Method for preparing cobaltous oxide/graphene nanometer composite material

A nano-composite material and graphene technology, which is applied in the field of preparing cobalt oxide/graphene nano-composite materials, can solve the problems of expensive, environmental, and toxic organic substances, and achieve the effect of high loading capacity, simple process, and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

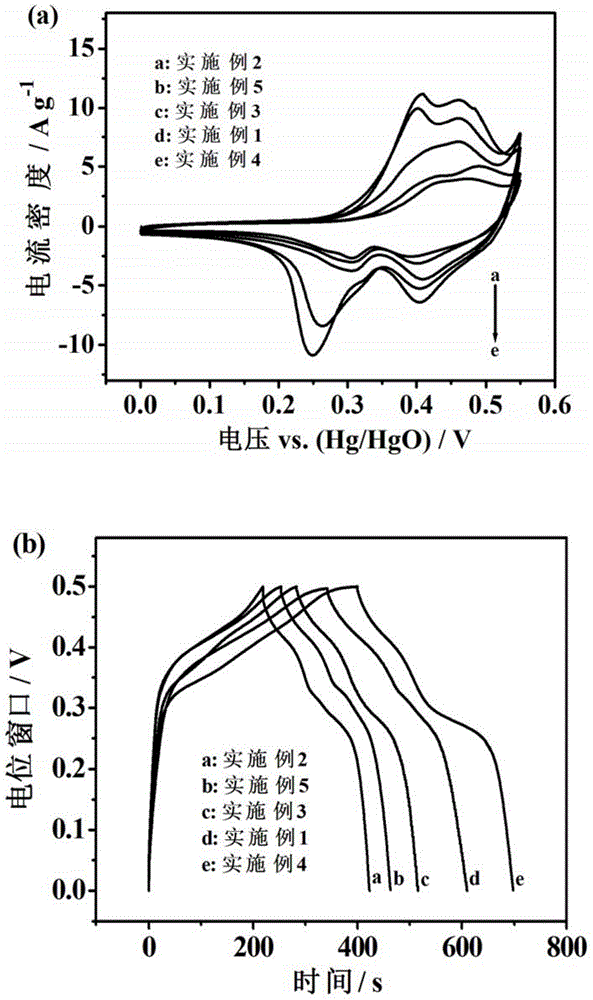

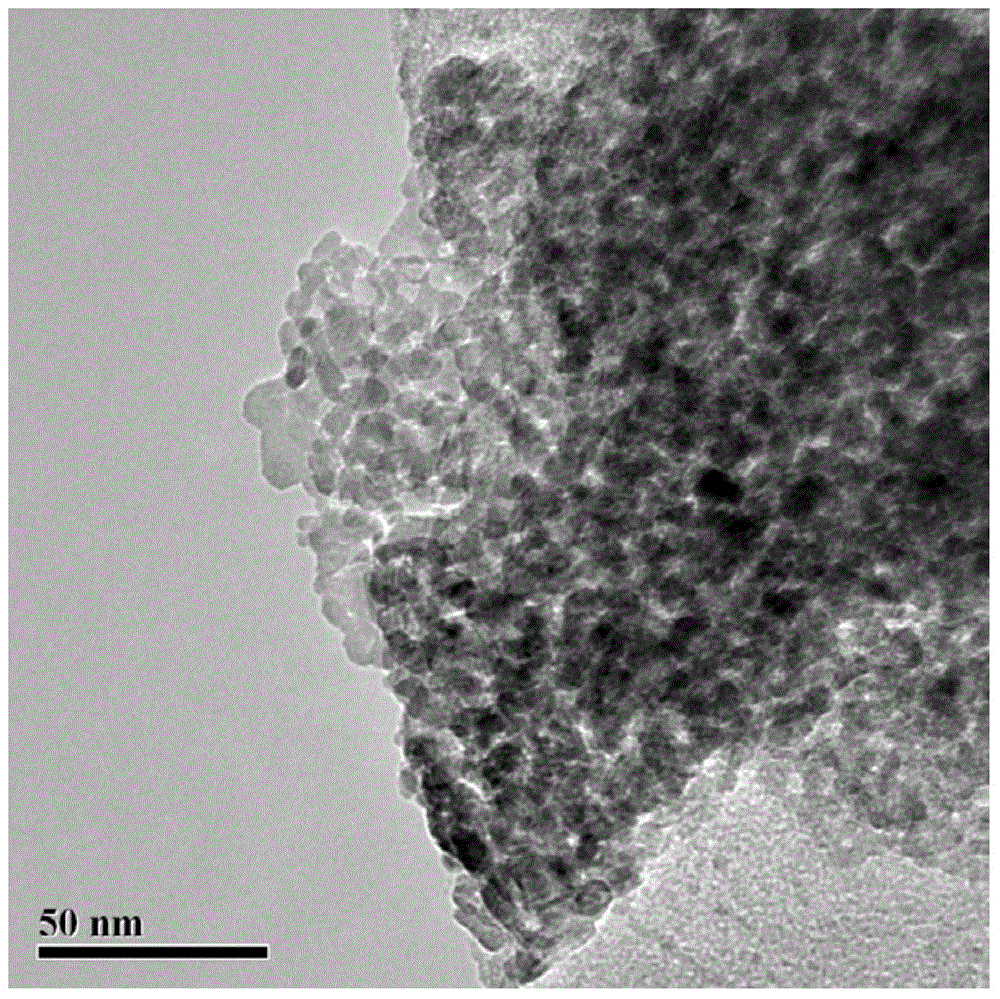

Embodiment 1

[0024] The graphite oxide produced by the Hummers method was ultrasonically treated in deionized water, the ultrasonic time was 5min, the ultrasonic power was 500W, and the obtained concentration was 0.1mg mL -1 Negatively charged graphene oxide solution; 1mmol of Co(NO 3 ) 2 ·6H 2 O was dissolved in 100ml of deionized water, magnetically stirred for 10min, and then NH 3 ·H 2 O and stirring continuously until the pH of the solution reaches 8, the resulting solid product is immediately centrifuged and dispersed in deionized water, left to stand for 12 h, and then ultrasonically treated for 0.5 h to obtain a positively charged cobalt hydroxide suspension. The graphene oxide aqueous solution and the cobalt hydroxide suspension are mixed according to the volume ratio of 1:5, filtered by suction, washed, and freeze-dried to obtain the cobalt hydroxide / graphene oxide precursor. Finally, the precursor was heat-treated at 250 °C for 1 h in an Ar atmosphere to obtain a specific sur...

Embodiment 2

