Preparation method of polyglycerol lactate

A technology of polyglycerol lactate and polyglycerol, which is applied to the preparation of carboxylic acid esters, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of no large-scale production, reduce operating steps, and improve reaction selectivity , reduce the effect of side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

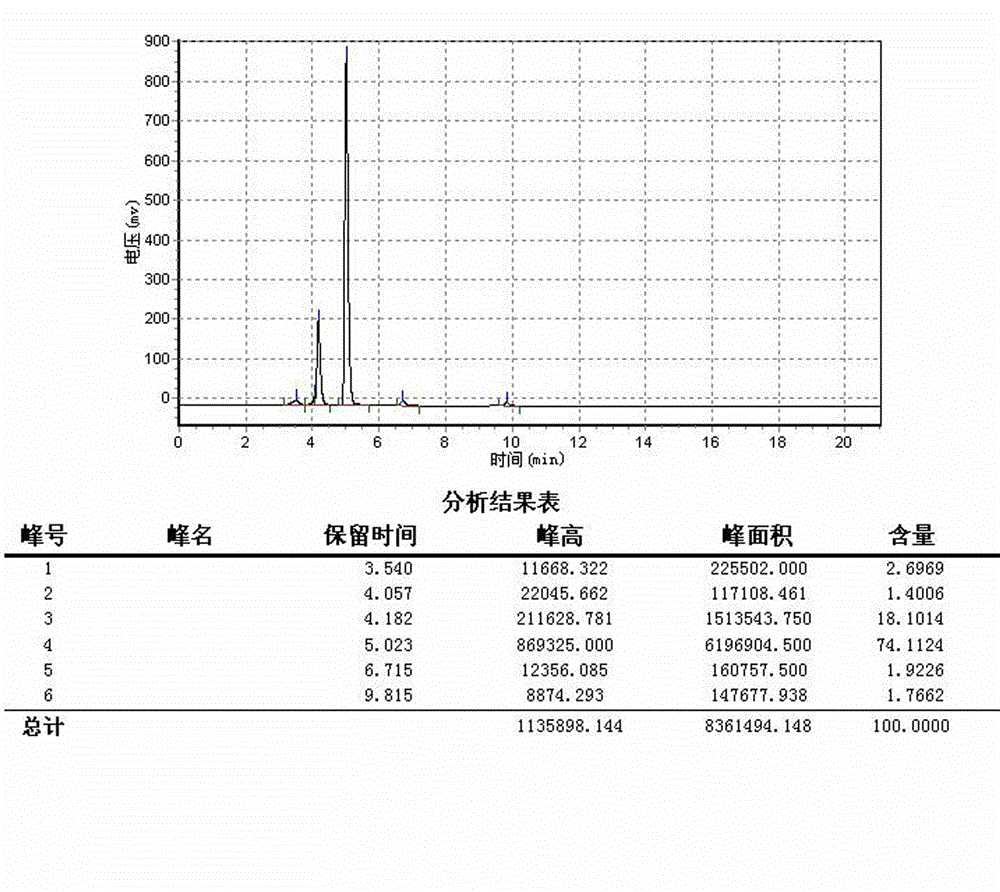

Embodiment 1

[0036] In the reactor, add 200 g of polyglycerol with a degree of polymerization of 3 to 8, and under nitrogen protection, add solid superacid SO 4 2- / Fe 2 o 3 Catalyst 0.4g, 80g of lactic acid with a mass percentage of 90% and toluene 55g, heated to reflux temperature for esterification reaction; refluxed until no water was separated, evaporated toluene, cooled to room temperature, and added the crude product of polyglyceryl lactate to 200ml Stir and dissolve in acetone, filter to remove the catalyst, the filtrate is separated by vacuum distillation and molecular distillation to obtain polyglycerol lactate, the ester content is 98.2%, the acid value is 0.6 mgKOH / g, and the saponification value is 217 mgKOH / g.

