Fast connection method of carbon/carbon composite material

A carbon composite material and quick connection technology, which is applied in the connection field of ceramic matrix composite materials, can solve the problems of use temperature and strength limitation, and achieve the effect of short connection time, simple process and tight interface bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

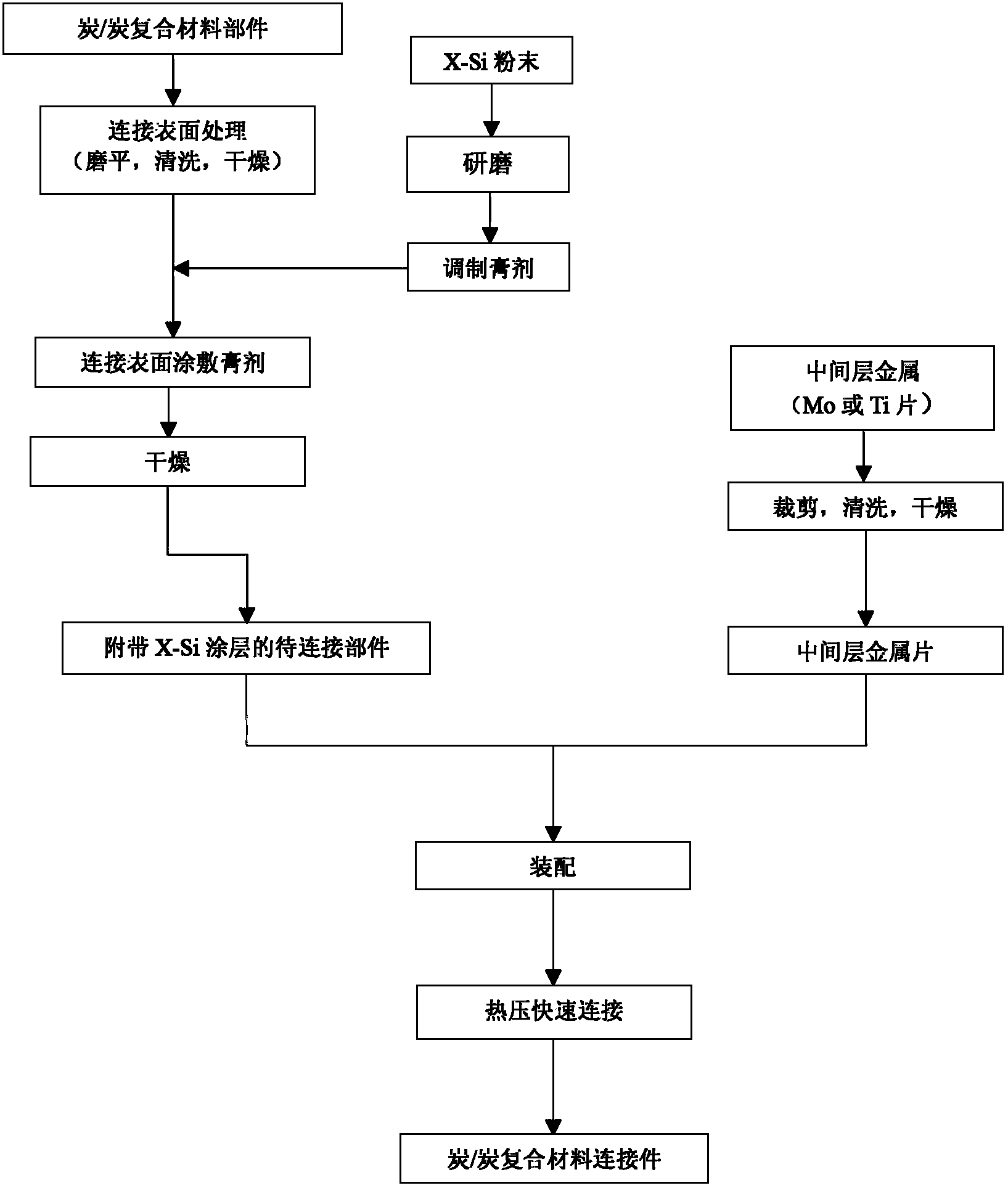

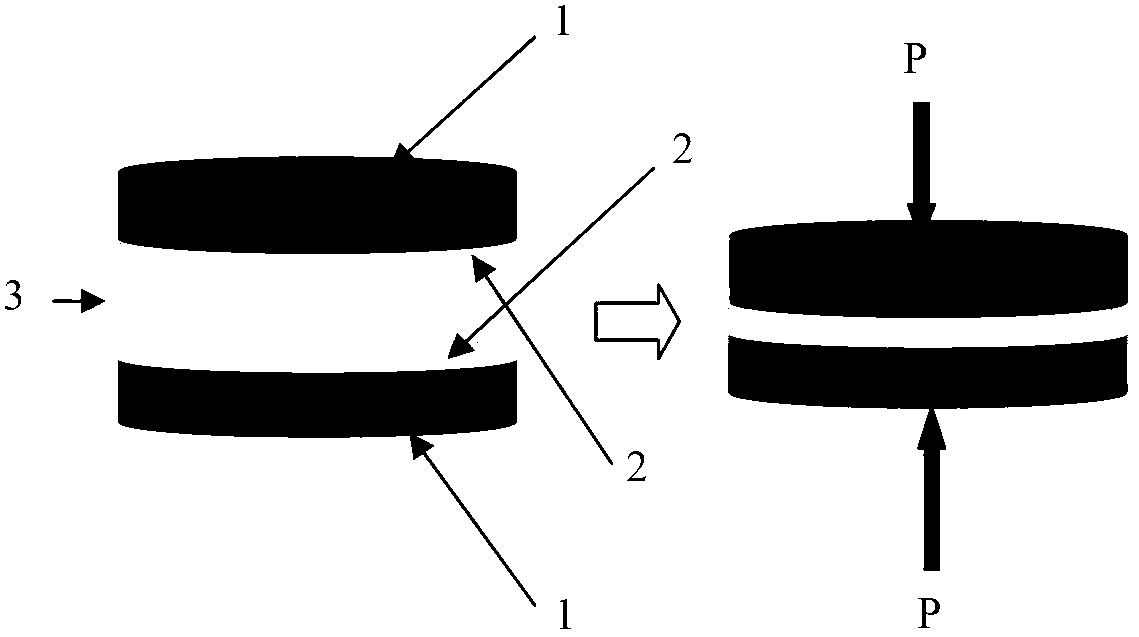

[0025] (1) Preparation of X-Si paste: commercially available or self-made (synthesized by high-energy ball milling) X-Si alloy (X is X=Ni, Co, Ti or Cr, Si content is 40-80%, Atomic percentage, the same below) powder is further ground, then add ethylene oxalate and collodion solution (according to X-Si powder: ethylene oxalate: collodion solution = 5g: 3 ~ 5ml: 6 ~ 10ml), and stir for 30min above to make X-Si ointment;

[0026] (2) Pretreatment of carbon / carbon composite materials: the connecting surfaces of the composite materials are sequentially ground, cleaned and dried;

[0027] (3) Pretreatment of the interlayer metal sheet: cutting and processing the interlayer metal (Mo or Ti) with a thickness of 50-200 μm into a metal sheet of the same size as the composite material connection surface, cleaning and drying;

[0028] (4) Coating of X-Si alloy paste on the connecting surface of the composite material: apply the X-Si paste adjusted according to step (1) on the connecting...

Embodiment 1

[0031] 1. Preparation of Ni-40Si ointment:

[0032] First grind the commercially available Ni-40Si alloy powder, add ethylene oxalate, ultrasonicate for 20 minutes, then add collodion solution (collodion) into the bottle, stir with a glass rod for more than 30 minutes, and set aside. Among them, Ni-Si powder: ethylene oxalate: collodion solution = 5g: 4ml: 8ml.

