Solder

A brazing material, weight percentage technology, applied in the direction of welding/cutting medium/material, welding medium, metal processing equipment, etc., can solve the problems of low joint strength, grain growth, high joint strength, etc., and achieve brazing quality and stability , The preparation method is simple, and the effect of brazing seam is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Using the atomization powder making process, first mix metal Ti, Cu, Ni and Cr, the composition of the mixed material is Ti45%, Cu30%, Ni15%, Cr10%; the mixed material is smelted into an alloy under vacuum-argon gas conditions Ingot, and then prepare powder on high-pressure gas-water atomization equipment, use high-pressure argon gas atomization, and the alloy liquid after atomization is dropped into the cooling water environment to obtain a mixture of alloy powder and water, and then the alloy powder and water The mixture is subjected to suction filtration, vacuum drying and sieving to obtain titanium-based powder solder; the particle size is -150 to -300 mesh.

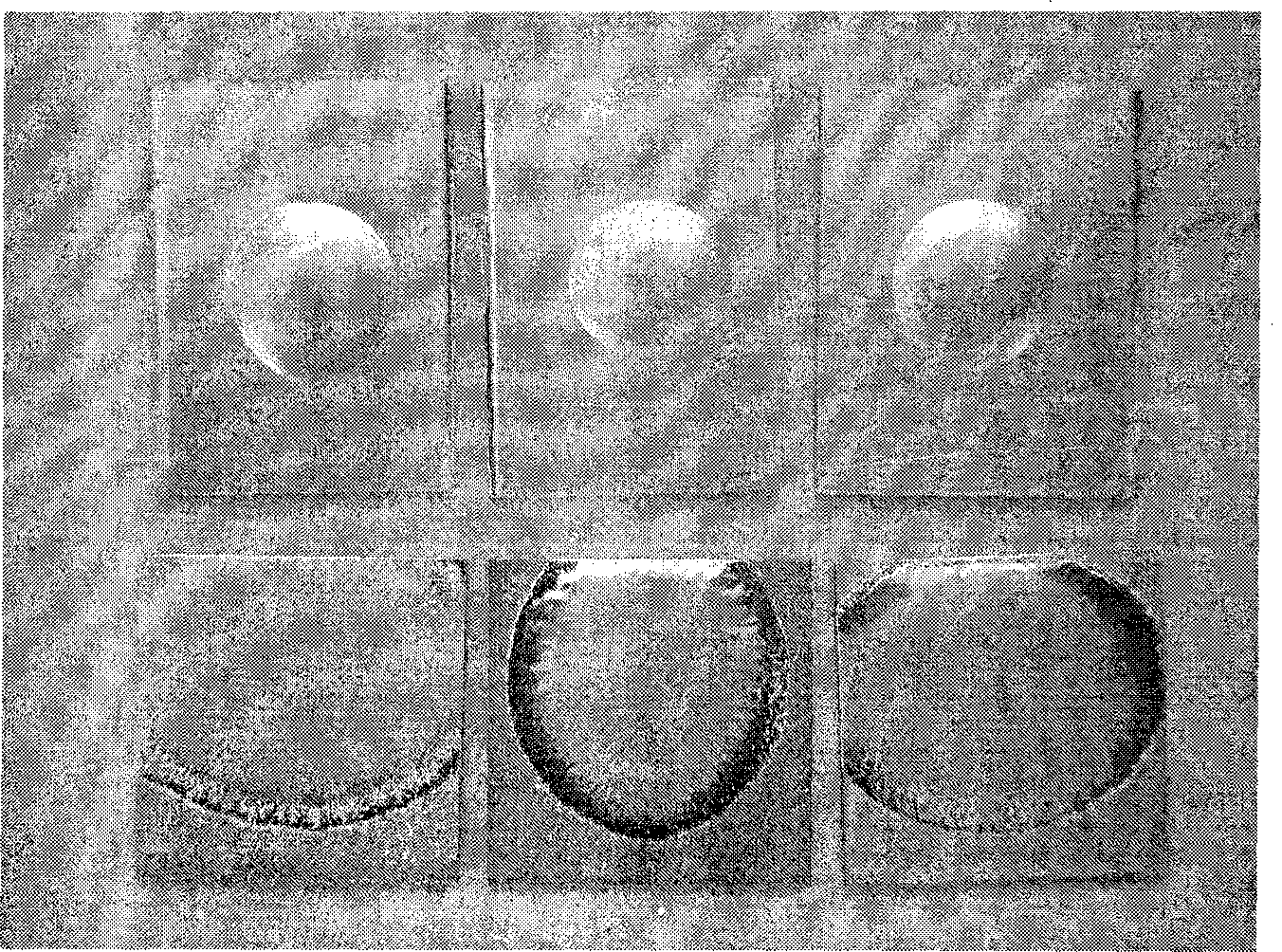

[0012] Carry out wettability test to this solder, test result is as follows figure 1 shown.

