Method for preparing diffusion couple by using powder

A technology of powder preparation and diffusion couple, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of high cost and complicated process, achieve low-cost preparation, increase the interface contact area, and improve the effect of sintering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

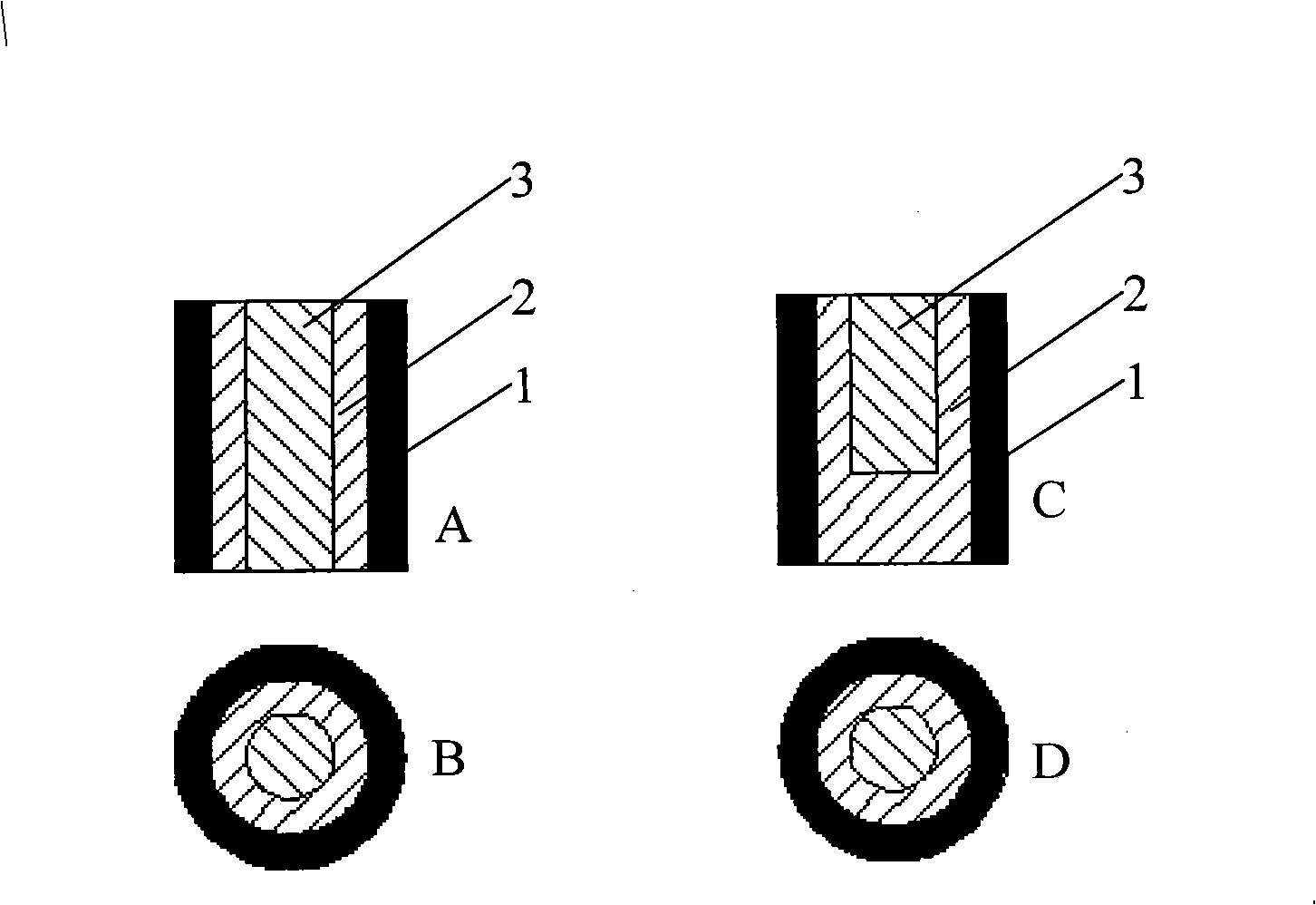

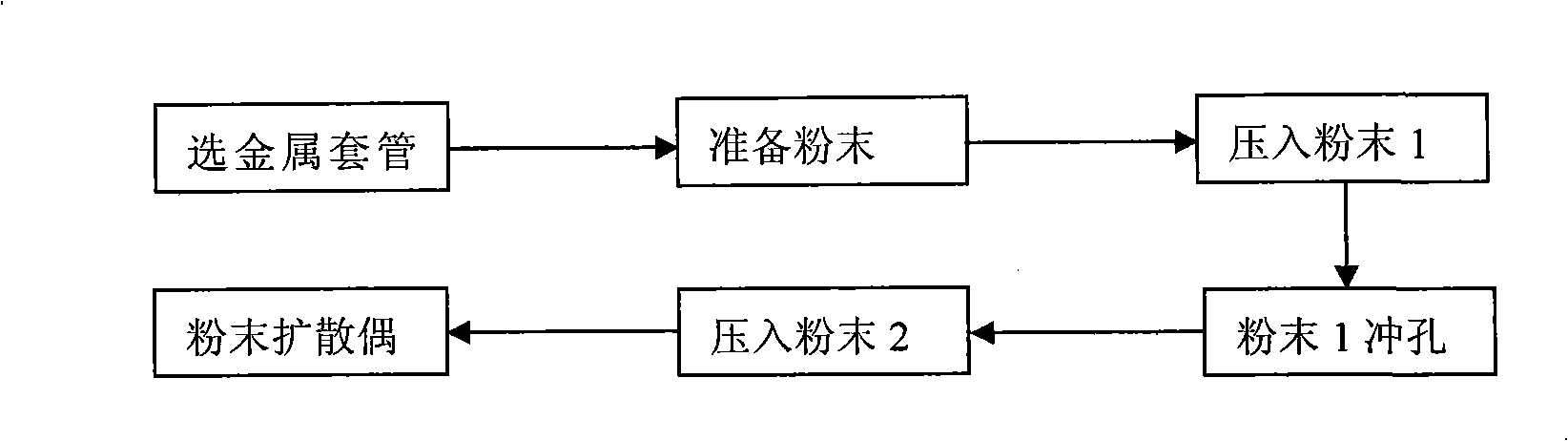

[0021] 1. see figure 1 , Fill the metal casing with calcium oxide (CaO) powder, and use a press to press it until it is tight to form a compact. The metal sleeve is made of low-carbon steel or stainless steel or copper alloy or titanium alloy. When selecting a metal sleeve, it should be chosen not to cause interdiffusion or chemical reaction with the powder in contact, and it is easy to peel off the metal sleeve. As in this embodiment, the metal tube sleeve should be selected that does not interdifgate or chemically react with calcium oxide, so as to avoid the impact of the metal tube on the diffusion sintering process and facilitate the removal of the sleeve. In addition, the selected metal sleeve should also be easy to cut and process, so that it can be processed according to the shape of the indexed diffusion couple. Melting of the tube produces liquid metal attack on the diffusion couple material and facilitates removal of the sleeve after sintering is complete.

[0022]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com