Method for in-situ synthesizing mullite whisker self-toughened mullite ceramics

A mullite whisker and in-situ synthesis technology, which is applied in the field of silicon-aluminum composite phase ceramics, can solve the problems of not using the mechanical properties of the matrix, improving the performance, and high energy consumption, and achieving the effect of avoiding cracking and uneven shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

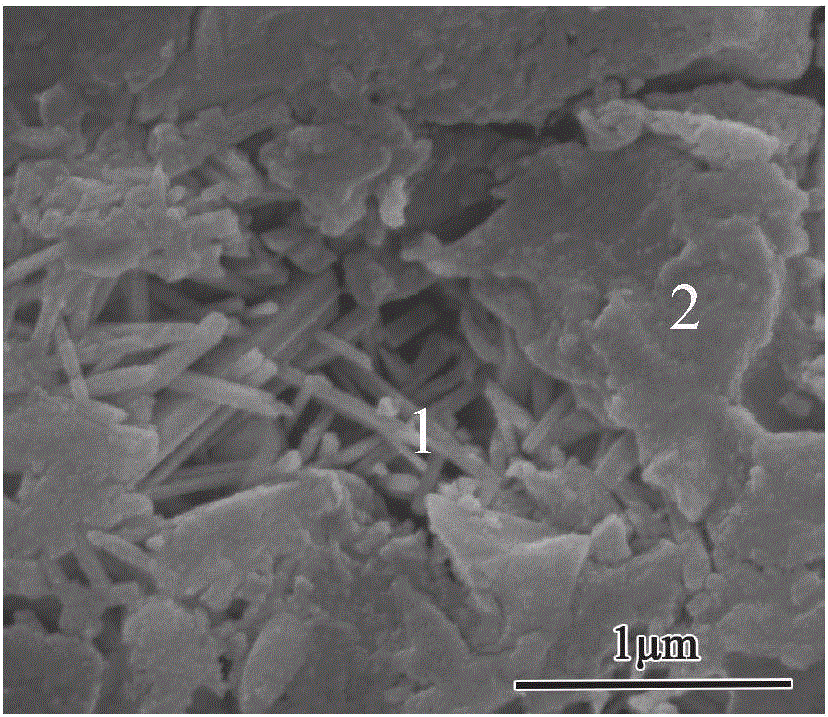

[0091] Step (a): Seed crystal preparation:

[0092] According to the composition formula Al 2 o 3 : SiO 2 =3:2. The mullite precursor was synthesized by the sol-gel method, using ethyl orthosilicate as the silicon source (0.1mol; 20.833g), Al(NO 3 ) 3 9H 2 O is the aluminum source, take X=2.4, dissolve the aluminum source and the silicon source in a molar ratio of (3-2.4):1 in 100mL of absolute ethanol, add 25g of glacial acetic acid, and Heat and reflux in a water bath at 60°C for 4 hours; then add the remaining aluminum nitrate so that the total Al / Si ratio conforms to the mullite stoichiometric ratio Al / Si=3:1, and add 1600 μL of hydrofluoric acid dropwise, and heat up to 85°C Heated in a water bath to reflux for 12 hours and then cooled to room temperature to obtain a precursor gel. Then the gel was dried, ball-milled for 2 hours, and heated at 10°C / min to 1000°C for calcining to obtain a mullite precursor powder (mullite whisker seed crystal), which was used as a s...

Embodiment 2

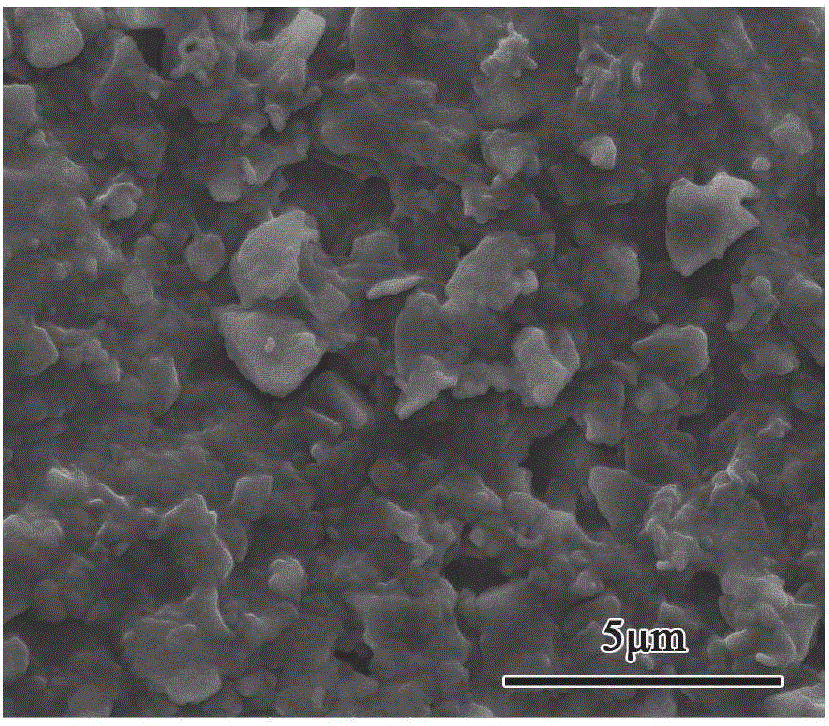

[0098] Step (a): Seed crystal preparation:

