Ultrathin composite solid-state electrolyte membrane and preparation method thereof

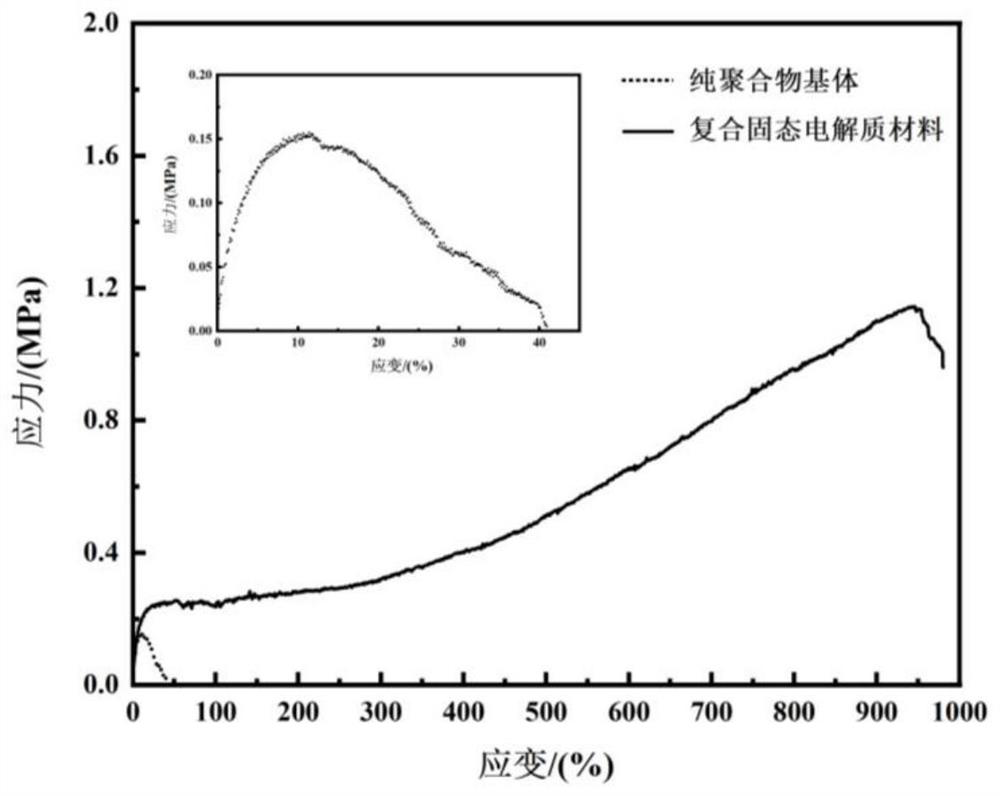

A technology of solid electrolyte membrane and solid electrolyte, applied in solid electrolyte, non-aqueous electrolyte, circuit, etc., can solve the problems of insufficient electrochemical performance, difficult demoulding, poor mechanical properties of composite solid electrolyte membrane, etc., and achieve good electrochemical performance , easy demoulding, excellent mechanical tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The application will be further described below in conjunction with the accompanying drawings and embodiments.

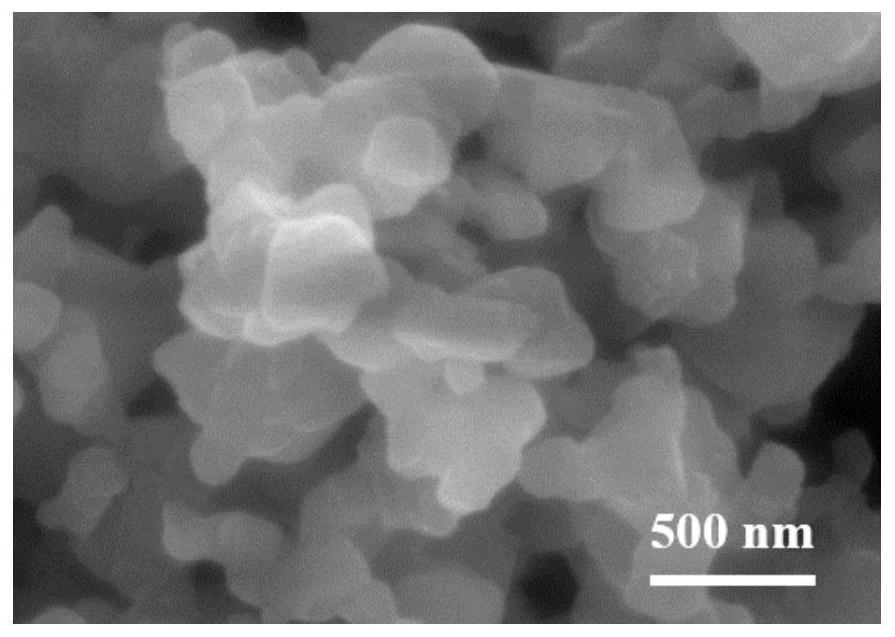

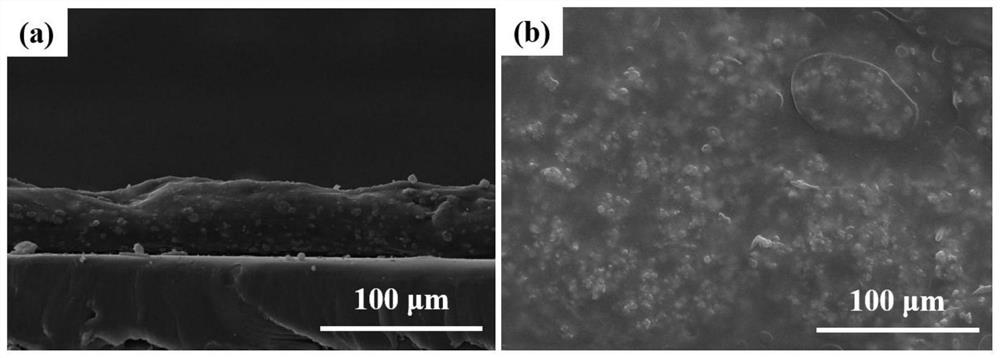

[0030] The ultra-thin composite solid electrolyte membrane disclosed by the invention has a thickness of about 20 to 50 μm. The composite solid electrolyte membrane is a thin film composed of an inorganic solid electrolyte and a polymer matrix prepared by casting on a surface-treated substrate. , wherein the content of the inorganic solid electrolyte is 5-30wt%, the inorganic solid electrolyte is the ceramic nano-particles of the oxide-based solid electrolyte modified by the binder, the polymer matrix is composed of the polymer-based electrolyte and lithium salt, and the ceramic nano-particles are It is added as an inorganic filler into a polymer matrix to obtain a composite solid electrolyte material. The oxide solid electrolyte is Li 1.4 Al 0.4 Ti 1.6 (PO 4) 3 , Li 1.5 Al 0.5 Ge 1.5 (PO 4 ) 3 , Li 0.24 La 0.587 TiO 3 , Li 0.33 La 0.557 TiO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com