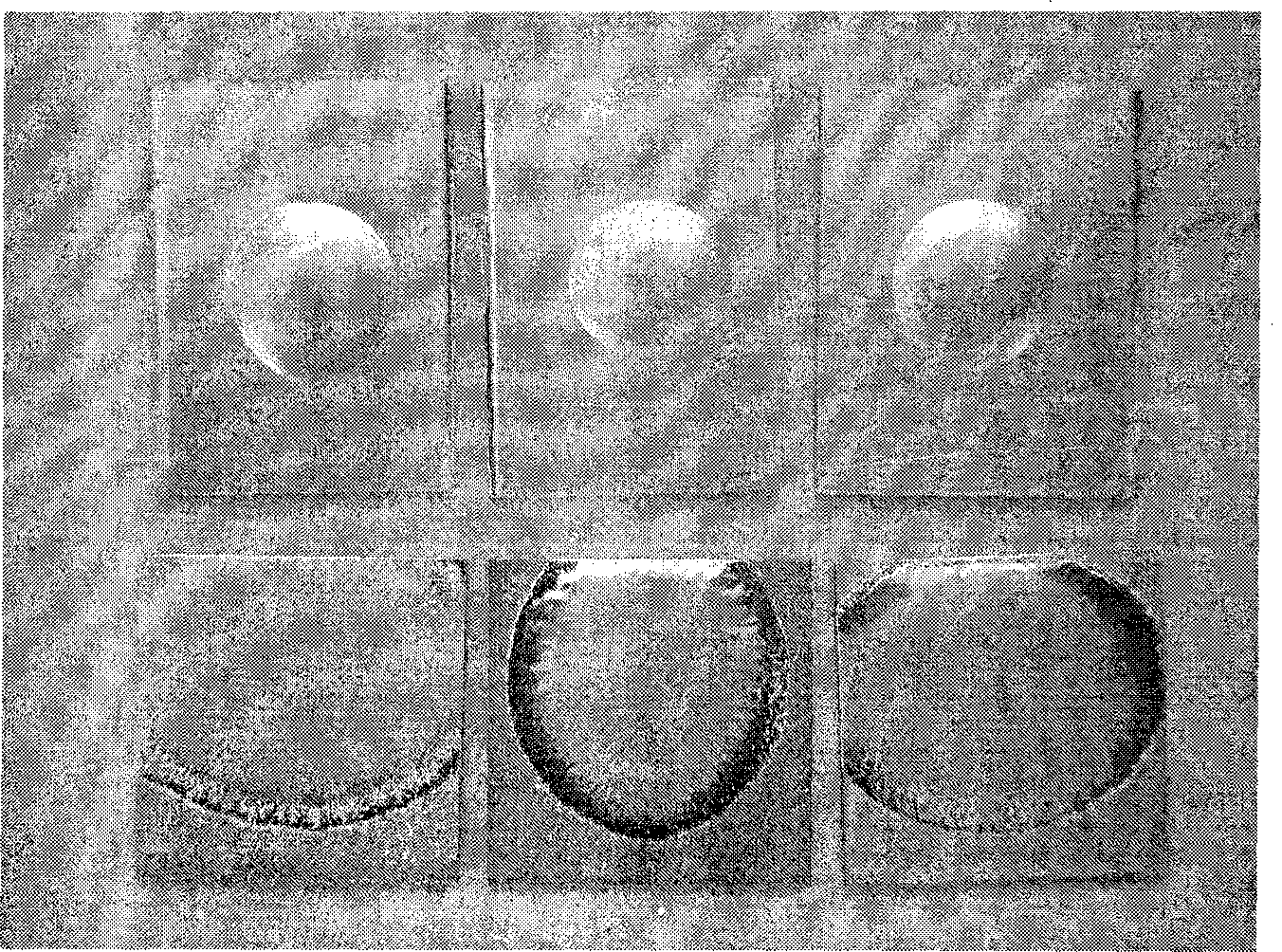

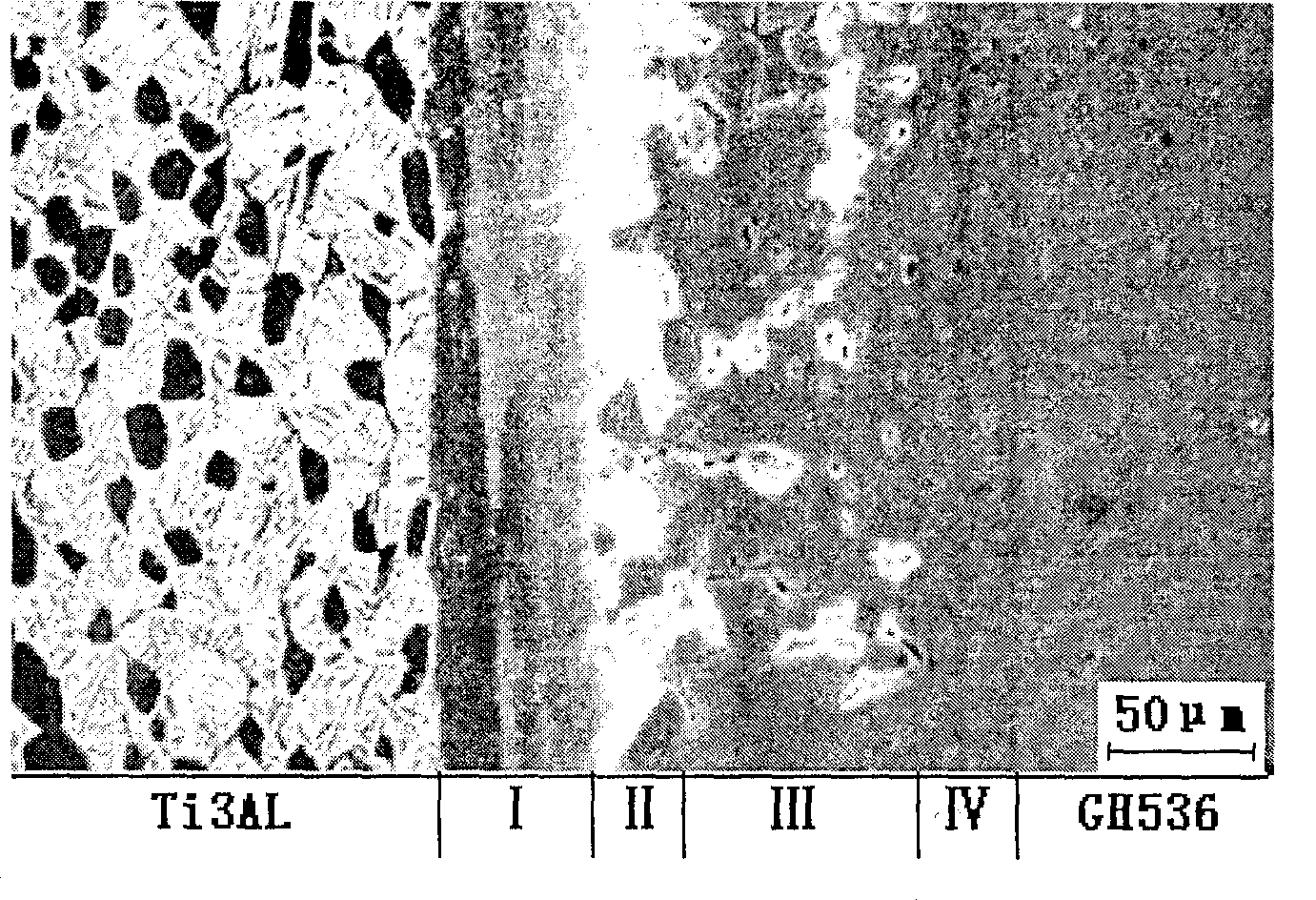

Solder

InactiveCN101439447AEasy to prepareWell-formed brazing seamWelding/cutting media/materialsSoldering mediaMaterials scienceBrazing

The invention relates to a brazing alloy, pertaining to the technical field of welding. The brazing alloy comprises the following components by the weight percentage: 40-80% of Ti, 10-35% of Cu, 5-20% of Ni and 5-15% of Cr. The brazing alloy of the invention can be coated at the joint of braze welding of Ti3Al-base alloy and GH536 alloy; braze welding is carried out under vacuum condition; after the braze welding, the brazing alloy is used for filling the clearance at the joint of braze welding so as to mould the brazing seam excellently and control the quality of the braze welding to be excellent and steady. The interface connecting parent material and the brazing alloy is tightly integrated that no defect, such as pore and crack, exists; therefore, the interface is excellently organized.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Bimetallic wear-resisting lining plate and preparation method thereof