[0099] According to the composition formula Al 2 o 3 : SiO 2 =3:2. The mullite precursor was synthesized by the sol-gel method, using tetraethyl orthosilicate as the silicon source (0.1mol; 20.833g), Al(NO 3 ) 3 9H 2 O is the aluminum source, take X=2.4, dissolve the aluminum source and the silicon source in a molar ratio of (3-2.4):1 in 100mL of absolute ethanol, add 25g of glacial acetic acid, and Heat and reflux in a water bath at 60°C for 4 hours; then add the remaining aluminum nitrate so that the total Al / Si ratio conforms to the mullite stoichiometric ratio Al / Si=3:1, and add 1600 μL of hydrofluoric acid dropwise, and heat up to 85°C Heated in a water bath to reflux for 12 hours and then cooled to room temperature to obtain a precursor gel. Then the gel was dried, ball-milled for 2 hours, and heated at 10°C / min to 1000°C for calcination to obtain a mullite precursor powder, which was used as a seed crystal for whisker ...

Embodiment 3

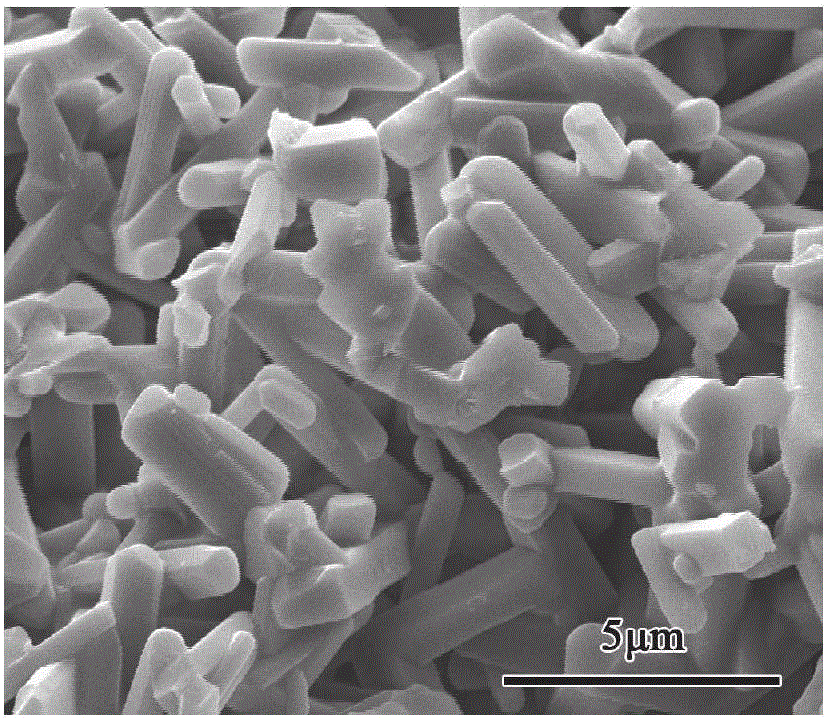

[0105] Step (a): Seed crystal preparation:

[0106] According to the composition formula Al 2 o 3 : SiO 2 =3:2. The mullite precursor was synthesized by the sol-gel method, using tetraethyl orthosilicate as the silicon source (0.1mol; 20.833g), Al(NO 3 ) 3 9H 2 O is the aluminum source, take X=2.4, dissolve the aluminum source and the silicon source in a molar ratio of (3-2.4):1 in 100mL of absolute ethanol, add 25g of glacial acetic acid, and Heat and reflux in a water bath at 60°C for 4 hours; then add the remaining aluminum nitrate so that the total Al / Si ratio conforms to the mullite stoichiometric ratio Al / Si=3:1, and add 1600 μL of hydrofluoric acid dropwise, and heat up to 85°C Heated in a water bath to reflux for 12 hours and then cooled to room temperature to obtain a precursor gel. Then the gel was dried, ball-milled for 2 hours, and heated at 10°C / min to 1000°C for calcination to obtain a mullite precursor powder, which was used as a seed crystal for whisker ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com