Method for electrodepositing iron-nickel alloy plating on surface of carbon-based material

An iron-nickel alloy and carbon-based material technology, applied in the field of surface treatment, can solve the problems of inability to realize the in-depth filling of the metal layer, limit the application and promotion, etc., and achieve the effects of large micro-interface bonding force, avoiding interface detachment, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

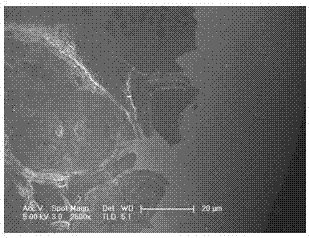

[0022] Embodiment 1: a kind of method for electrodepositing iron-nickel alloy coating on the surface of carbon / carbon composite material, concrete steps are:

[0023] (1) The carbon / carbon composite material is subjected to heat treatment after being sanded and cleaned, and ultrasonically cleaned in deionized water until no black particles are precipitated to obtain a pretreated carbon-based material. The heat treatment atmosphere is air atmosphere, and the heat treatment temperature is 200°C. The heat treatment time is 20min;

[0024] (2) Prepare the iron-nickel alloy electrodeposition solution, wherein the composition of the iron-nickel alloy electrodeposition solution is NiSO 4 0.5mol / L, NiCl 2 0.2 mol / L, FeSO 4 0.1 mol / L, H 3 BO 3 0.25 mol / L, NaCl 0.15 mol / L, ascorbic acid 1 g / L, o-sulfonyl benzimide 2g / L, additive A (additive A is 1,4-butynediol) 0.15g / L, the remaining The amount is deionized water;

[0025] (3) ultrasonically treat the iron-nickel alloy electro...

Embodiment 2

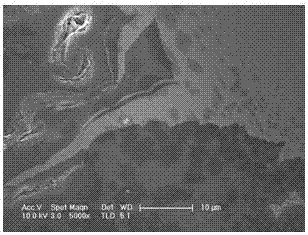

[0027] Embodiment 2: a kind of method on carbon / silicon carbide composite material surface electrodeposition iron-nickel alloy coating, concrete steps are:

[0028] (1) The carbon / silicon carbide composite material is sanded and cleaned, then heat treated, and ultrasonically cleaned in deionized water until no black particles are precipitated to obtain a pretreated carbon-based material. The heat treatment atmosphere is air atmosphere, and the heat treatment temperature is 350°C , the heat treatment time is 20min;

[0029] (2) Prepare the iron-nickel alloy electrodeposition solution, wherein the composition of the iron-nickel alloy electrodeposition solution is NiSO 4 0.3mol / L, NiCl 2 0.1 mol / L, FeSO 4 0.08mol / L, H 3 BO 3 0.5 mol / L, NaCl 0.25 mol / L, ascorbic acid 2 g / L, o-sulfonyl benzimide 2.5g / L, additive A (additive A is o-closyl cinnamic acid) 0.08g / L, the balance is Deionized water;

[0030] (3) ultrasonically treat the iron-nickel alloy electrodeposition soluti...

Embodiment 3

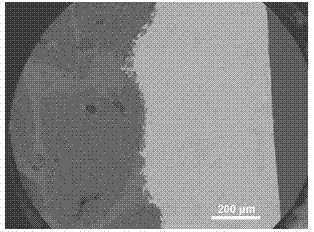

[0032] Embodiment 3: a kind of method at graphite surface electrodeposition iron-nickel alloy coating, concrete steps are:

[0033] (1) After the bulk graphite is sanded and cleaned, heat treatment is carried out, and the pretreated carbon-based material is obtained by ultrasonic cleaning in deionized water until no black particles are precipitated. The heat treatment atmosphere is air atmosphere, and the heat treatment temperature is 150°C. The time is 10 minutes;

[0034] (2) Prepare the iron-nickel alloy electrodeposition solution, wherein the composition of the iron-nickel alloy electrodeposition solution is NiSO 4 0.2mol / L, NiCl 2 0.15 mol / L, FeSO 4 0.03mol / L, H 3 BO 30.2 mol / L, NaCl 0.1 mol / L, ascorbic acid 0.5g / L, o-sulfonyl benzimide 1g / L, additive A (additive A is phenylpropiolic acid) 0.05g / L, the balance is to Ionized water;

[0035] (3) Ultrasonically treat the iron-nickel alloy electrodeposition solution in step (2) for 8 minutes, use the pretreated bulk ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com