InactiveCN106350738AIncrease composite areaThe interface is tightly combinedGrain treatmentsQuenching agentsManganeseAlloy

The invention discloses a bimetallic wear-resisting lining plate and a preparation method thereof and belongs to the technical field of metal material casting. The bimetallic wear-resisting lining plate comprises a matrix layer and a wear-resisting layer, wherein the wear-resisting layer is provided with more than two T-type projections inlaid into the matrix layer, the height ratio of every T-type projection to the wear-resisting layer is 1:1.2-1:2, the height ratio of the wear-resisting layer to the matrix layer is 1:1-1:3, the width ratio of every T-type projection to the lining plate is 1:8-1:15, the wear-resisting layer and the T-type projections are made of medium-carbon low-alloy silicon-manganese steel, the matrix layer is made of low-alloy carbon steel, and the bimetallic wear-resisting lining plate is prepared through compounding, smelting, casting, annealing and isothermal quenching. The bimetallic wear-resisting lining plate and the preparation method thereof have the advantages that through adoption of reasonable structural design and a layered casting technology, combination of a composite layer at an interface is closer, and the composite layer is less prone to separation; produced through the thermal treatment technology of simple isothermal quenching, the bimetallic wear-resisting lining plate is highly resistant to wear, high in tenacity, simple in preparation technology and convenient to produce, and production cost can be reduced effectively.

