Low-temperature-resistant and abrasion-resistant polyurethane coating and preparation method thereof

A technology of polyurethane coatings and low temperature resistance, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of reduced mechanical properties of coatings, small size of particle materials, concentration of internal stress in coatings, etc., and achieve strong adhesion and tight interface , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

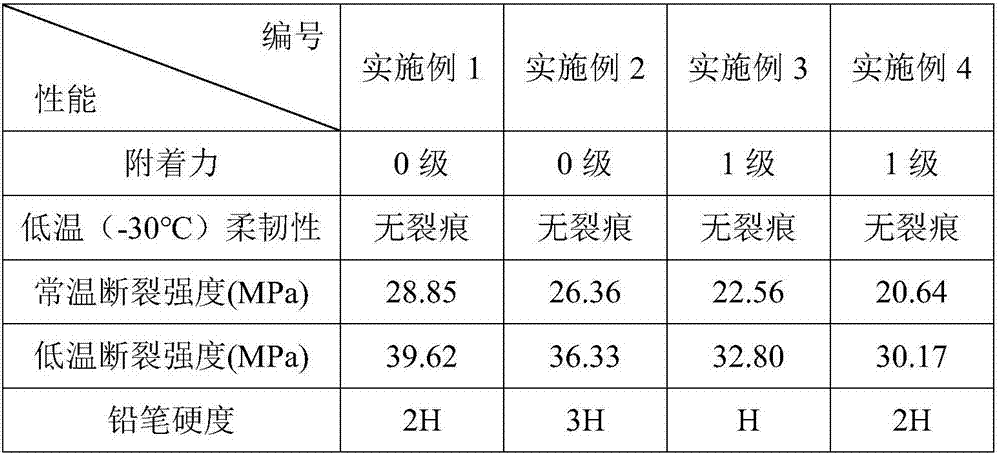

Embodiment 1

[0029] 50g of polysebacic acid-polybutadiene glycol ester polyol, 2g of low temperature resistant polyester polyol BY3001, 17g of spherical aluminum powder with a diameter of 13-18μm treated with imidazoline laurate, 30g of n-butanol, Mix 0.5 g of defoamer evenly, weigh 10 g of 4,4-diphenylmethane diisocyanate curing agent and add to the mixture, mix evenly to obtain polyurethane coating.

[0030] The obtained polyurethane coating is applied to the surface of the material, and cured for 24 hours at room temperature to obtain a modified polyurethane coating. The surface scanning electron microscope picture is as follows: figure 1 shown, from figure 1 It can be seen that the spherical aluminum powder treated with imidazoline laurate is uniformly dispersed in the layer without obvious phase separation.

Embodiment 2

[0032] 45g of polysebacic acid-polybutadiene glycol ester polyol, 0.5g of low-temperature resistant polyester polyol BY3001, 10g of flaky aluminum powder with a diameter of 5-8μm treated with n-butanol acetate, and 50g of composite solvent (Xylene and methyl acetate are mixed at a ratio of 2:1), 1g of defoamer is mixed evenly, 5g of methylcyclohexyl diisocyanate curing agent is weighed and added to the mixture, and mixed evenly to obtain a polyurethane coating.

[0033] The obtained polyurethane coating is coated on the surface of the material, and cured at room temperature for 24 hours to obtain a modified polyurethane coating.

Embodiment 3

[0035] Combine 60g of one of 2-methyl-1,5-pentanediol, 6g of low-temperature resistant polyester polyol BY3022, 20g of spherical copper powder with a diameter of 10-15μm treated with dibutyl adipate, and 35g Solvent (mixture of isopropanol and n-butanol at a ratio of 1:2), 1.5g of defoamer were mixed uniformly, and 10.8g of xylylene diisocyanate curing agent was weighed and added to the mixture, and mixed uniformly to obtain a polyurethane coating.

[0036] The obtained polyurethane coating is coated on the surface of the material, and cured at room temperature for 24 hours to obtain a modified polyurethane coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com