Steel-based composite and preparation method and preparation device thereof

A composite material and steel technology, applied in the field of steel-based composite materials, can solve the problems of brittle fracture, cumbersome pretreatment process, long preparation cycle, etc., and achieve the advantages of increased strength and toughness, wide choice of particle size, and shortened production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

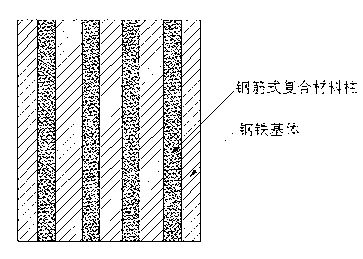

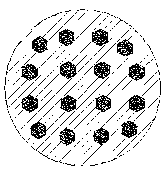

[0032] Such as figure 1 , 2 As shown in the structural schematic diagram of the steel-based composite material of the present invention, the steel-based composite material includes a steel matrix and a reinforced composite column, and the reinforced composite columns are arranged in parallel in the steel matrix with a column spacing of 10 mm, wherein the reinforced composite column is horizontal The cross-section is quadrilateral and the cross-sectional area is 7mm 2 , and accounts for 30% of the volume of the steel matrix composite.

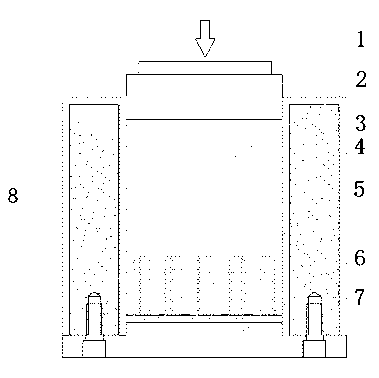

[0033] The preparation method of steel-based composite material of the present invention, concrete steps are as follows:

[0034] (1) First, the adhesive mixture (adhesive mixture is a mixture of adhesive and water mixed uniformly at a mass ratio of 5:4, wherein the adhesive is a mass ratio of 5:1Na 2 SiO 3 and PVA) and alumina ceramic particles with a particle size of 20 mesh according to the mass ratio of 5:100, and then pressed into a rei...

Embodiment 2

[0038] Such as figure 1 , 2 As shown in the structural schematic diagram of the steel-based composite material of the present invention, the steel-based composite material includes a steel matrix and a reinforced composite column, and the reinforced composite columns are arranged in parallel in the steel matrix with a column spacing of 2 mm, wherein the reinforced composite column The cross-section is pentagonal and the cross-sectional area is 1000mm 2 , and accounts for 50% of the volume of the steel matrix composite.

[0039] The preparation method of steel-based composite material of the present invention, concrete steps are as follows:

[0040] (1) First, the adhesive mixture (adhesive mixture is a mixture of adhesive and water mixed uniformly at a mass ratio of 6:10, where the adhesive is H 3 PO 4 ) and zirconia ceramic particles with a particle size of 300 mesh according to the mass ratio of 6:100, and then pressed into a reinforced composite material column, sintere...

Embodiment 3

[0044] Such as figure 1 , 2 As shown in the structural schematic diagram of the steel-based composite material of the present invention, the steel-based composite material includes a steel matrix and reinforced composite material columns, and the reinforced reinforced composite material columns are arranged in parallel in the steel matrix with a column spacing of 1 mm, wherein the reinforced reinforced composite material columns are horizontal The cross-section is hexagonal and the cross-sectional area is 100mm 2 , and accounts for 75% of the volume of the steel matrix composite.

[0045] The preparation method of steel-based composite material of the present invention, concrete steps are as follows:

[0046] (1) First, the adhesive mixture (adhesive mixture is a mixture of adhesive and water mixed uniformly at a mass ratio of 5:8, wherein the adhesive is Na 2 SiO 3 ) and tungsten carbide ceramic particles with a particle size of 200 mesh according to the mass ratio of 5.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com