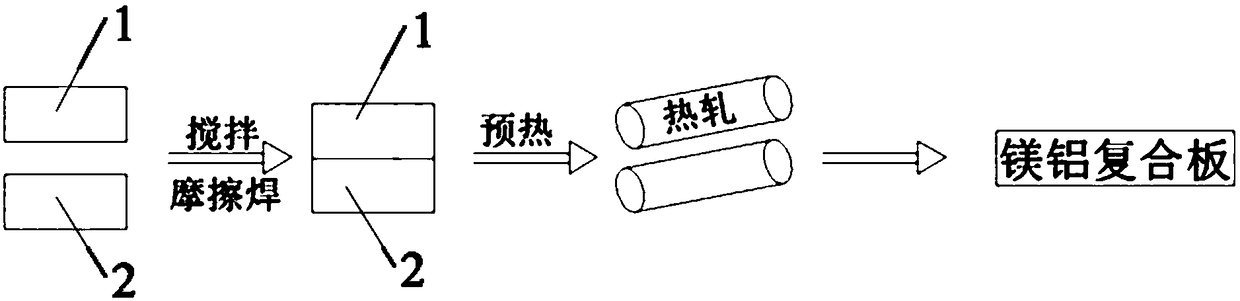

Aluminum magnesium alloy composite board and preparing method thereof

A technology for aluminum alloy sheets and composite sheets, applied in chemical instruments and methods, metal layered products, lamination devices, etc., can solve the problems of reducing interface density, reducing the strength of composite sheets, complex riveting process, etc., and achieving plastic processing. Excellent performance and corrosion resistance, reduction of compound formation, excellent effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

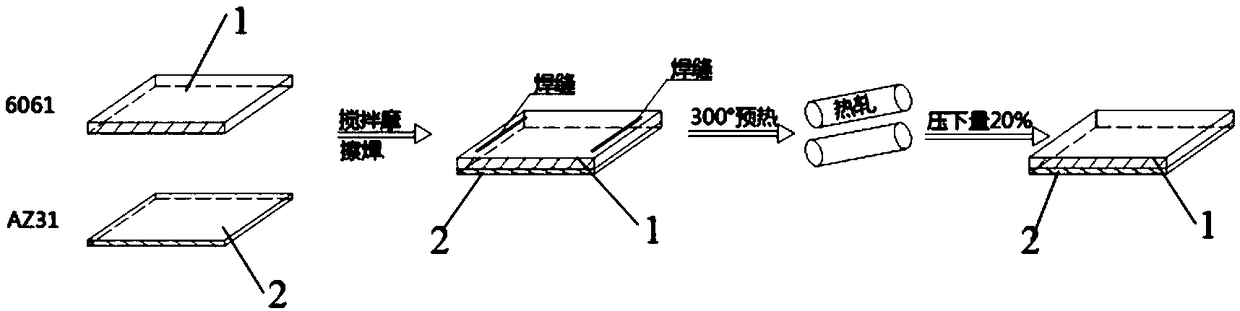

Embodiment 1

[0043] Select an AZ31 magnesium alloy plate with a length of 100mm, a width of 50mm, and a thickness of 1mm, and a piece of 6061 aluminum alloy plate with a length of 100mm, a width of 50mm, and a thickness of 2mm, and polish it to remove the oxide layer, oil and defects on the surface. , then rinse and blow dry. Fix the aluminum alloy plate on the top and the magnesium alloy plate on the bottom of the welding table, and then the welding machine stirrer enters the plate at a speed of 800r / min~1000r / min, and the welding speed is 100mm / min~200mm / min , the inclination angle of the stirring head is 2°~5° when the stirring head advances, and the friction stir seam welding is performed on both sides (parallel sides) of the plate. Wrap the welded plate with aluminum foil and put it into a common box-type resistance furnace for preheating. The preheating temperature is 300°C and the preheating time is 10 minutes. Put the preheated plate into a rolling mill for hot rolling and compoun...

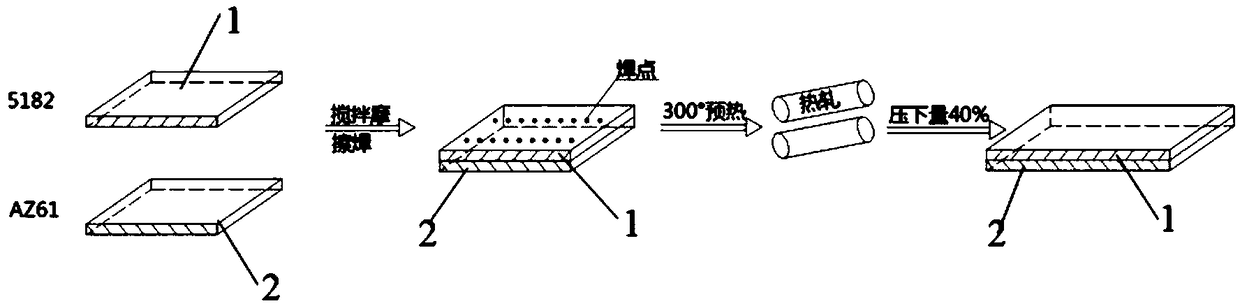

Embodiment 2

[0045] Select an AZ61 magnesium alloy plate with a length of 200mm, a width of 100mm, and a thickness of 2mm, and a 5182 aluminum alloy plate with a length of 200mm, a width of 100mm, and a thickness of 2mm. Grind the surface of the plate, remove the oxide layer, oil stains and defects, etc., then clean and dry it, and fix it on the backing plate of the welding workbench in the order that the aluminum alloy plate is on top and the magnesium alloy plate is on the bottom, and then the stirring head is 800r / min~1000r / min The speed of min enters the plate, and friction stir spot welding is performed on both sides of the plate (two parallel sides). Wrap the welded plate with aluminum foil and put it into a common box-type resistance furnace for preheating. The preheating temperature is 300°C and the preheating time is 15 minutes. The plate after preheating is put into rolling mill and carry out hot-rolling composite, and rolling speed is 0.1m / s, and deformation amount is 40%, makes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com