[0033] 2. Pretreatment of carbon / carbon composite materials: first make the density about 1.70g / cm 3 Commercially available carbon / carbon composites were processed into (where the connecting surface is perpendicular to the carbon fiber), the connecting surface is ground on a diamond grinding disc, ultrasonically cleaned with absolute ethanol, and dried in an oven.

[0034] 3. Pretreatment of the metal sheet in the middle layer: the pure Ti sheet with a thickness of 200 μm is processed by wire cutting into The thin discs were boiled and washed in weak lye for 15 minutes, lightly polished on both sides, ultrasonica...

Embodiment 2

[0038] 1. Preparation of Co-Si paste:

[0039] First mix commercially available Co and Si powders according to the atomic percentage Co:Si=27.5:72.5 and place them in a high-energy ball mill to obtain Co-72.5Si alloy powders, then add ethylene oxalate after grinding, and ultrasonically treat for 20 minutes , and then add collodion solution (collodion) into the bottle, stir with a glass rod for more than 30 minutes, and set aside. Among them, Co-Si powder: ethylene oxalate: collodion solution = 5g: 3ml: 6ml.

[0040] 2. Pretreatment of carbon / carbon composite materials: first make the density about 1.70g / cm 3 Commercially available carbon / carbon composites were processed into (where the connecting surface is perpendicular to the carbon fiber), the connecting surface is polished on a diamond grinding disc, ultrasonically cleaned with absolute ethanol and dried in an oven.

[0041] 3. Pretreatment of the metal sheet in the middle layer: the pure Mo sheet with a thickness of 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com