[0027] The graphite oxide prepared by the electrochemical oxidation method was ultrasonically treated in deionized water, the ultrasonic time was 90min, the ultrasonic power was 500W, and the obtained concentration was 0.5mg mL -1 Negatively charged graphene oxide solution; 5mmol of Co(NO 3 ) 2 ·6H 2 O was dissolved in 100ml of deionized water, magnetically stirred for 50min, and then NH 3 ·H 2 O and stirring continuously until the pH of the solution reaches 9, the resulting solid product is immediately centrifuged and dispersed in deionized water, left to stand for 36 h, and then ultrasonically treated for 2 h to obtain a positively charged cobalt hydroxide suspension. The graphene oxide aqueous solution and the cobalt hydroxide suspension were mixed at a ratio of 5:1, suction filtered, washed, and freeze-dried to obtain a cobalt hydroxide / graphene oxide precursor. Finally, the precursor was heat-treated at 150 °C for 6 h in an Ar atmosphere to obtain a specific surface a...

Embodiment 3

[0030] Graphite oxide produced by the Brodie method was ultrasonically treated in deionized water for 90 min and ultrasonic power of 1000 W to obtain a concentration of 5 mg mL -1 Negatively charged graphene oxide solution; 3mmol of Co(NO 3 ) 2 ·6H 2 O was dissolved in 100ml of deionized water, magnetically stirred for 30min, and then NH 3 ·H 2 O and stirring continuously until the pH of the solution reaches 10, the resulting solid product is immediately centrifuged and dispersed in deionized water, left to stand for 12 h, and then ultrasonically treated for 1 h to obtain a positively charged cobalt hydroxide suspension. The graphene oxide aqueous solution and the cobalt hydroxide suspension were mixed at a ratio of 1:3, filtered by suction, washed, and freeze-dried to obtain a cobalt hydroxide / graphene oxide precursor. Finally, the precursor was heat-treated at 200 °C for 4 h under Ar atmosphere to obtain a specific surface area of 116.5 m2 g -1 , a cobalt oxide / reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com