Owner:KUNMING UNIV OF SCI & TECH

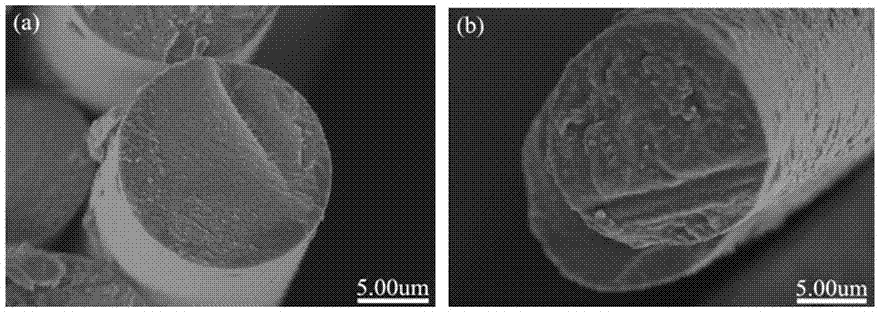

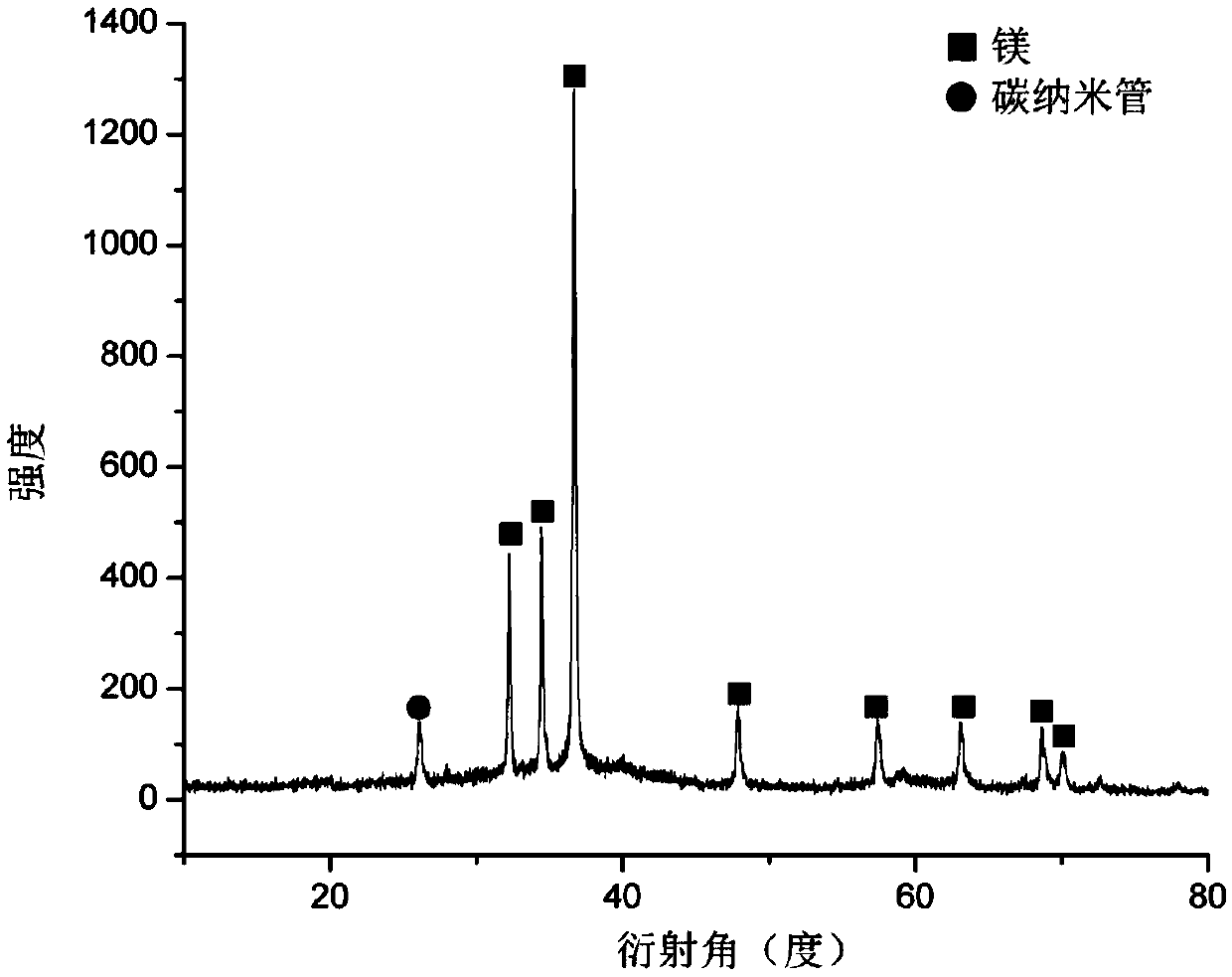

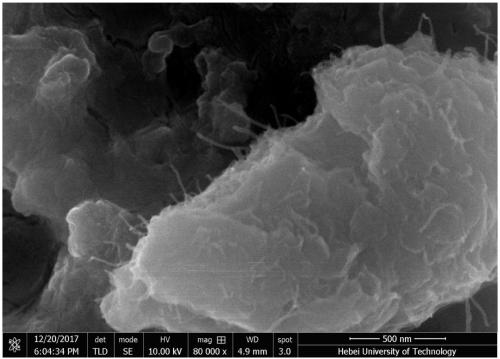

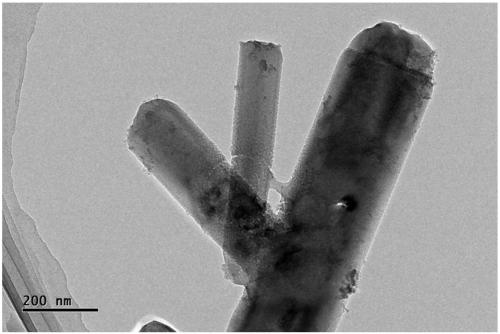

Preparation method of carbon-nanotube-reinforced magnesium-based composite material

ActiveCN109666816AThe interface is tightly combinedGood comprehensive mechanical propertiesNanometer sizeCarbon nanotube

The invention discloses a preparation method of a carbon-nanotube-reinforced magnesium-based composite material and relates to a non-metal fiber-containing alloy characterized by a matrix material. According to the method, nanometer-sized magnesium particles are synthesized on the surface of a carbon nanotube in situ so as to obtain a magnesium-coated carbon nanotube composite powder; and then themagnesium-coated carbon nanotube composite powder is subjected to an ultrasonic extrusion casting process to form the carbon-nanotube-reinforced magnesium-based composite material. The defects of a method for preparing the carbon-nanotube-reinforced magnesium-based composite material in the prior art that the carbon nanotube agglomeration results in uneven dispersion of the carbon nanotube in a magnesium matrix, the preparation process results in structural damage of the carbon nanotube, consequently, the reinforcing effect is reduced, different degrees of oxidation of the magnesium matrix are difficult to avoid, the carbon nanotube and magnesium interface in the composite material has poor wettability, and only weak interface bonding is formed, so that the carbon-nanotube-reinforced magnesium-based composite material has poor comprehensive mechanical properties are overcome.