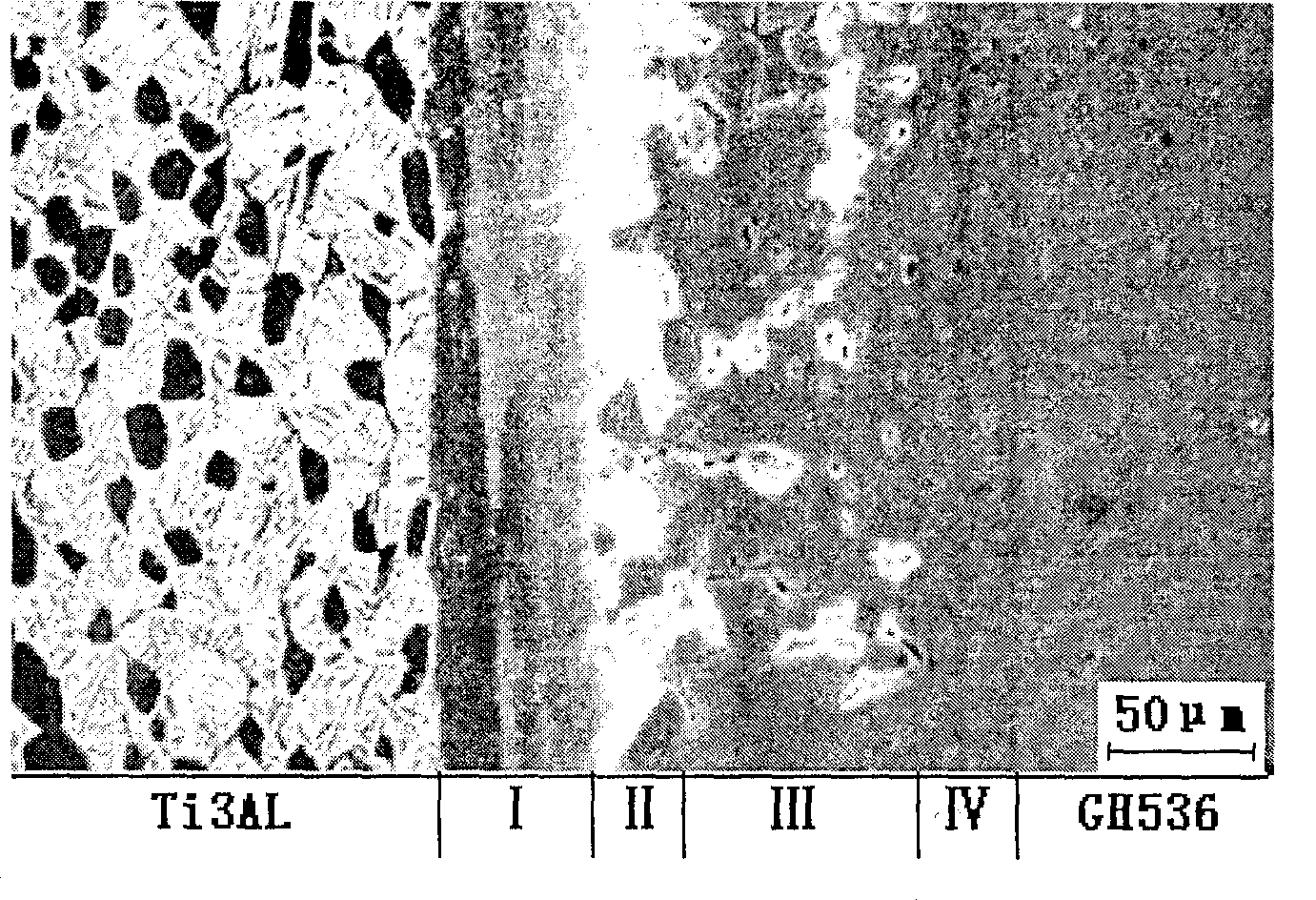

[0013] Coated with this solder on Ti 3 The brazing joint between Al-based alloy and GH536 alloy is brazed under vacuum conditions. After brazing, the brazing material fills the gap at the brazing joint, the brazing ...

Embodiment 2

[0016] Using the atomization powder making process, firstly mix the metals Ti, Cu, Ni and Cr, the composition of the mixed material is Ti55%, Cu20%, Ni10%, Cr15%; the mixed material is smelted into alloy under the condition of vacuum-argon gas Ingot, and then prepare powder on high-pressure gas-water atomization equipment, use high-pressure argon gas atomization, and the alloy liquid after atomization is dropped into the cooling water environment to obtain a mixture of alloy powder and water, and then the alloy powder and water The mixture is subjected to suction filtration, vacuum drying and sieving to obtain titanium-based powder solder; the particle size is -150 to -300 mesh.

[0017] Coated with this solder on Ti 3 The brazing joint between Al-based alloy and GH536 alloy is brazed under vacuum conditions. After brazing, the brazing material fills the gap at the brazing joint, the brazing seam is well formed, and the brazing quality is excellent and stable; the base metal a...

Embodiment 3

[0020] Using the atomization powder making process, first mix metal Ti, Cu, Ni and Cr, the composition of the mixture is Ti70%, Cu15%, Ni7%, Cr8%; the mixture is smelted into an alloy under vacuum-argon gas conditions Ingot, and then prepare powder on high-pressure gas-water atomization equipment, use high-pressure argon gas atomization, and the alloy liquid after atomization is dropped into the cooling water environment to obtain a mixture of alloy powder and water, and then the alloy powder and water The mixture is subjected to suction filtration, vacuum drying and sieving to obtain titanium-based powder solder; the particle size is -150 to -300 mesh.

[0021] The brazing material is coated on the brazing joint of Ti3Al-based alloy and GH536 alloy, and brazed under vacuum conditions. After brazing, the brazing material fills the gap at the brazing joint, the brazing seam is well formed, and the brazing quality is excellent and stable. ; The interface between the base metal a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com