Preparation method for Ti3Al-TiAl laminated composite material

A layered composite material, tial3-ti technology, applied in the direction of metal layered products, chemical instruments and methods, lamination, etc., can solve the problems of high cost, complicated process, high equipment requirements, etc., and achieve low cost and simple production process Ease of operation and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: this embodiment Ti 3 The preparation method of Al-TiAl layered composite material is realized by the following steps:

[0018] 1. Cut the surface-treated Ti foil and Al foil into small pieces, alternately stack 10-30 layers, the top and bottom of the stack are both coated with BN or Y 2 O 3 Then, wrap a layer of Ti foil coated with BN on the alternately stacked Ti foil and Al foil, then place it in a graphite mold, and then put the graphite mold into a vacuum hot pressing sintering furnace to heat to 300~ 500℃, apply 10~30MPa pressure at the same time, keep for 0.5~1h to obtain laminated foil;

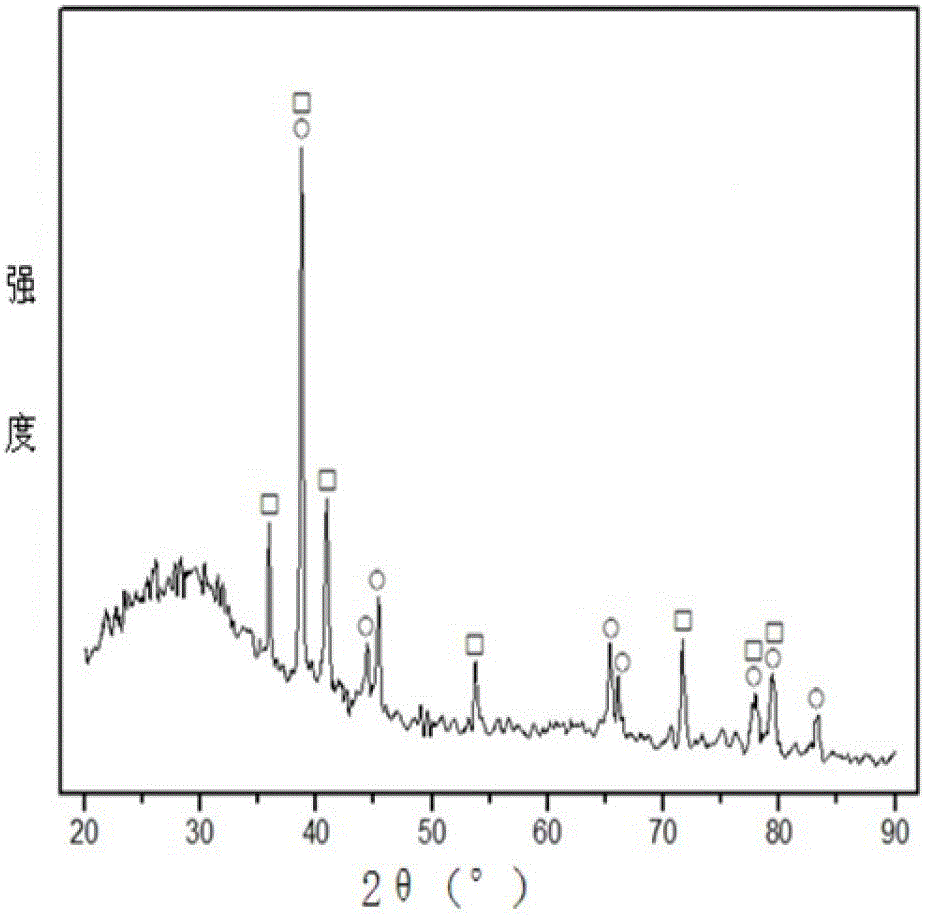

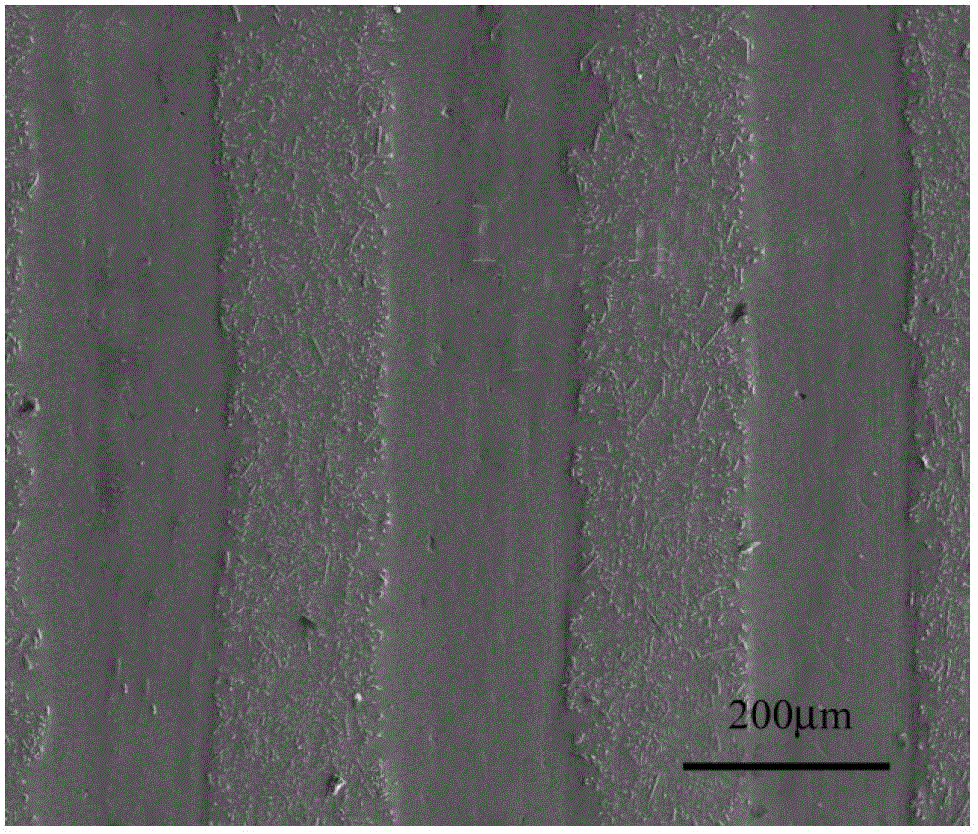

[0019] 2. Unload the pressure on the laminated foil in the first step, heat the laminated foil to 600~800℃ at a heating rate of 10℃ / min, keep it for 2~40h, so that the Ti foil and Al foil will undergo diffusion reaction to produce TiAl 3 -Ti layered composite material, and then heated to 900~1300℃ at a heating rate of 10℃ / min, while applying a pressure of 10~3...

specific Embodiment approach 2

[0026] Specific embodiment two: This embodiment is different from specific embodiment one in that step one is placed in a vacuum hot-pressing sintering furnace and heated to 330-450°C while applying a pressure of 15-26 MPa. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0027] Specific embodiment three: This embodiment is different from specific embodiment one in that step one is placed in a vacuum hot-pressing sintering furnace and heated to 380°C while applying a pressure of 23 MPa. Other steps and parameters are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com