Wear-resisting gear with multi-material combined tooth face

A multi-material, tooth surface technology, applied in the direction of elements with teeth, belts/chains/gears, portable lifting devices, etc., can solve the problems of easy formation of brittle fracture, poor fatigue performance, high brittleness, and achieve good impact resistance. , good wear resistance, good wear resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

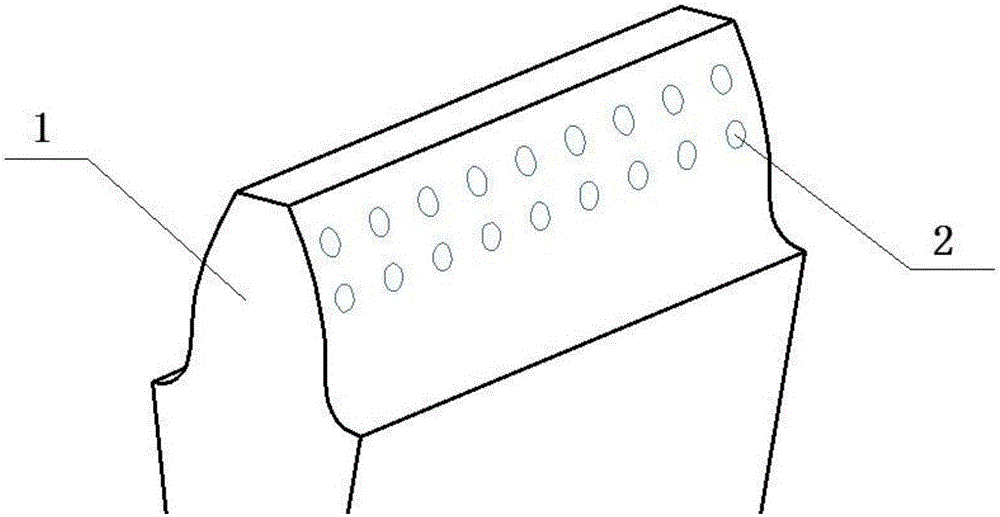

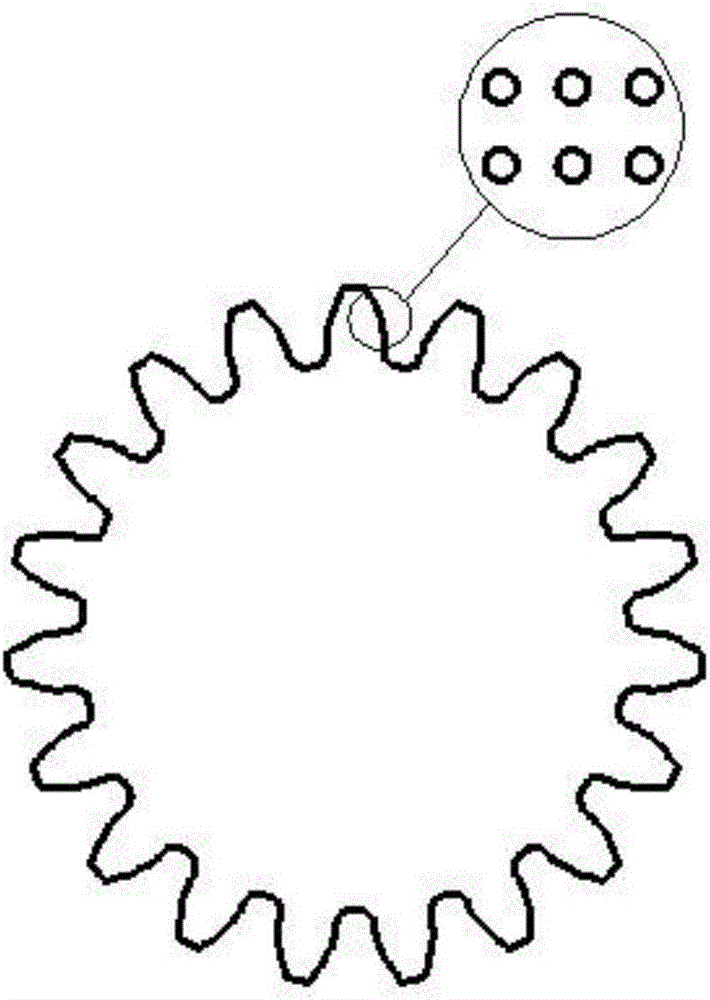

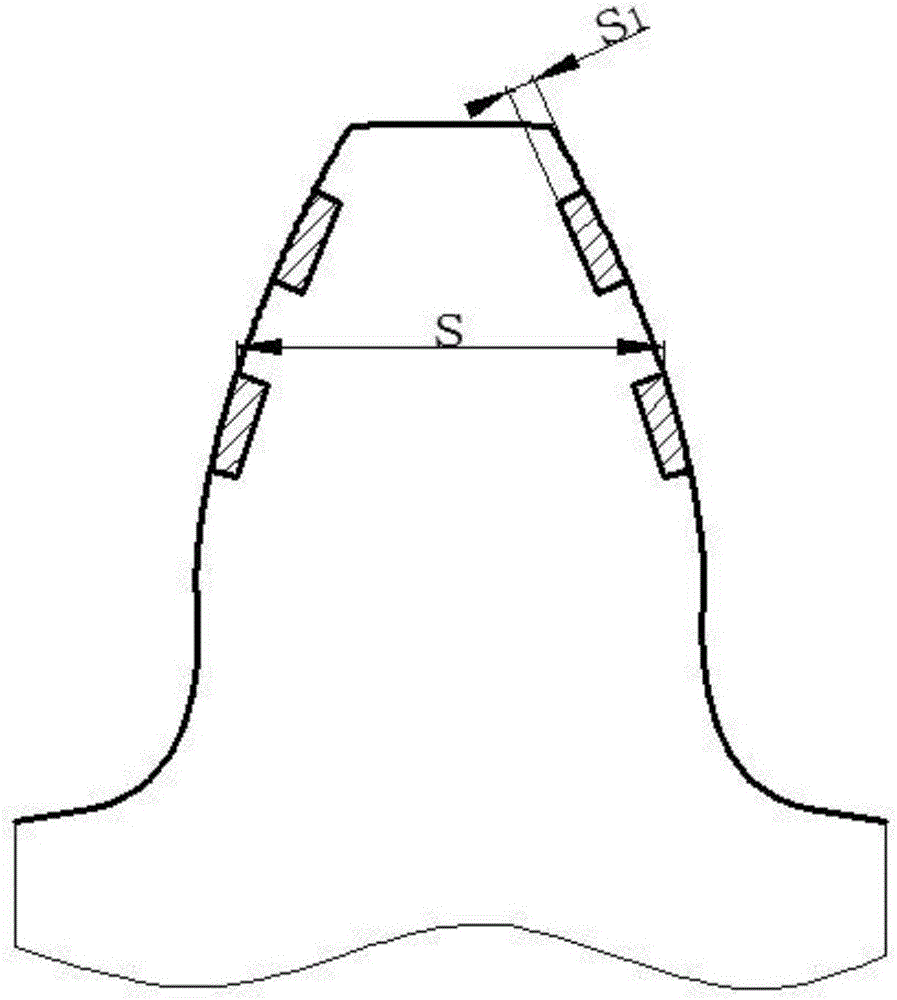

[0014] see figure 1 , the gear base 1 is mainly made of a metal material with good impact resistance, and at the same time, a circular unit body 2 made of a ceramic material is inlaid on the tooth surface of the metal material; the gear used in this experiment test, The metal material is 38CrMoAlA, quenched and tempered, the hardness is 230HB, and the precision is 7; the material of the circular unit body 2 is silicon nitride ceramics.

[0015] The impact force during the gear meshing process is borne by the metal material 38CrMoAlA and silicon nitride ceramics on the tooth surface at the same time, which can ensure that the silicon nitride ceramics will not undergo brittle fracture during the gear transmission process and continue to exert its good wear resistance; while in the gear During the wear process, the loss is also borne by the metal material 38CrMoAlA and silicon nitride ceramics on the tooth surface, so it can take advantage of the good wear resistance of ceramic m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com