Owner:HEBEI UNIV OF TECH +1

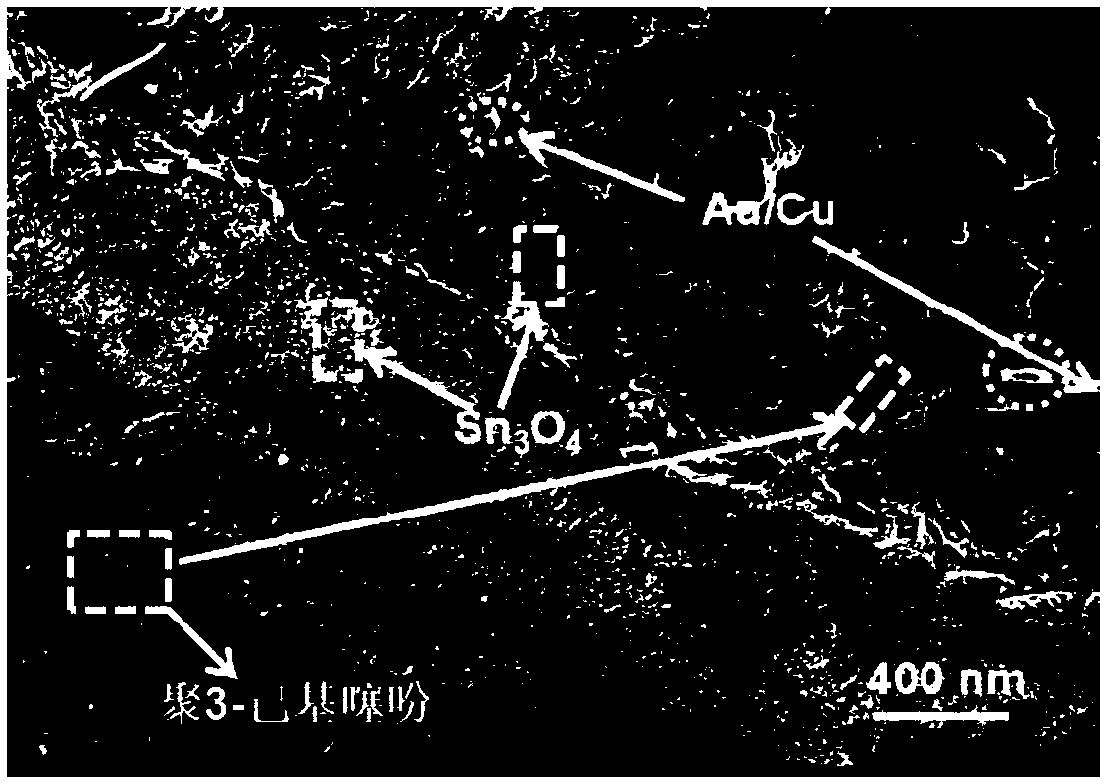

Preparation method of poly(3-hexylthiophene) (P3HT)/metal-modified Sn3O4 nano composite photocatalytic material

InactiveCN109092369AImprove stabilityGood dispersionGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsHeterojunctionPhotocatalytic reaction

The invention discloses a preparation method of a poly(3-hexylthiophene) (P3HT) / metal-modified Sn3O4 nano composite photocatalytic material. According to the method, a composite photocatalyst materialis obtained by loading and dispersing a metal-modified Sn3O4 semiconductor heterojunction in poly(3-hexylthiophene) in the form of chemical bond complexation; wherein the metal-modified Sn3O4 is prepared by loading Sn3O4 with metal nanoparticles of a one-component mental or a multi-component alloy with a plasmon resonance effect such as Pt, Au, Ag, Cu and the like, respectively. According to theinvention, the visible light photocatalytic redox properties of Sn3O4, the plasmon resonance effect of metal nanoparticles, the electrical conductivity of poly(3-hexylthiophene) and a heterojunction structure with chemical bonding among the three components are utilized to fully enhance the photo-generated electrons-hole separation rate of the nano composite photocatalytic material in a photocatalytic reaction, so that the improvements on the performance of photocatalytic redox degradation of pollutants and photocatalytic decomposition of hydrogen produced by water of the nano composite photocatalytic material are facilitated. At the same time, the characteristics of being easy to be molded of poly(3-hexylthiophene) can effectively avoid the problem of difficulty in recovery of powder materials.

Owner:PINGDINGSHAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com