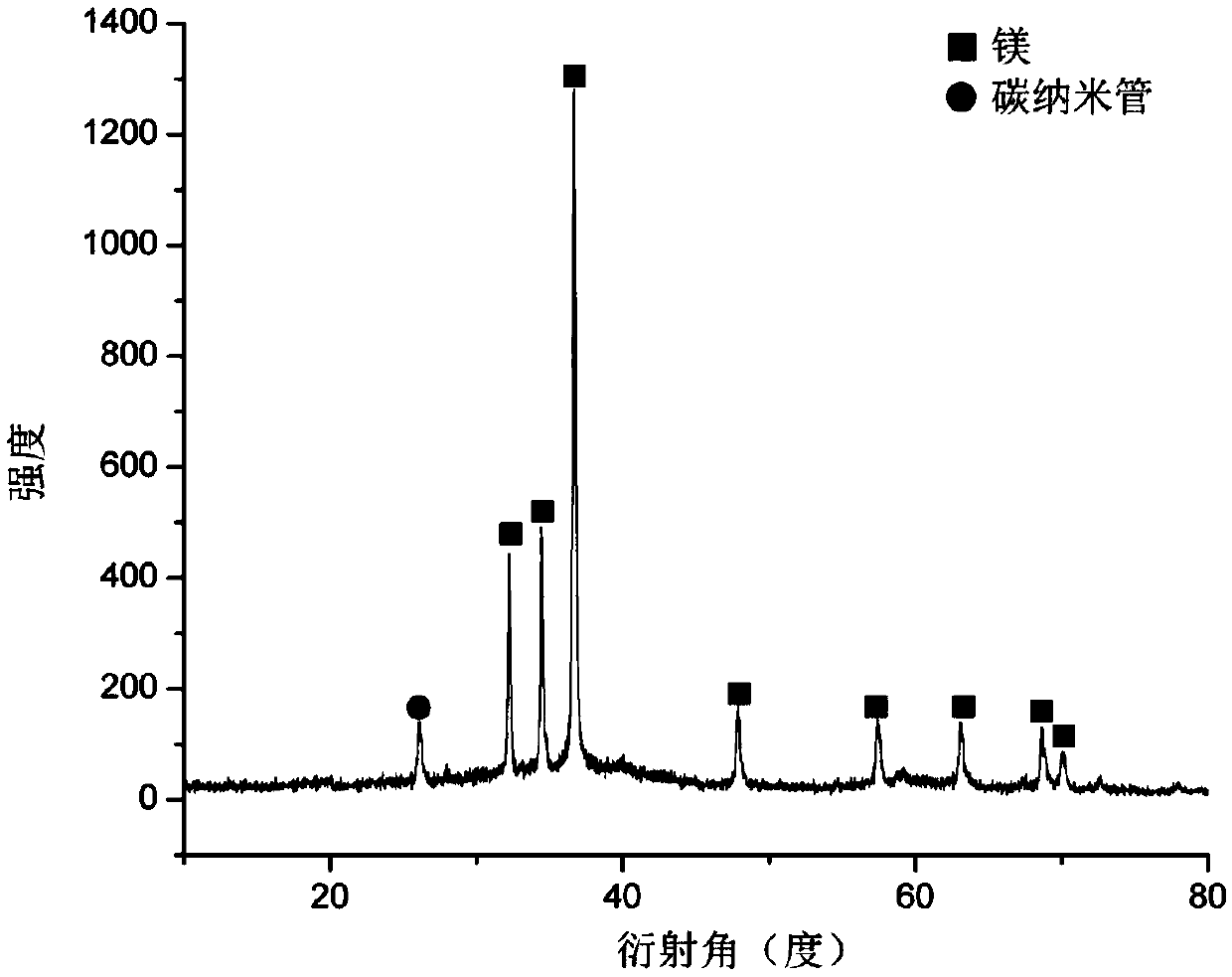

Preparation method of carbon-nanotube-reinforced magnesium-based composite material

A nanotube composite, carbon nanotube technology, applied in the field of alloys containing non-metallic fibers, can solve the problem of poor carbon nanotube-magnesium interface wettability, weak interface bonding, and poor comprehensive mechanical properties of carbon nanotube-reinforced magnesium matrix composites. It can achieve the effect of excellent comprehensive mechanical properties and tight interfacial bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The first step, preparation of magnesium-coated carbon nanotube composite powder:

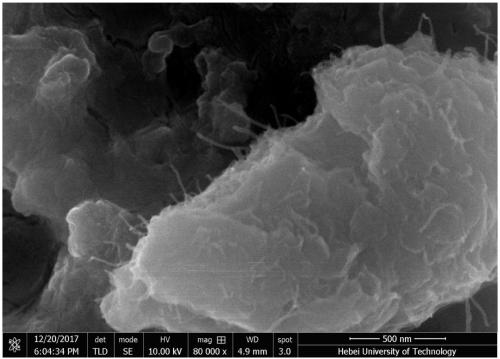

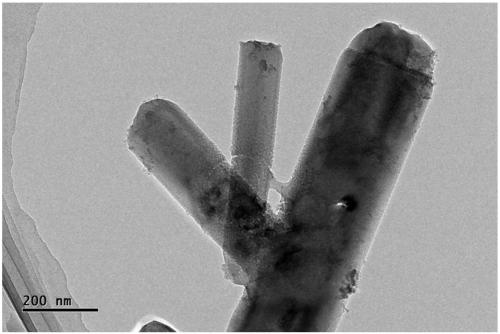

[0046] Add 0.4 g of carbon nanotubes into tetrahydrofuran to form a suspension, ensuring that the mass concentration of carbon nanotubes in tetrahydrofuran is 4×10 -3 g / mL, ultrasonically treat the tetrahydrofuran suspension containing carbon nanotubes for 40 min with an ultrasonic disperser, so that the carbon nanotubes are uniformly dispersed in tetrahydrofuran, and then 1.6 g of naphthalene, 5.2 g of lithium powder with a particle size of 55 μm and 35.2 g of anhydrous magnesium chloride solids are sequentially added to the above-mentioned tetrahydrofuran suspension, and the suspension is placed in a high-purity argon glove box filled with a purity of 99.9%. The suspension was stirred for 45 hours at a rotating speed of 45 h, thereby synthesizing magnesium-coated carbon nanotube composite powder in situ in tetrahydrofuran, and then using a microporous filter membrane and absolute ethan...

Embodiment 2

[0056] The first step, preparation of magnesium-coated carbon nanotube composite powder:

[0057] Add 0.01 g of carbon nanotubes to tetrahydrofuran to form a suspension, ensuring that the mass concentration of carbon nanotubes in tetrahydrofuran is 1×10 -4 g / mL, ultrasonically treat the above tetrahydrofuran suspension containing carbon nanotubes for 20 min with an ultrasonic disperser, so that the carbon nanotubes are uniformly dispersed in tetrahydrofuran, and then 4.5 g of naphthalene, 14.6 g of lithium powder with a particle size of 80 μm and 99.0 g of anhydrous magnesium chloride solids are sequentially added to the above-mentioned tetrahydrofuran suspension, and the suspension is placed in a high-purity argon glove box filled with a purity of 99.9%. The suspension was stirred at a speed of 12 hours to in-situ synthesize magnesium-coated carbon nanotube composite powder in tetrahydrofuran, and then use a microporous filter membrane and absolute ethanol to compound the mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com