Embodiment 2

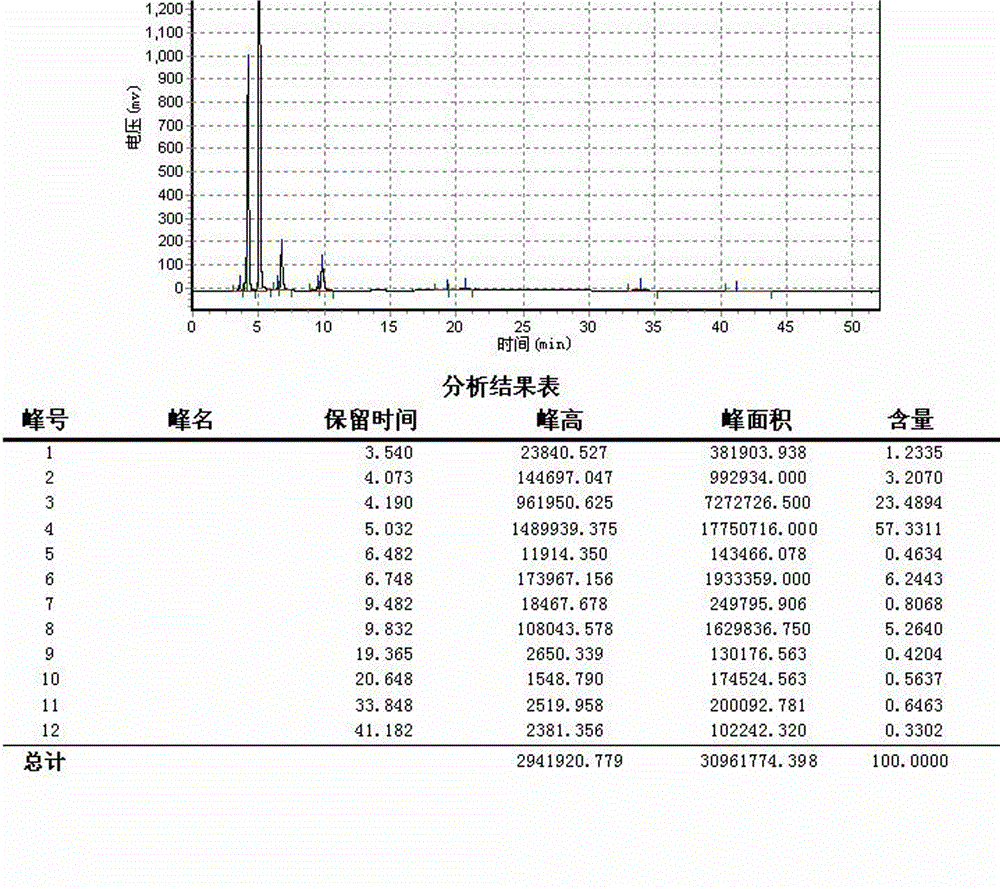

[0038] In the reactor, add 200 g of polyglycerol with a degree of polymerization of 3 to 8, and under nitrogen protection, add solid superacid SO 4 2- / TiO 2 0.2g of catalyst, 75g of lactic acid with a mass percentage of 90% and 55g of toluene, heated to reflux temperature for esterification reaction; refluxed until no water was separated, evaporated toluene, added the crude product of polyglyceryl lactate to 200ml of methanol and stirred to dissolve , Remove the catalyst by filtration, the filtrate is separated by vacuum distillation and molecular distillation to obtain polyglycerol lactate, the ester content is 97.6%, the acid value is 0.5 mgKOH / g, and the saponification value is 223 mgKOH / g.

Embodiment 3

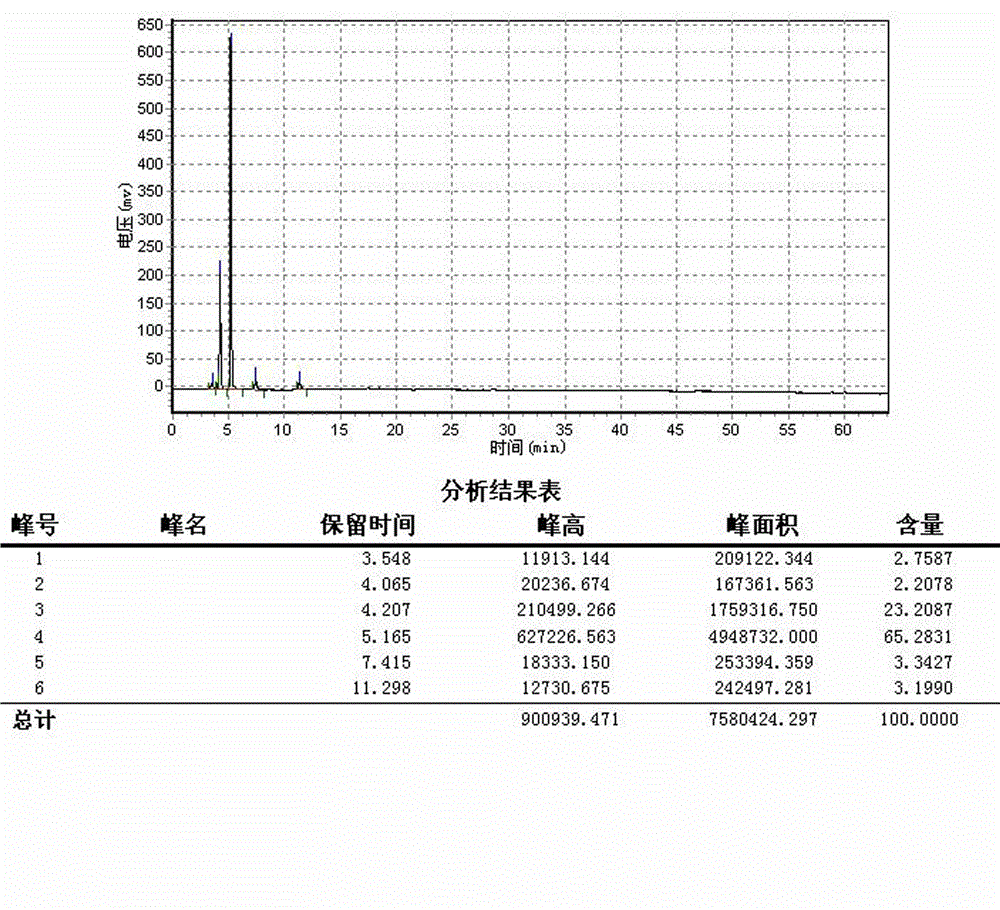

[0040] In the reactor, add 200 g of polyglycerol with a degree of polymerization of 3 to 8, and under nitrogen protection, add solid superacid SO 4 2- / ZrO 2 Catalyst 0.3g, 80g of lactic acid with a mass percentage of 90% and cyclohexane 60g, heated to reflux temperature for esterification reaction; The product was added to 250ml of ethanol and stirred to dissolve, and the catalyst was removed by filtration. The filtrate was subjected to vacuum distillation and molecular distillation to obtain polyglycerol lactate. The ester content was 96.8%, the acid value was 0.7 mgKOH / g, and the saponification value was 215 mgKOH / g. .

[0041] Depend on Figure 4 It can be seen that the synthetic polyglycerol lactate composition of the present invention is as follows:

[0042] Mass Spectrometry Molecular Weight Corresponding substance name 311.78 Tripolyglycerol Monolactate 385.8 tetrapolyglycerol monolactate 459.96 Pentaglycerol Monolactate 533.87 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com